Aluminum alloy plate for can lid and manufacturing method thereof

A technology of aluminum alloy plate and manufacturing method, applied in the direction of metal rolling, container, rigid container, etc., can solve the problems of limited ear-making rate control, ear-making control, etc., and achieve easy control, small anisotropy, and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

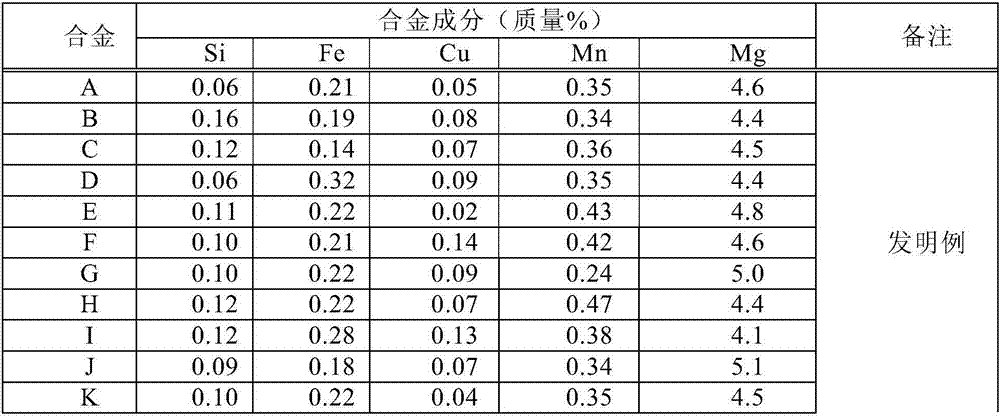

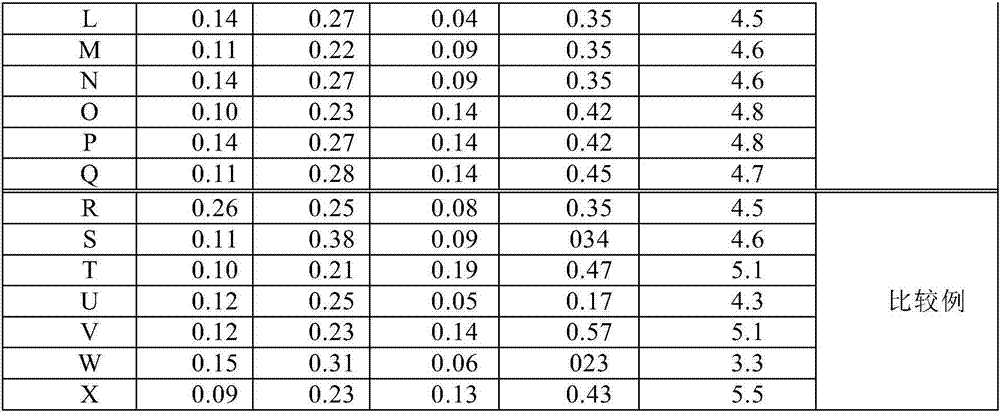

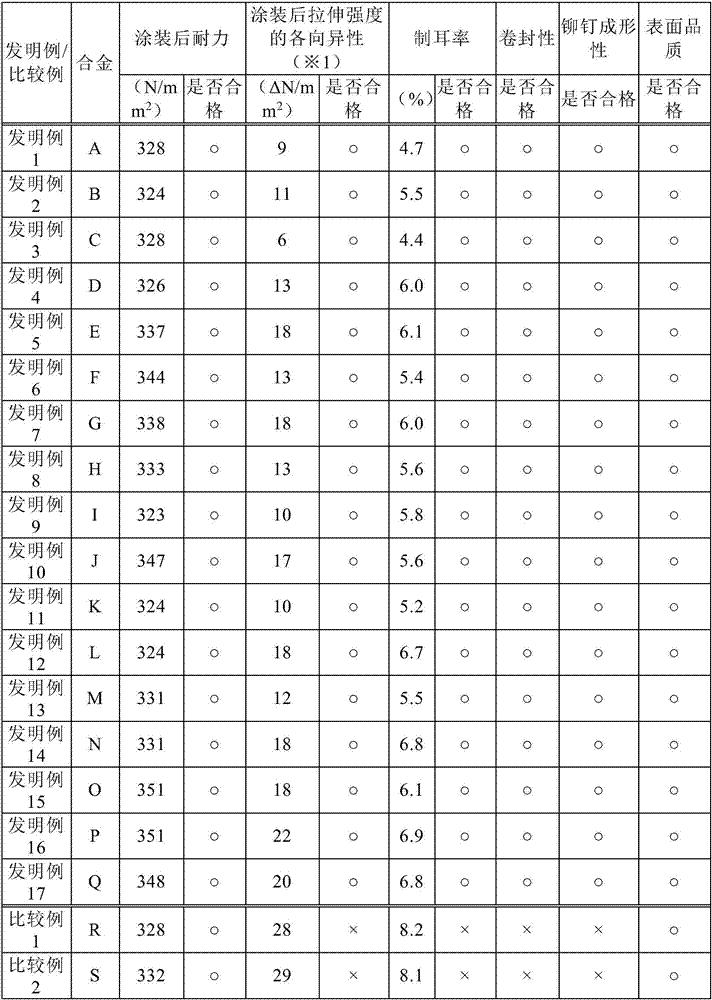

[0073] [Example 1: Invention Example 1 to Invention Example 17 and Comparative Example 1 to Comparative Example 7]

[0074] Aluminum alloys with the compositions shown in Table 1 were cast by the DC casting method, and the obtained ingot was subjected to a homogenization treatment at 490°C for 1 hour, followed by hot rough rolling with a reversing hot roughing mill, and then four-stage The tandem hot finishing mill implements hot finishing rolling. Hot rough rolling was performed at a starting temperature of 485°C. In addition, the hot finish rolling was started at a material temperature of 440°C (±5°C), with a total reduction rate of 90.7%, and a strain rate of 90sec for the final finish rolling pass. -1 To carry out hot finish rolling, the coil temperature on the side where the material is sent out is controlled at 345°C (±5°C). Thereafter, cold rolling was performed at a final cold rolling ratio of 90%, coating with an epoxy-based paint, and firing treatment at 260° C.×20...

Embodiment 2

[0105] [Example 2: Invention Example 18 to Invention Example 26 and Comparative Example 8 to Comparative Example 18]

[0106] Aluminum alloys corresponding to alloy M, alloy K, and alloy O of the present invention in Table 1 are cast by DC casting, and the obtained ingots are subjected to homogenization treatment, hot rolling, and cold casting under the manufacturing conditions shown in Table 3. After rolling, it is painted with an epoxy-based paint and fired at 260°C for 20 sec. In addition, Comparative Example 15 in Table 3 is a comparative example in which hot finish rolling is performed by a reversing rolling mill, and Comparative Example 17 is a continuous annealing line (Continuous Annealing Line, CAL) that performs rapid heating and rapid cooling after hot rolling. comparative example.

[0107] [table 3]

[0108]

[0109] With respect to the aluminum alloy plate for can ends obtained as described above, the resistance after coating and firing and the selvage rate w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com