Production technology of phenyl sulfuryl chloride

A production process, the technology of benzenesulfonyl chloride, applied in the field of benzenesulfonyl chloride production technology, to achieve the effects of saving ice, avoiding environmental pollution, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

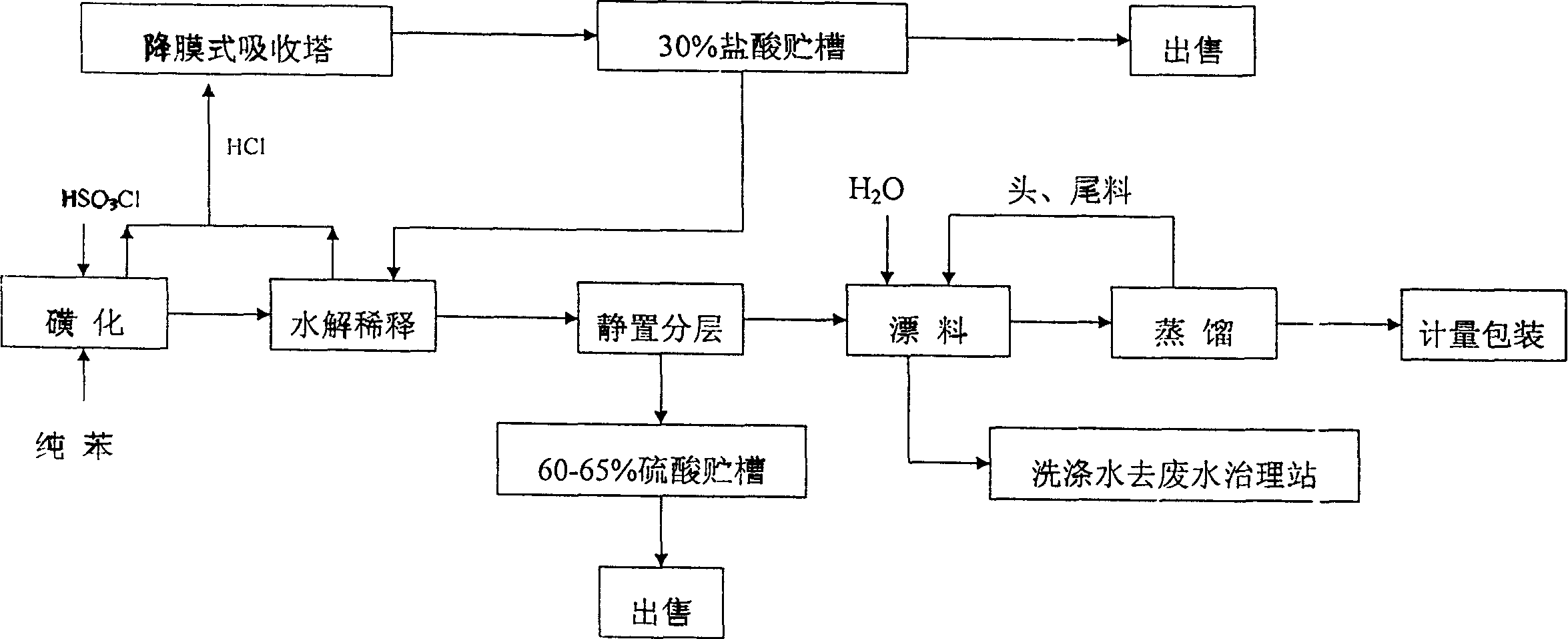

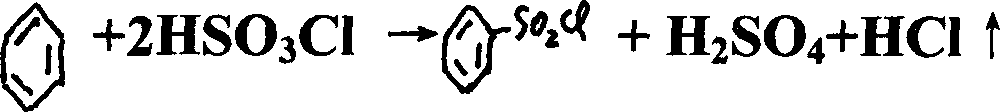

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 Benzenesulfonyl chloride production process

[0028] (1) Raw materials

[0029] Chlorosulfonic acid content ≥ 96%, produced by Suzhou Fine Chemical Co., Ltd.

[0030] Benzene Petroleum grade, produced by Yangzi Petrochemical Company

[0031] (2) Production equipment

[0032] Serial number Equipment name Specification Model Material Quantity

[0033] (1) Sulfonation reaction kettle volume 1500L enamel 1 set

[0034] (2) Hydrolysis dilution kettle volume 2000L enamel 1 set

[0035] (3) Bleaching kettle volume 2000L enamel 1 set

[0036](4) Distillation kettle volume 1500L enamel 1 set

[0037] (5) Tube and tube condenser heat exchange area 10M 2 Enamel 1 set

[0038] (6) Water ring vacuum pump model 2SK-6 1 set

[0039] (7) Water jet homemade polypropylene 1 set

[0040] (8) Graphite polypropylene falling film absorption tower heat transfer area 10M 2 Graphite polypropylene 1 set

[0041] (3) Production control conditions

[0042] (1) Feed molar ...

Embodiment 2

[0057] Embodiment 2 Benzenesulfonyl chloride production process

[0058] (1) Raw materials are the same as in Example 1.

[0059] (2) Production equipment With embodiment 1.

[0060] (3) Production control conditions

[0061] (1) Feed molar ratio proportioning benzene: chlorosulfonic acid=1: 3,

[0062] Among them, benzene 300kg, chlorosulfonic acid 1343kg;

[0063] (2) Sulfonation reaction Stirring speed 70 rpm, reaction temperature ≤ 55 ℃,

[0064] Benzene dropwise reaction time is 5 hours,

[0065] Reaction end point Dropwise reaction finishes and continues to stir for 0.5 hour;

[0066] Hydrolysis dilution Stirring speed 45 rpm, reaction temperature ≤ 50 ° C,

[0067] The total dripping amount of hydrochloric acid is 678kg,

[0068] Control the hydrochloric acid drop rate first slow and then fast 50-200kg / hour,

[0069] Adding time is 4.5 hours, stop stirring immediately after dropp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com