Metal conductive agent and lithium ion battery using conductive agent

A lithium-ion battery, metal conductive technology, applied in non-aqueous electrolyte battery electrodes, battery electrodes, secondary batteries, etc., can solve problems such as insufficient battery performance, improve practicality, and large irreversible capacity loss, and achieve maintenance cycle life, The effect of maintaining conductivity and suppressing dislocation and peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

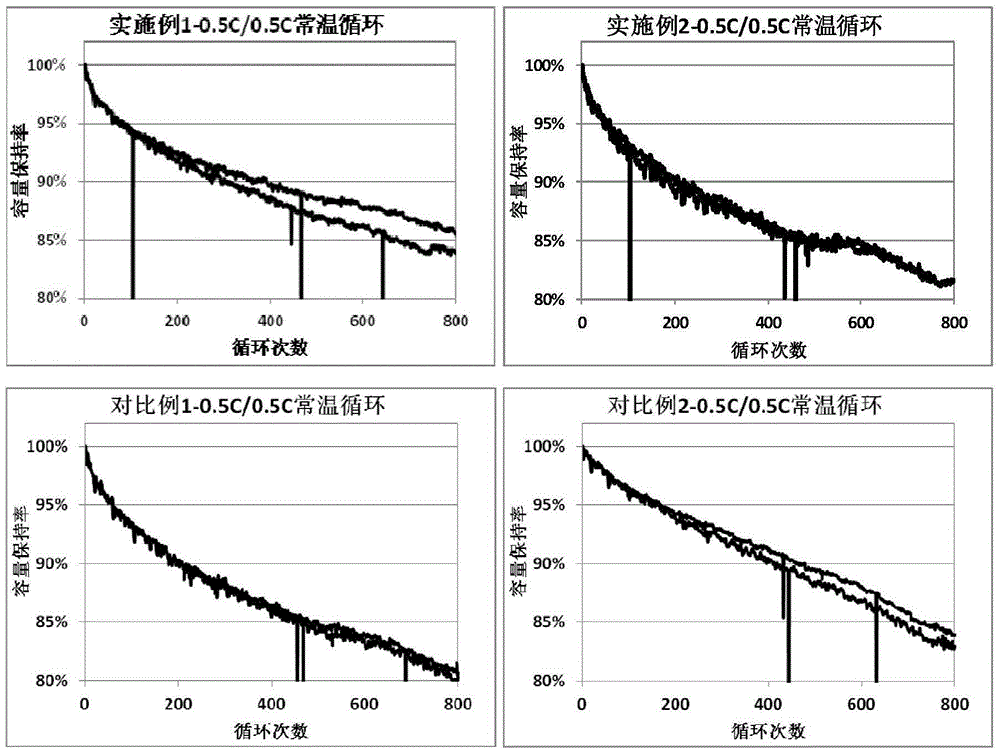

Embodiment 1

[0047] Preparation of negative electrode: Dissolve 0.035kg of CMC in deionized water to make glue. 0.23kg of spring-like copper (D50=1.0um) and 0.012kg of CNT were made into dispersions respectively. Stir CMC glue, copper powder dispersion, CNT dispersion, 2.00kg of silicon oxide / graphite composite material, SBR glue (SBR solid mass 0.035kg), and appropriate amount of deionized water to make negative electrode slurry. Coat the slurry on the copper foil, dry, roll, cut into a size of 53×550cm, and weld a nickel tab at one end. During rolling, the porosity of the negative electrode is controlled at 23.0%±0.5%.

[0048] Preparation of positive electrode: Dissolve 0.062g PVDF in NMP to make glue. Stir PVDF glue, 4.00kg lithium cobaltate, 0.062kg SP, and an appropriate amount of NMP evenly to make positive electrode slurry. Coat the slurry on an aluminum foil, dry, roll, cut into a size of 51.5×548mm, and weld an aluminum tab at one end.

[0049]Electrolyte preparation: Mix EC,...

Embodiment 2

[0052] Preparation of negative electrode: Dissolve 0.039kg of CMC in deionized water to make glue. 0.50kg of spring-like copper (D50=1.0um) and 0.012kg of CNT were respectively made into dispersion liquids. Stir CMC glue, copper powder dispersion, CNT dispersion, 2.00kg silicon oxide / graphite composite material, SBR glue (SBR solid mass 0.039kg), and appropriate amount of deionized water to make negative electrode slurry. Coat the slurry on a non-woven fabric separator, dry, roll, cut into a size of 53×550 cm, and stick a nickel tab on one end. During rolling, the porosity of the negative electrode is controlled at 23.0%±0.5%.

[0053] The positive electrode, electrolyte, and battery manufacturing process are the same as in Example 1.

Embodiment 3

[0055] Preparation of negative electrode: Dissolve 0.035kg of CMC in deionized water to make glue. 0.25kg of spring-like copper (D50=1.0um) was made into a dispersion. Stir the CMC glue, copper powder dispersion, 2.00kg of silicon oxide / graphite composite material, SBR glue (SBR solid mass 0.039kg), and appropriate amount of deionized water to make negative electrode slurry. Coat the slurry on the copper foil, dry it, roll it, cut it into a size of 53×550cm, and stick a nickel tab on one end. During rolling, the porosity of the negative electrode is controlled at 23.0%±0.5%.

[0056] The positive electrode, electrolyte, and battery manufacturing process are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com