Different-orientation spherical natural graphite negative electrode material and preparation method thereof

A technology of natural graphite and negative electrode material, applied in the field of electrochemical power supply, can solve the problems of accelerated capacity decay, exfoliation of graphite layers, etc., and achieve the effects of inhibiting exfoliation of layers, easy operation and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

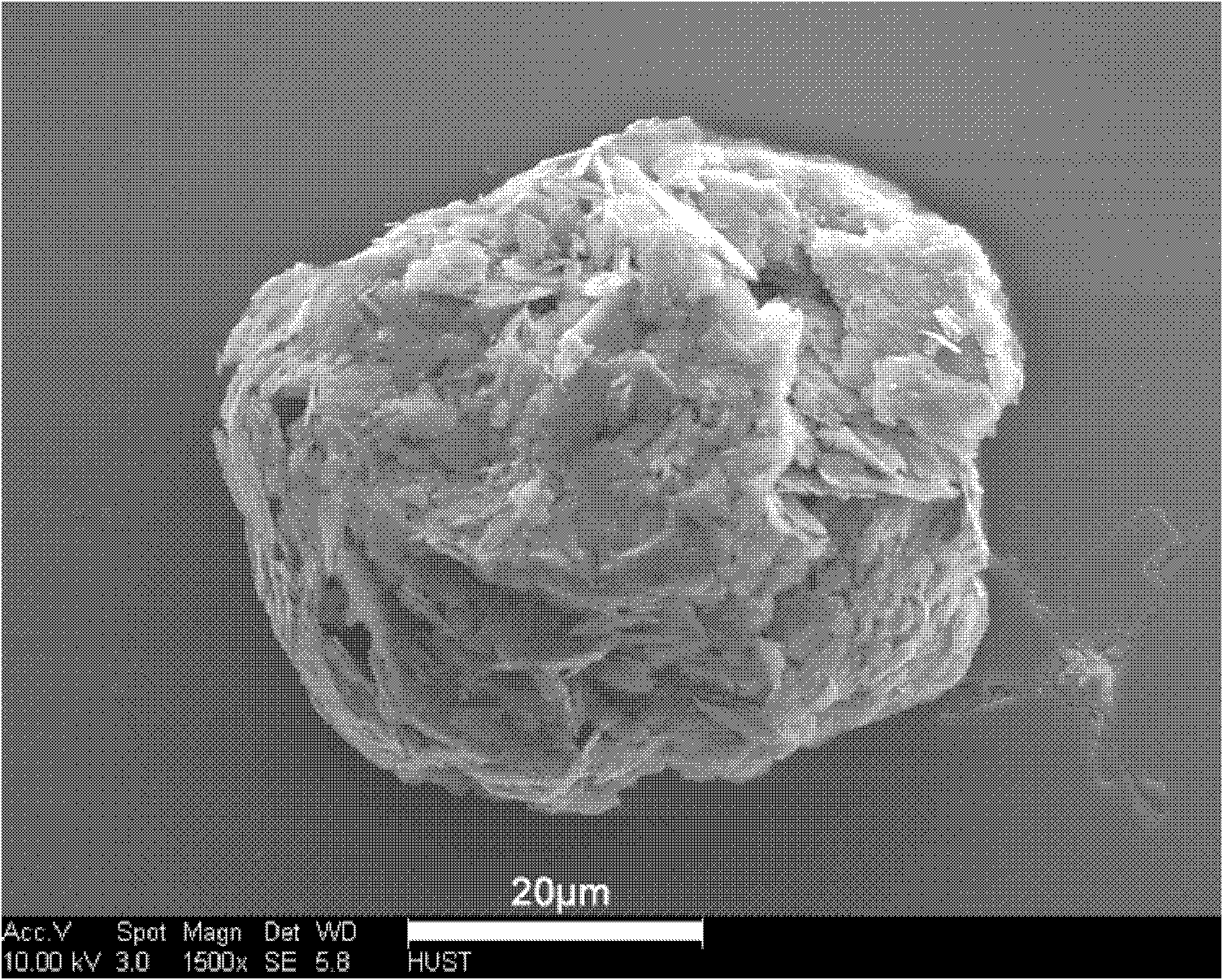

[0026]Embodiment 1. with natural flake graphite micropowder, purity >=99%, mixes with deionized water, adds deflocculating agent and regulates solid content to 30~50% by mass percentage, then adds the PVA of natural flake graphite micropowder weight 5% and The mixture of CMC is used as a binder, and after adding a small amount of defoamer, it is stirred in a mixer for 2 to 5 hours. The obtained slurry is atomized, dried and granulated on a spray dryer, and the obtained powder is placed in a rotary kiln for heat treatment in a nitrogen atmosphere. The temperature is controlled at 600-1000°C for 2-5 hours, and the rotation speed is 3-5 rpm. The obtained powder material is the hetero-orientation spherical natural graphite negative electrode material. The obtained hetero-orientation spherical natural graphite negative electrode material was used to prepare electrodes for electrochemical tests. The electrode preparation method, battery assembly and test conditions are the same as ...

Embodiment 2

[0027] Embodiment 2. with natural flake graphite micropowder, purity >=99%, mix with deionized water, add deflocculating agent and regulate solid content to 30~50% by mass percentage, then add the PVA of natural flake graphite micropowder weight 10% and The mixture of CMC is used as a binder, and then the binder and a small amount of defoamer are added and stirred in a mixer for 2 to 5 hours. The obtained slurry is atomized, dried and granulated on a spray dryer, and the obtained powder is placed in a rotary kiln for heat treatment in a nitrogen atmosphere at a temperature of 600-1000°C for 2-5 hours and a rotary kiln speed of 3-5 rpm , the obtained powder material is the different orientation spherical natural graphite negative electrode material. The obtained hetero-orientation spherical natural graphite negative electrode material was used to prepare electrodes for electrochemical tests. The electrode preparation method, battery assembly and test conditions are the same as...

Embodiment 3

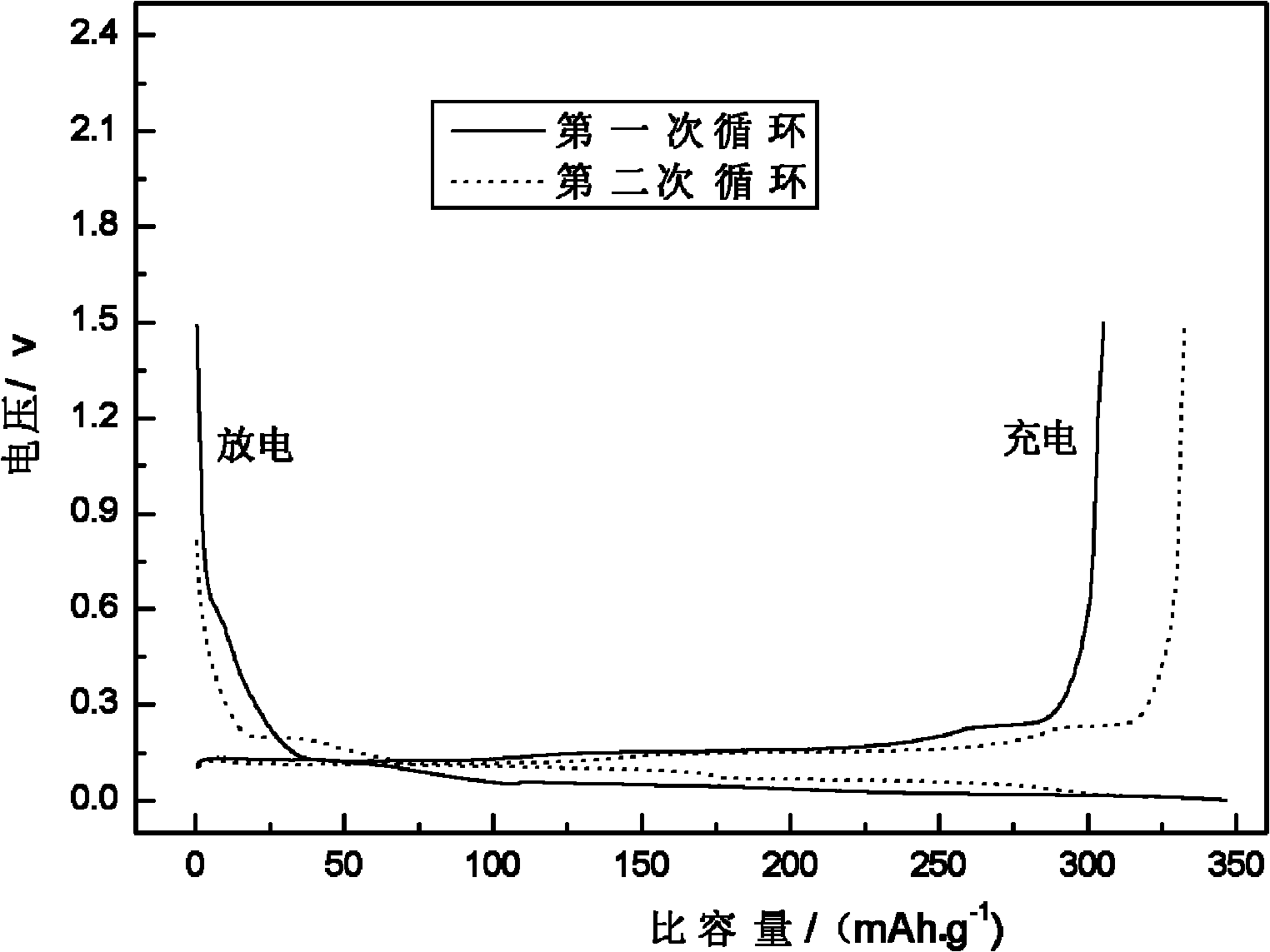

[0028] Embodiment 3. with natural flake graphite powder, purity ≥ 99%, mix with dehydrated alcohol and add deflocculant to regulate solid content to 30~50% by mass percentage, then add the polyvinyl alcohol of natural flake graphite powder quality 5% Butyral PVB is used as a binder, and it is stirred in a mixer for 2 to 5 hours. The obtained slurry is atomized, dried and granulated on a spray dryer, and the obtained powder is placed in a rotary kiln for heat treatment in a nitrogen atmosphere. The temperature is controlled at 600-1000°C for 2-5 hours, and the rotation speed is 3-5 rpm. The obtained powder material is the hetero-orientation spherical natural graphite negative electrode material. The obtained hetero-orientation spherical natural graphite negative electrode material was used to prepare electrodes for electrochemical tests. The electrode preparation method, battery assembly and test conditions are the same as in Comparative Example 1. The first lithium intercala...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com