Cold-rolled aluminum alloy sheet for bottle can

A technology of aluminum alloy and cold-rolled sheet is applied in the field of raw material sheets for bottles and cans to achieve the effects of reducing soaking temperature, reducing manufacturing cost and suppressing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

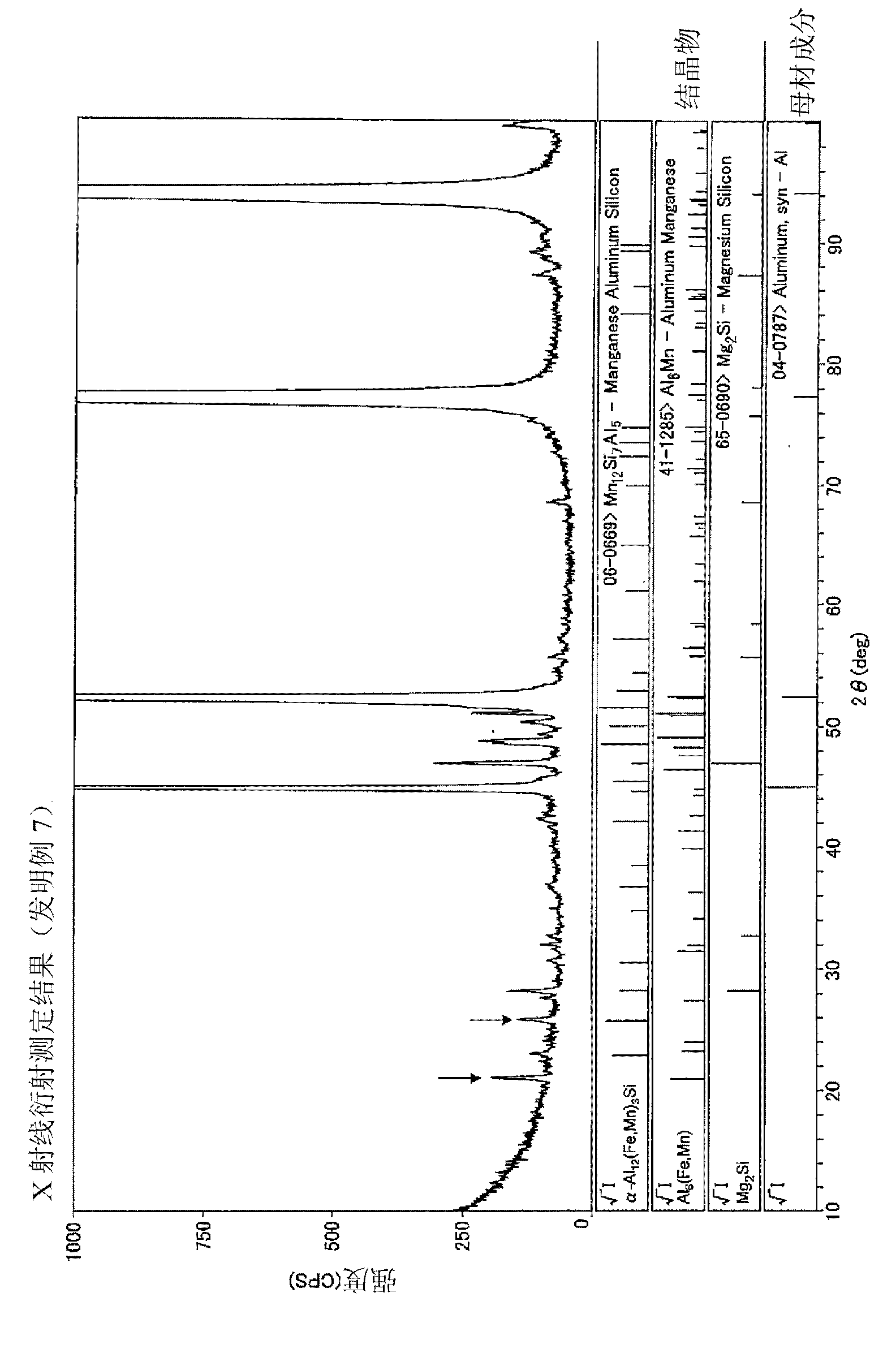

Image

Examples

Embodiment Construction

[0048] (Al alloy cold-rolled sheet composition)

[0049] First, the chemical composition of the aluminum alloy cold-rolled sheet (ingot) of the present invention, including the reason for limitation of each element, will be described below.

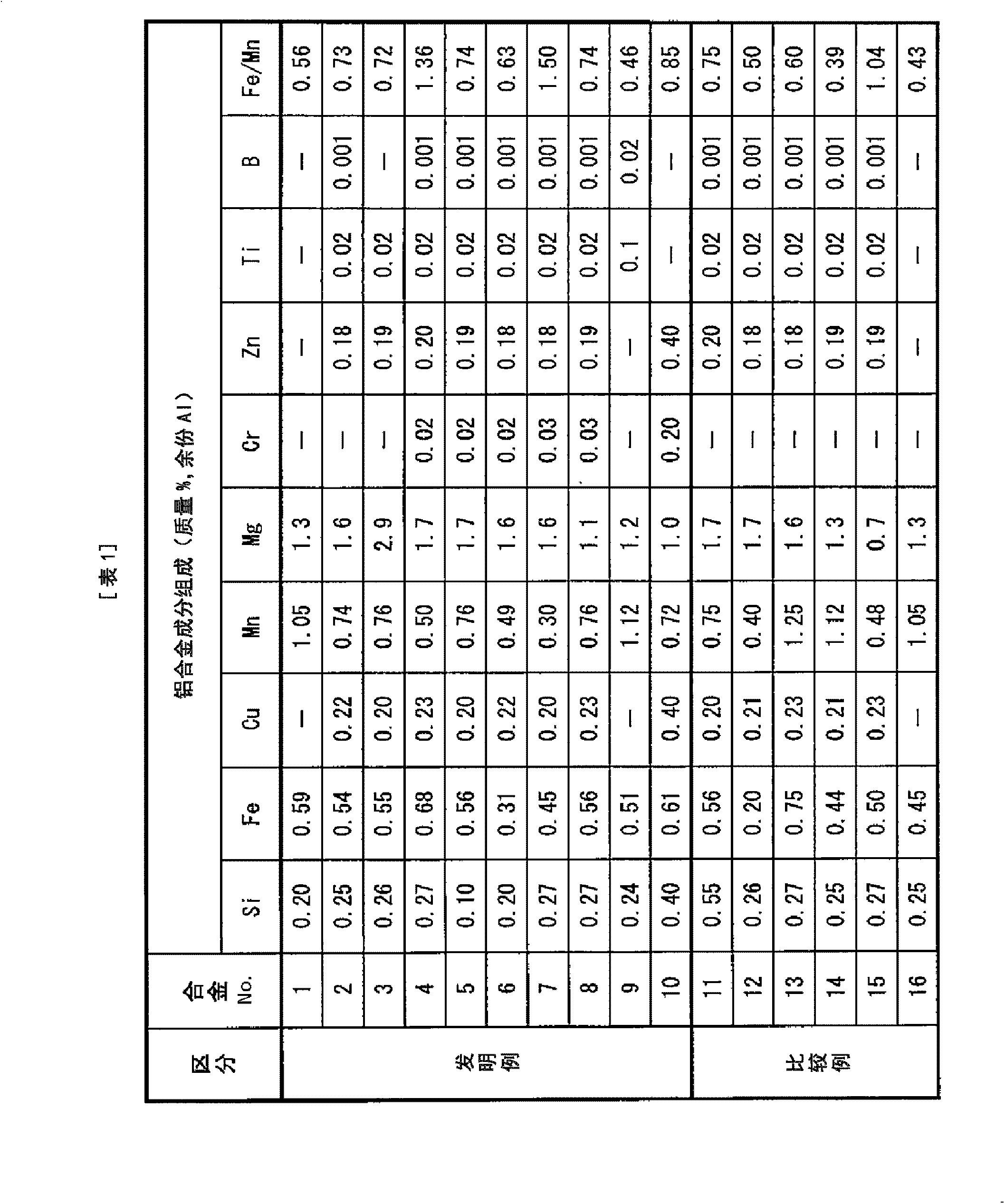

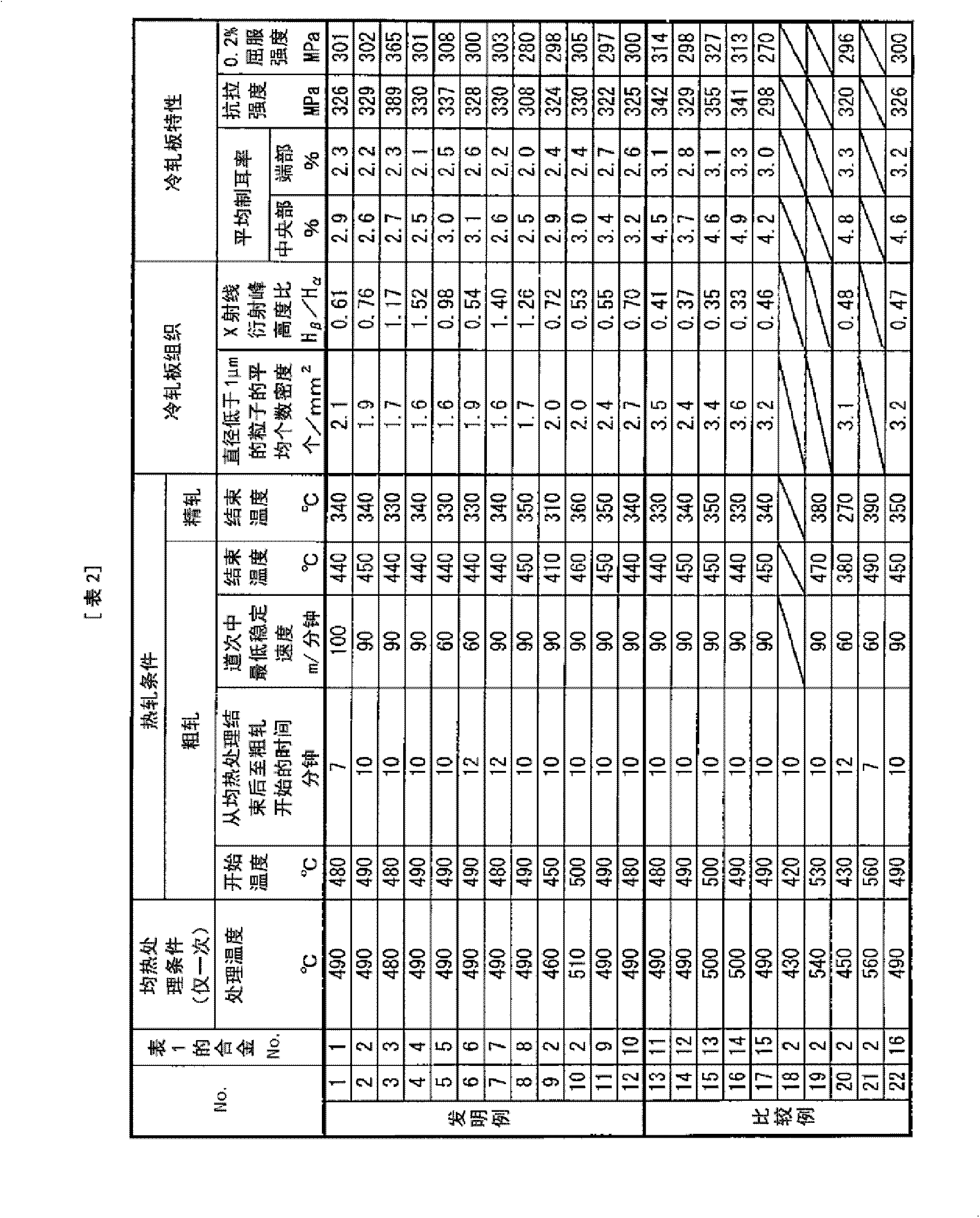

[0050] The chemical composition of the aluminum alloy cold-rolled sheet of the present invention, as a raw material for bottles and cans, needs to satisfy the above-mentioned necessary characteristics such as the formability and strength of cans, and from the point of view of the chemical composition, it is necessary to satisfy the required properties. Describe the organization specified by the present invention. Therefore, the aluminum alloy cold-rolled sheet of the present invention has the following composition: containing Mn: 0.3-1.2 mass%, Mg: 1.0-3.0 mass%, Fe: 0.3-0.7 mass%, Si: 0.1-0.5 mass%, and the Fe The mass composition ratio (Fe / Mn) with Mn is in the range of 0.45 to 1.5, and the balance is composed of Al and unavoidable imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com