Wheel diameter difference member speed reducer

A differential reducer and reducer technology, applied in transmission parts, gear transmissions, belts/chains/gears, etc., can solve the problems of high process requirements, no impact resistance, limited friction transmission speed, etc. Tooth surface technology and surface heat treatment technology, strong impact resistance, and the effect of improved processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

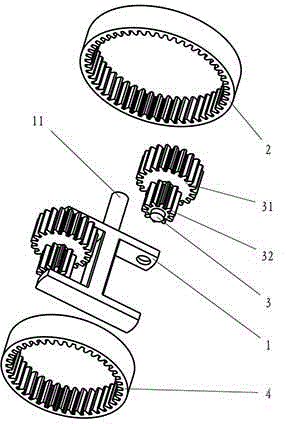

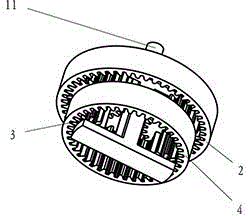

[0019] see figure 1 and figure 2 , the present invention discloses a radial differential sub-reducer, including a radial differential sub-frame 1, a fixed mother shell wheel 2, a radial differential sub-3, and a differential shell wheel 4, wherein: the radial differential sub-frame 3 includes a differential sub-main wheel 31 and Difference sub-wheel 32, diameter difference sub-frame axle 11.

[0020] Implementation details: the working principle of the radial differential sub-reducer, the differential sub-frame is set as the input speed shaft, the differential sub-frame and the radial differential sub-frame are linked, the differential sub-gear wheel of the radial differential sub-gear is meshed with the fixed mother shell wheel, and the fixed mother shell wheel It exists in a fixed and non-rotating form, and can obtain the linear velocity of the input speed reflected on the differential sub-master wheel. The angular velocity corresponding to the speed is the same as the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com