Detection of surface defects employing subsampled images

a surface defect and subsampling technology, applied in image enhancement, image data processing, instruments, etc., can solve problems such as object inspection systems, achieve the effects of reducing limitations, improving the functionality of object inspection systems, and increasing the diversity of objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Overview

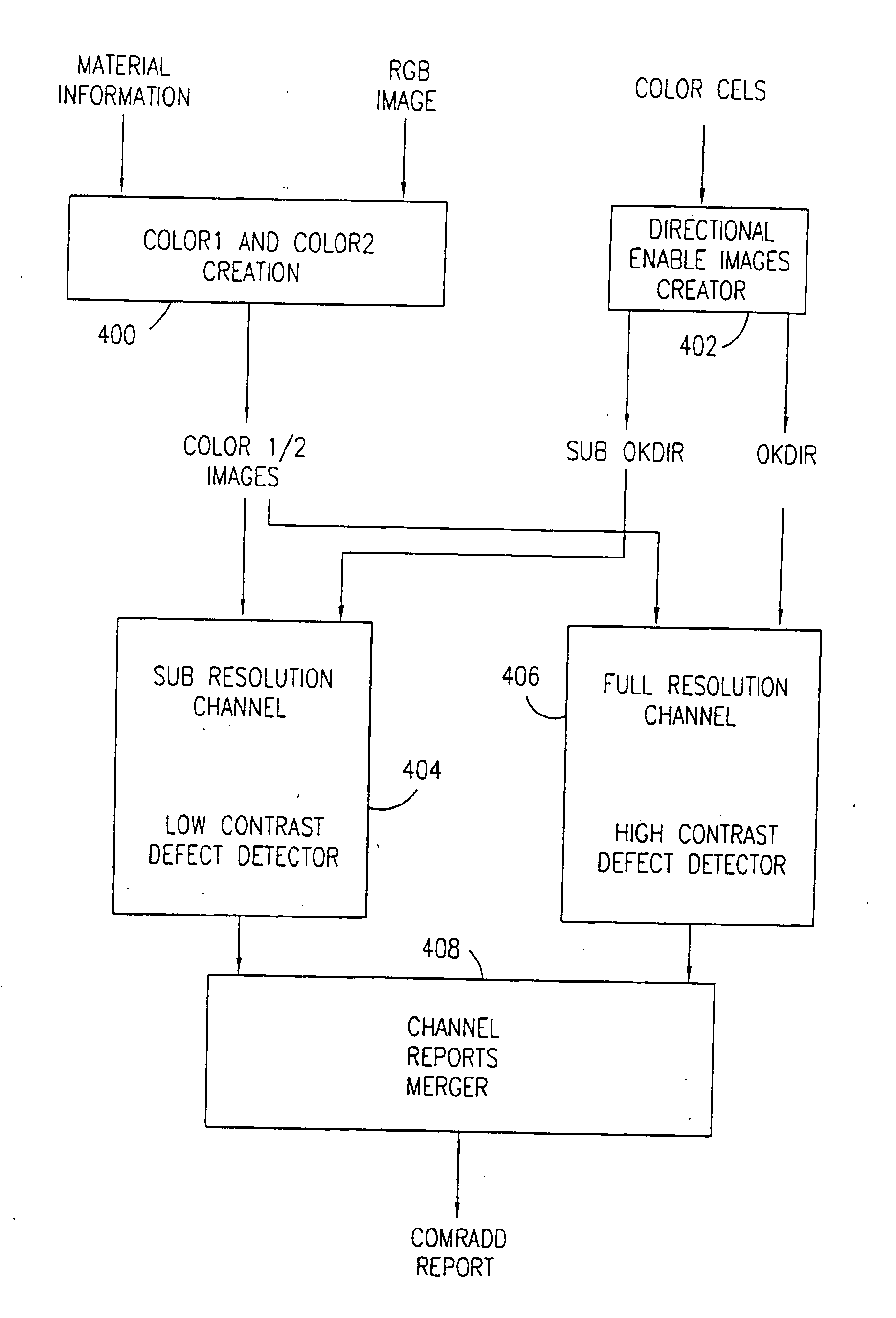

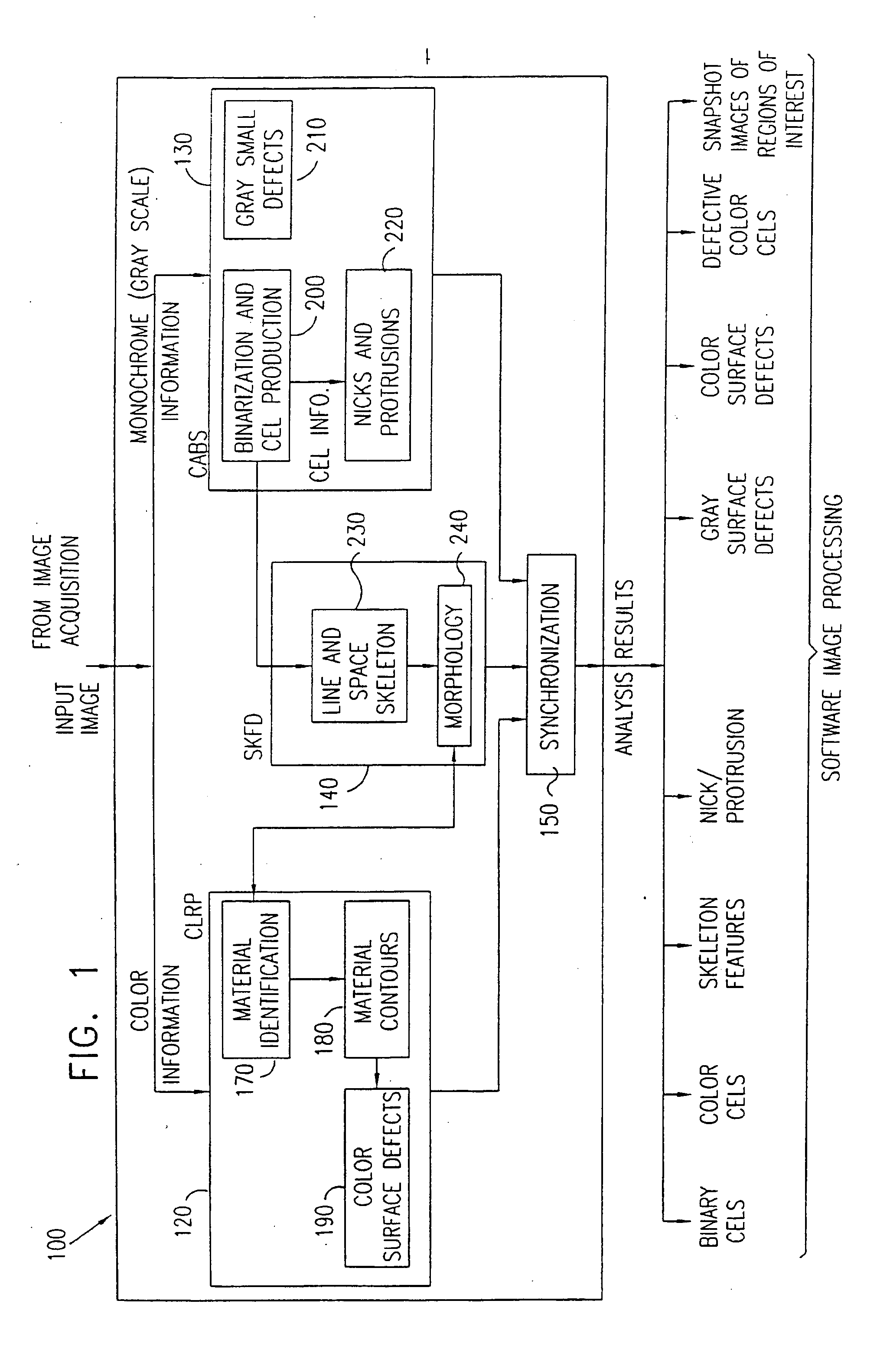

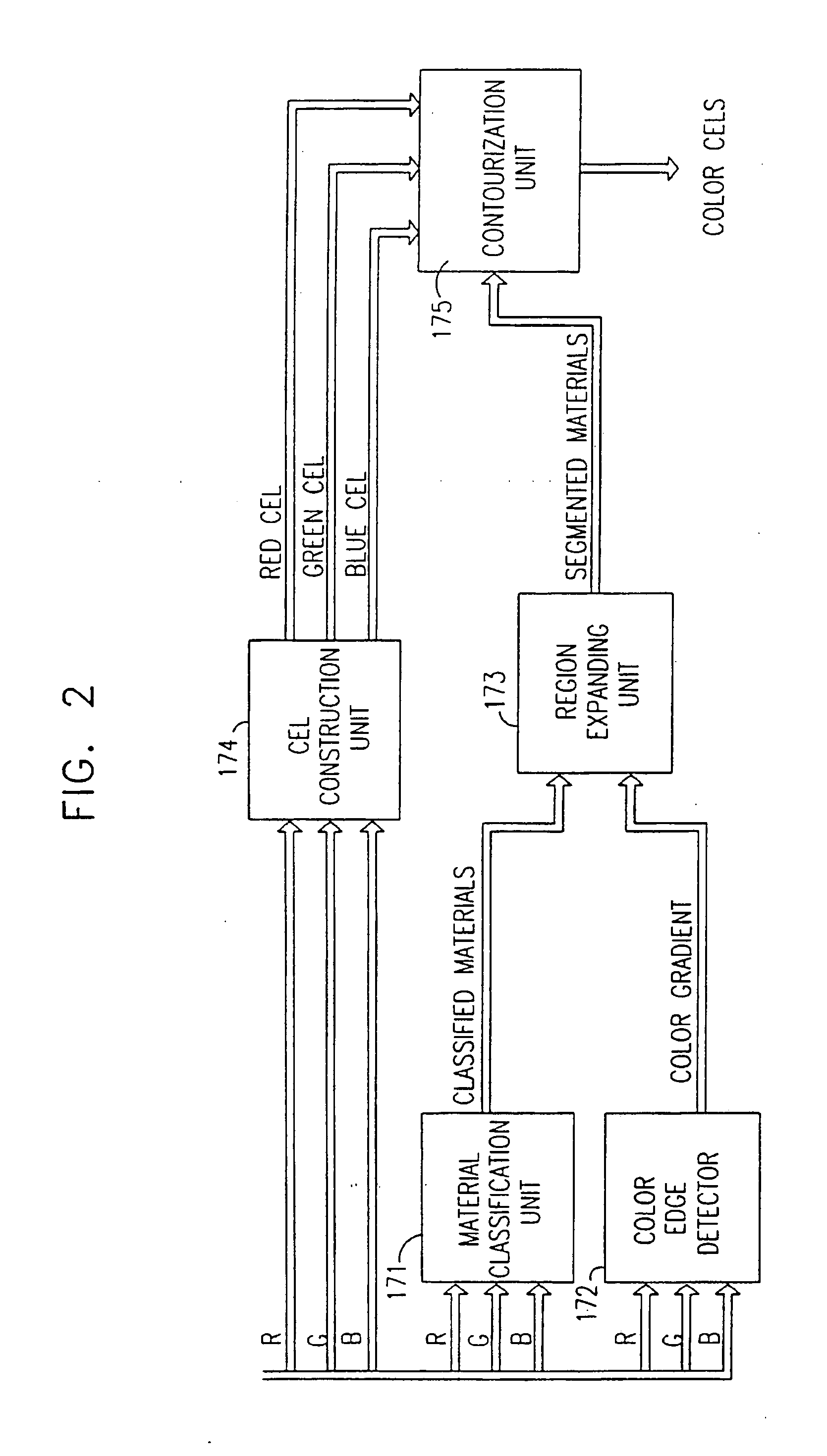

[0284] Reference is now made to FIG. 1 which is a simplified block diagram illustration of an image analysis system 100 constructed and operative in accordance with a preferred embodiment of the present invention. It is appreciated that, while the system of FIG. 1 is particularly useful in analyzing an image which represents a patterned object, for example a BGA or other electric circuit, the system of FIG. 1 may generally be useful in image analysis, whether or not an image being analyzed represents a patterned object or any other object. Although reference in the present specification is made to BGAs for the purposes of illustrating the present invention, the term BGA as used in the present specification shall be deemed to refer to and additionally include printed circuit board substrates, laminated printed circuit boards, lead frames, flat panel displays, hybrid chip packaging substrates, tape automated bonding substrates, and any suitable patterned object including vari...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| break angle | aaaaa | aaaaa |

| surface defect | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com