A kind of production method of aluminum plate and aluminum strip for cosmetic mirror aluminum cover

A technology of aluminum cover aluminum plate and cosmetics, which is applied in the production of aluminum strips and the field of aluminum plates for cosmetic mirror aluminum covers, which can solve problems such as tissue segregation, stamping cracks, uneven grains, etc., and achieve large additions, no streaks, and a finer surface. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

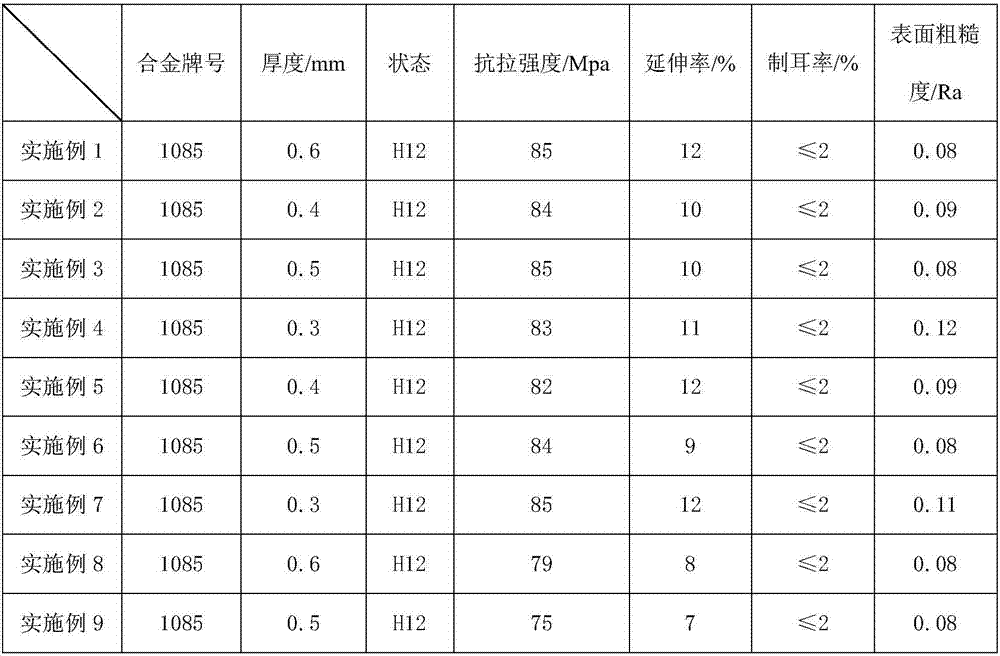

Examples

example 1

[0030] An aluminum plate and aluminum strip for cosmetic mirror aluminum cover, the mass percentage of its chemical composition is Al≥99.85%, Ti0.020~0.030%, and the rest are impurity elements, among which Si≤0.10%, Fe≤0.10%, Cu <0.01%, Mn<0.01%, Mg<0.01%, Cr<0.01%, Zn<0.01%.

[0031] The production method of the aluminum plate and strip for the above-mentioned cosmetic mirror aluminum cover includes the following steps: (1) Melting: 30 tons of aluminum ingots with a purity ≥ 99.9% are put into the melting furnace, and melted for 4 hours to obtain aluminum with a melt temperature of 720-750°C. Stir the molten aluminum at 720-750°C for 5 minutes; after the smelting is completed, use a nitrogen-chlorine mixture to refine the molten aluminum for 30 minutes in a stationary furnace and remove surface scum. The temperature of the stationary furnace is controlled at 710-730°C;

[0032] (2) Casting: The molten aluminum is introduced into the casting device from the static furnace thro...

example 2

[0047] An aluminum plate and aluminum strip for cosmetic mirror aluminum cover, the mass percentage of its chemical composition is Al≥99.85%, Ti0.020~0.030%, and the rest are impurity elements, among which Si≤0.10%, Fe≤0.10%, Cu <0.01%, Mn<0.01%, Mg<0.01%, Cr<0.01%, Zn<0.01%.

[0048] The production method of the aluminum plate and the aluminum strip for the above-mentioned cosmetic mirror aluminum cover comprises the following steps:

[0049] (1) Melting: Put 32 tons of aluminum ingots with a purity ≥ 99.9% into the melting furnace, melt for 5 hours to obtain molten aluminum with a melt temperature of 720-750°C, and stir the molten aluminum at 720-750°C for 5 minutes; after the smelting is completed, Refining the liquid aluminum for 32 minutes with nitrogen-chlorine mixed gas in the static furnace and removing the scum on the surface, the temperature of the static furnace is controlled at 710-730°C;

[0050] (2) Casting: The molten aluminum is introduced into the casting dev...

example 3

[0065] An aluminum plate and aluminum strip for cosmetic mirror aluminum cover, the mass percentage of its chemical composition is Al≥99.85%, Ti0.020~0.030%, and the rest are impurity elements, among which Si≤0.10%, Fe≤0.10%, Cu <0.01%, Mn<0.01%, Mg<0.01%, Cr<0.01%, Zn<0.01%.

[0066] The production method of the aluminum plate and the aluminum strip for the above-mentioned cosmetic mirror aluminum cover comprises the following steps:

[0067] (1) Melting: Put 34 tons of aluminum ingots with a purity ≥ 99.9% into the melting furnace, melt for 4.5 hours to obtain molten aluminum with a melt temperature of 720-750°C, and stir the molten aluminum for 5 minutes at 720-750°C; after the smelting is completed, Refining molten aluminum for 34 minutes with nitrogen-chlorine mixed gas in the static furnace and removing surface scum, the temperature of the static furnace is controlled at 710-730°C;

[0068] (2) Casting: The molten aluminum is introduced into the casting device from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com