Production method of aluminum plates and aluminum strips for cosmetic mirror surface aluminum caps

The technology of an aluminum cover aluminum plate and a production method is applied to the production of aluminum strips and the field of aluminum plates for cosmetic mirror aluminum covers. The effect of reducing the large liquid level drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

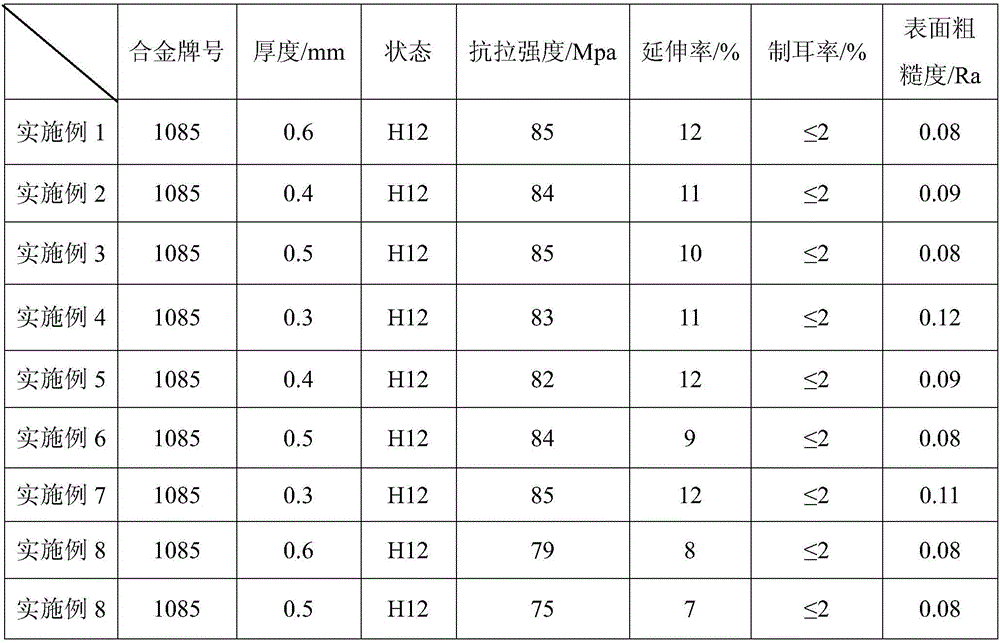

Examples

example 1

[0029] An aluminum plate and aluminum strip for cosmetic mirror aluminum cover, the mass percentage of its chemical composition is Al≥99.85%, Ti0.020~0.030%, and the rest are impurity elements, among which Si≤0.10%, Fe≤0.10%, Cu <0.01%, Mn<0.01%, Mg<0.01%, Cr<0.01%, Zn<0.01%.

[0030] The production method of the aluminum plate and the aluminum strip for the above-mentioned cosmetic mirror aluminum cover comprises the following steps:

[0031] (1) Melting: Put 30 tons of aluminum ingots with a purity ≥ 99.9% into the melting furnace, melt for 4 hours to obtain molten aluminum with a melt temperature of 720-750°C, and stir the molten aluminum for 5 minutes at 720-750°C; after the smelting is completed, Refining the liquid aluminum for 30 minutes with nitrogen-chlorine mixed gas in the static furnace and removing the scum on the surface, the temperature of the static furnace is controlled at 710-730°C;

[0032] (2) Casting: The molten aluminum is introduced into the casting dev...

example 2

[0047] An aluminum plate and aluminum strip for cosmetic mirror aluminum cover, the mass percentage of its chemical composition is Al≥99.85%, Ti0.020~0.030%, and the rest are impurity elements, among which Si≤0.10%, Fe≤0.10%, Cu <0.01%, Mn<0.01%, Mg<0.01%, Cr<0.01%, Zn<0.01%.

[0048] The production method of the aluminum plate and the aluminum strip for the above-mentioned cosmetic mirror aluminum cover comprises the following steps:

[0049] (1) Melting: Put 32 tons of aluminum ingots with a purity ≥ 99.9% into the melting furnace, melt for 5 hours to obtain molten aluminum with a melt temperature of 720-750°C, and stir the molten aluminum at 720-750°C for 5 minutes; after the smelting is completed, Refining the liquid aluminum for 32 minutes with nitrogen-chlorine mixed gas in the static furnace and removing the scum on the surface, the temperature of the static furnace is controlled at 710-730°C;

[0050] (2) Casting: The molten aluminum is introduced into the casting dev...

example 3

[0065] An aluminum plate and aluminum strip for cosmetic mirror aluminum cover, the mass percentage of its chemical composition is Al≥99.85%, Ti0.020~0.030%, and the rest are impurity elements, among which Si≤0.10%, Fe≤0.10%, Cu <0.01%, Mn<0.01%, Mg<0.01%, Cr<0.01%, Zn<0.01%.

[0066] The production method of the aluminum plate and the aluminum strip for the above-mentioned cosmetic mirror aluminum cover comprises the following steps:

[0067] (1) Melting: Put 34 tons of aluminum ingots with a purity ≥ 99.9% into the melting furnace, melt for 4.5 hours to obtain molten aluminum with a melt temperature of 720-750°C, and stir the molten aluminum for 5 minutes at 720-750°C; after the smelting is completed, Refining molten aluminum for 34 minutes with nitrogen-chlorine mixed gas in the static furnace and removing surface scum, the temperature of the static furnace is controlled at 710-730°C;

[0068] (2) Casting: The molten aluminum is introduced into the casting device from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com