Opposite plug type pliers

A technology of opposing pistons and caliper bodies, applied in the direction of brake actuators, gear transmission mechanisms, axial brakes, etc., can solve the problems of low cutting efficiency, difficulty in direct use, poor assembly of pistons, etc., and achieve manufacturing Efficiency improvement, suppression of liquid leakage, and reduction in the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, preferred embodiments of the opposed-piston caliper according to the present invention will be described based on the relationship between the opposed-piston caliper and a brake caliper to which the opposed-piston caliper is applied, with reference to the accompanying drawings. Describe in detail.

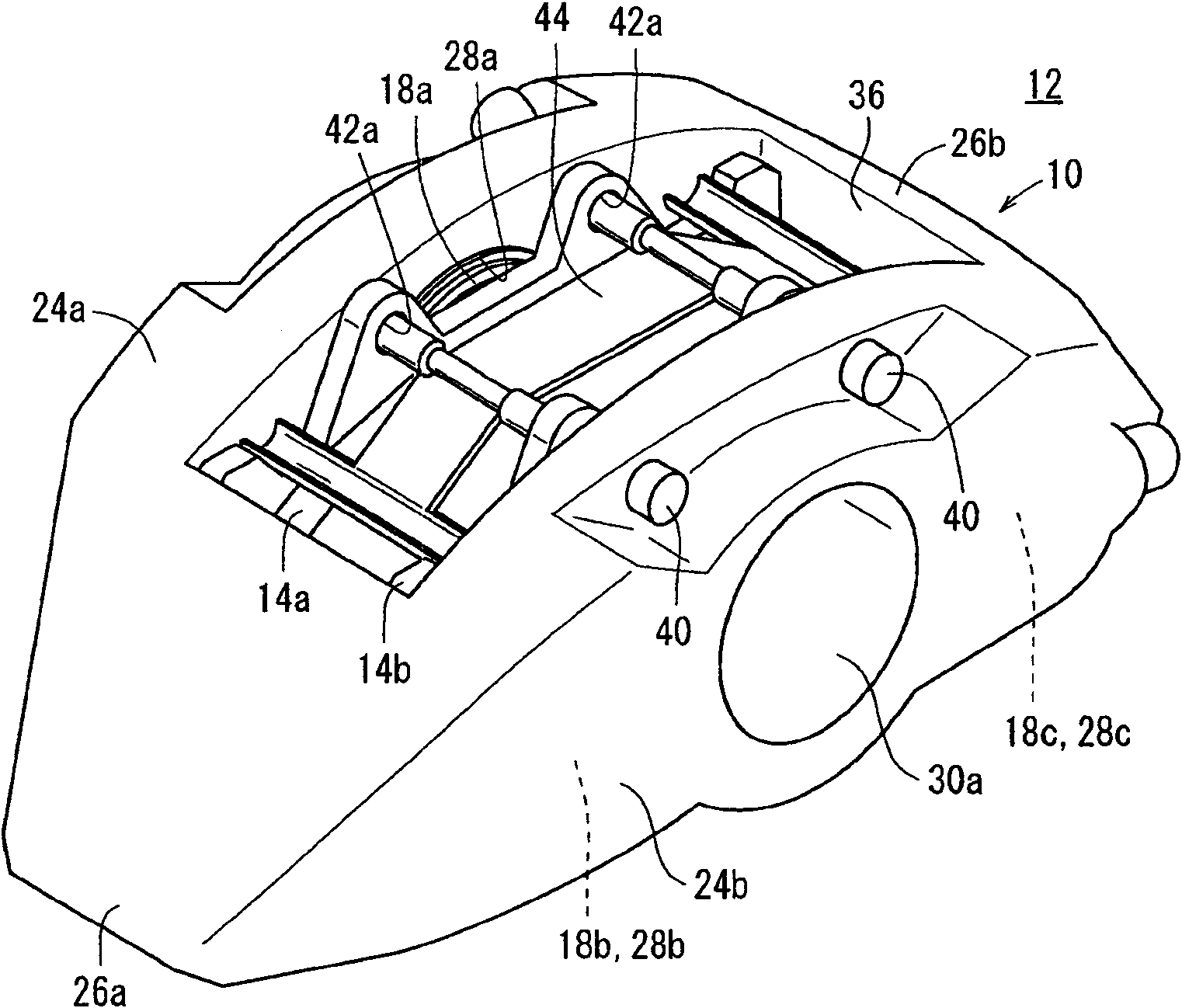

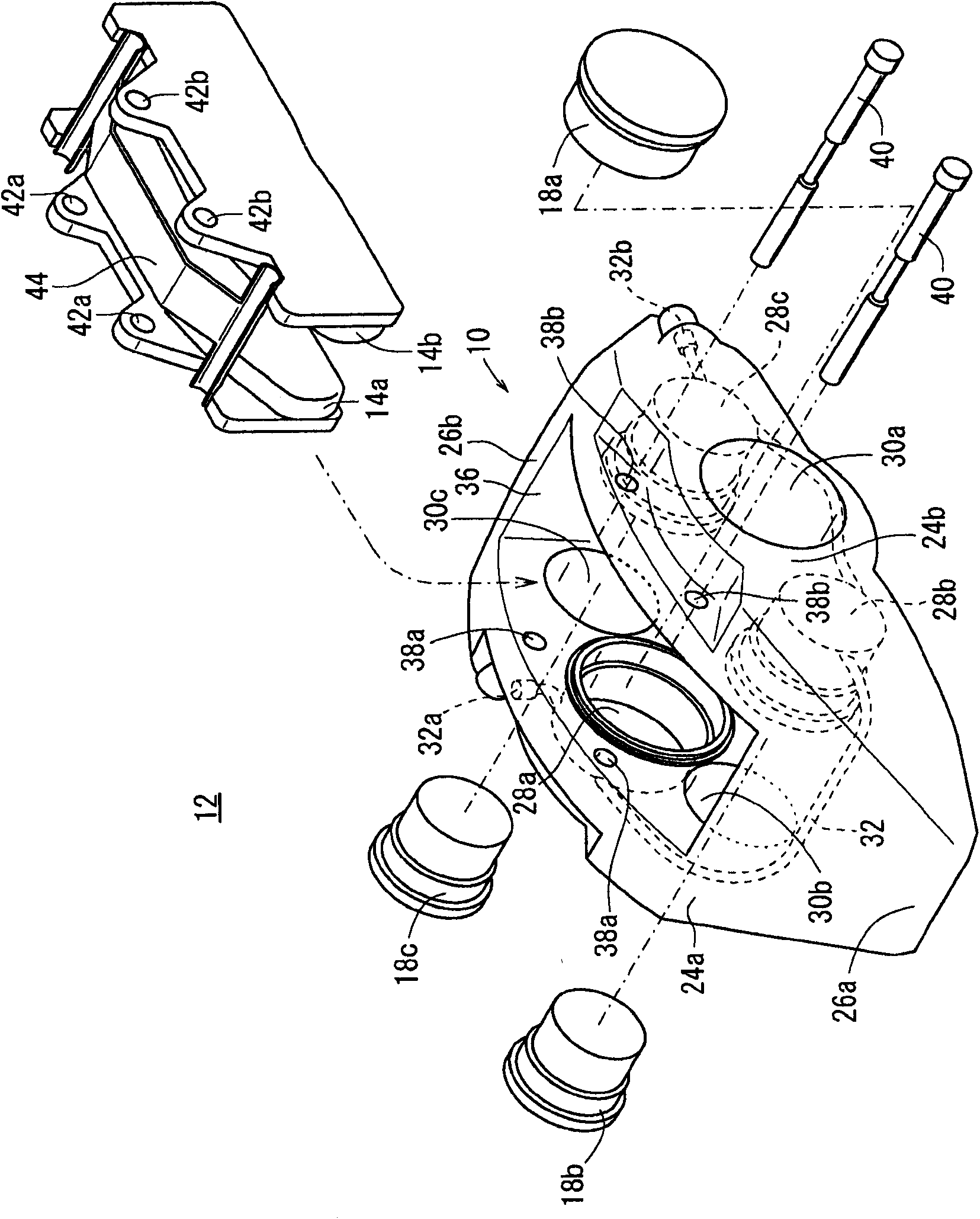

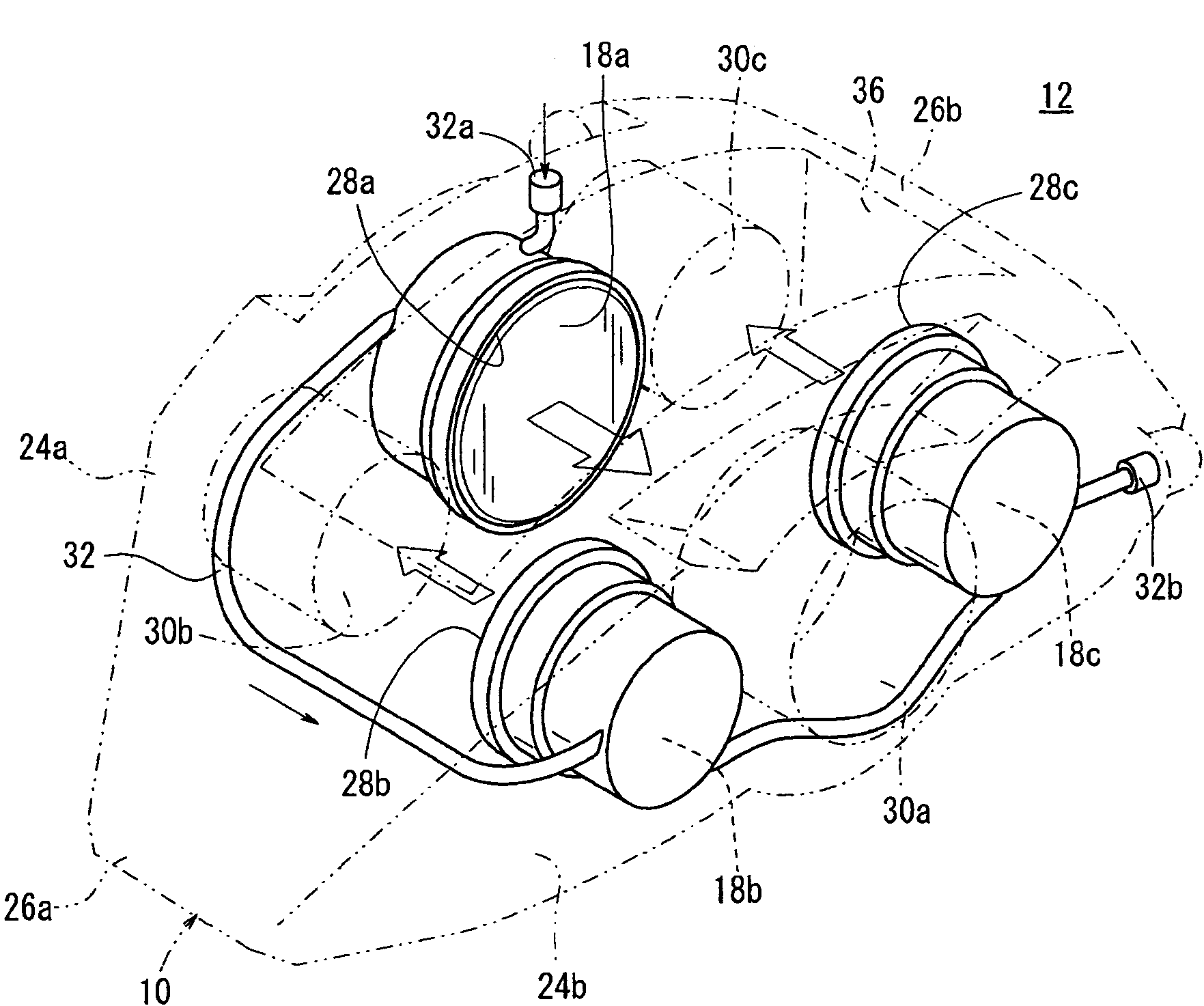

[0031] figure 1 It is a perspective view of a brake caliper 12 to which an opposed-piston caliper body 10 according to an embodiment of the present invention is applied, figure 2 yes figure 1 An exploded perspective view of the brake caliper 12 is shown. in addition, image 3 yes means figure 1 A perspective view of the hydraulic system of the brake caliper 12 is shown.

[0032] Such as figure 1 with figure 2 As shown, the brake caliper 12 is a brake mechanism for clamping a disc rotor that rotates together with a wheel of a motor vehicle, etc. ”); a pair of brake blocks 14a, 14b configured in the caliper body 10; Figure 5 ) a plurality of (three in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com