High hardness, high wear resistant and non-polished iron based microcrystalline glass ceramic composite plate and preparation method thereof

A glass-ceramic, high wear-resistant technology, applied in clay products, other household appliances, household appliances, etc., can solve the problems of high firing temperature and thermal expansion coefficient, high production efficiency, complex production, etc., to improve wear resistance. anti-slip performance, poor wear resistance, and the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A method for preparing the high-hardness, high-abrasion-free polishing-free iron-based glass-ceramic composite plate, the preparation method comprising the following steps:

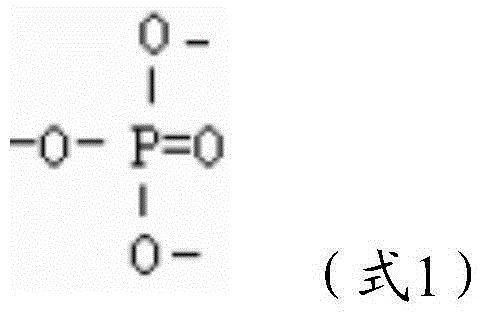

[0045] Preparation of frit dry granules: use lithium feldspar, boric acid, quartz, alumina, calcium hydrogen phosphate, calcined talc, and zircon powder as raw materials, add metal oxides accounting for 1-20% of the raw materials, mix well and send Melting into a melt in a glass tank kiln; after water quenching, drying, crushing, and screening of the melted melt, dry frits are obtained for use;

[0046] Preparation of ceramic green body: use super-strength ball clay, Rongfa kaolin, fruit tree mud, Yinfeng sodium sand, high-alumina medium-temperature sand, potassium-sodium sand, good aluminum potassium sand, Fogang potassium sand, and burnt talc as raw materials for ceramic green bodies. Add 0.3-0.5% water-reducing agent to the raw material of the ceramic green body, grind it into a slurry with a ba...

Embodiment 1

[0084] A high-hardness, high-abrasion-free polishing-free iron-based glass-ceramic composite plate, prepared according to the above method; wherein

[0085] The ceramic green body comprises the following components in parts by weight: SiO 2 50 parts, Al 2 o 3 20 parts, MgO1 part, K 2 O2 parts, Na 2 O2 parts, 2 parts of water reducer;

[0086] The bottom glaze comprises the following components in parts by weight: SiO 2 40 parts, Al 2 o 3 26 parts, CaO0 parts, MgO8 parts, K 2 O+Na 2 O5 parts, ZnO10 parts, ZrO 2 15 parts, 1 part water reducer, 1 part thickener;

[0087] The frit dry granules comprise the following components in parts by weight: SiO 2 50 parts, CaO10 parts, B 2 o 3 15 parts, ZrO 2 6 servings, Al 2 o 3 12 parts, MgO10 parts, P2 o 5 5 copies, K 2 O+Na 2 O+Li 2 O10 parts, TiO 2 1 part, Sb 2 o 3 +Fe 2 o 3 20 servings.

[0088] After testing, the hardness of the high-hardness, high wear-resistant and non-polishing iron-based glass-ceramic com...

Embodiment 2

[0090] A high-hardness, high-abrasion-free polishing-free iron-based glass-ceramic composite plate, prepared according to the above method; wherein

[0091] The ceramic green body comprises the following components in parts by weight: SiO 2 60 parts, Al 2 o 3 22 parts, MgO1.5 parts, K 2 O3 parts, Na 2 3 parts of O, 1.5 parts of water reducer;

[0092] The bottom glaze comprises the following components in parts by weight: SiO 2 50 parts, Al 2 o 3 20 parts, CaO10 parts, MgO5 parts, K 2 O+Na 2 O8 parts, ZnO5 parts, ZrO 2 10 parts, 1 part of water reducer, 1 part of thickener;

[0093] The frit dry granules comprise the following components in parts by weight: SiO 2 60 parts, 5 parts of CaO, B 2 o 3 10 parts, ZrO 2 7 copies, Al 2 o 3 15 parts, MgO5 parts, P 2 o 5 8 copies, K 2 O+Na 2 O+Li 2 O5 parts, TiO 2 5 parts, Sb 2 o 3 +Fe 2 o 3 10 servings.

[0094] After testing, the hardness of the high-hardness, high wear-resistant and non-polishing iron-based ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com