Patents

Literature

159results about How to "Inhibit flaking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

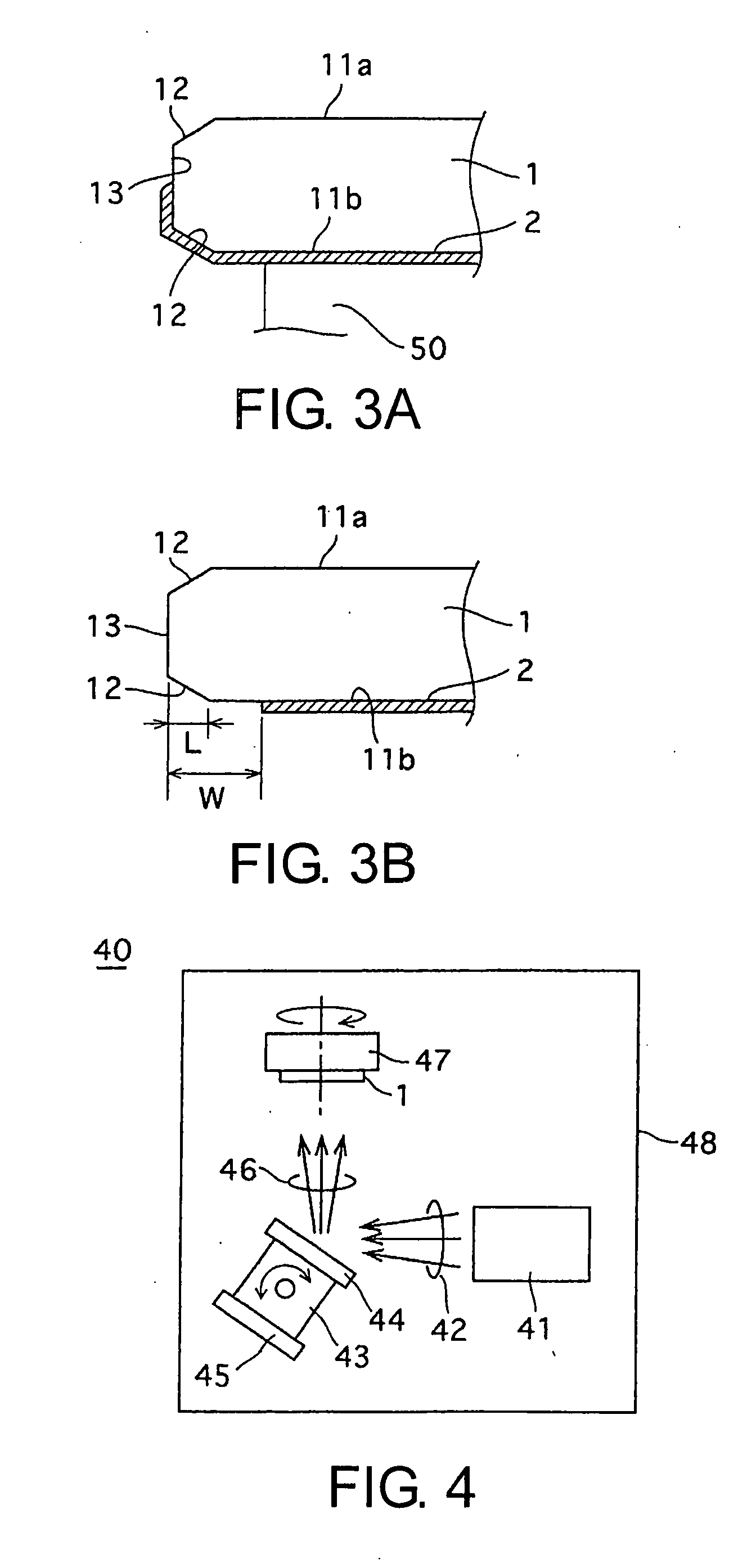

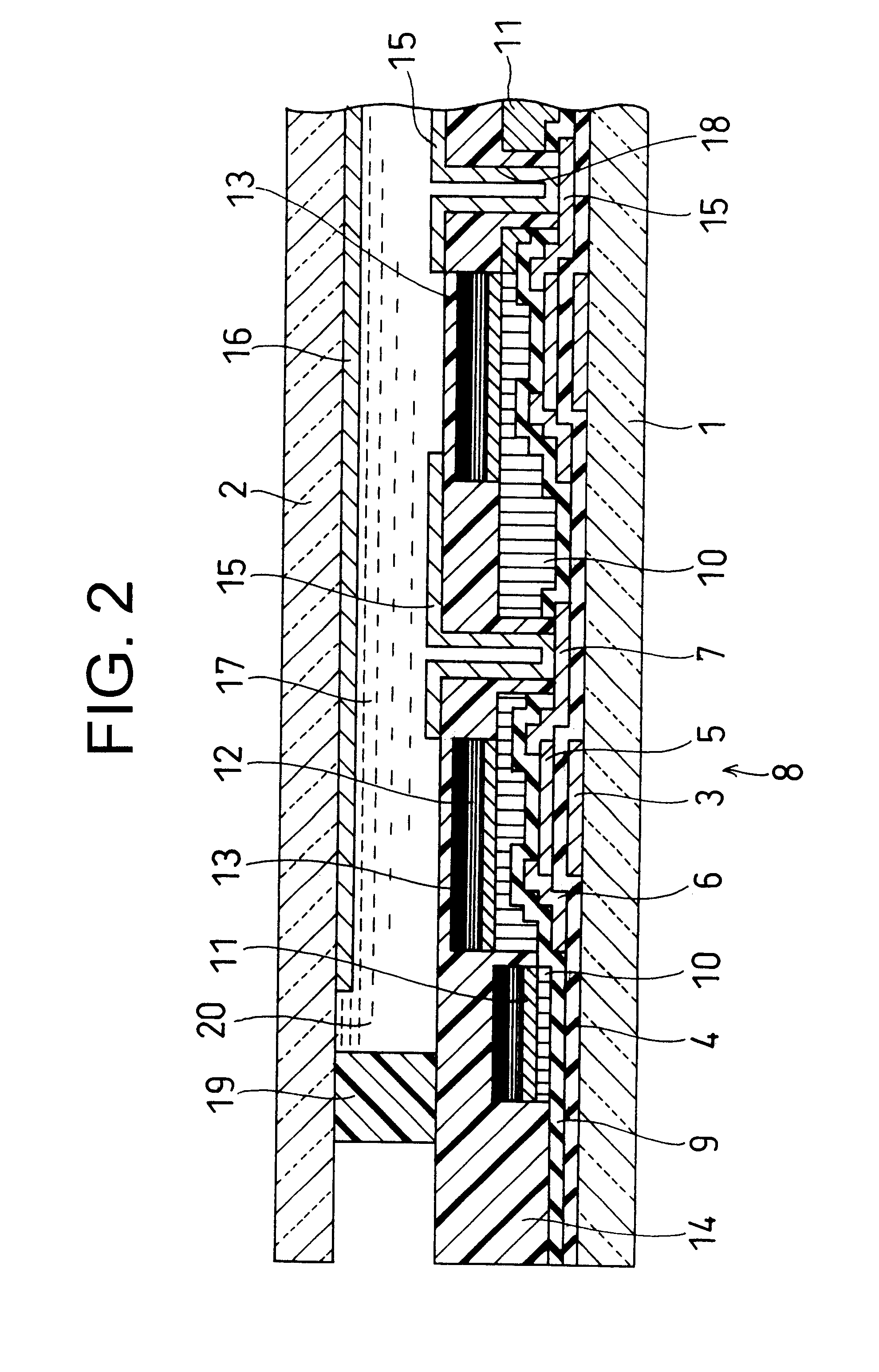

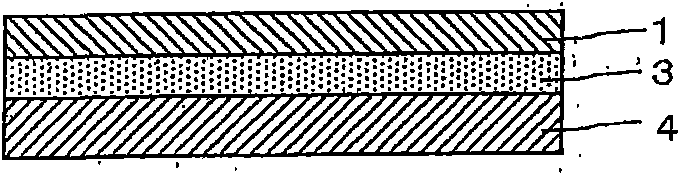

Substrate with a multilayer reflection film, reflection type mask blank for exposure, reflection type mask for exposure and methods of manufacturing them

InactiveUS20050238922A1Avoid it happening againMinimizing surface defectRadiation/particle handlingNanoinformaticsNitrogenOptoelectronics

A multilayer-reflection-film-coated substrate includes a substrate, a multilayer reflection film formed on the substrate and reflecting an exposure light, and a conductive film formed on an opposite side of the substrate from the multilayer reflection film in a region excluding at least a peripheral portion of the substrate. The conductive film is made of a material containing chromium (Cr). The conductive film contains nitrogen (N) on a substrate side and at least one of oxygen (O) and carbon (C) on a surface side. A reflection type mask blank for exposure is obtained by forming an absorber film for absorbing the exposure light on the multilayer reflection film of the multilayer-reflection-film-coated substrate. A reflection type mask is obtained by forming a pattern on the absorber film of the reflection type mask blank for exposure.

Owner:HOYA CORP

Implant having a coating containing cholesterol or cholesterol ester

InactiveUS20070299512A1Improve ductilityEasy to processSurgeryCoatingsCholesteryl esterHDL cholesterol ester

A coated implant and a method of use of cholesterol or a cholesterol ester. The implant has a coating which contains one or more components selected from the group of cholesterol and cholesterol esters.

Owner:BIOTRONIK VI PATENT

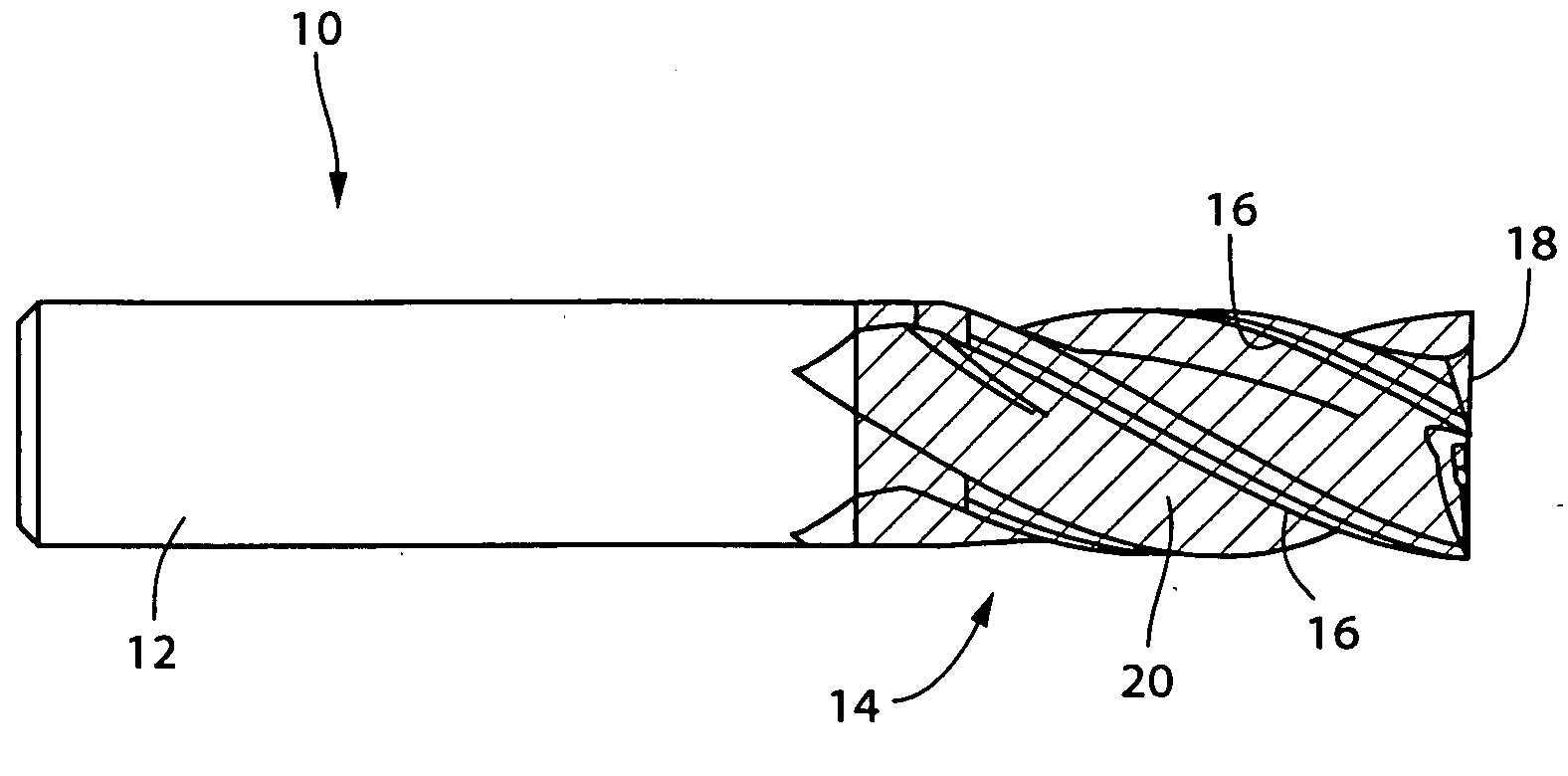

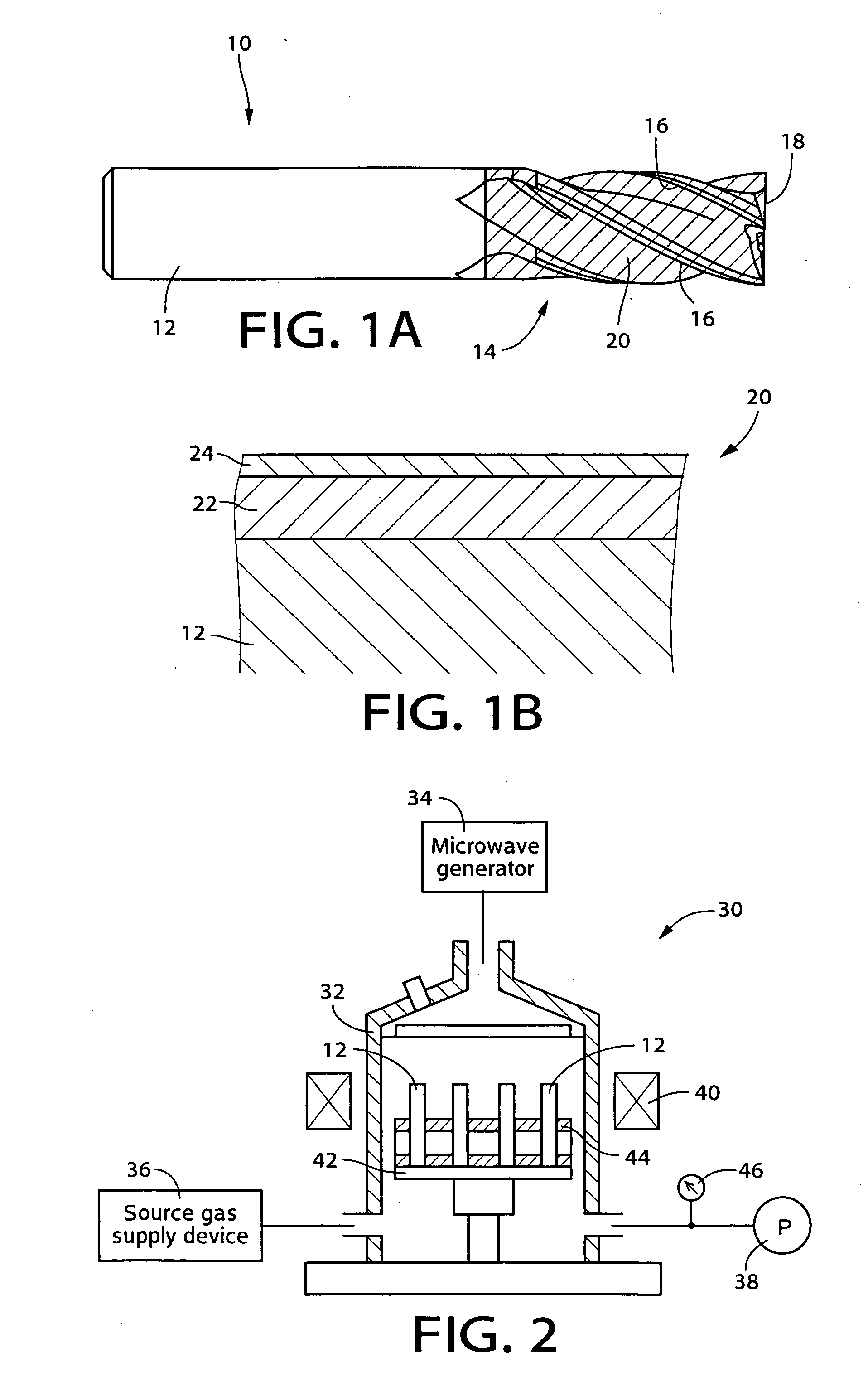

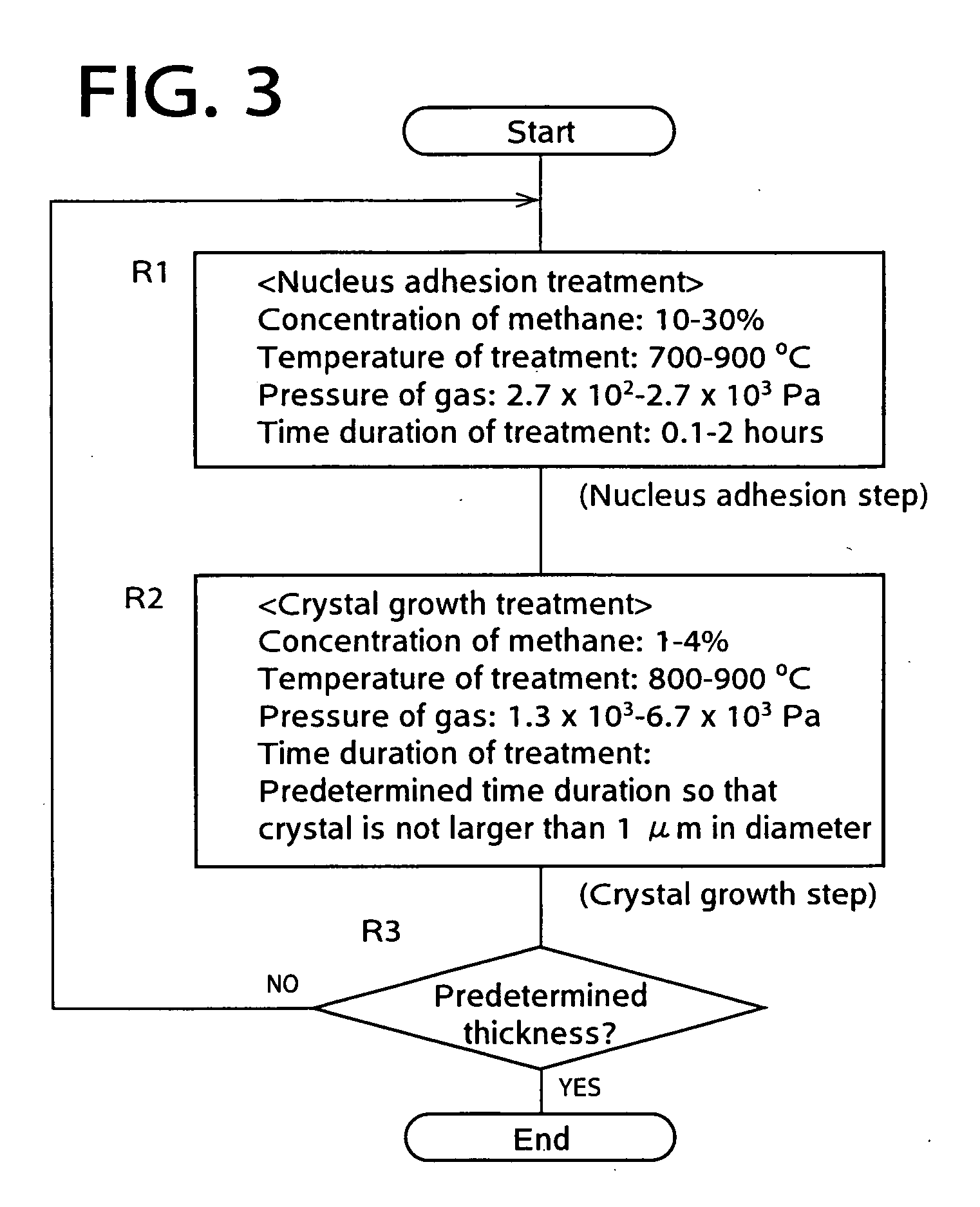

Hard coating and machining tool disposed with hard coating

ActiveUS20060115650A1Procures electrical conductivityImprove adhesionThread cutting toolsPigmenting treatmentBoronMachining

A hard coating that is to be disposed on a surface of a body includes a diamond layer which includes a plurality of diamond grains and is doped with boron, and an outer layer which includes an intermetallic compound and is disposed on the diamond layer by a physical vapor deposition method.

Owner:OSG

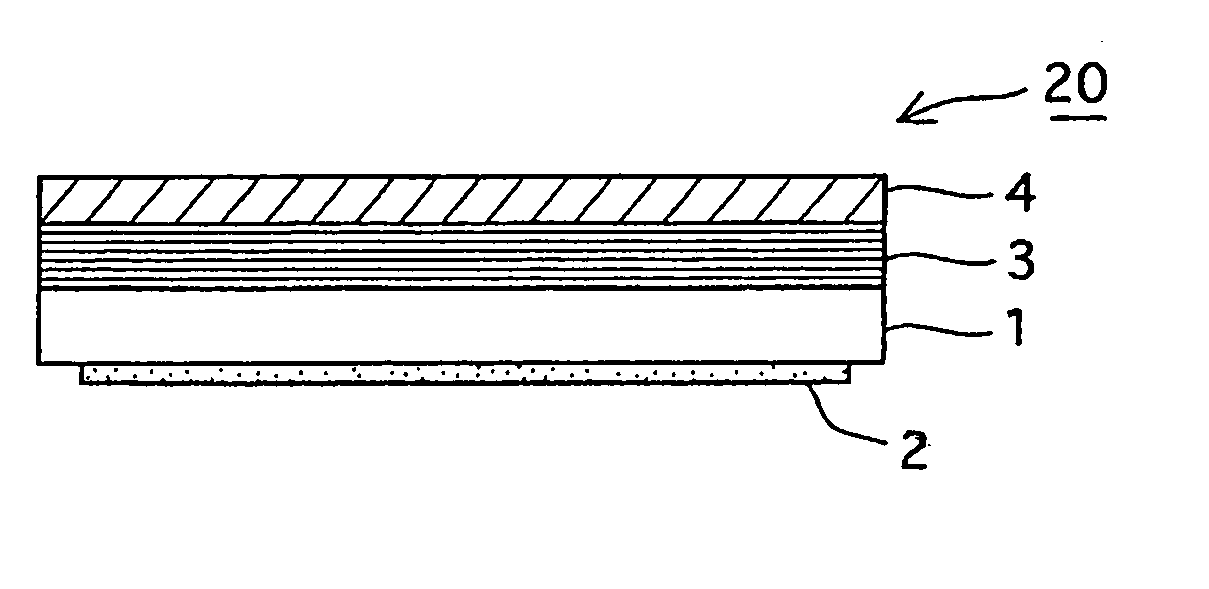

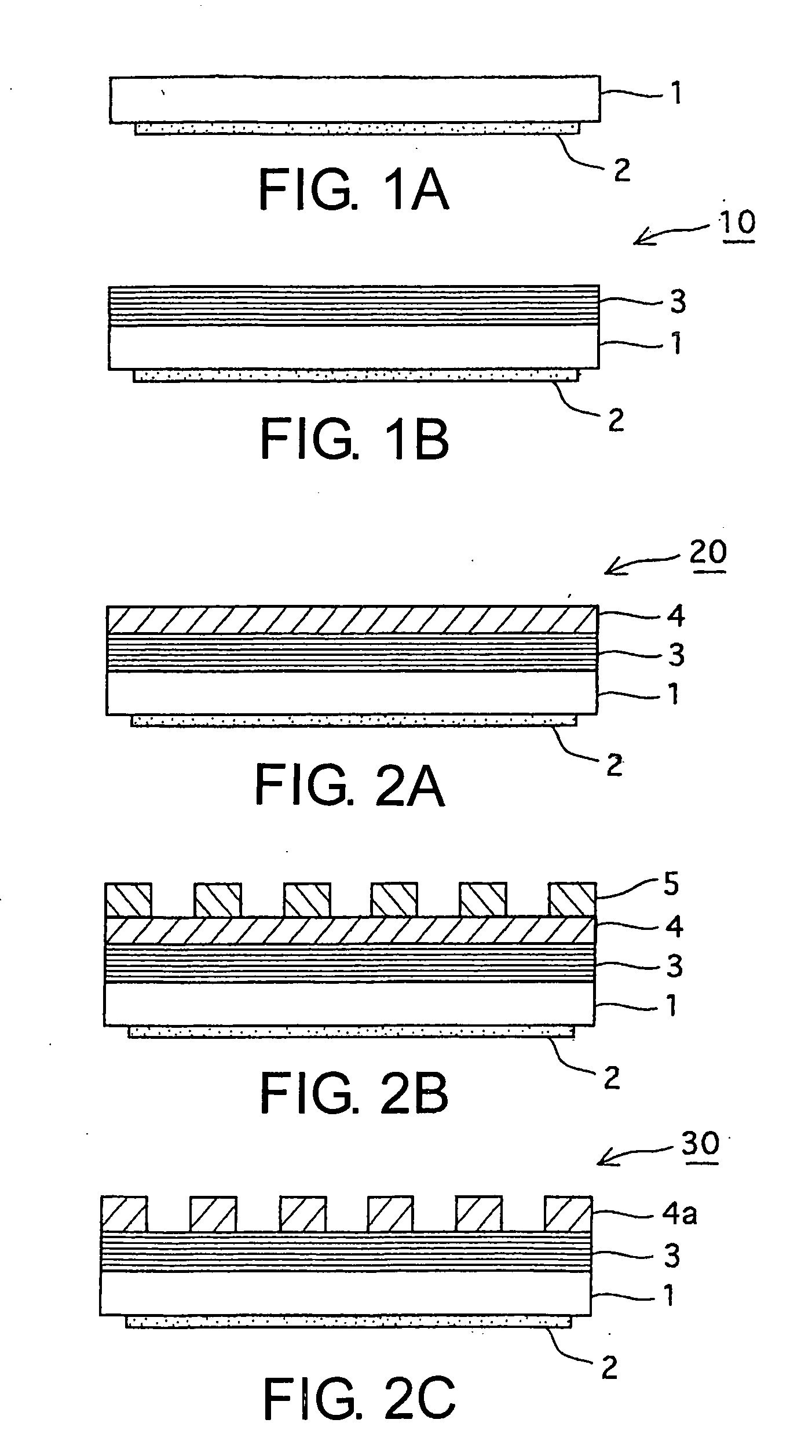

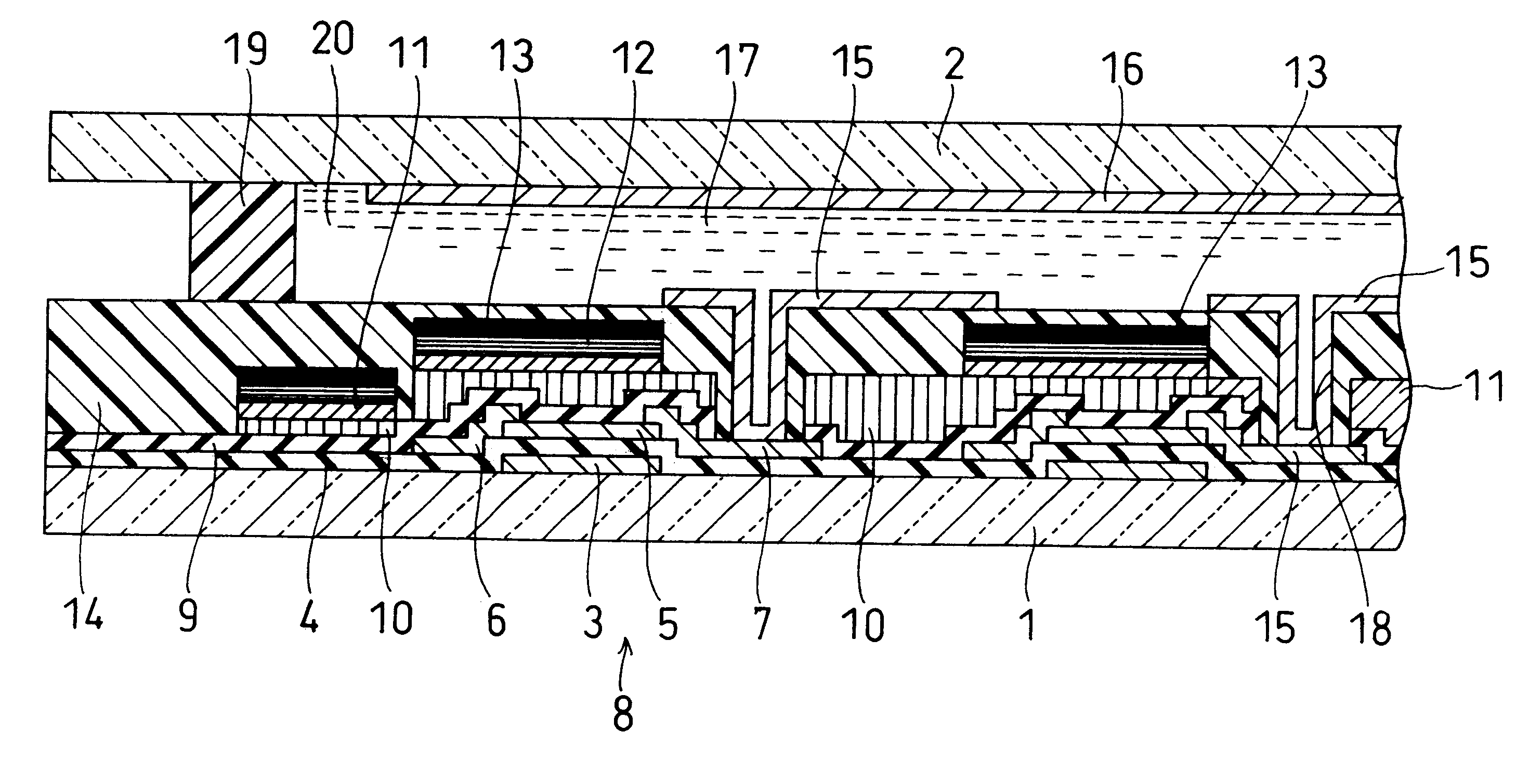

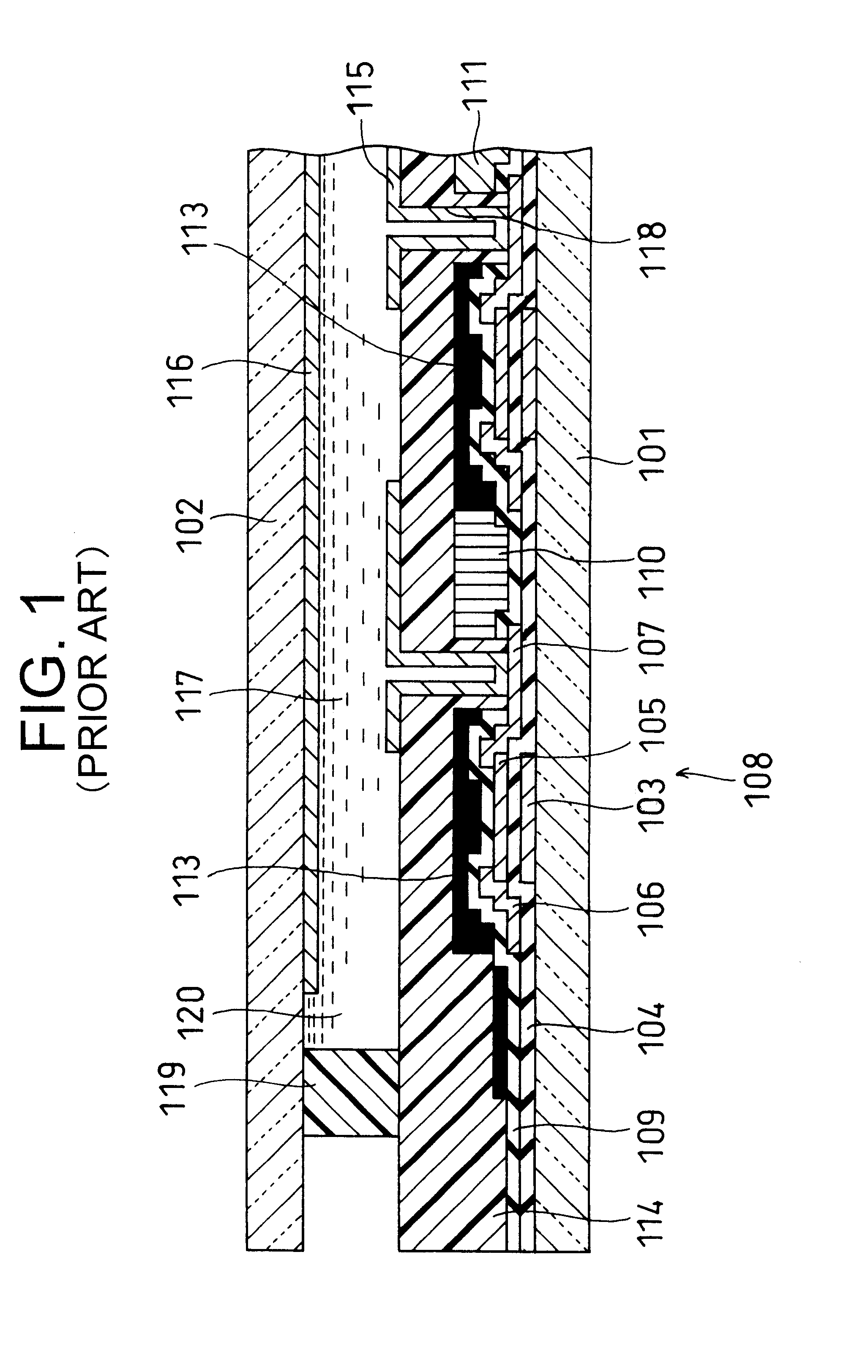

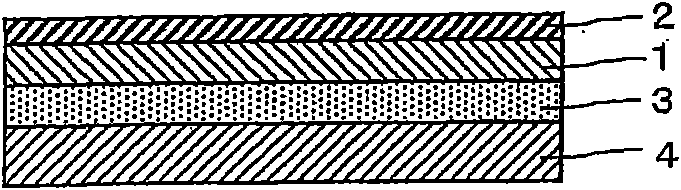

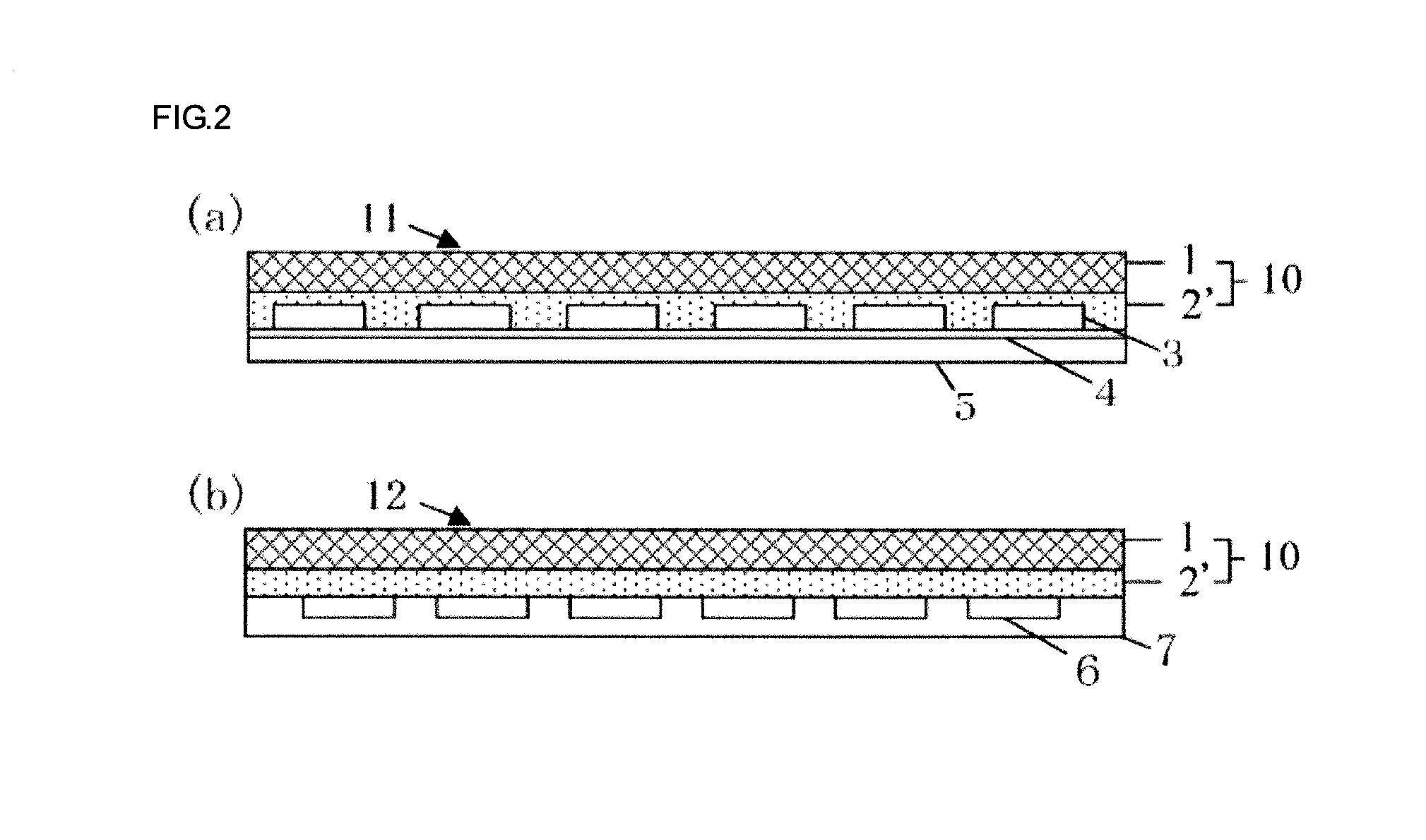

Color liquid crystal display panel

InactiveUS6445432B2Inhibit flakingHigh optical densityTelevision system detailsStatic indicating devicesInsulation layerLiquid-crystal display

First and second transparent substrates which are arranged to face each other are provided to a color liquid crystal display panel. A liquid crystal layer is provided between the first and the second transparent substrates. A plurality of thin film transistors are provided on the first transparent substrate. An insulation film provided on the first transparent substrate so as to cover the thin film transistors. A color filter which includes first to third color layers stacked on the insulation layer is provided. A contacting color layer is provided on the insulation film in a region above the thin film transistors. The contacting color layer has at least one color layer selected from a group of composed of the first to third color layers. A black matrix is provided on the contacting color layer. The black matrix has opening portions for transmitting light from the color filter.

Owner:NEC LCD TECH CORP

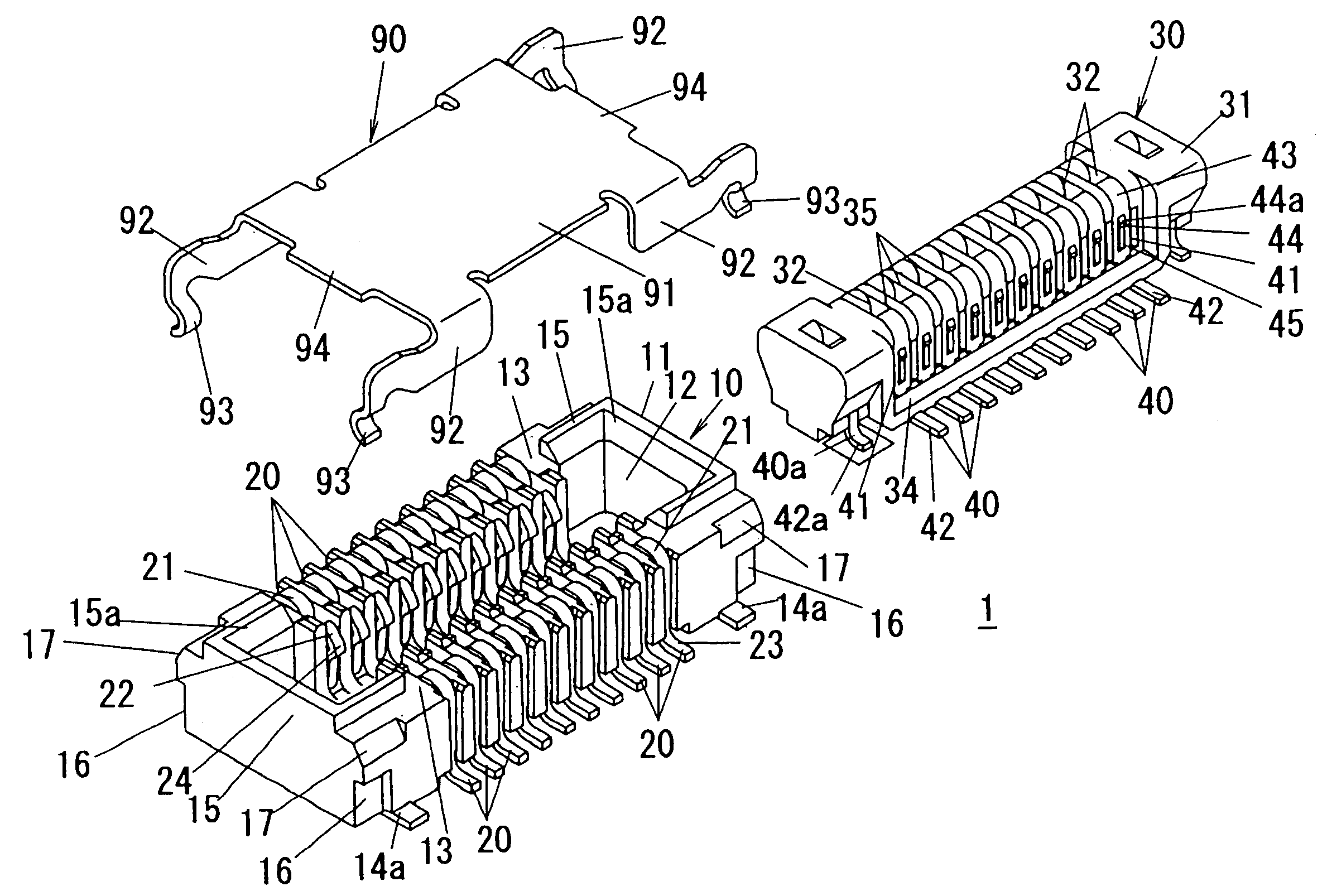

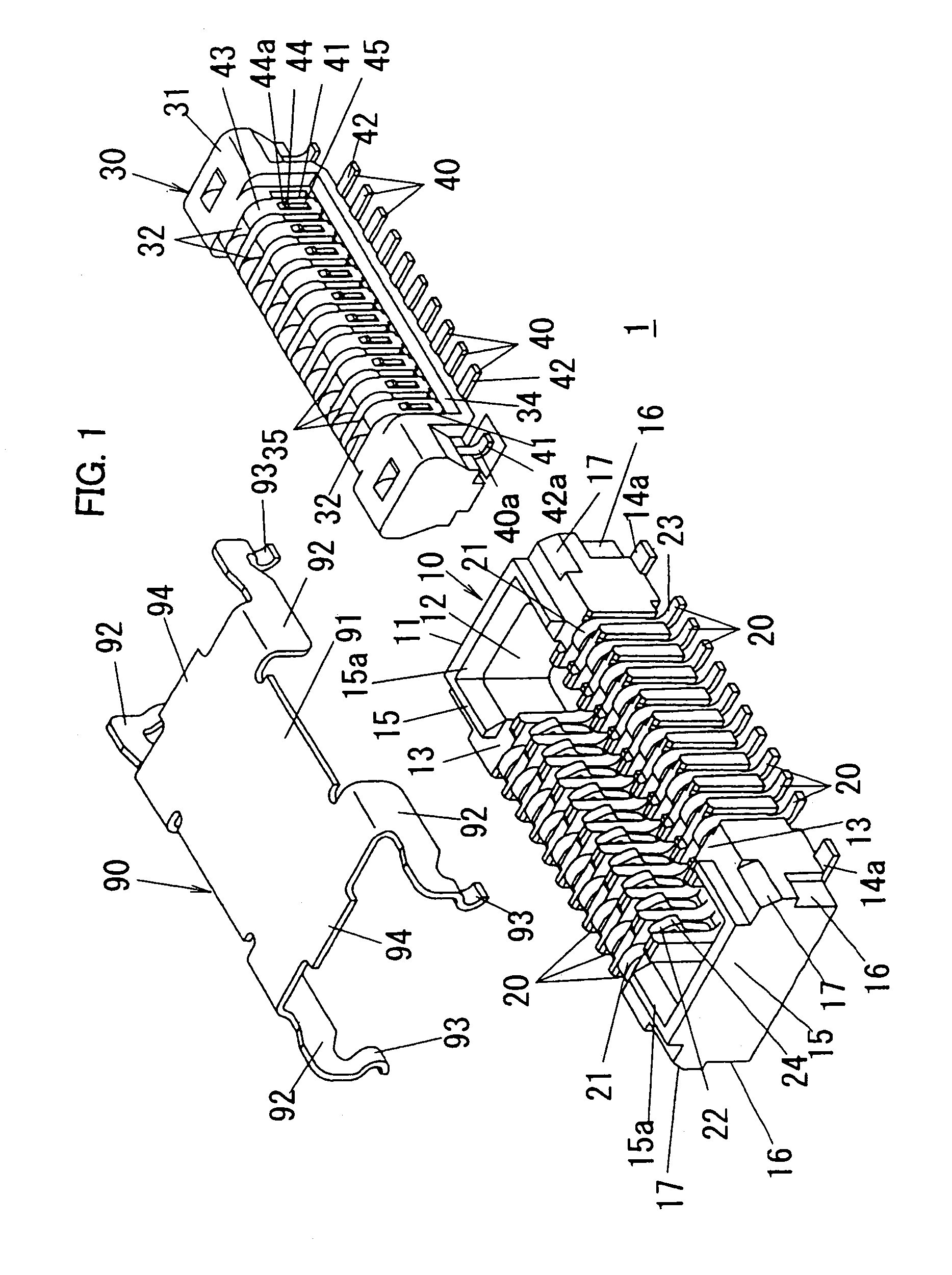

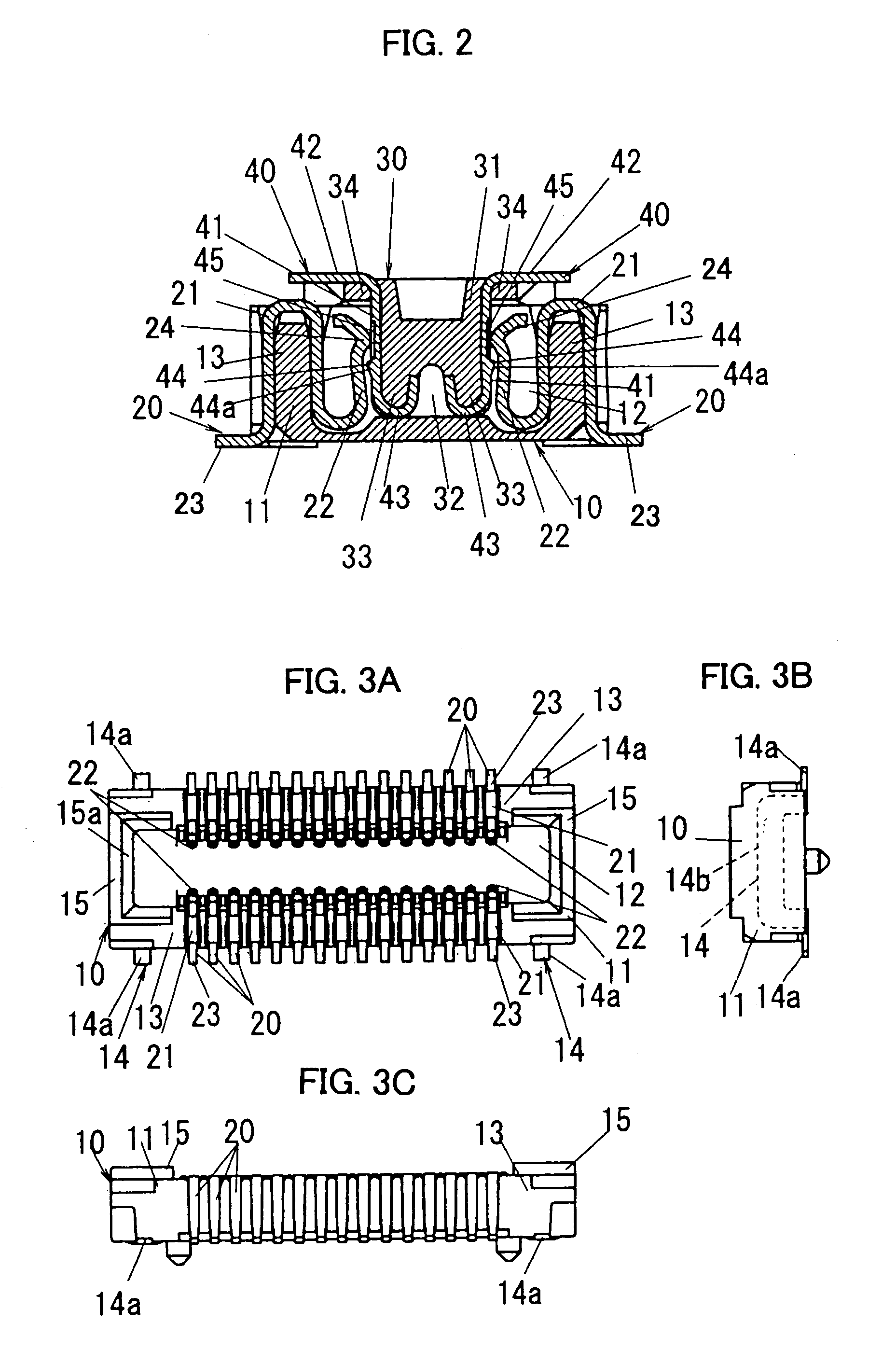

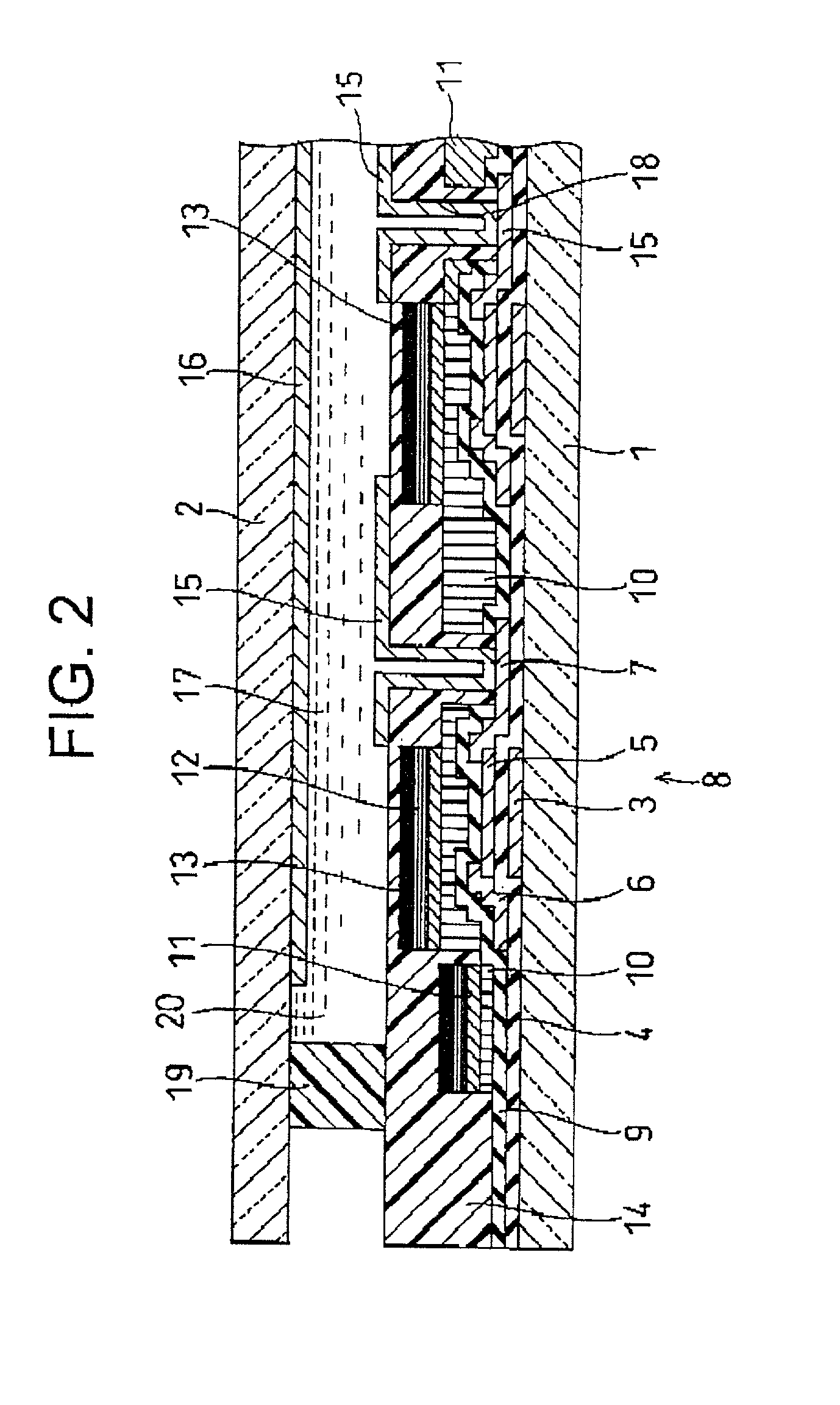

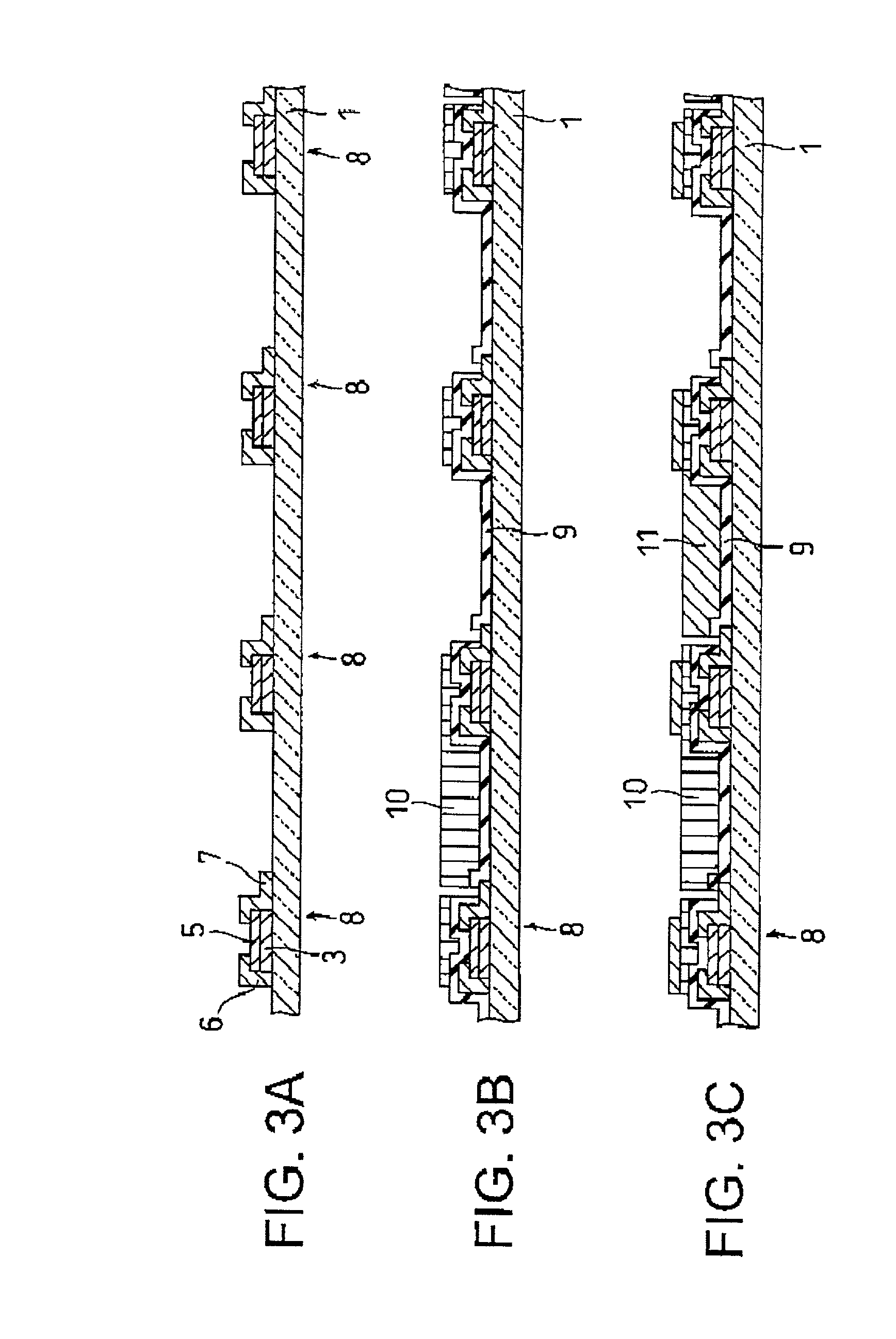

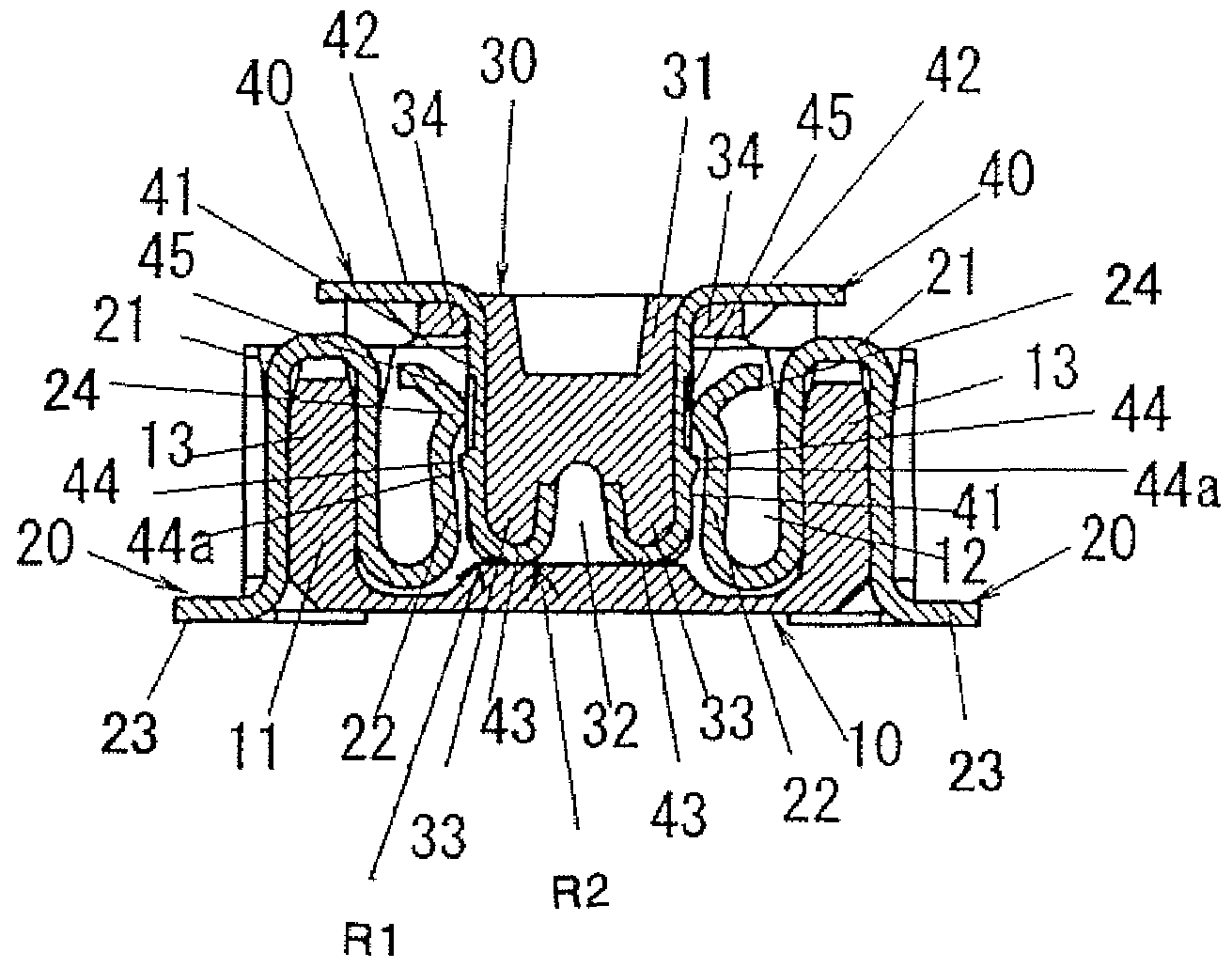

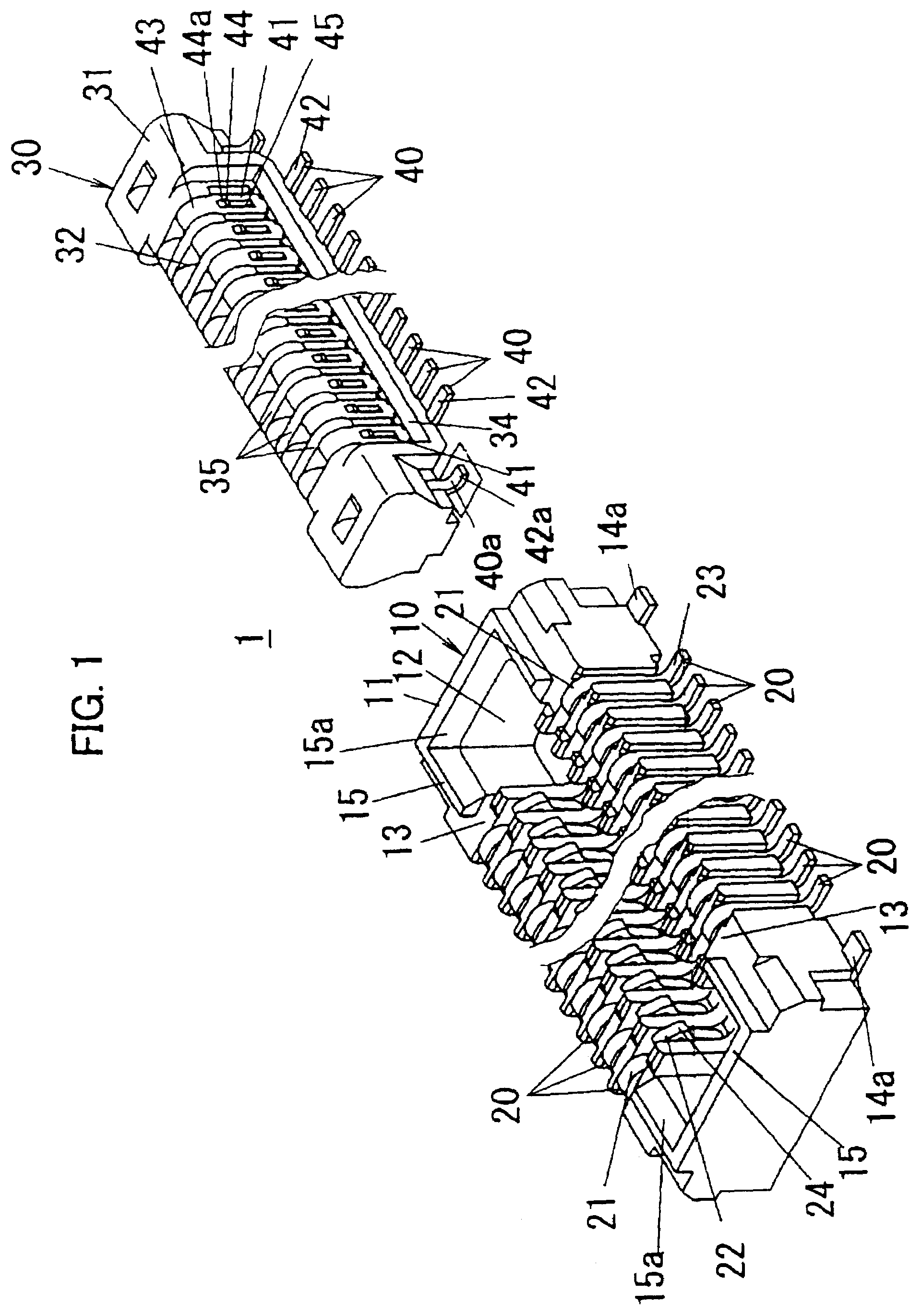

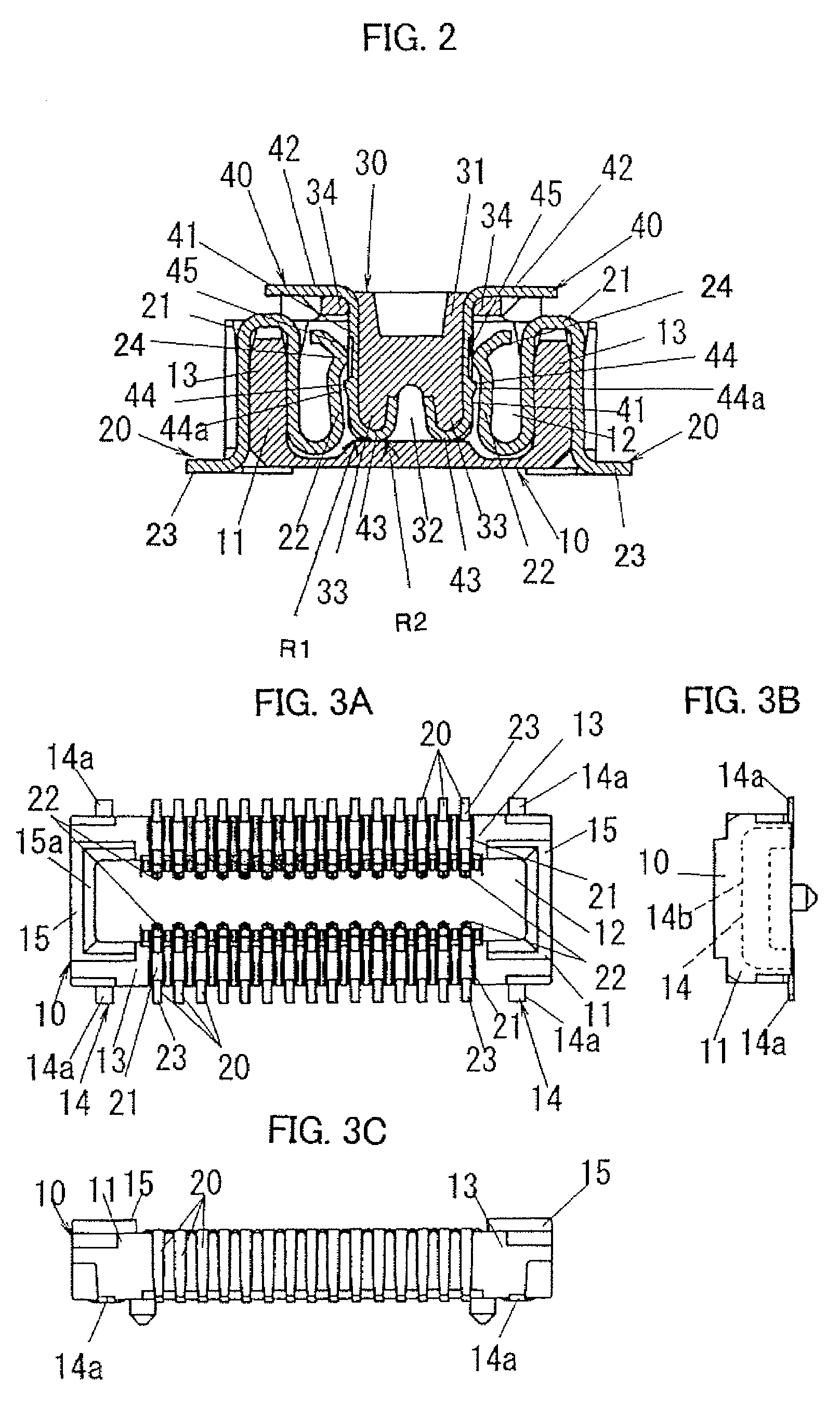

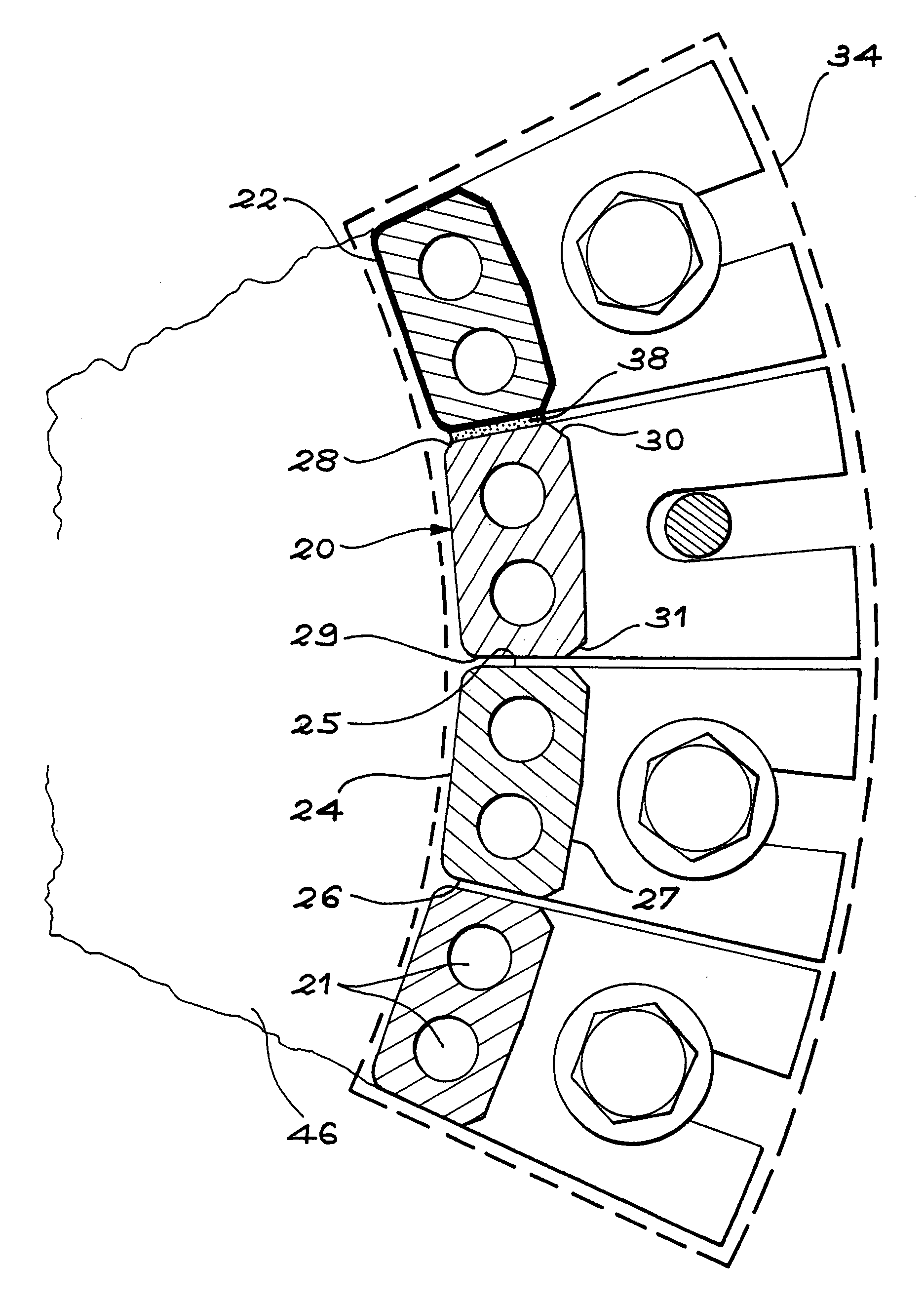

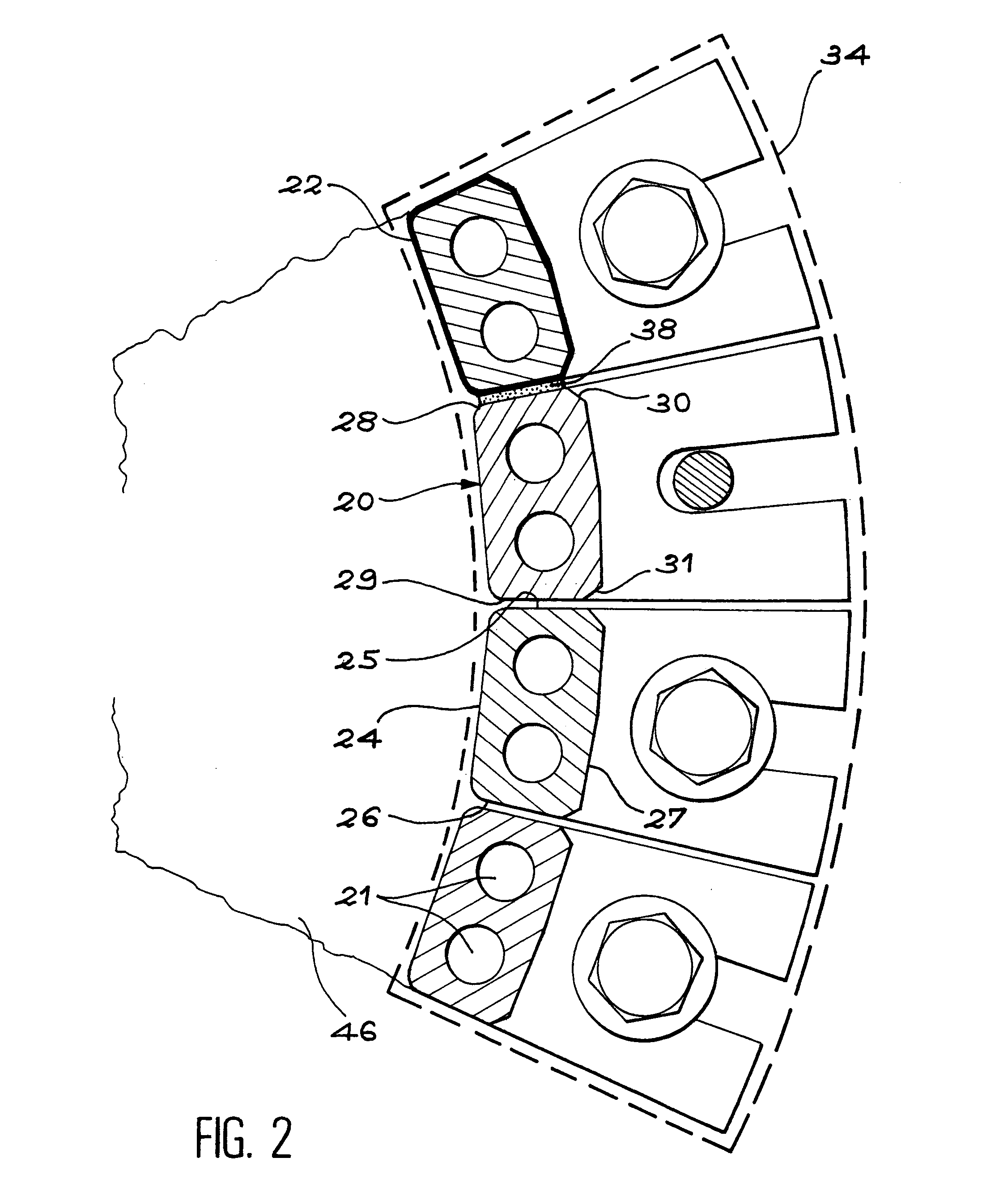

Connector for electrically connecting electronic components

ActiveUS7232317B2Flaking of the header post from the header body can be preventedInhibit flakingVehicle connectorsContact member cases/bases manufactureCross wallEngineering

A protruding table which was conventionally provided in a center portion of a socket body is eliminated, so that a dimension of a socket in widthwise direction is reduced. When the socket is mounted on a circuit board, an adsorption cover is attached to the socket, and the socket is adsorbed by and held on an adsorption nozzle via the adsorption cover. On the other hand, with respect to a header, gaps between header posts arranged in longitudinal direction are separated by cross walls, so that concave portions are formed between the cross walls. Under a state that an adsorption face of the adsorption nozzle is contacted with the header so that a suction opening of the adsorption nozzle face the concave portion, an enclosed space is formed by at least two cross walls, a bottom face of the concave portion and the adsorption face of the adsorption nozzle. When air in the enclosed space is sucked from the suction opening of the adsorption nozzle, negative pressure occurs, so that the header is adsorbed by and held on the adsorption nozzle. Consequently, it enables the adsorption and holding by the adsorption nozzle, and enables to reduce a dimension of the socket in widthwise direction.

Owner:MATSUSHITA ELECTRIC WORKS LTD

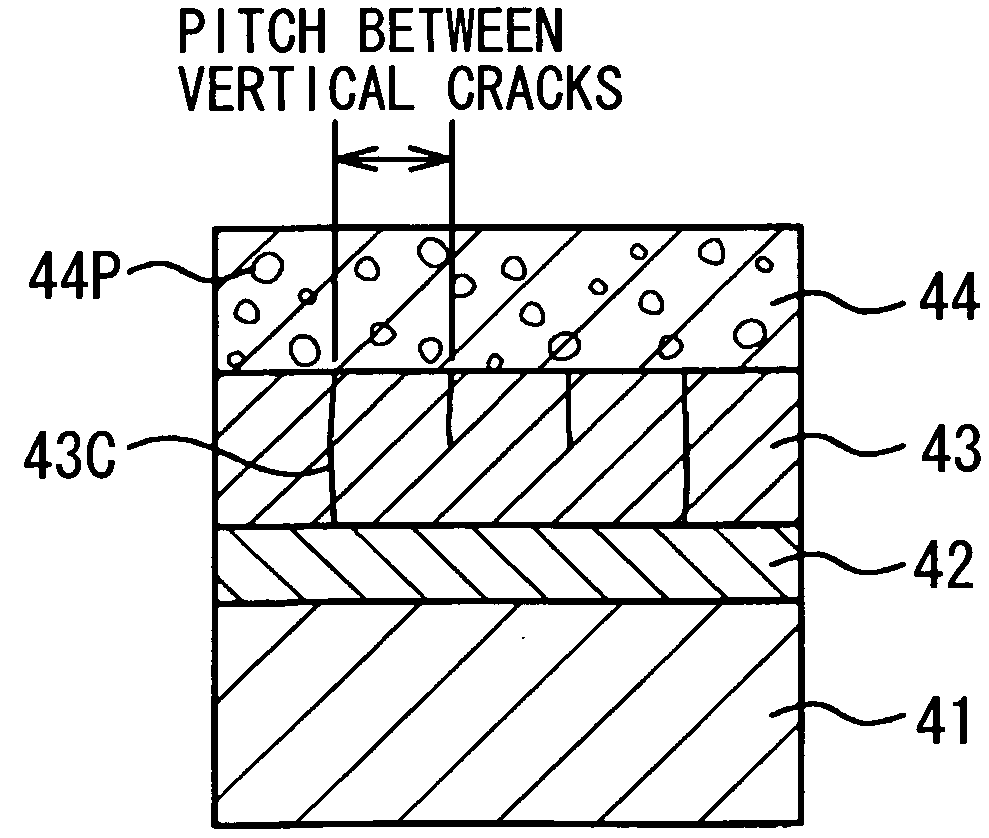

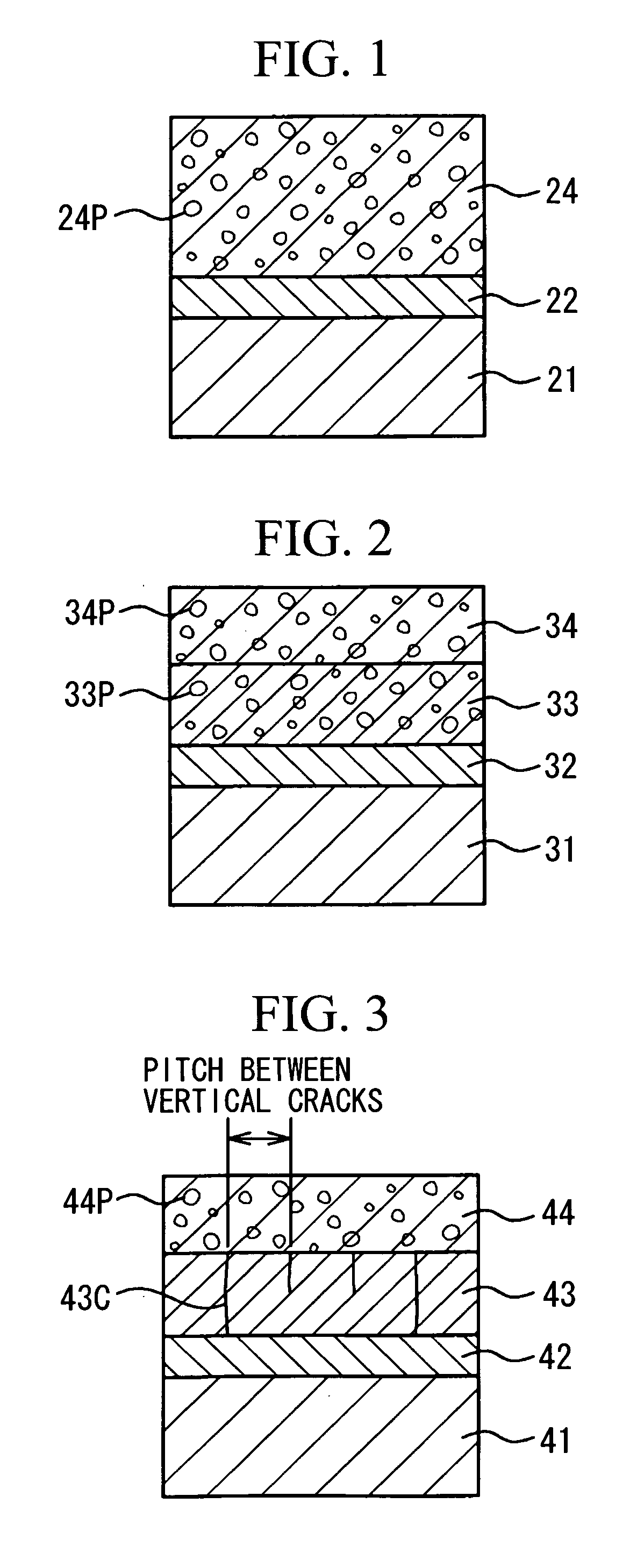

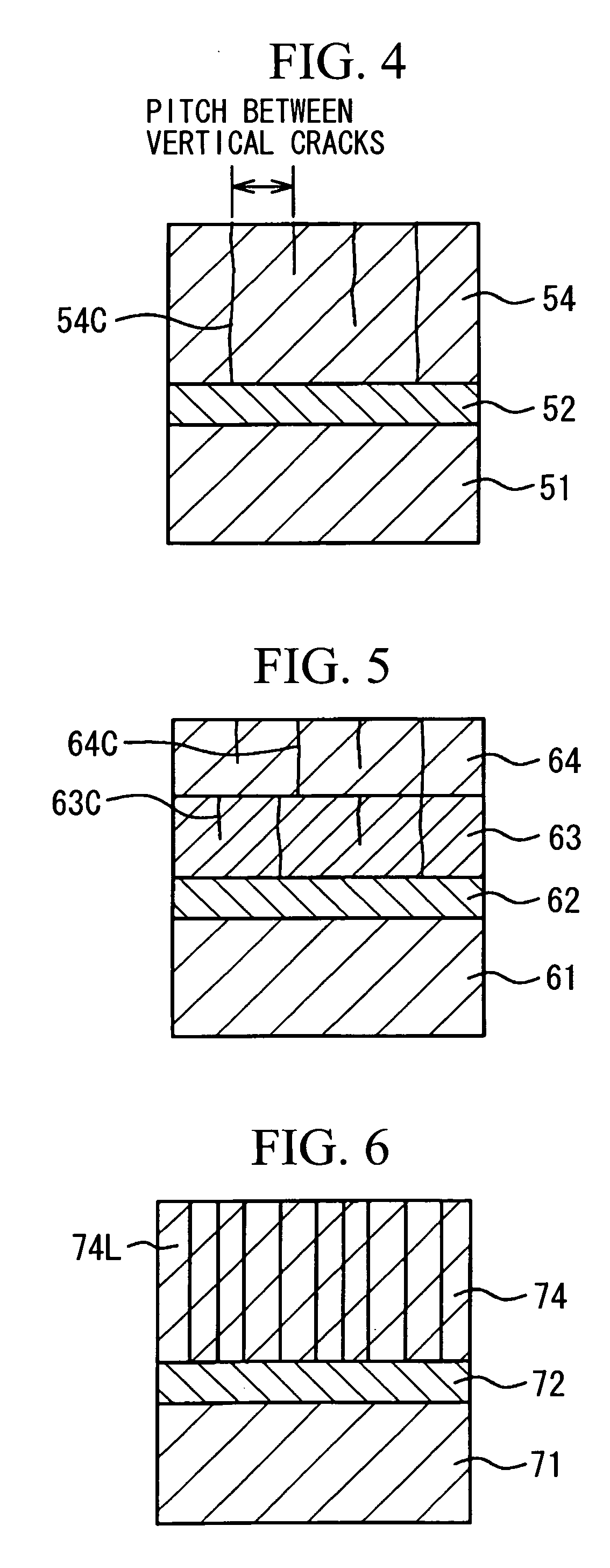

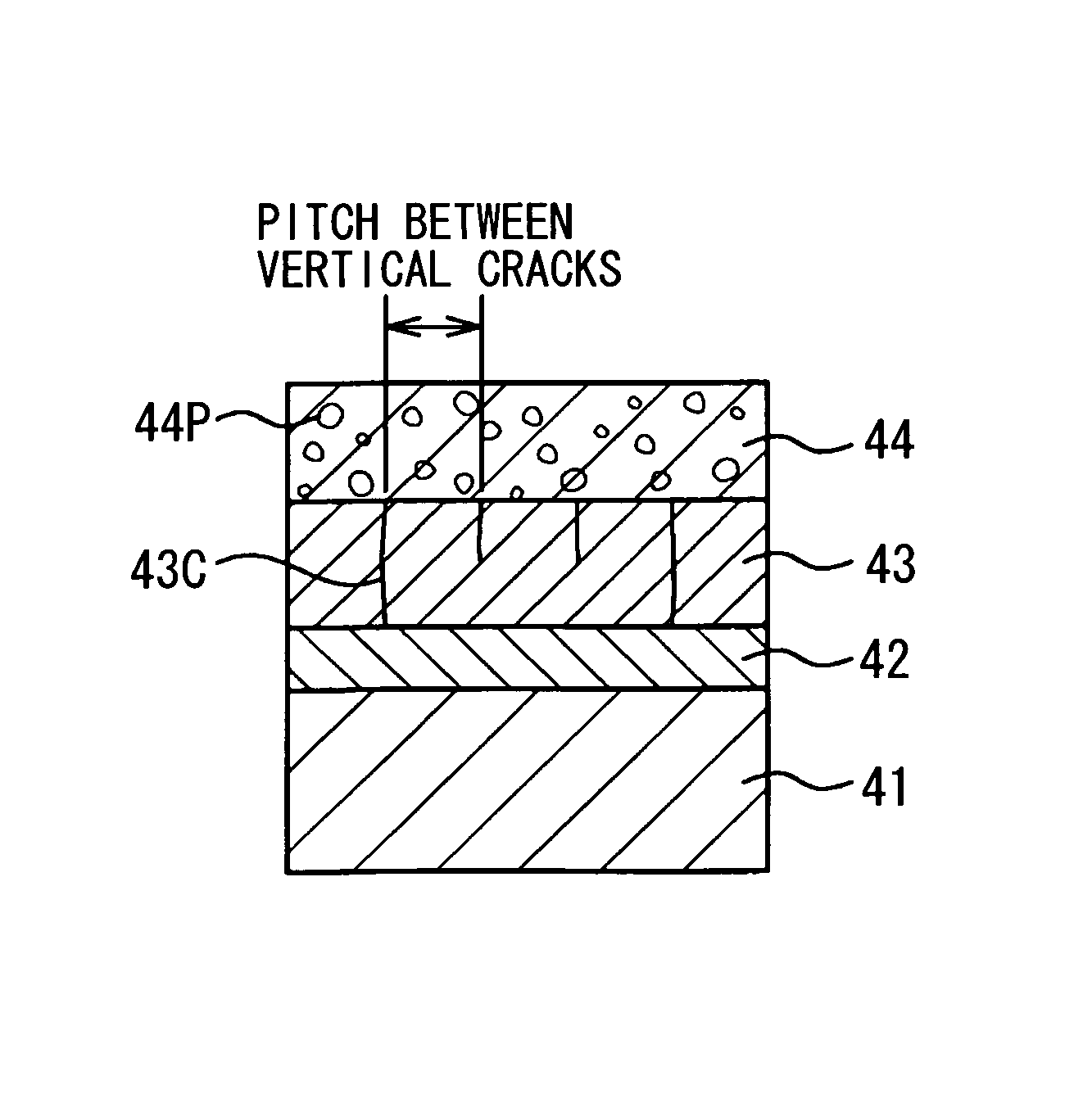

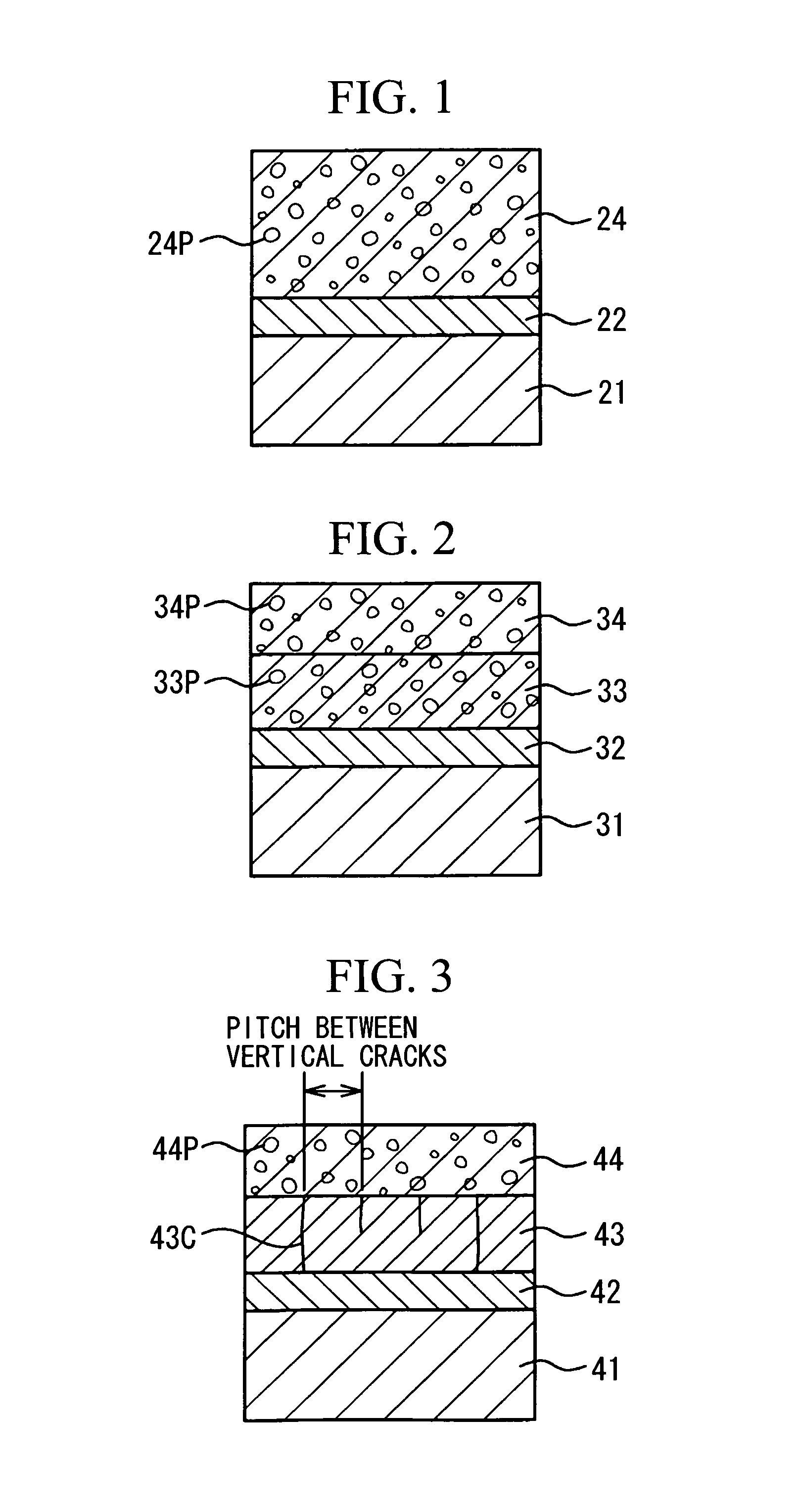

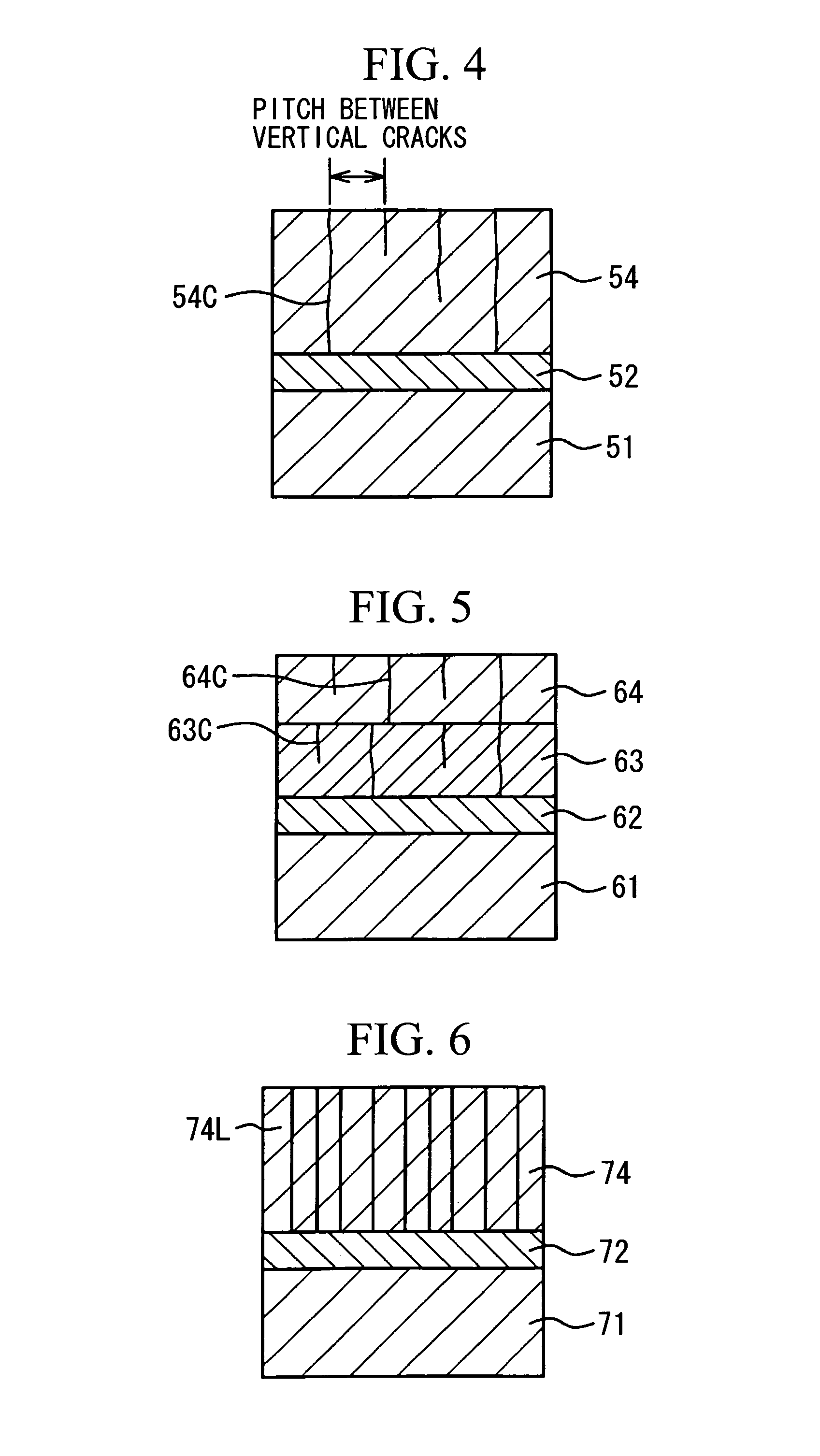

Thermal Barrier Coating Member, Method for Producing the Same, Thermal Barrier Coating Material, Gas Turbine, and Sintered Body

ActiveUS20090176059A1Low thermal conductivityGood heat insulationMolten spray coatingBlade accessoriesCrystal structureBarrier effect

There are provided a thermal barrier coating material and a thermal barrier coating member that can suppress spalling when used at a high temperature and have a high thermal barrier effect, a method for producing the same, a turbine member coated with a thermal barrier coating, and a gas turbine. The thermal barrier coating member comprises a heat resistant substrate, a bond coat layer formed thereon, and a ceramic layer formed further thereon, wherein the ceramic layer comprises an oxide which consists of an oxide represented by the general formula A2Zr2O7 doped with a predetermined amount of CaO or MgO and has 10 volume % or more of a pyrochlore type crystal structure, where A represents any of La, Nd, Sm, Gd, and Dy.

Owner:MITSUBISHI POWER LTD

Adhesive composition for optical member, adhesive layer for optical member, adhesive optical member, transparent conductive laminate, touch panel, and image display device

ActiveCN101679819AAvoid yellowingAvoid foamingConductive layers on insulating-supportsNon-macromolecular adhesive additivesMeth-High humidity

Disclosed is an adhesive composition for optical members, which contains a (meth)acrylic polymer containing 0.2-20 parts by weight of a carboxyl group-containing monomer as a monomer unit, namely as acopolymerization component, per 100 parts by weight of an alkyl (meth)acrylate having an alkyl group with 4-14 carbon atoms. The adhesive composition for optical members also contains, as crosslinking agents, 0.02-2 parts by weight of a peroxide and 0.005-5 parts by weight of an epoxy crosslinking agent per 100 parts by weight of the (meth)acrylic polymer. The adhesive composition for optical members can be suppressed in yellowing at high temperatures and in high-temperature high-humidity environments. Consequently, the adhesive composition enables formation of an adhesive layer which is suppressed in foaming, separation and the like at high temperatures and in high-temperature high-humidity environments.

Owner:NITTO DENKO CORP

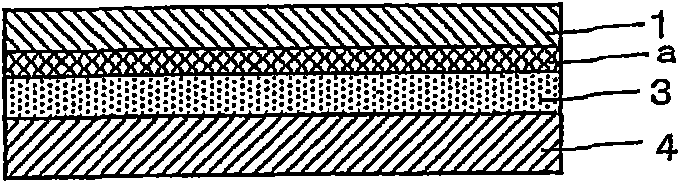

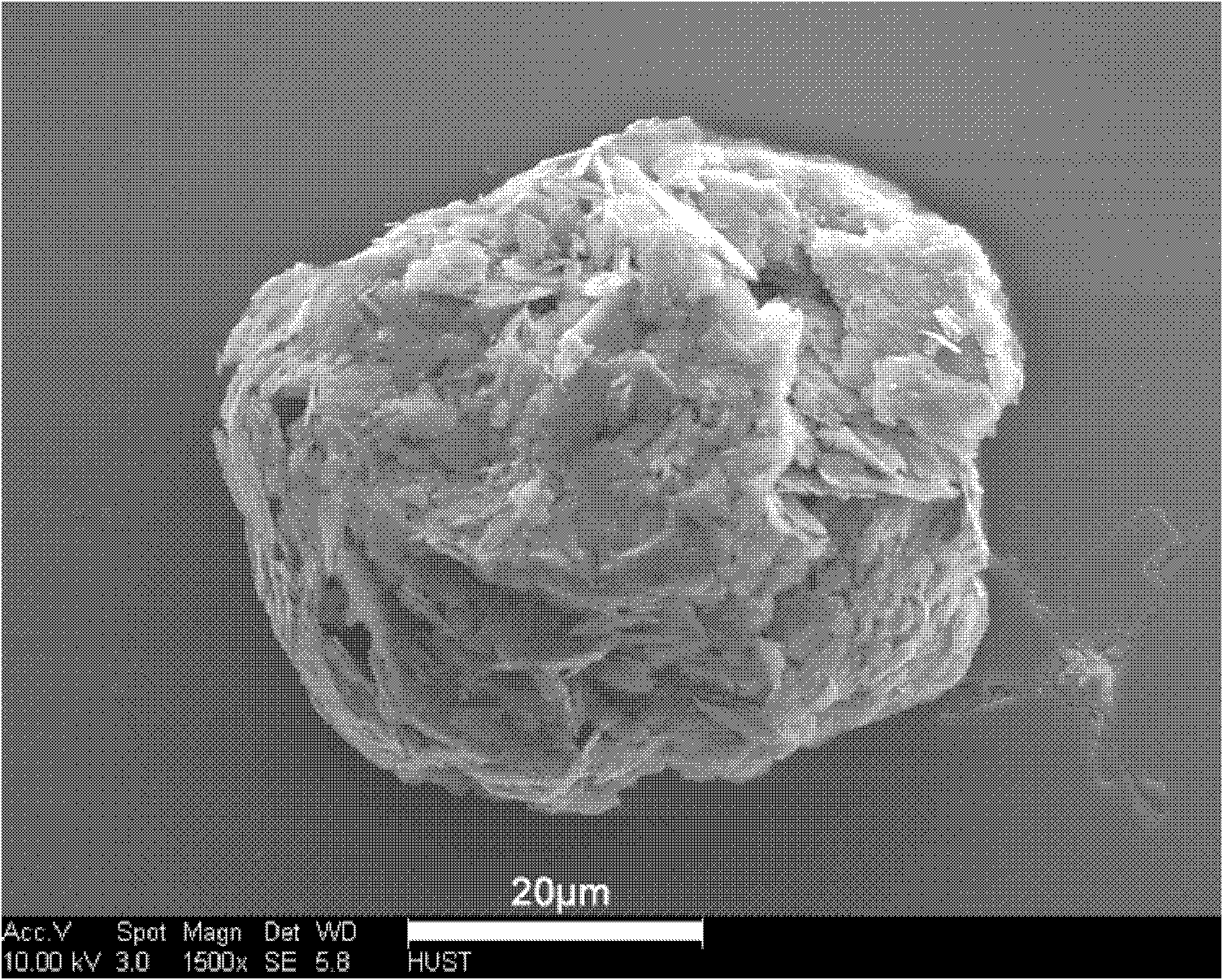

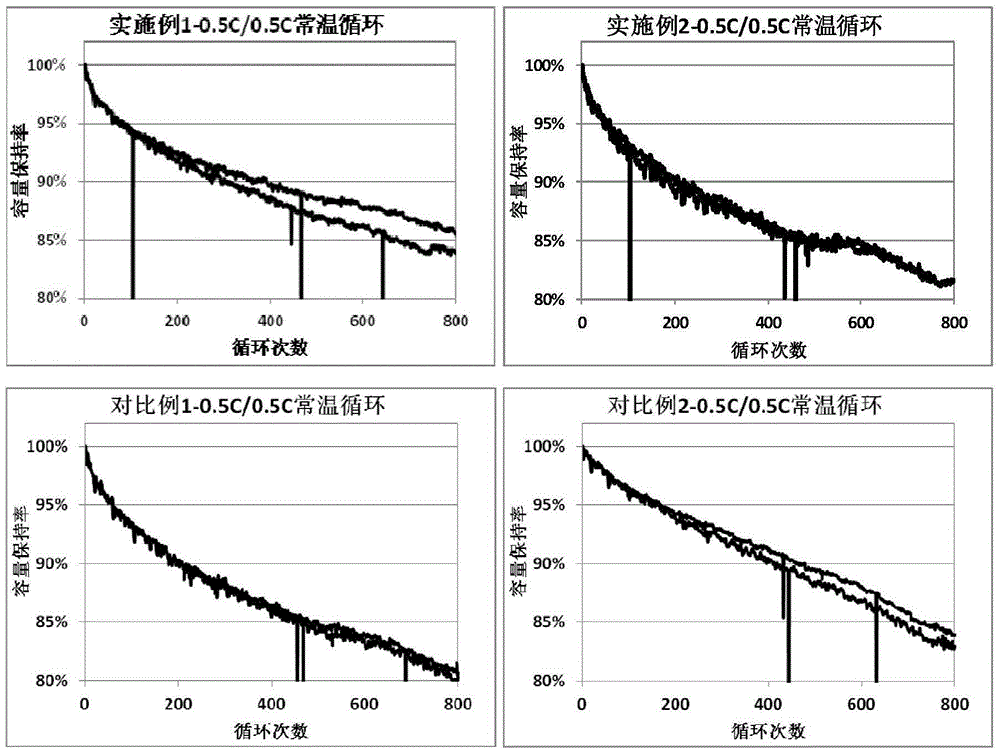

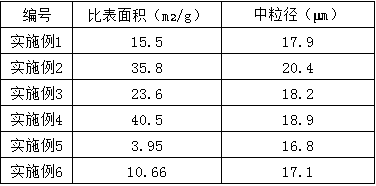

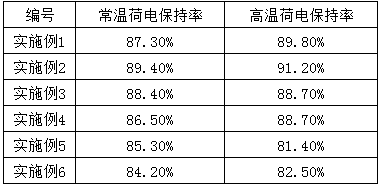

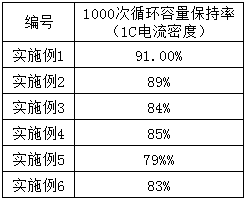

Different-orientation spherical natural graphite negative electrode material and preparation method thereof

ActiveCN101800304AHigh specific capacityImprove cycle stabilityCell electrodesNitrogen gasFlake graphite

The invention relates to a different-orientation spherical natural graphite negative electrode material and a preparation method thereof. The method comprises the following steps: mixing natural crystalline flake graphite micro powder and dispersion medium; adding deflocculants for regulating the solid content; then, placing materials and bonding agents into a pulp mixing machine to be stirred; carrying out atomization, drying and granulation on the pulp on a spraying drying machine to obtain powdery materials; carrying out heat treatment on the powdery materials in nitrogen gas atmosphere through a revolving furnace; and cooling the obtained powder to obtain the different orientation spherical natural graphite negative electrode material. The graphite negative electrode material consists of a plurality of layered graphite crystalline flakes, and the layered graphite crystalline flakes are glued and have different orientations. The graphite negative electrode material prepared by the method of the invention has the obvious characteristics that the specific capacity of the material is high, the circulation stability is high, the micro spheres formed by the graphite flakes of the graphite with different orientations can effectively inhabit the layer flake peeling caused by deep lithium insertion, the graphite flake adhesion and the carbon coverage can be realized at the same time, the powder agglomeration can be avoided through dynamic sintering, and the invention is favorable for obtaining the spherical natural graphite micro powder with uniform granularity.

Owner:CHINA THREE GORGES UNIV +1

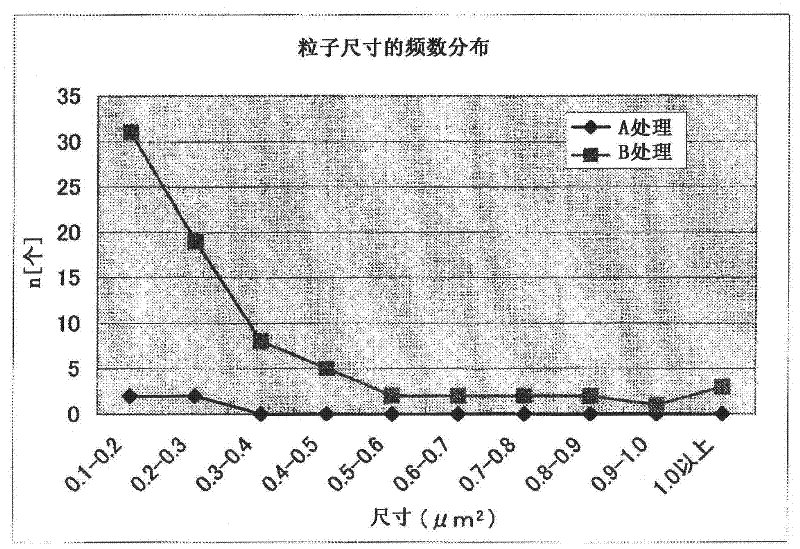

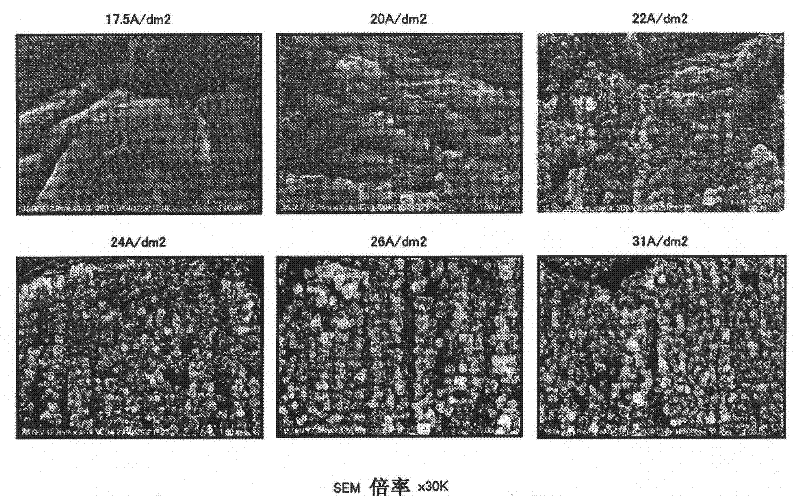

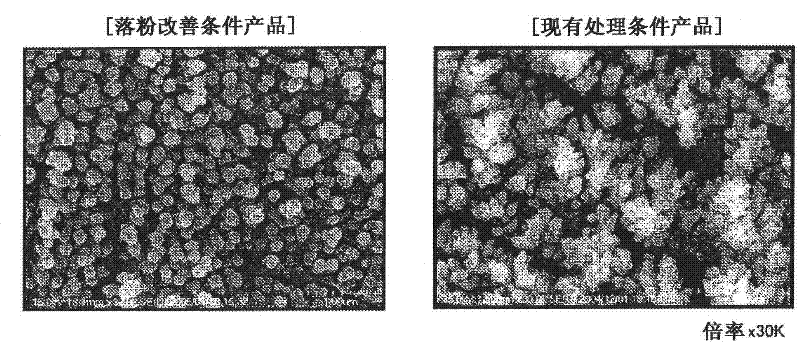

Copper foil for printed circuit

ActiveCN102224281AMiniaturizationHigh integration improvesPrinted circuit aspectsPrinted circuit manufactureCobalt nickel alloyCopper foil

A copper foil for printed circuits which comprises a copper foil and, formed on the surfaces thereof, an electrodeposited ternary-alloy layer comprising copper, cobalt, and nickel. The copper foil for printed circuits is characterized in that the electrodeposited layer is constituted of dendritic particles grown on the copper foil surfaces and that the copper foil has been entirely coated with the particles, which comprise particles having a size of 0.1-0.5 [mu]m2, in terms of the area of each particle viewed from over the copper foil surfaces, at a density of 1,000 particles / 10,000 [mu]m2 or lower, particles larger than 0.5 [mu]m2 at a density of 100 particles / 10,000 [mu]m2 or lower, and particles smaller than 0.1 [mu]m2 as the remainder. In a roughening treatment comprising plating with a copper-cobalt-nickel alloy, roughening particles which are being dendritically formed are inhibited from shedding from the surfaces of the copper foil and thereby causing the phenomenon generally called powder falling and resulting in treatment unevenness.

Owner:JX NIPPON MINING & METALS CORP

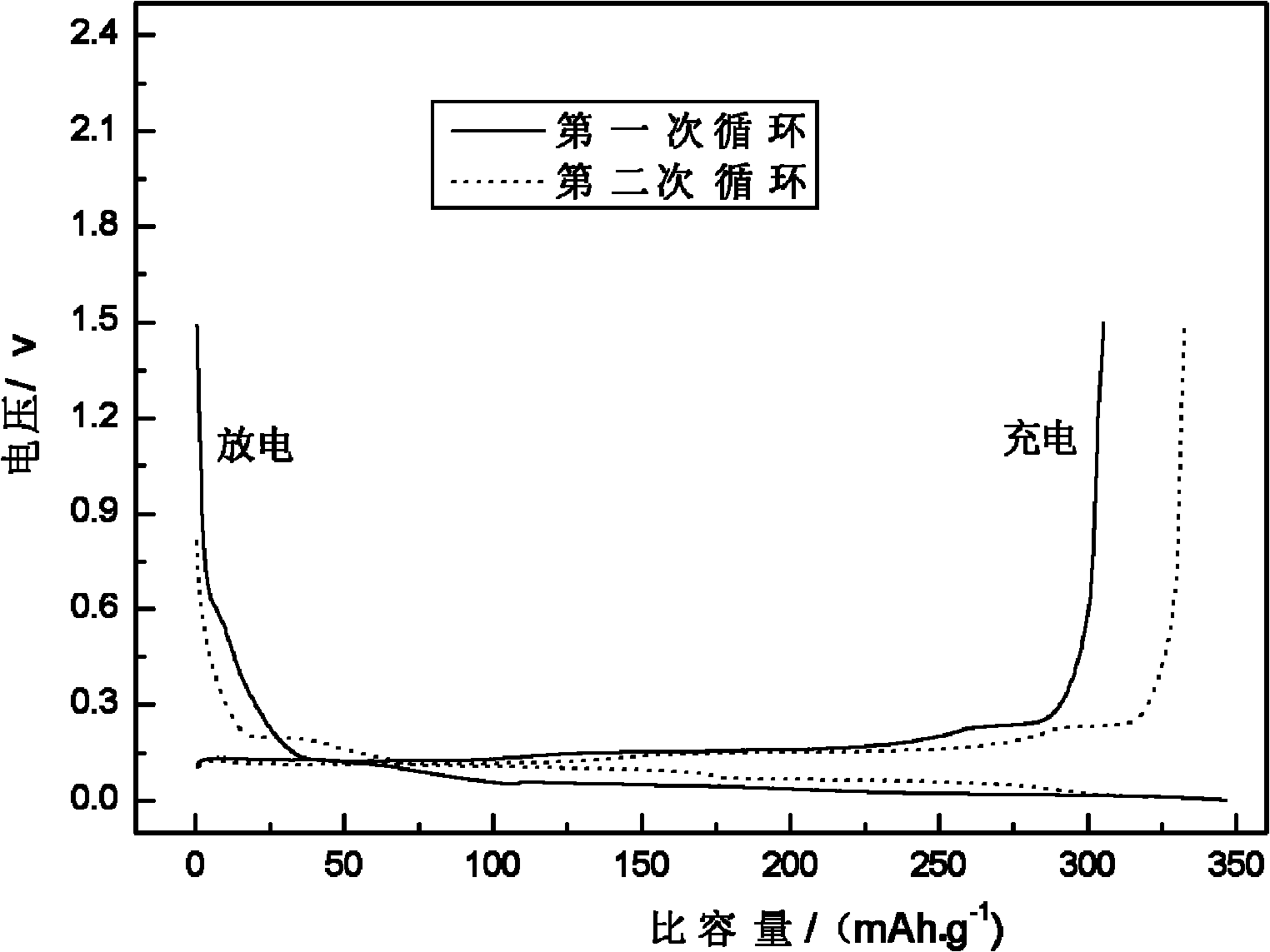

Silicon-based negative electrode material with multi-buffer structure, and preparation method thereof

InactiveCN107623104AInhibition of polymerizationInhibit flakingCell electrodesElectrolytic agentMaterials processing

The invention relates to a silicon-based negative electrode material with a multi-buffer structure, and a preparation method thereof, and belongs to the technical field of material processing. According to the silicon-based negative electrode material provided by the invention, a nanometer titanium dioxide layer is coated on the surface of nanometer silicon powder, the stable structure of the nanometer titanium dioxide is used as a buffer layer of volume change of silicon particles in a lithium embedding and removing process to successfully inhibit the polymerization and peeling of the siliconparticles, and the electrochemical performance of the electrode material is also improved, then an amorphous carbon layer is coated to prepare a silicon-based electrode material with a double-layer coating structure, the volume expansion of the core of the activated silica is effectively buffered by the double-layer coating structure in a charge and discharge process, the stability of an electrode / electrolyte interface and a surface SEI film is maintained, and thus the composite material exhibits good cycle performance.

Owner:常州市宇科不绣钢有限公司

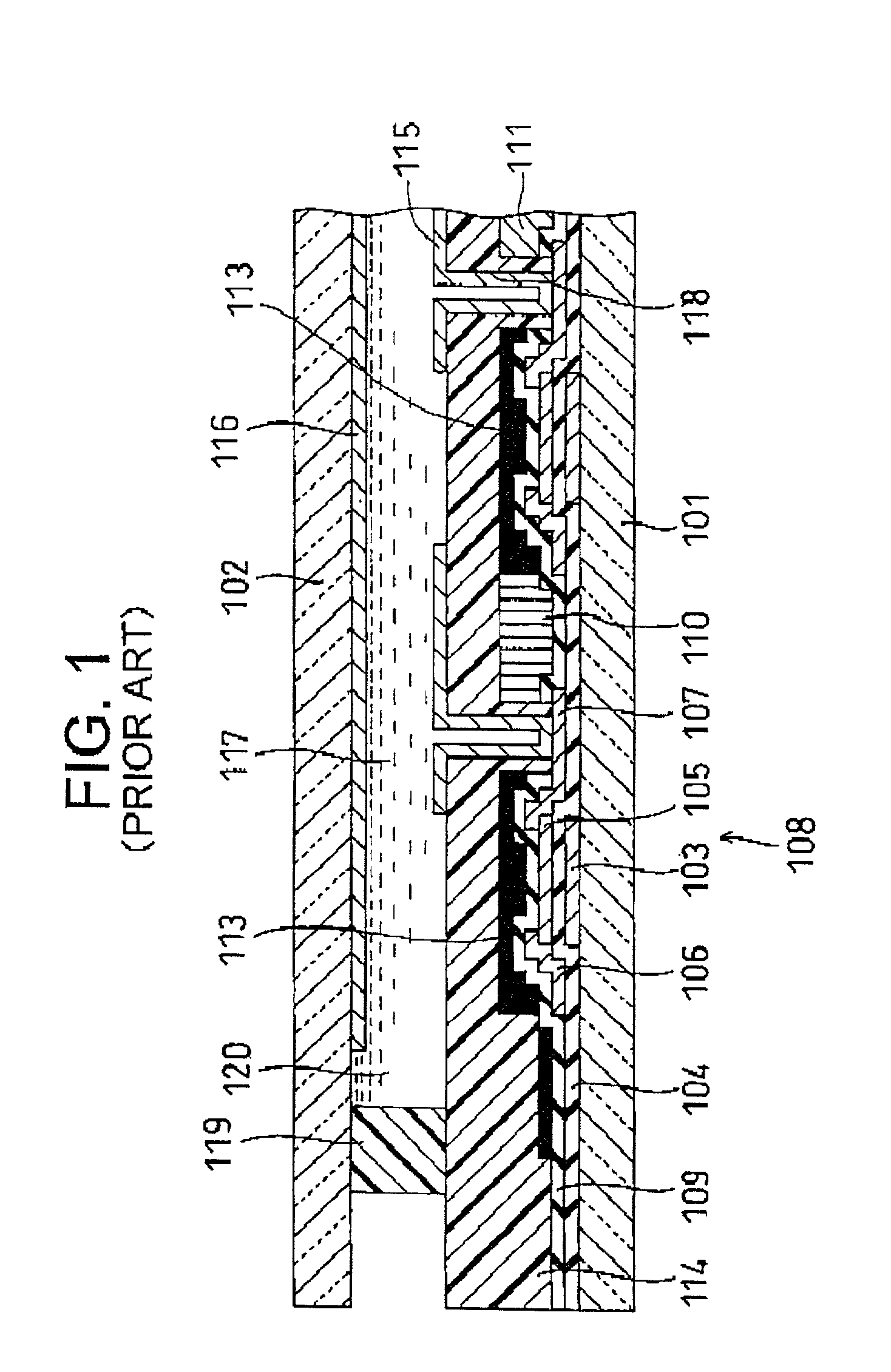

Color liquid crystal display panel

InactiveUS20010012079A1Inhibit flakingHigh optical densityTelevision system detailsPicture reproducers using solid-state color displayInsulation layerLiquid-crystal display

First and second transparent substrates which are arranged to face each other are provided to a color liquid crystal display panel. A liquid crystal layer is provided between the first and the second transparent substrates, A plurality of thin film transistors are provided on the first transparent substrate. An insulation film provided on the first transparent substrate so as to cover the thin film transistors. A color filter which includes first to third color layers stacked on the insulation layer is provided. A contacting color layer is provided on the insulation film in a region above the thin film transistors. The contacting color layer has at least one color layer selected from a group of composed of the first to third color layers. A black matrix is provided on the contacting color layer. The black matrix has opening portions for transmitting light from the color filter.

Owner:NEC LCD TECH CORP

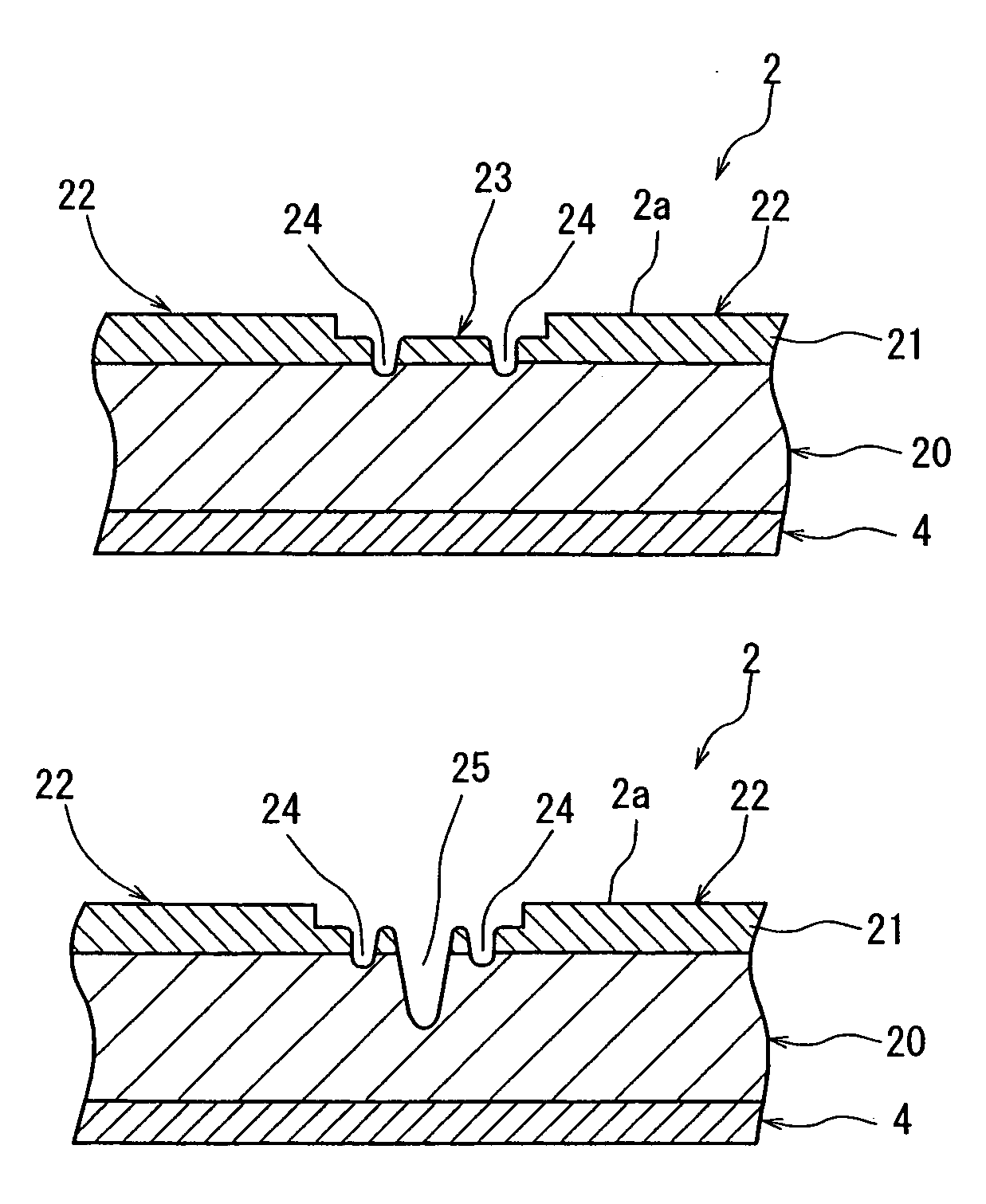

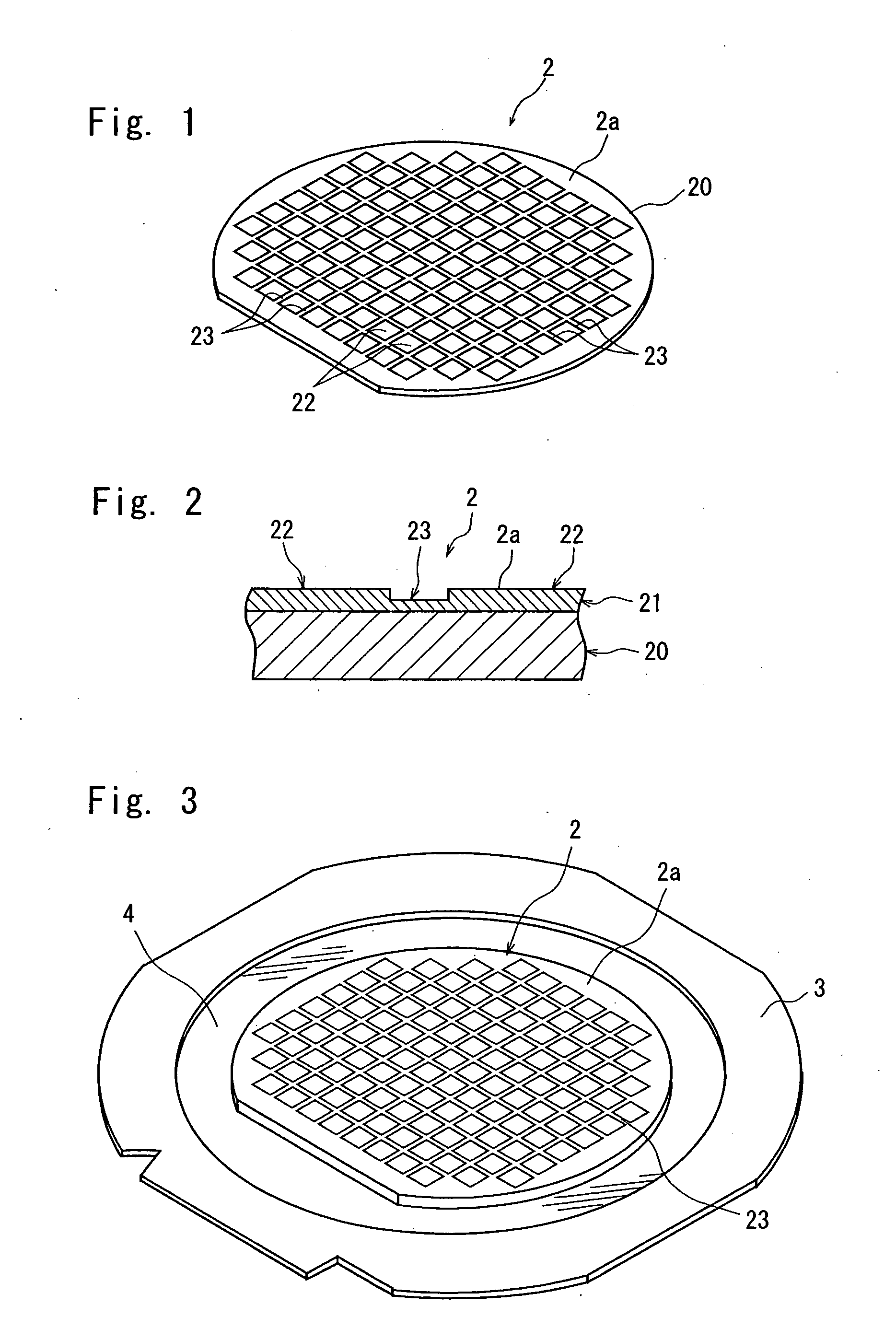

Sealant laminated composite, sealed semiconductor devices mounting substrate, sealed semiconductor devices forming wafer, semiconductor apparatus, and method for manufacturing semiconductor apparatus

ActiveUS20130200534A1Suppress contraction stressImprove sealing propertiesSemiconductor/solid-state device detailsSynthetic resin layered productsEngineeringSealant

Described herein is a sealant laminated composite for collectively sealing a semiconductor device's mounting surface of a substrate on which semiconductor devices are mounted or a semiconductor device's forming surface of a wafer on which semiconductor devices are formed. The composite can include a support wafer and an uncured resin layer constituted of an uncured thermosetting resin formed on one side of the support wafer. In certain aspects, the sealant laminated composite is very versatile, even when a large diameter or thin substrate or wafer is sealed. In certain aspects, this can prevent the substrate or wafer from warping and the semiconductor devices from peeling; can collectively seal a semiconductor device's mounting surface of a substrate on which semiconductor devices are mounted or a semiconductor device's forming surface of a wafer on which semiconductor devices are formed on a wafer level; and can provide a sealant laminated composite that is excellent in the heat resistance and humidity resistance after sealing.

Owner:SHIN ETSU CHEM IND CO LTD

Connector for electrically connecting electronic components

ActiveUS7195494B2Reduced dimensionFlaking of a header post from a header body can be preventedCoupling device connectionsFixed connectionsEngineeringElectronic component

A socket body is reinforced by inserted or press-fitted reinforcing members inserted so that a protruding table is eliminated and a width dimension thereof is reduced. Each socket contact has a first contact portion formed in substantially U-shape for elastically deformable. A header body has concave portions on upper face of the socket body (SIC). Each header post has a second contact portion disposed along a side wall of the header body and to be contacted with a first contact portion of the socket contact, and a curved portion formed in substantially reverse U-shape toward the concave portion from a vicinity of an upper end portion of the side wall of the header body. A curvature radius of the curved portion of the header post is established to be the smallest in a scope that a free end of the first contact portion of the socket contact contacts in the second contact portion side from a peak of the curved portion, and the socket contact is rarely buckled due to scratching with the curved portion.

Owner:MATSUSHITA ELECTRIC WORKS LTD

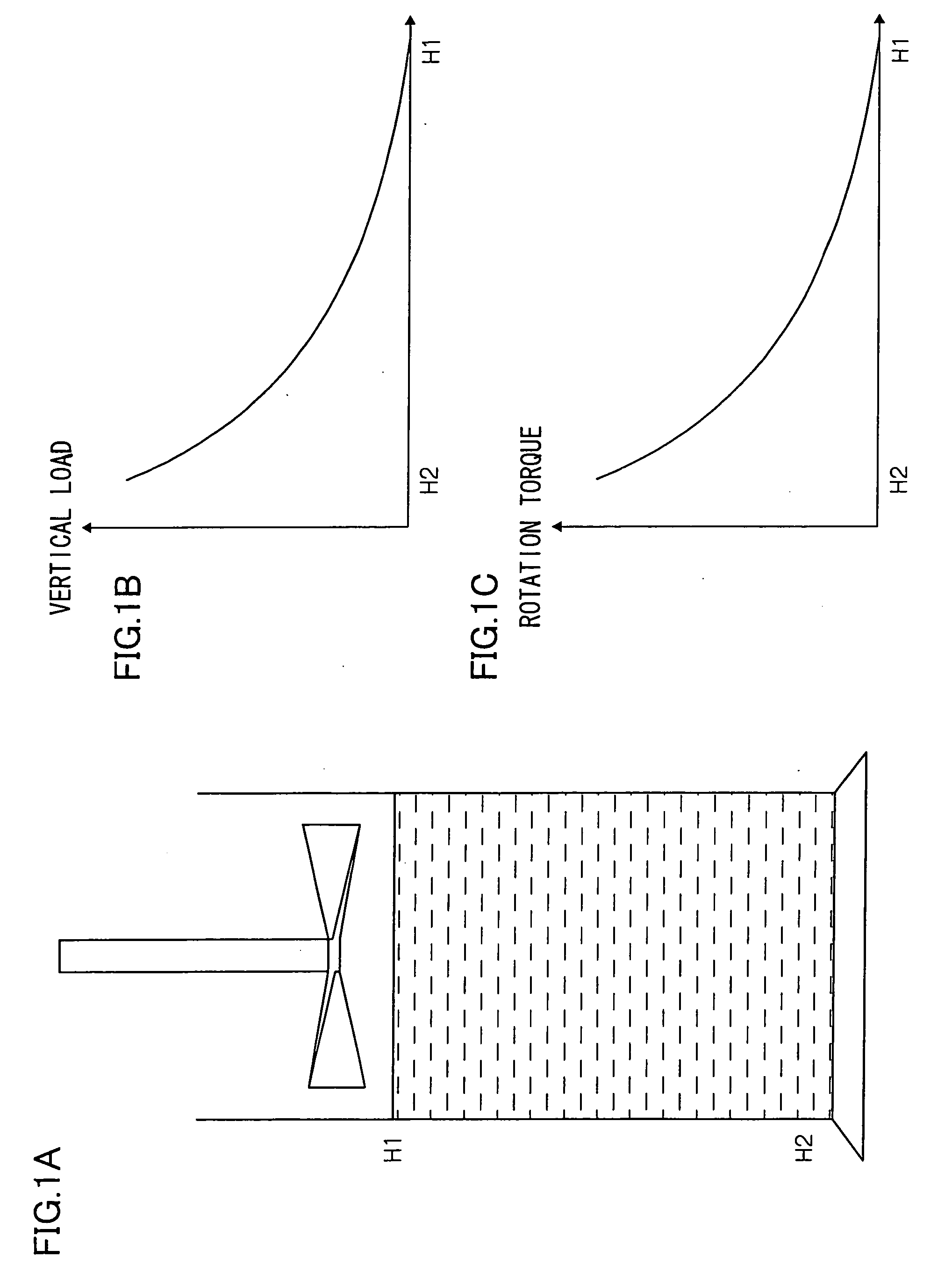

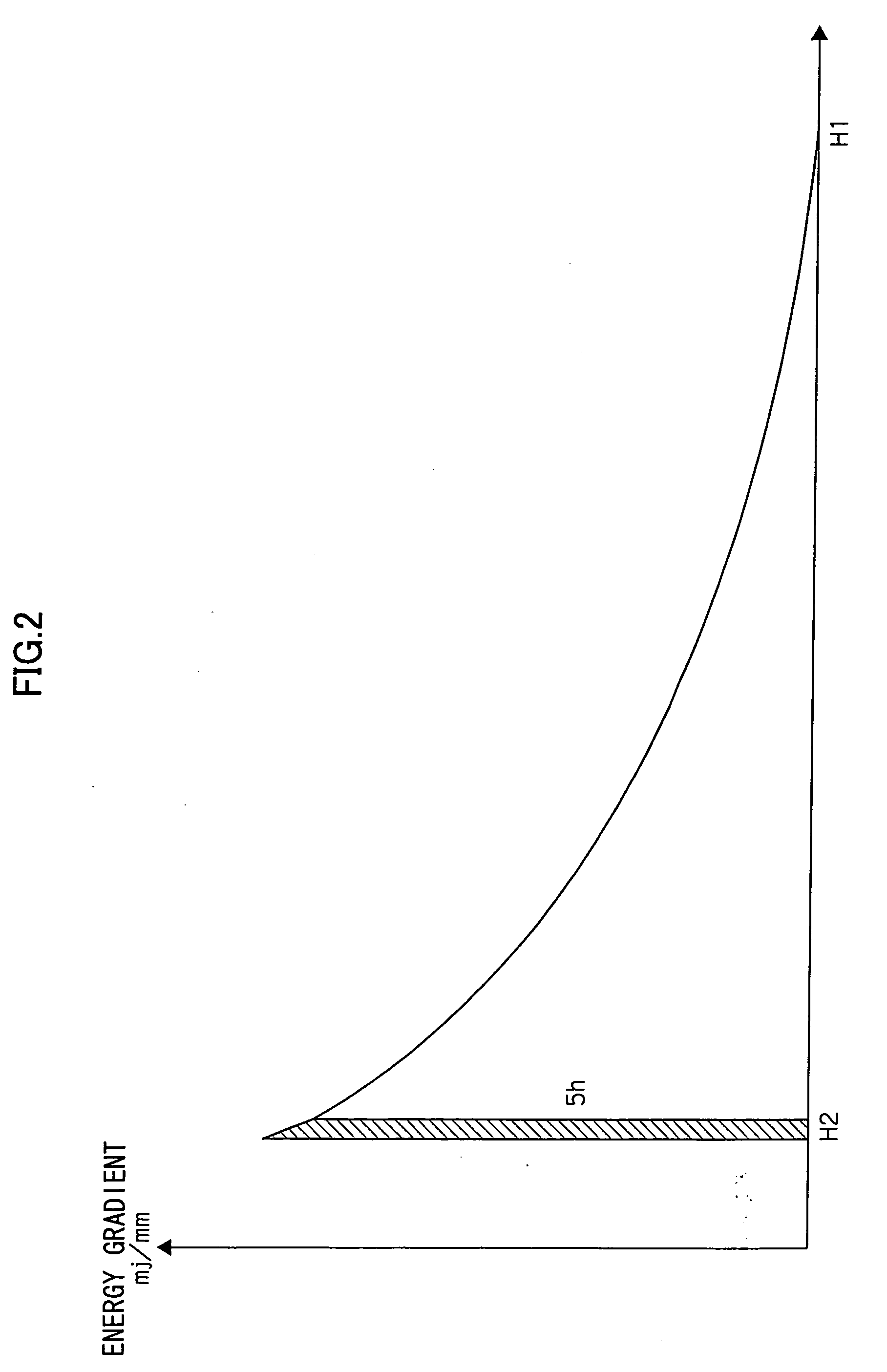

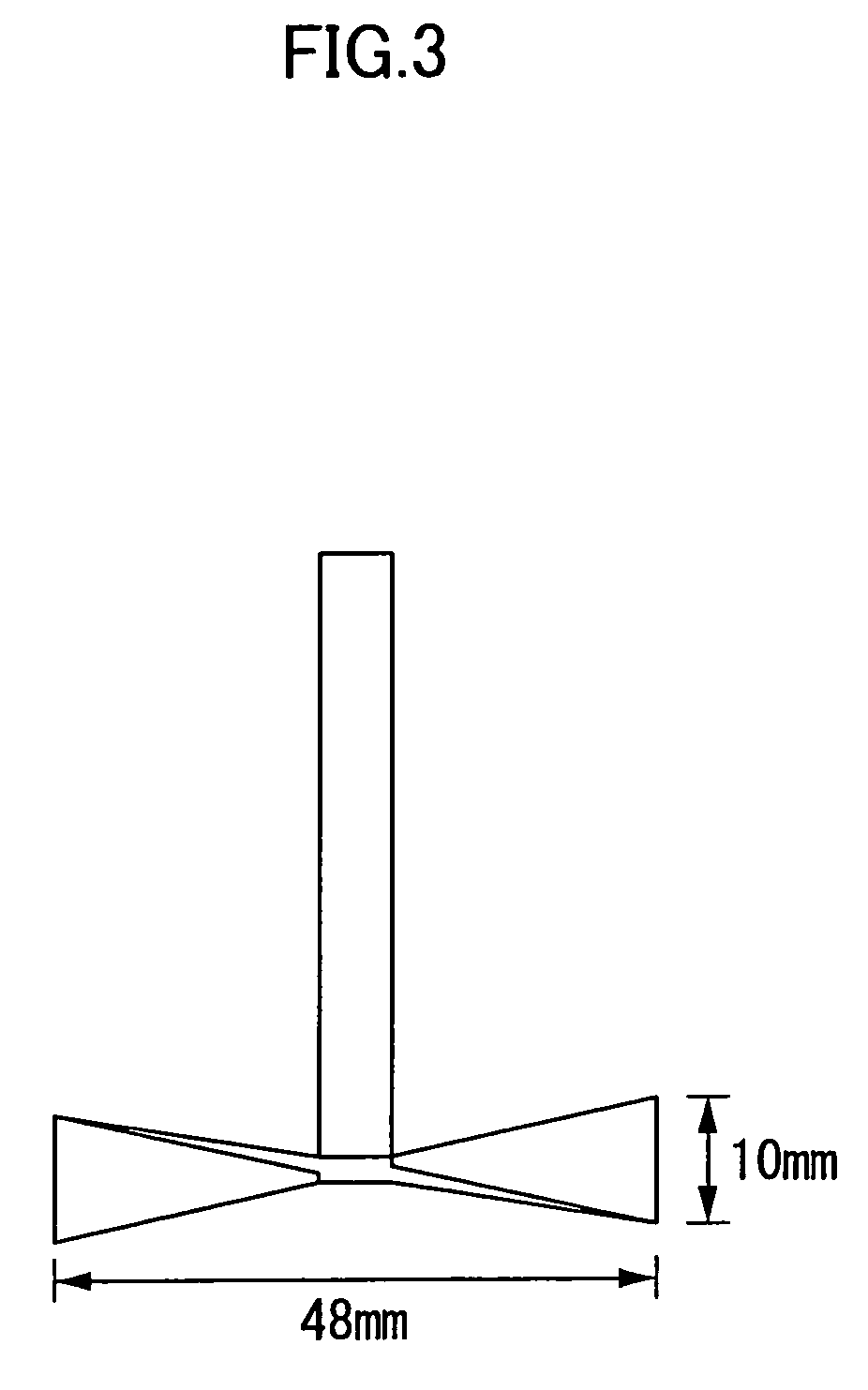

Carrier and developer for electrostatic image development, and image formation method and apparatus

InactiveUS20070020552A1Improve liquidityAvoid stickingElectrographic process apparatusDevelopersImage formationEngineering

The present invention provides a carrier for electrostatic image development, and a developer, an image formation method and an image formation apparatus using the carrier. The carrier is carrier particles. When the carrier particles each have a coating layer on a magnetic particle, the carrier has a total energy amount of 1500 to 3000 mJ. When the carrier particles each have a coating layer on a magnetic powder-dispersed particle, the carrier has a total energy amount of 1000 to 1500 mJ. The total energy amount is measured with a powder rheometer at a tip end speed of a rotor of 100 mm / s and a helix angle of the rotor of −5°. The total energy amount is a value of a portion of the carrier in a measurement container which portion is contained in the region between the packed surface of the carrier and a surface disposed under the packed surface by 70 mm.

Owner:FUJIFILM BUSINESS INNOVATION CORP

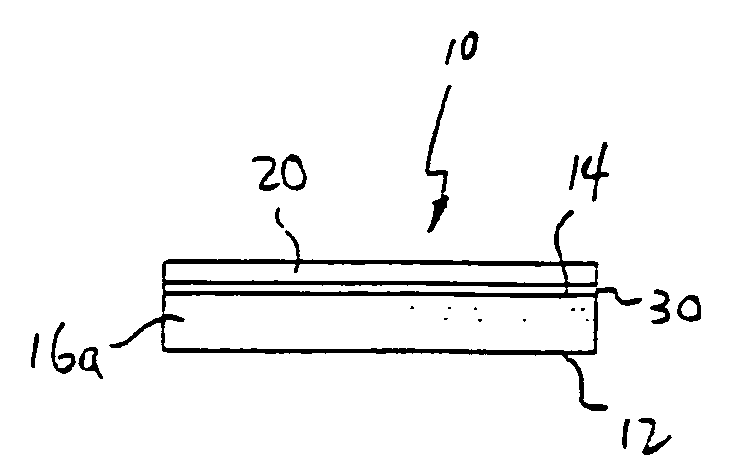

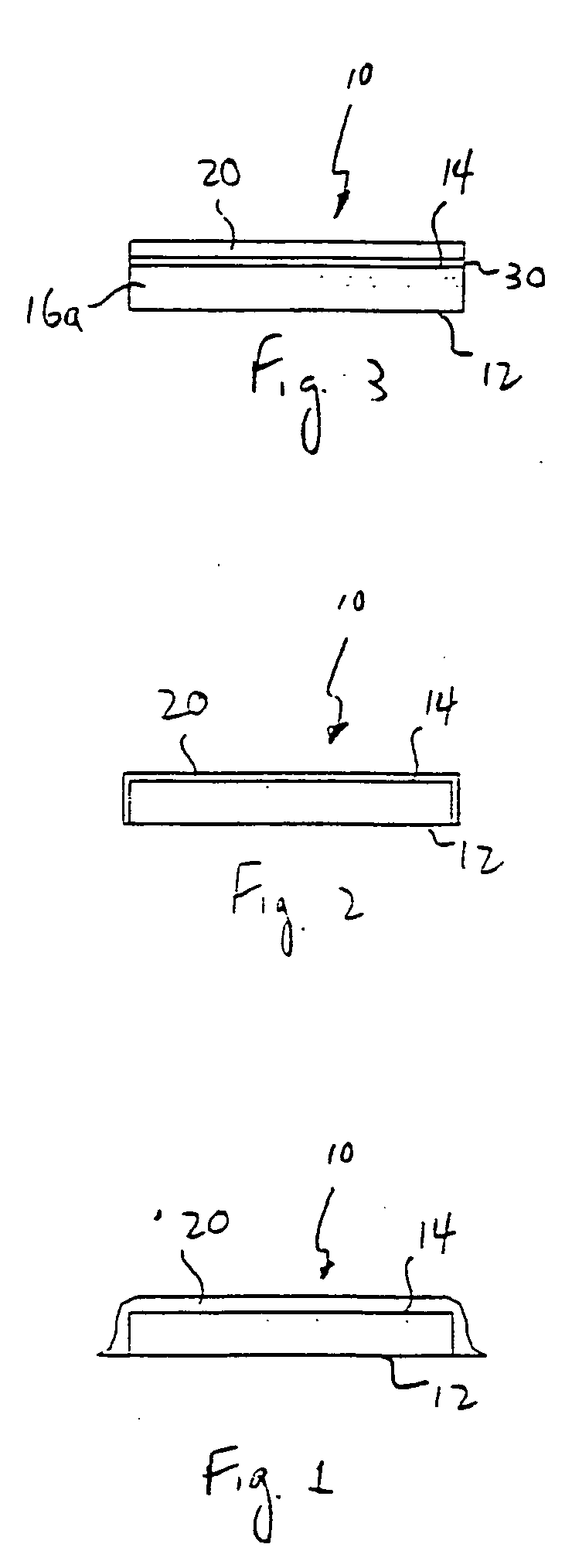

Heat spreader for display device

ActiveUS20050142317A1Good thermal contactPrevent and reduce possibilityDigital data processing detailsLayered productsLiquid-crystal displayDisplay device

A heat spreader (10) for a display device, such as a plasma display panel, a light emitting diode or a liquid crystal display, comprising at least one sheet of compressed particles of exfoliated graphite having a surface area greater than the surface area of that part of the back surface of the display device where a localized region of higher temperature is generated.

Owner:NEOGRAF SOLUTIONS LLC

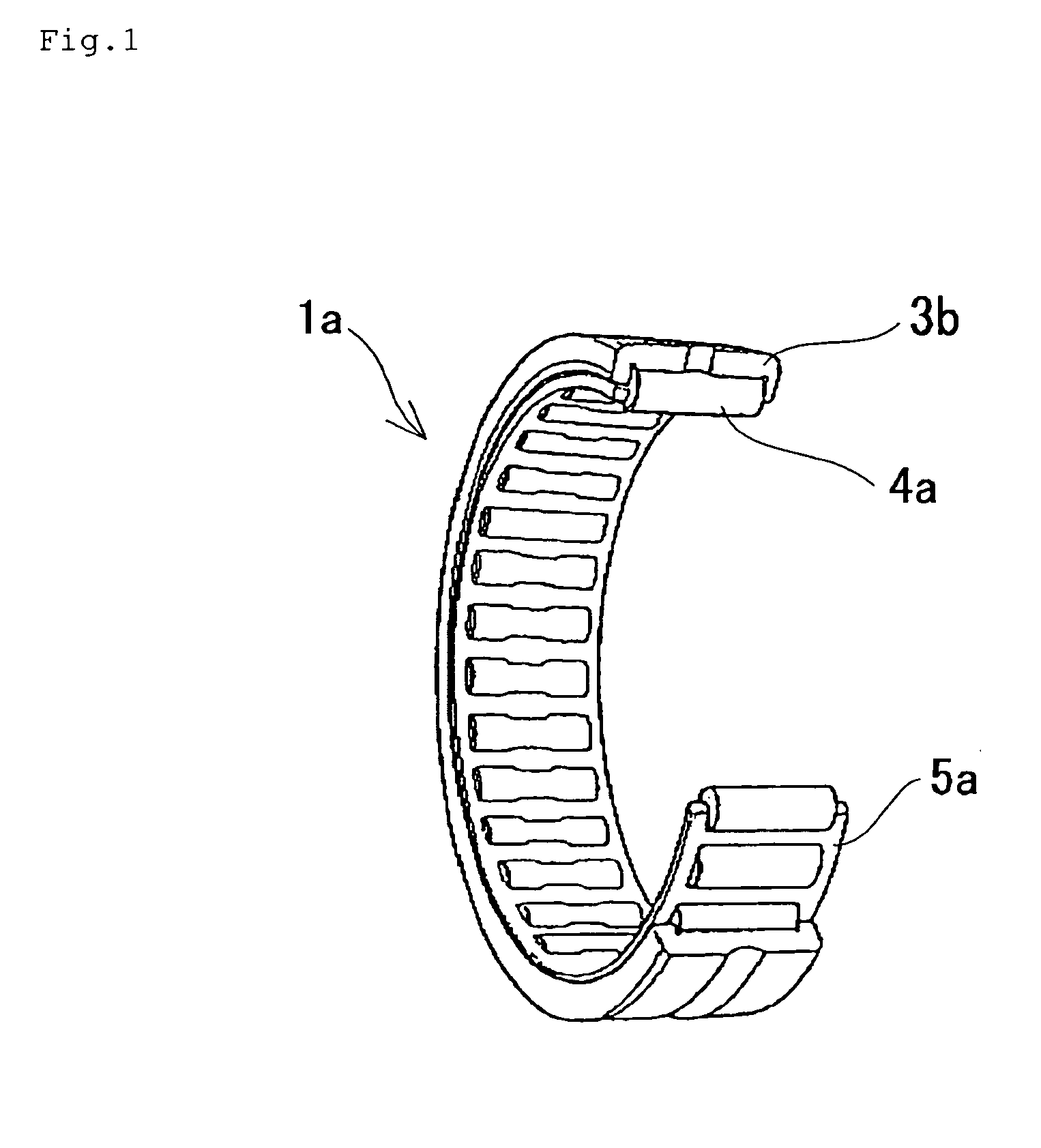

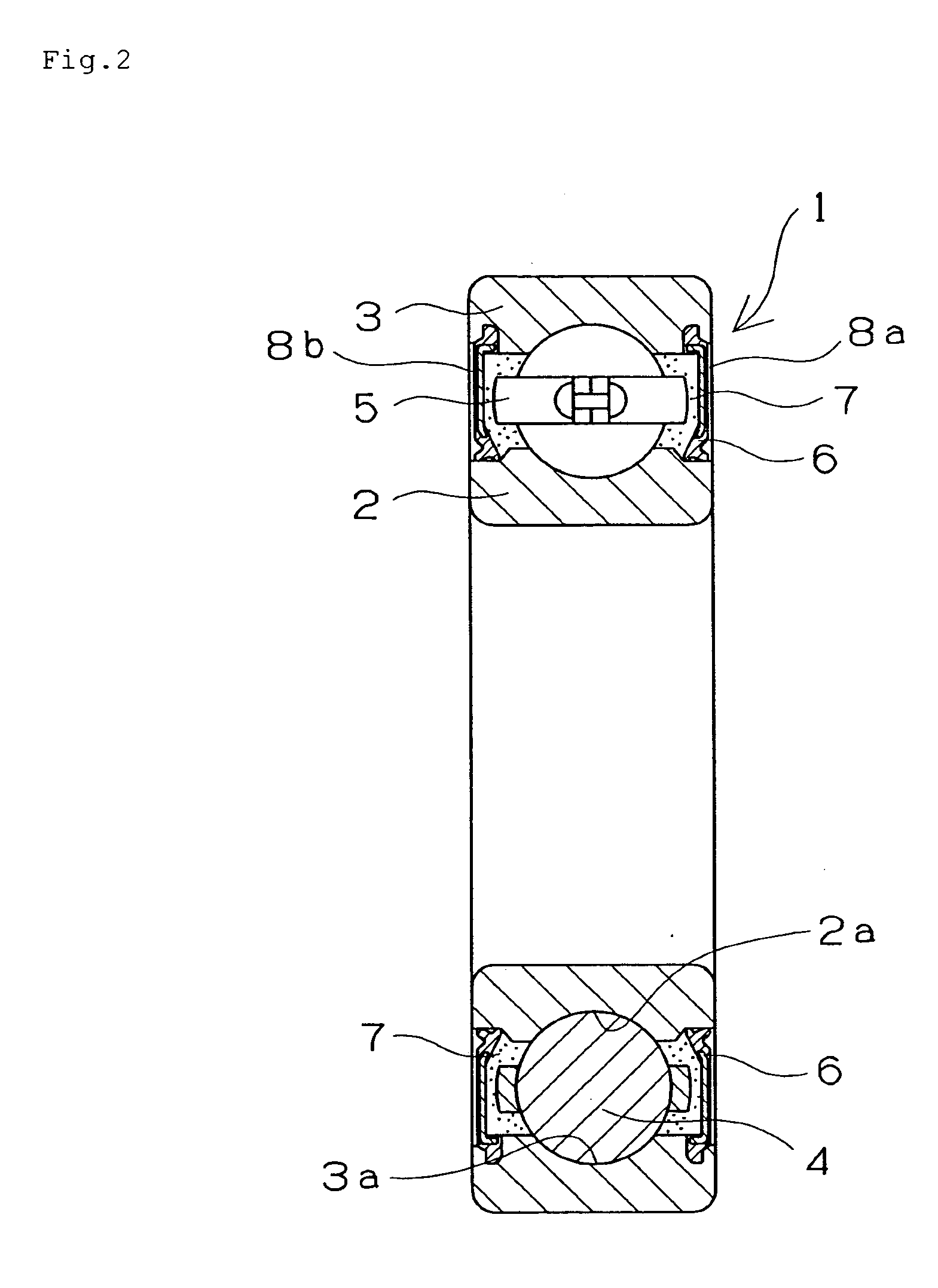

Lubricant composition and bearing using same

ActiveUS20050009713A1Prevent surfaceIncreased durabilityGroup 1/11 element organic compoundsMixingPotassiumSodium salt

A lubricant composition capable of effectively preventing a rolling surface of a bearing from flaking owing to hydrogen embrittlement. The bearing is lubricated with the lubricant composition. The lubricant composition is lubricating oil or grease. The lubricant composition contains a molybdate. The lubricant composition also contains an organic acid salt. At least one molybdate is selected from sodium molybdate, potassium molybdate, and lithium molybdate. The organic acid salt is a sodium salt of an organic acid having one to 20 carbon atoms. 0.01 to 5 wt % of the molybdate is added to the entirety of the lubricant composition. 5 wt % to 70 wt % of the organic acid salt is added to the addition amount of the molybdate. The lubricant composition has a function of forming a film containing a molybdenum compound in addition to an iron oxide film on a worn surface of the bearing or on a fresh surface of an iron-based metal generated by wear. The bearing is used as a rolling bearing for use in electric parts and auxiliary machines of a vehicle. The bearing is also used as a bearing, for a motor, in which the lubricant composition is sealed.

Owner:NTN CORP

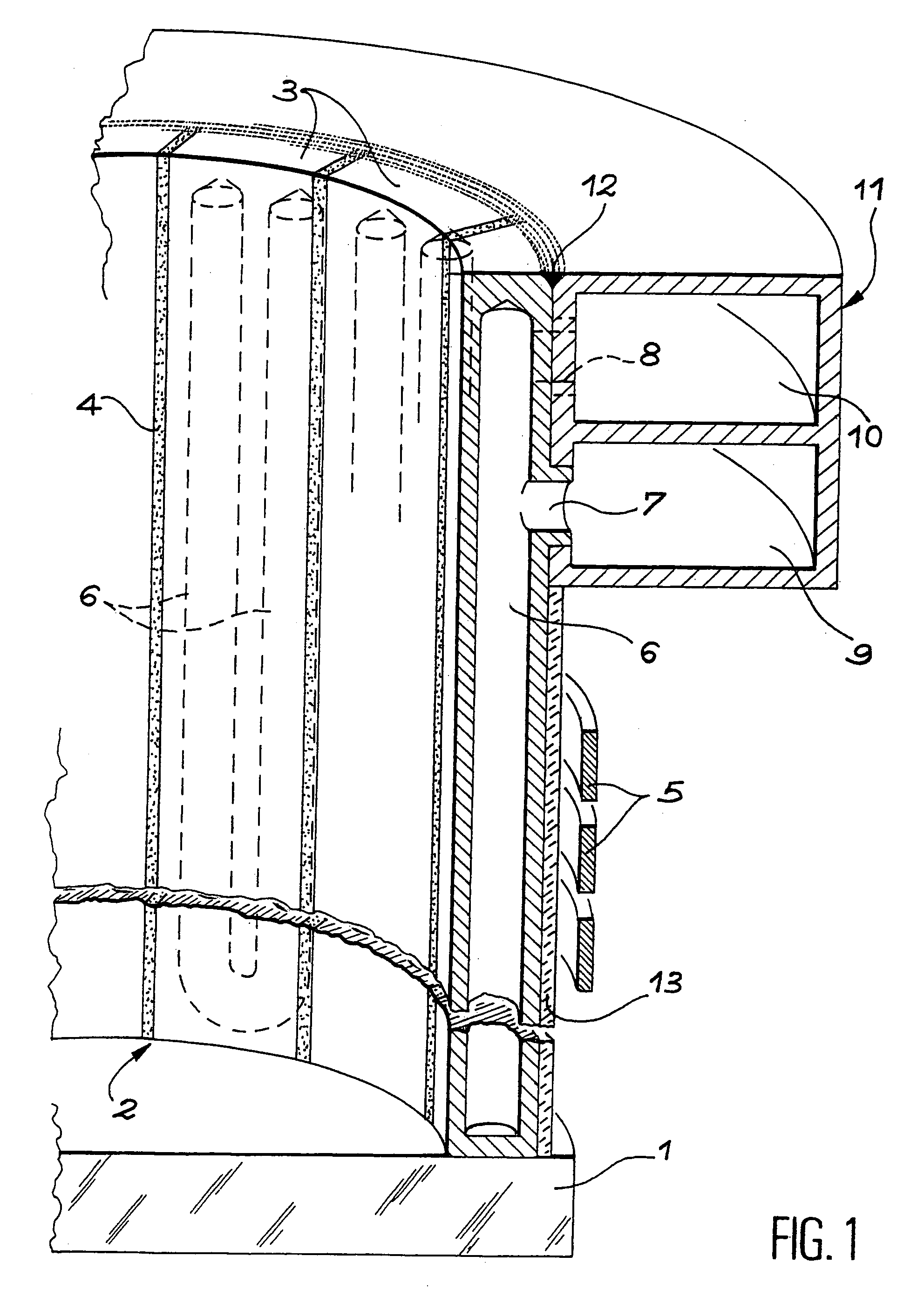

Core-type furnace

InactiveUS6996153B2Perfect electric protectionImprove protectionFurnaces without endless coreFurnace cooling arrangementsCeramic coatingEngineering

Vertical segments of a side wall of a crucible for an induction furnace are assembled at an adjustable, invariable position by screws screwed into tapped holes of a flange common to all segments. A precise assembly is thus obtained producing no deformation and no internal stresses. The segments are coated with a ceramic coating for their protection and to prevent formation of electric arcs. Junction edges of faces are rounded to achieve the same effect. Water cooling boxes of the lower furnace hearth are similarly constructed. The apparatus can, as an example, be applied to vitrification techniques.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +2

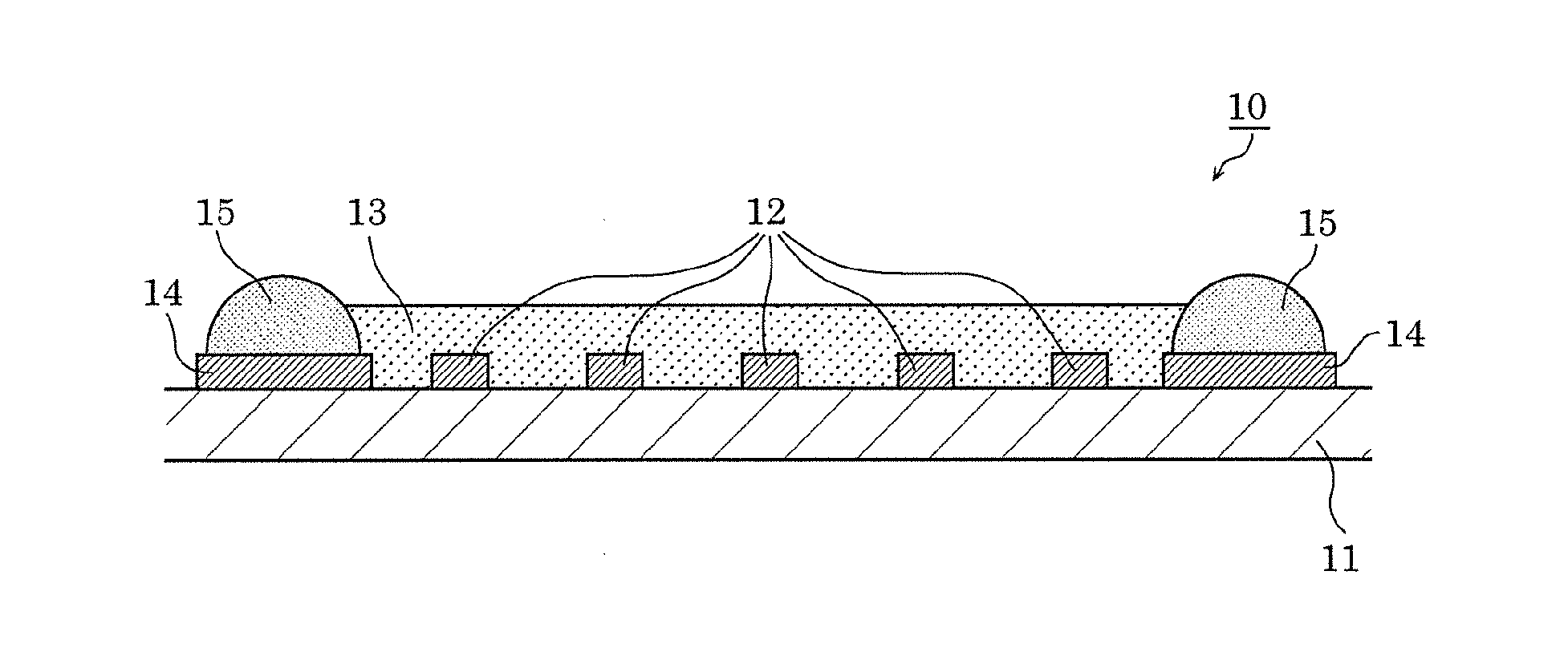

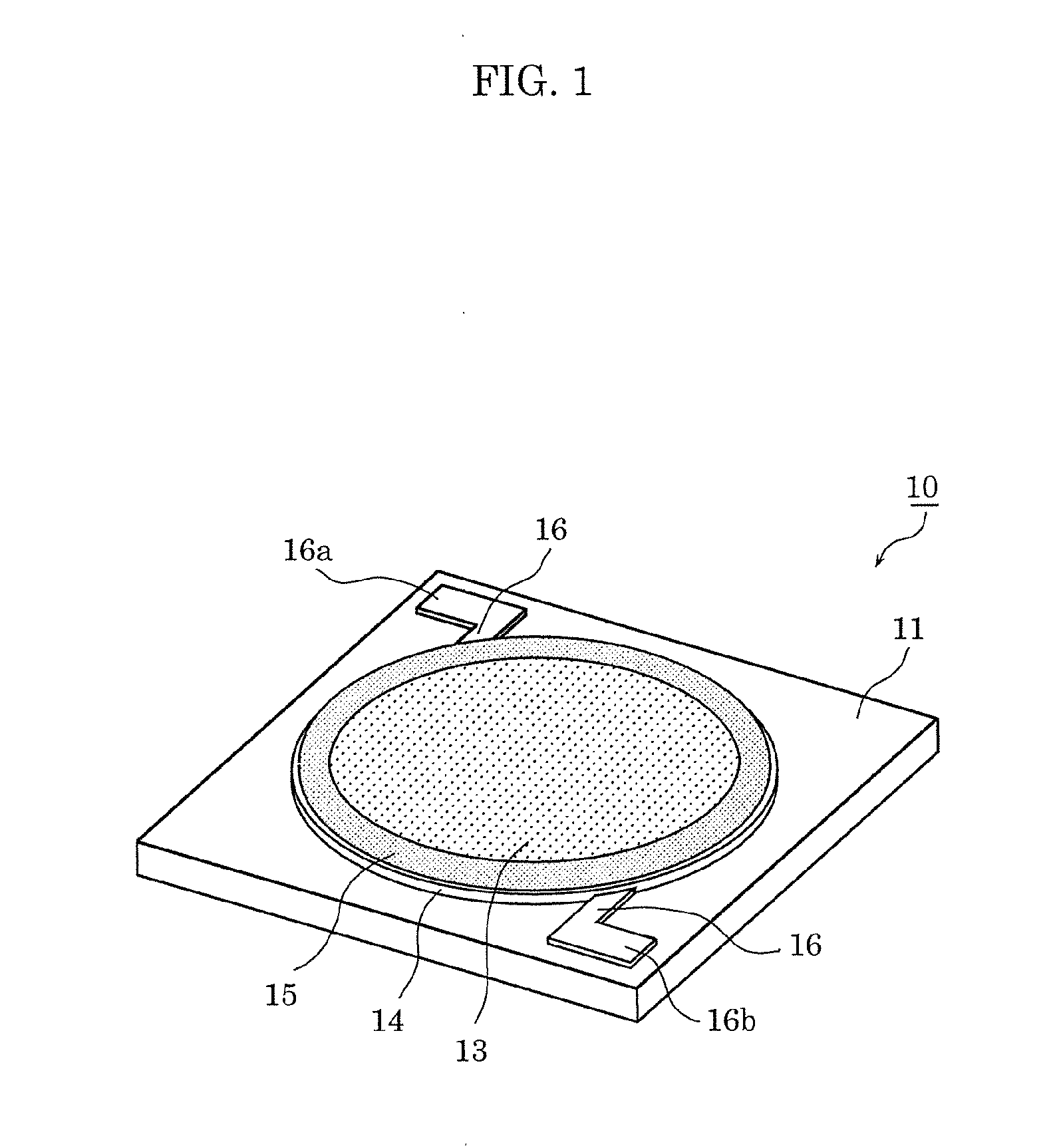

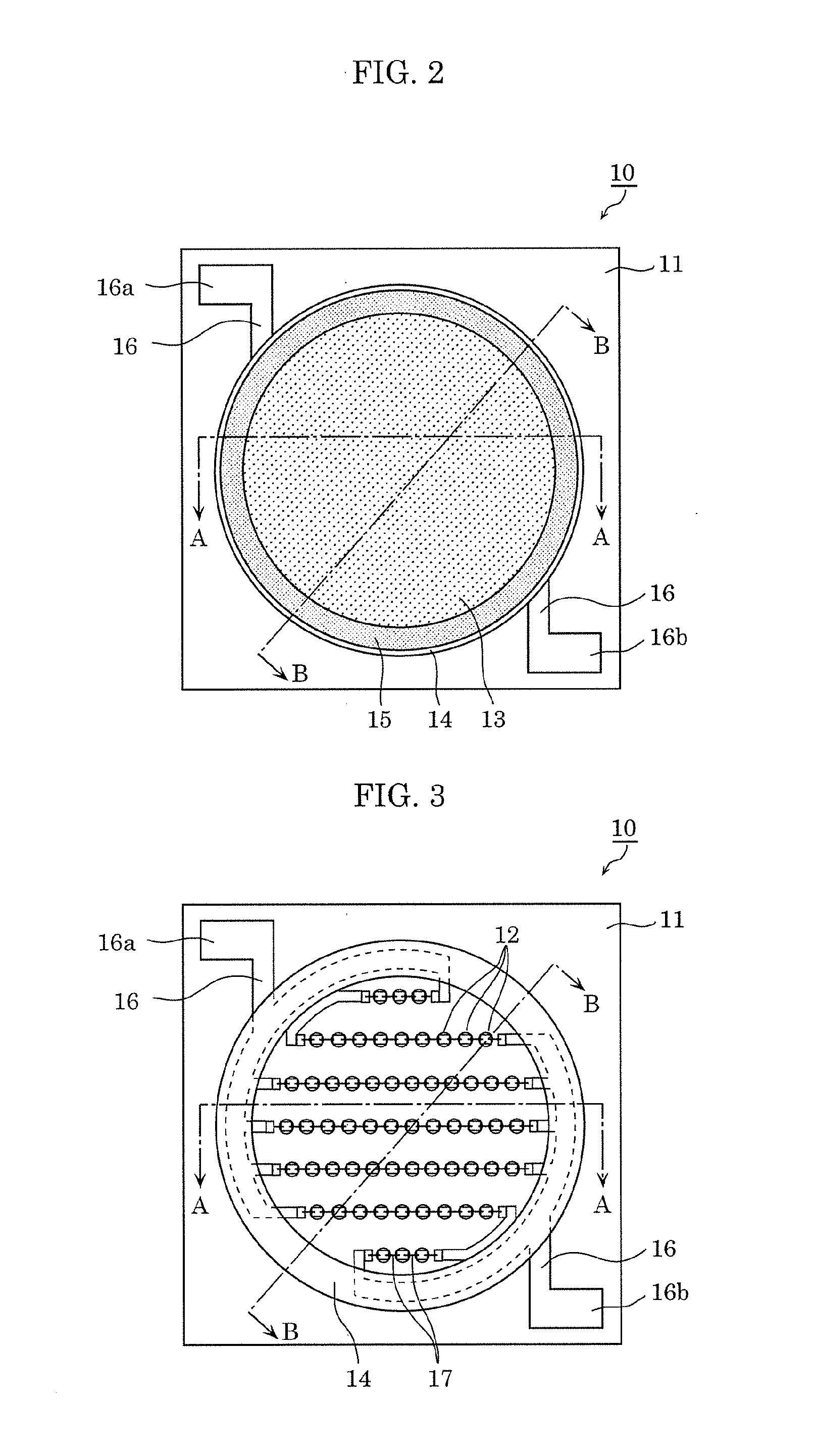

Light emitting apparatus and lighting apparatus

InactiveUS20160079492A1Inhibit flakingImprove reliabilitySolid-state devicesSemiconductor devicesMaterials scienceUltimate tensile strength

Light emitting apparatus including: substrate; LED chips on substrate; sealing member sealing LED chips; buffer layer on substrate; and dam material on the top surface of buffer layer, for holding back sealing member, wherein the adhesive strength of buffer layer to substrate and the adhesive strength of dam material to buffer layer are higher than the adhesive strength of dam material to substrate.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

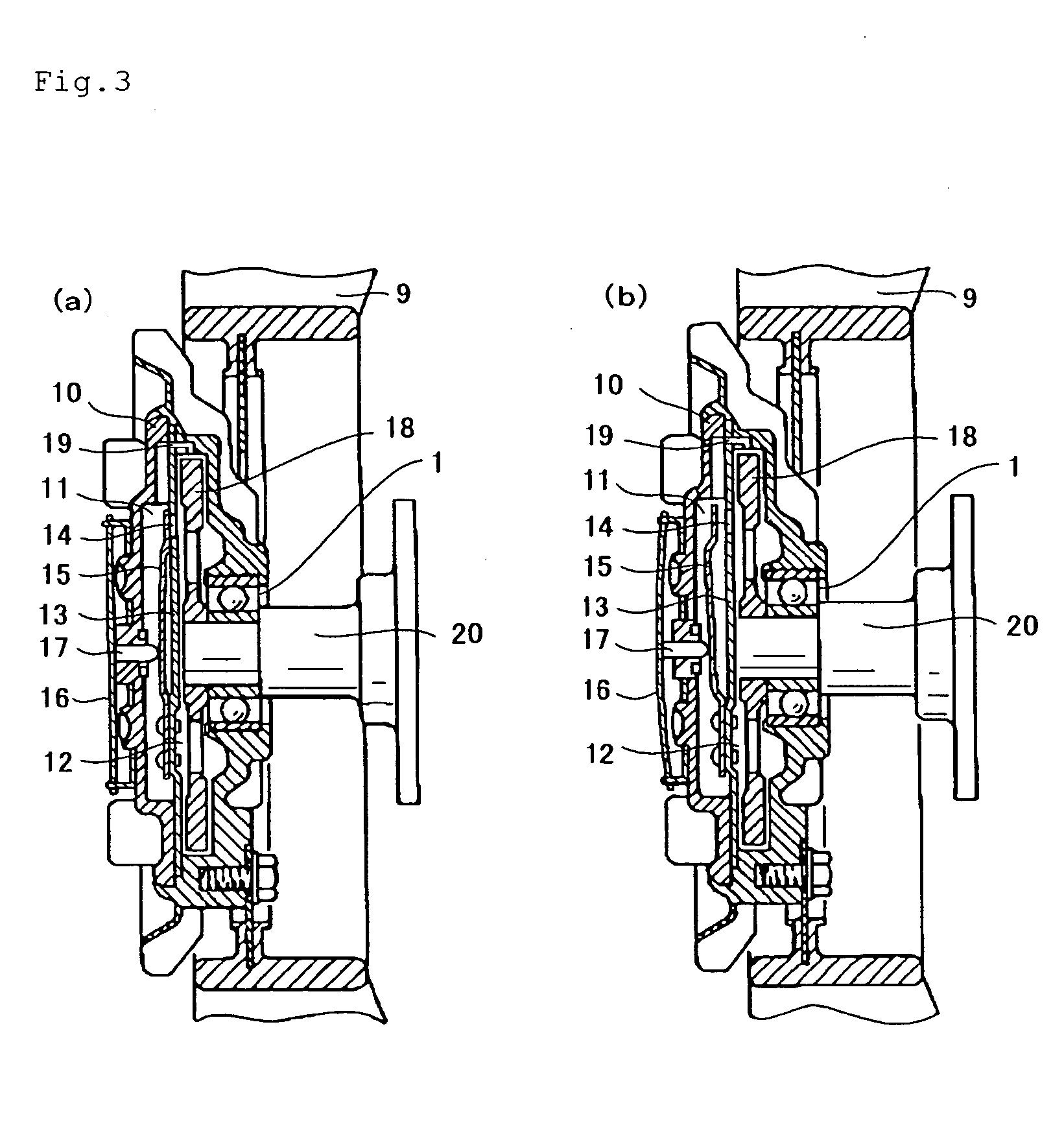

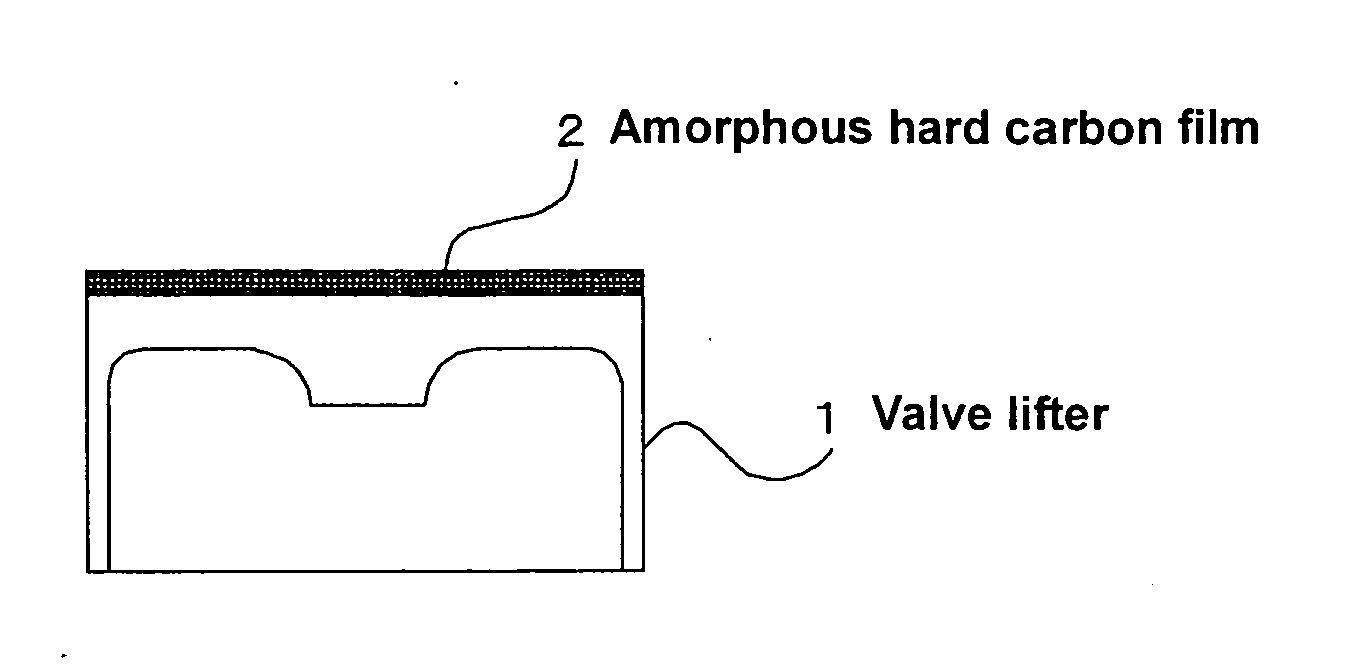

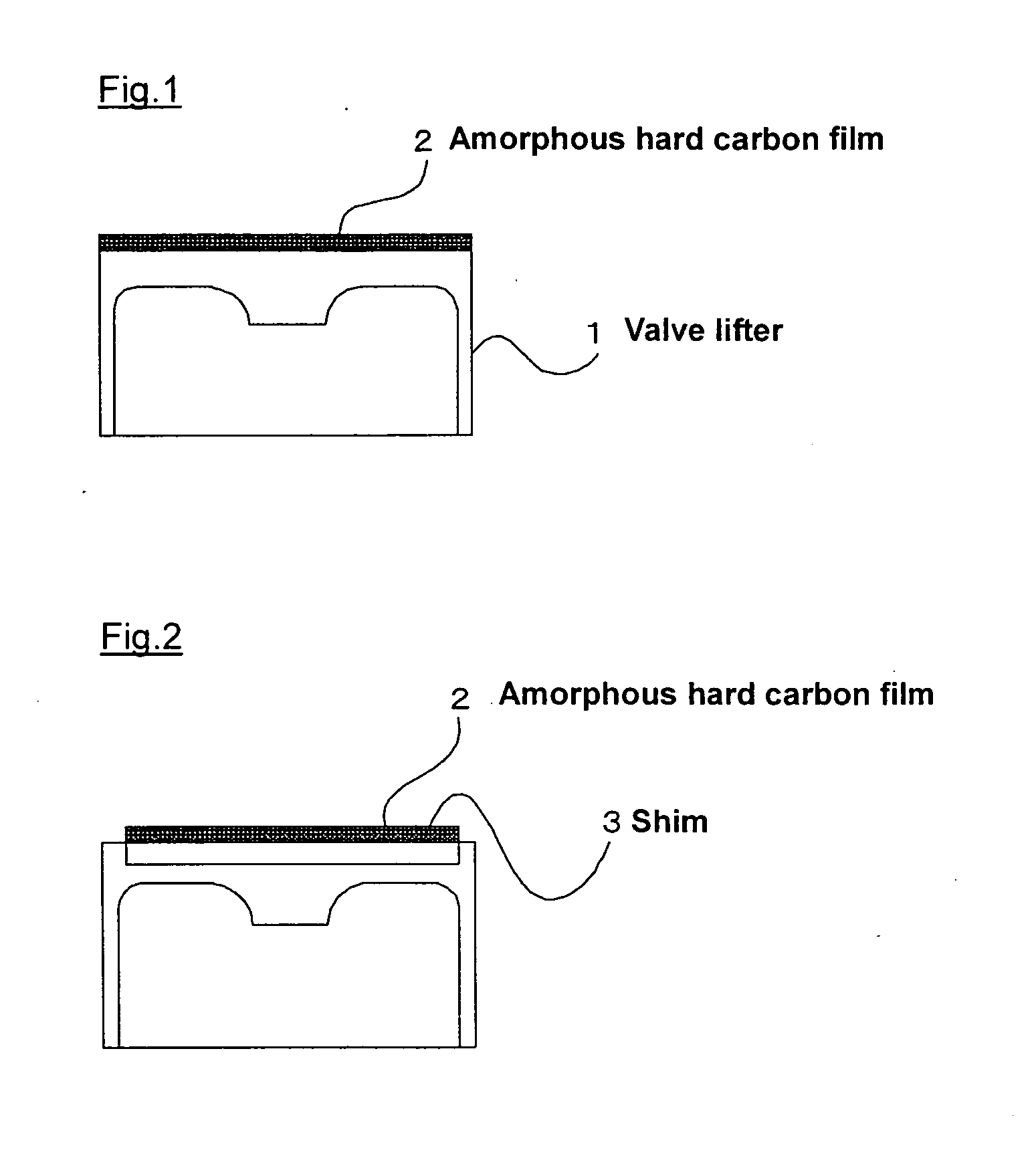

Valve lifter

InactiveUS20060207540A1Prevent developmentHighly reliable adhesionValve arrangementsCam-followersCarbon filmMicrometer

A valve lifter, in which an amorphous hard carbon film is coated at least on the surface that slides against a cam, is characterized in that the surface of a base material (substrate) has an arithmetic mean roughness of Ra 0.01 to 0.03 micrometers, and the maximum length of the scratch on the base surface is made to be equal to or shorter than 250 micrometers.

Owner:RIKEN CO LTD +1

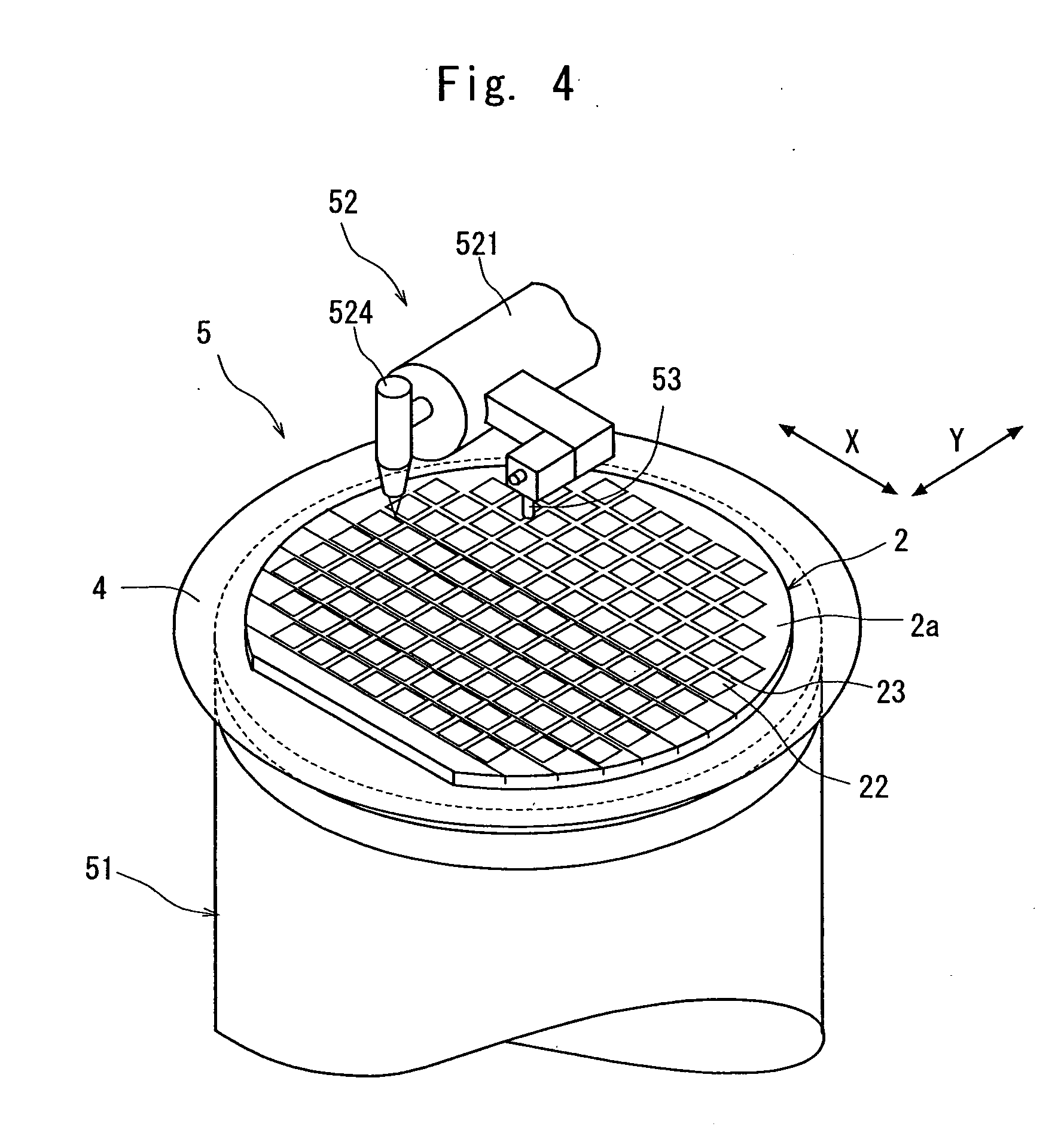

Method of laser processing a wafer

InactiveUS20060154449A1Inhibit flakingPromote divisionSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesLaser processingEngineering

A method of laser processing a wafer having a plurality of devices that are composed of a laminate layer laminated on the front surface of a substrate, along a plurality of streets for sectioning the devices, comprising a first groove forming step for applying a first laser beam having absorptivity for the wafer along the streets of the wafer at predetermined intervals to form two grooves for preventing the flaking of a layer, which divide the laminate layer; and a second groove forming step for applying a second laser beam having absorptivity for the wafer to the center between the two grooves for preventing the flaking of a layer, which have been formed along the streets of the wafer by the first groove forming step, along the streets of the wafer to form a dividing groove having a predetermined depth in the laminate layer and the substrate.

Owner:DISCO CORP

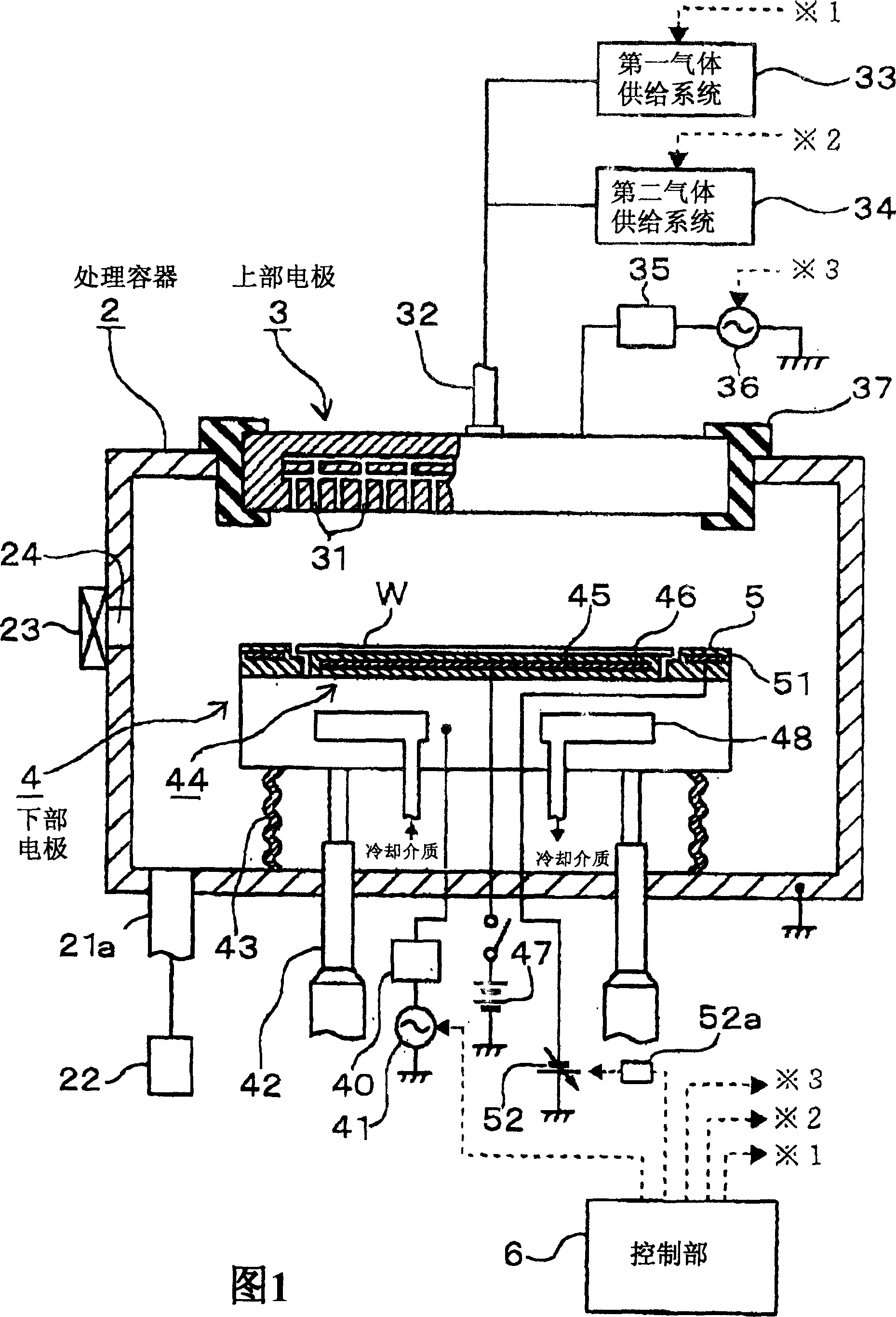

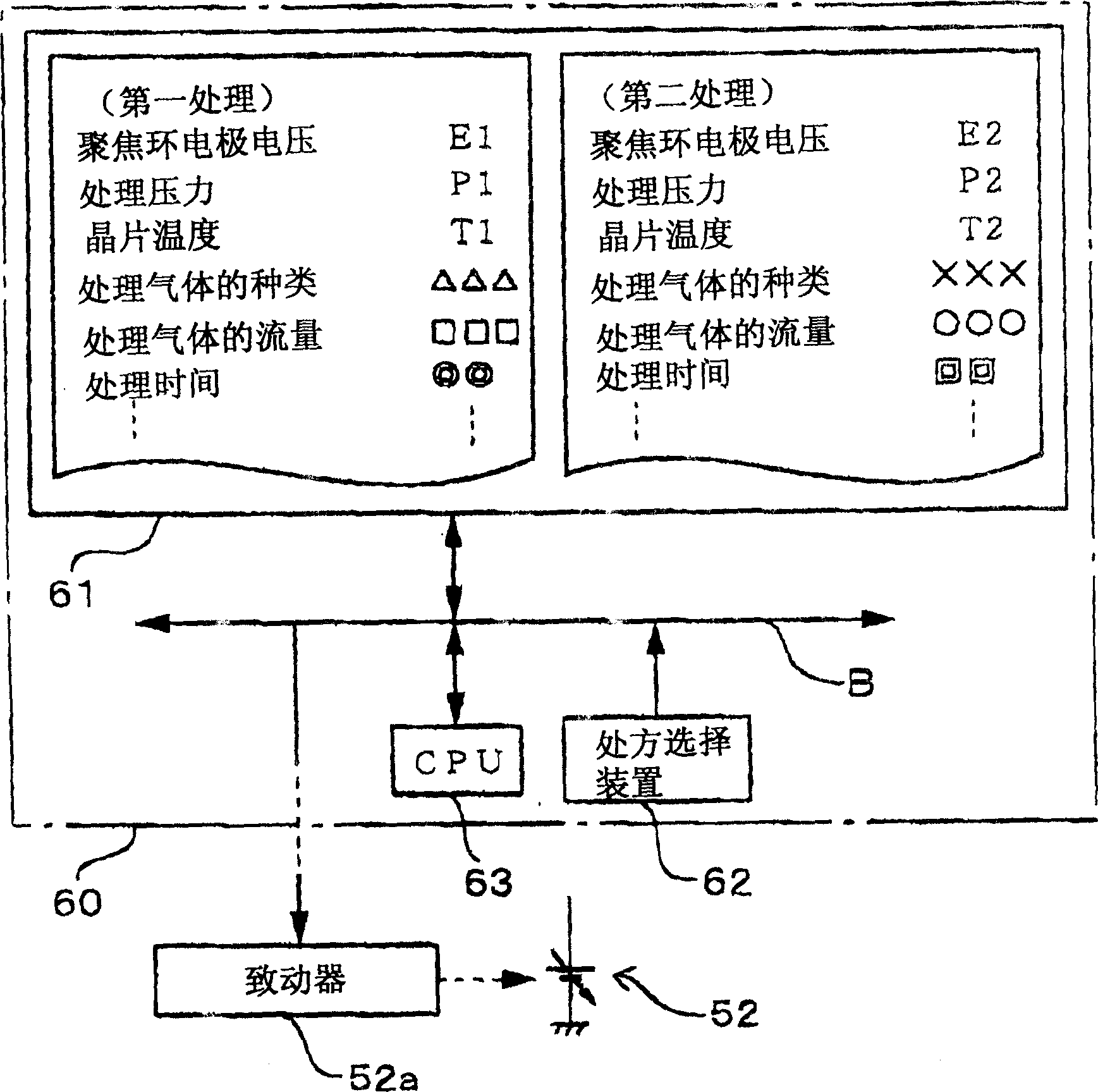

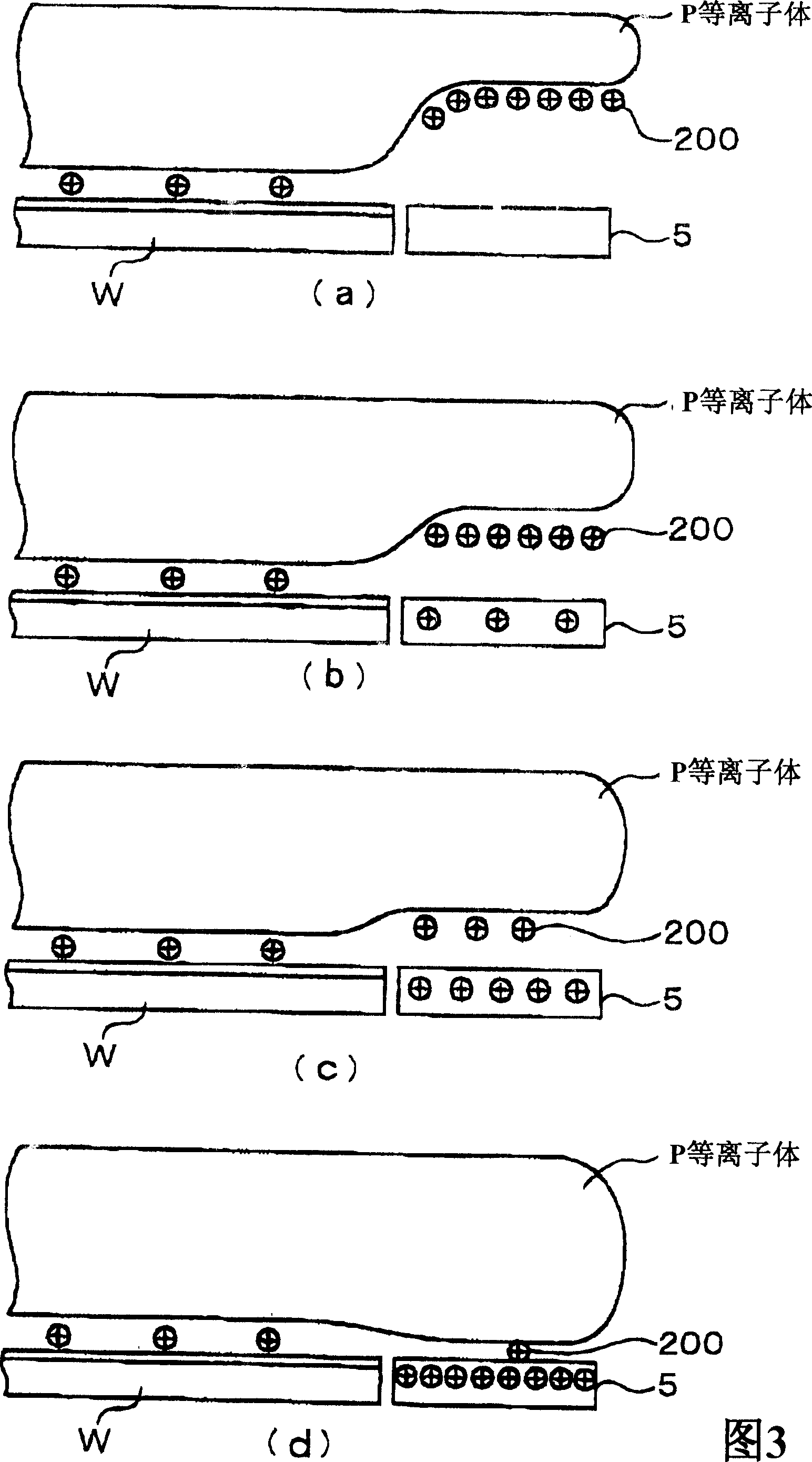

Plasma processing device, annular element and plasma processing method

InactiveCN1521805ARealize common useEasy to adjustElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringPlasma processing

To share the use of plasma treatment apparatuses when performing a plurality of processes that are different from one another, in the plasma treatment apparatuses that use plasma, and to provide the apparatuses, ring members and a plasma treatment method that can easily align states of plasma between the apparatuses when performing the same processes by using a plurality of the apparatuses. A substrate to be treated in a treatment container is surrounded by a ring member made of an insulating material. In this ring member, electrodes are provided to adjust a plasma sheath region. When performing a first process on the substrate to be treated, for example, a first direct-current voltage is applied to the electrodes. When performing a second process on the substrate, a second direct-current voltage is applied to the electrodes. This method is applicable to a suitable direct-current voltage for each process or for each of the apparatuses performing the same processes so that the apparatuses have the same plasma conditions, enabling the shared use of the apparatuses and the easy adjustment of the plasma condition.

Owner:TOKYO ELECTRON LTD

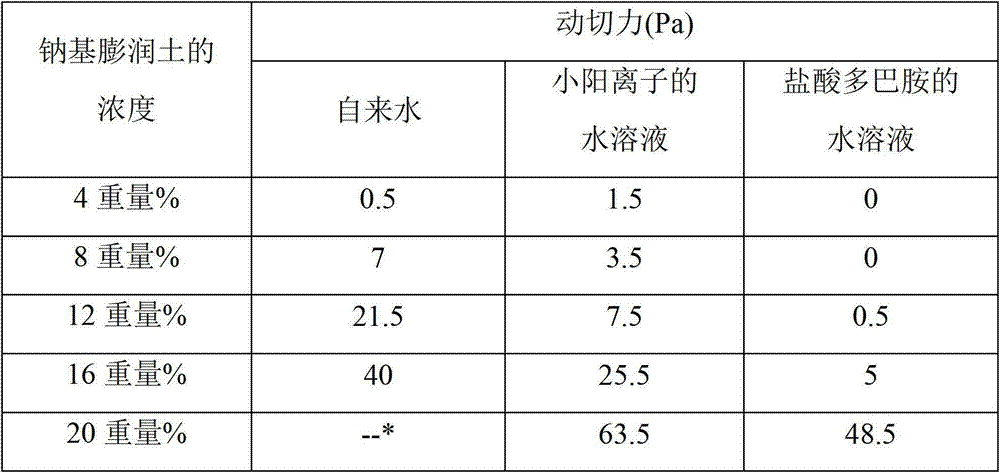

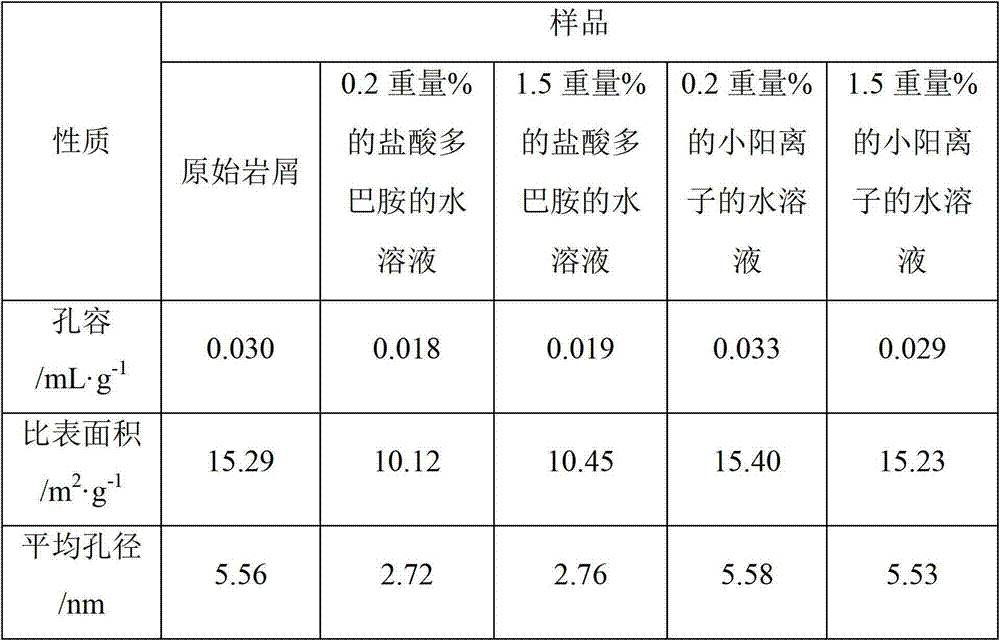

Application of aromatic amine hydrochloride serving as shale inhibitor for drilling fluid

ActiveCN103087690AInhibition dispersionInhibit flakingDrilling compositionAromatic amineHydrochloride

The invention discloses an application of aromatic amine hydrochloride serving as a shale inhibitor for a drilling fluid. The aromatic amine hydrochloride, specifically dopamine hydrochloride, can be used for effectively inhibiting clay hydration and swelling as well as inhibiting dispersion and flaking of the shale, and also can be used for effectively plugging the pores and micro cracks on the near surface of the shale.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Preparation method and application method of electrocatalysis electrode

ActiveCN105776431ALarge specific surface areaExtended service lifeWater/sewage treatment with mechanical oscillationsWater/sewage treatment by electrochemical methodsHeat depositionTitanium

The invention provides a preparation method and an application method of an electrocatalysis electrode. The preparation method includes: taking titanium as a substrate, depositing Bi-SnO2-Sb2O3-CNT on the titanium substrate by means of heat deposition, and then depositing a PbO2 active surface layer on a Bi-SnO2-Sb2O3-CNT interlayer by the aid of electrodeposition to prepare a Ti / Bi-SnO2-Sb2O3-CNT / PbO2 electrocatalysis electrode. The electrocatalysis electrode is used for ultrasound electrocatalysis algae killing and microcystin degradation. The electrocatalysis electrode is taken as an anode, a stainless steel or copper sheet is taken as a cathode, microcystis aeruginosa solution added with electrolyte is subjected to electrolysis, and ultrasonic treatment is applied in the electrolytic process. The preparation method and the application method of the electrocatalysis electrode have the advantages that the electrode has more catalytic activity sites, and catalytic activity of the electrode is improved; electrical conductivity of the electrode can be improved, and energy consumption can be lowered; electrocatalytic activity is high, and service life is long; ultrasonic oxidation and electrocatalytic oxidation are combined, synergistic effect is generated, and efficiency of algae killing and microcystin degradation is highly increased.

Owner:HARBIN ENG UNIV

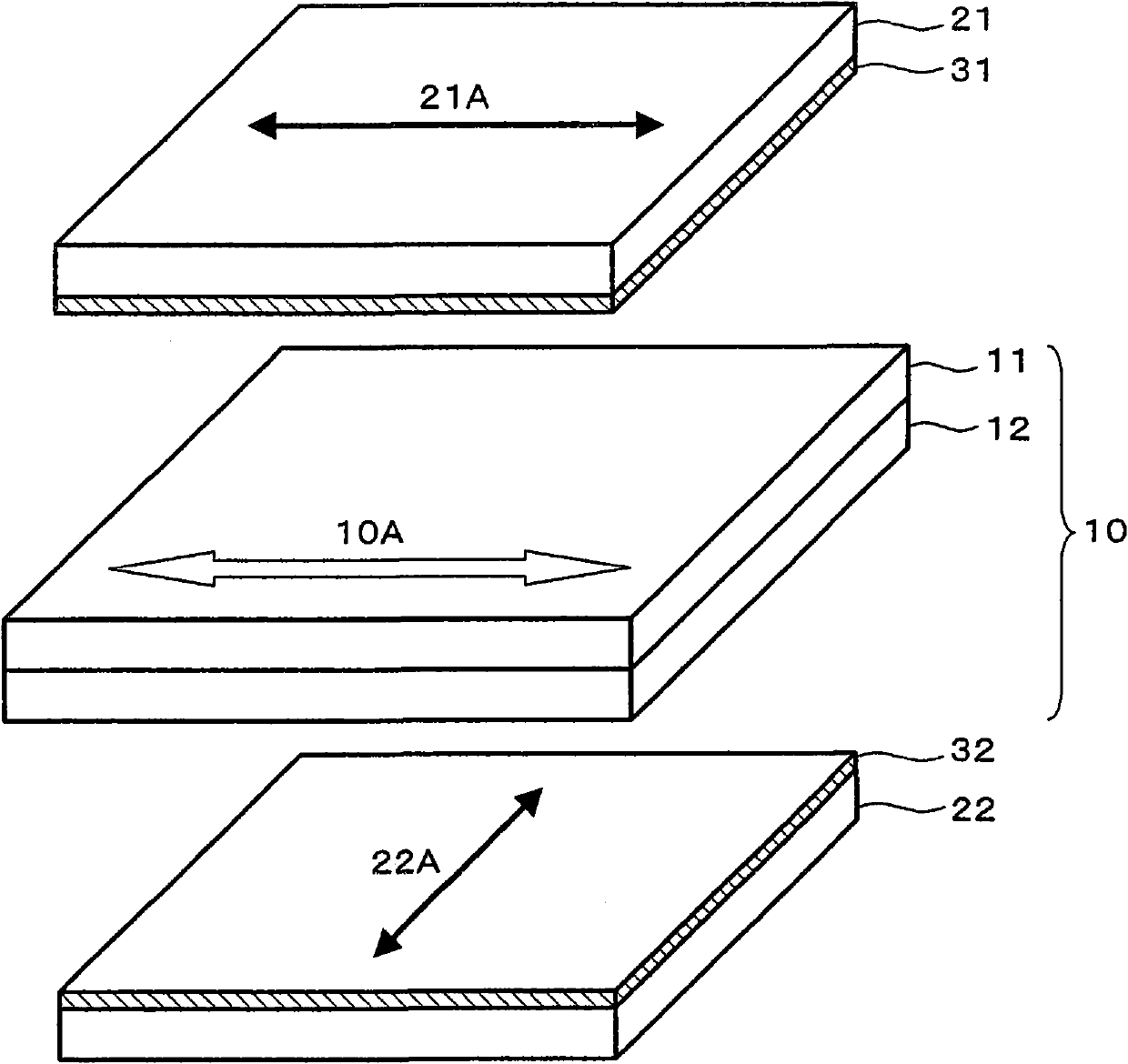

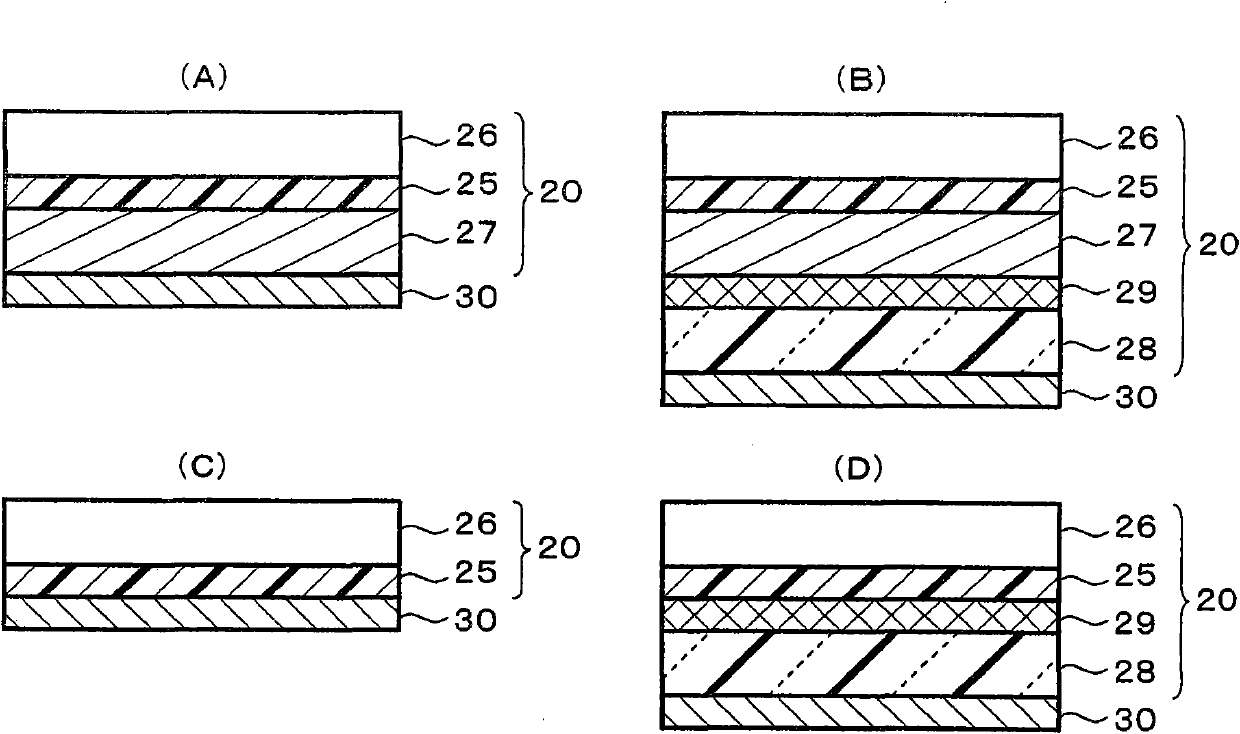

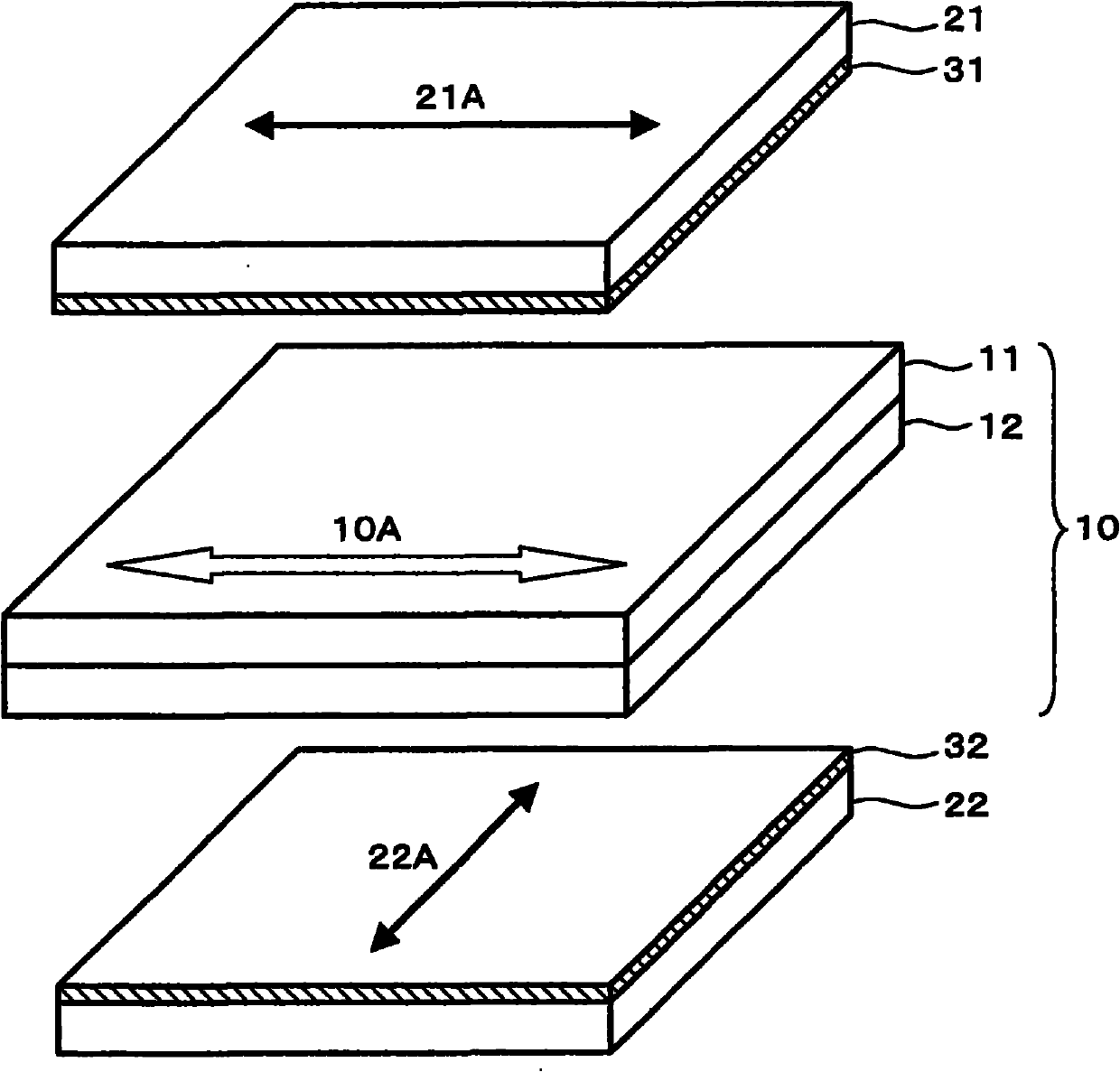

A liquid crystal panel

ActiveCN102033355APrevent optical defectsInhibit whiteningFilm/foil adhesivesPolarising elementsAcrylic resinPolarizer

The present invention provides a liquid crystal panel which is obtained through: adhibiting a first polarizing sheet (21) to one surface of a liquid crystal unit (10) through a first adhesive layer (31) with a mode that an absorption axis (21A) is parallel with a long edge (10A) of a liquid crystal unit, and adhibiting a second polarizing sheet (22) to the other surface of the liquid crystal unit (10) through a second adhesive layer (32) with a mode that an absorption axis (22A) is orthogonal with the absorption axis (21A) of the first polarizing sheet. At least one layer selected from the adhesive layers (31,32) is composed of the adhesive composition. The adhesive composition comprises 100 weight parts of acrylic resin (A) and 0.01-5 weight parts of crosslinking agent (B), wherein the acrylic resin is obtained through copolymerizing 80-96% by weight of (methyl)alkyl acrylate, 3-15% by weight of aromatic ring monomer and 0.1-15% by weight of polar functional groups and has 1000,000-2000,000 of weight average molecular weight and 3-7 of molecular weight distribution. The gel fractions of the adhesive layers are set to 60-99wt%. According to the liquid crystal panel, two surfaces of the liquid crystal unit are respectively adhibited with a pair of polarizing sheet through the adhesive layer. The liquid crystal panel can restrain white discharge even when size is enlarged.

Owner:SUMITOMO CHEM CO LTD

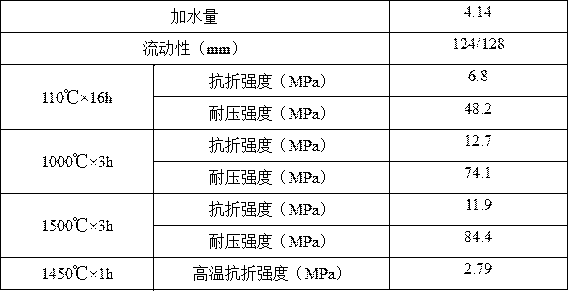

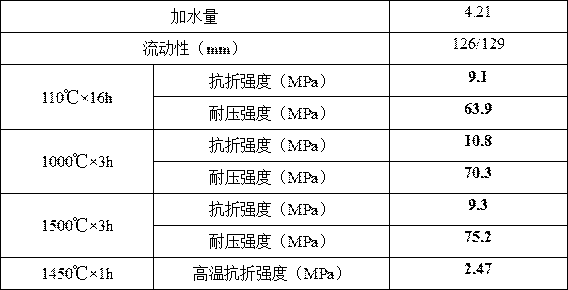

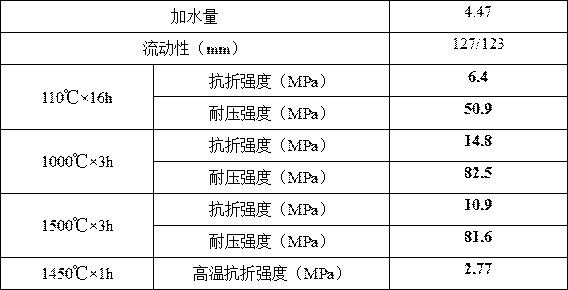

Anti-erosion iron runner castable for large blast furnace

InactiveCN111574206APrevent penetrationLow apparent porosityCeramicwareOxidation resistantCarbon black

The invention relates to an anti-erosion iron runner castable for a large blast furnace. The material comprises, according to weight percentage, 58-64 parts of compact brown fused alumina particles, 2-5 parts of white corundum particles, 16-23 parts of silicon carbide, 5-7 parts of aluminum oxide micro-powder, 2-3 parts of pure calcium aluminate cement, 2-3 parts of silicon dioxide micro-powder, 1.5-2.5 parts of spherical asphalt particles, 0.5-1.2 parts of carbon black powder, 1.5-3.5 parts of metal silicon powder, 0.2-0.6 part of boron carbide, 0.1-0.2 part of metal aluminum powder, 0.15-0.2part of a water reducing agent, 0.6-1 part of an anti-erosion agent and 0.05-0.08 part of explosion-proof fibers. According to the castable, the service life of a primary runner of a main runner is prolonged, and the stability of safe operation of an iron runner is improved. It is verified that the requirements for rapid baking without cracking, erosion resistance, oxidation resistance, slag adhesion resistance and iron flux can be met, the iron flux can reach 180000 tons or above without repairing, and good application prospects are achieved.

Owner:TANGSHAN GUOLIANG SPEICAL REFRACTORY MATERIAL

Metal conductive agent and lithium ion battery using conductive agent

InactiveCN105244509APrevent dislocationInhibit flakingSecondary cellsNon-aqueous electrolyte accumulator electrodesCopper platingSodium-ion battery

The invention relates to a metal conductive agent and a lithium ion battery using the conductive agent. The metal conductive agent is made of metal which has stable properties under a negative pole potential, such as silver, copper, nickel, stainless steel, nickel-plated silver or nickel-plated copper; and the metal conductive agent has a powder shape or spring shape or hollow semispherical shape or other hollow shapes. In a negative pole, the hollow metal conductive agent is used; by controlling the compaction density of a pole piece, the conductive agent keeps a certain hollow structure after being ground; when a silicon-containing negative pole is charged and expanded, the metal conductive agent is deformed along the expansion direction of negative pole particles to form a certain space, so that the staggering and stripping of the negative pole particles are inhibited to a certain extent; and meanwhile, the contact area of metal and the negative pole particles keeps unchanged or is relatively large when the negative pole particles are extruded and enough conductivity is kept, so that the cycling service life is maintained.

Owner:TIANJIN ENERGIES

Composite copper foil, method of production thereof and high frequency transmission circuit using said composite copper foil

InactiveUS20060147742A1Improve conductivityMaintain strengthPrinted circuit aspectsThin material handlingCopper platingSilver plate

A composite copper foil excellent in conductivity and surface shape, having high strength and able to be used for applications such as high frequency transmission circuits and a method of production of the same are provided. A composite copper foil characterized by having a copper foil on at least one surface of which a copper and / or silver smoothing layer is provided. Further, producing this by processing an ingot having a copper alloy to a foil having a desired thickness by rolling, then forming on at least one surface of the processed copper alloy foil a smoothing layer by copper plating and / or silver plating. Alternatively, producing this by processing an ingot having a copper alloy to a foil having a thickness of an intermediate size by rolling, forming on at least one surface of the foil a smoothing layer by copper plating and / or silver plating, then rolling the result to a foil having a desired thickness or applying heat treatment or applying heat treatment and rolling to thereby make the thickness of at least the copper and / or silver plating layer at the surface of the foil 0.01 μm or more. Further, a high frequency transmission circuit characterized by being prepared using the above composite copper foil or the composite copper foil produced by the above method of production.

Owner:FURUKAWA ELECTRIC CO LTD

Thermal barrier coating member, method for producing the same, thermal barrier coating material, gas turbine, and sintered body

ActiveUS8586169B2Increased durabilityInhibit flakingPropellersMolten spray coatingCrystal structureBarrier effect

There are provided a thermal barrier coating material and a thermal barrier coating member that can suppress spalling when used at a high temperature and have a high thermal barrier effect, a method for producing the same, a turbine member coated with a thermal barrier coating, and a gas turbine. The thermal barrier coating member comprises a heat resistant substrate, a bond coat layer formed thereon, and a ceramic layer formed further thereon, wherein the ceramic layer comprises an oxide which consists of an oxide represented by the general formula A2Zr2O7 doped with a predetermined amount of CaO or MgO and has 10 volume % or more of a pyrochlore type crystal structure, where A represents any of La, Nd, Sm, Gd, and Dy.

Owner:MITSUBISHI POWER LTD

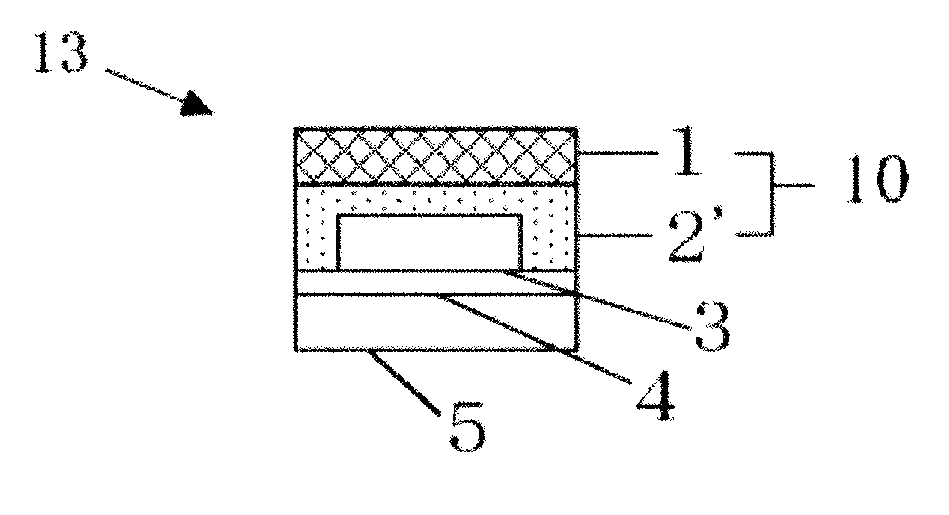

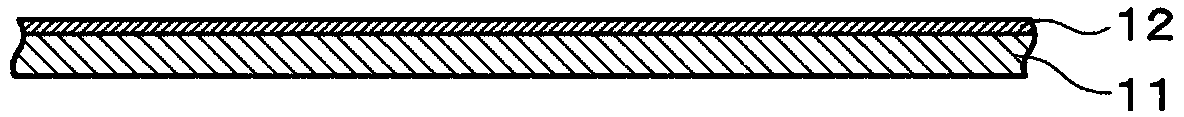

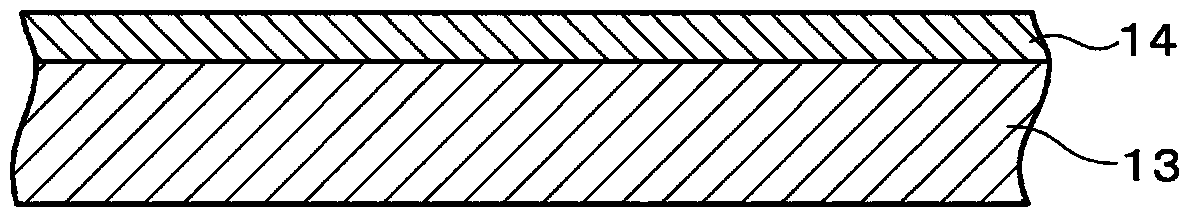

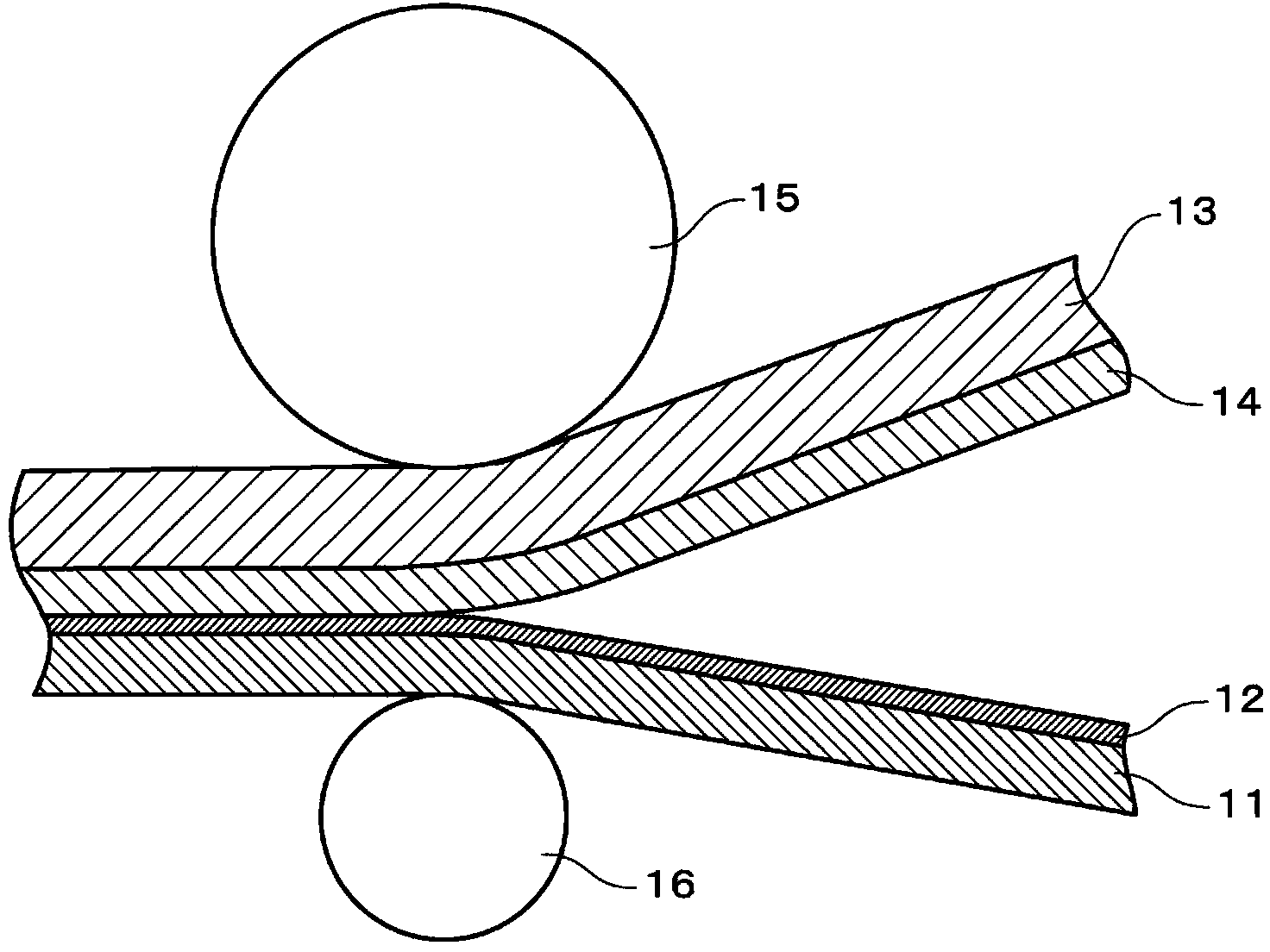

Method for producing multilayer structure, multilayer structure and electronic device

InactiveCN104395083AInhibit flakingConductive layers on insulating-supportsNon-conductive material with dispersed conductive materialMetal foilUltraviolet

A multilayer structure is produced by bonding one or more graphene layers (12), which are formed on a first substrate (11), and a second substrate (13) with each other by a roll-to-roll method by means of an adhesive layer (14) that is formed of a delayed ultraviolet-curable resin. A metal foil is used as the first substrate (11), while a transparent substrate is used as the second substrate (13).

Owner:SONY CORP

Method for coating waste lithium battery negative electrode materials with carbon

ActiveCN110098443ASuppression of co-insertionInhibit swellingReclaiming serviceable partsWaste accumulators reclaimingNano siliconTriethoxysilane

The invention discloses a method for coating waste lithium battery negative electrode materials with carbon, which comprises the following steps: (1) dismantling and cleaning waste batteries, and carrying out acid treatment to obtain surface-carboxylated nanographite sheets; (2) reacting nano-silicon powder with 3-aminopropyl triethoxysilane to obtain surface-aminated nano-silicon powder; (3) ball-milling the mixture of the surface-carboxylated nanographite sheets and the surface-aminated nano-silicon powder to obtain a silicon-graphite sheet composite material; (4) obtaining a coated sample by taking hexuronic acid as a coating carbon source and adopting a liquid impregnation approach; (5) carbonizing the coated sample at 300-400 DEG C in a tubular furnace and carrying out heat preservation; and (6) ball-milling and sieving the product obtained in step (5) to obtain a carbon-coated silicon-based graphite sheet negative electrode material. The coated negative electrode material has high charge retention rate and good cycling performance. The decommissioned negative electrode material can be re-applied to lithium batteries.

Owner:浙江卡波恩新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com