Method for coating waste lithium battery negative electrode materials with carbon

A technology for waste lithium batteries and anode materials, applied in battery recycling, recycling by waste collectors, regeneration of useful parts, etc., can solve problems such as low density, rising graphite material prices, small thermal expansion coefficient, etc., and achieve charge retention High, high specific capacity, stable graphite structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

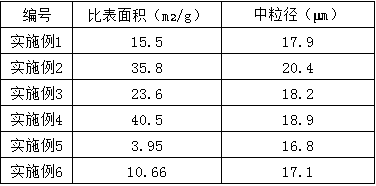

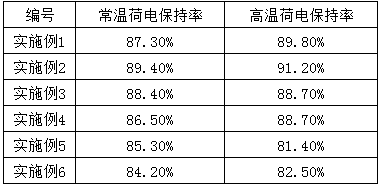

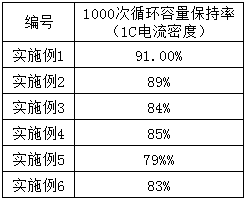

Embodiment 1

[0020] Put the waste lithium battery into the electric tank and soak it for 100 minutes to dry, then disassemble the packaged waste lithium battery by combining manual and machine methods, and disassemble the rolled lithium battery negative electrode material into strips of carbon-coated copper Foil, put the carbon-coated copper foil into a temperature-controlled water washing pool with a stirring device, pour clean water into the pool until all the copper foil is submerged, heat the water in the pool to 70°C, and wait until the carbon powder is completely removed from the copper foil Stop stirring after washing, take out the copper foil without carbon powder attached after wet separation from the washing tank, dry and pack to complete the recovery of metal copper, at this time, the remaining material in the temperature-controlled washing tank is carbon powder ;

[0021] The above carbon powder was reflux treated with 3 M nitric acid at 60°C for 8 hours, and washed with water ...

Embodiment 2

[0025] Put the waste lithium battery into the electric tank and soak it for 100 minutes to dry, then disassemble the packaged waste lithium battery by combining manual and machine methods, and disassemble the rolled lithium battery negative electrode material into strips of carbon-coated copper Foil, put the carbon-coated copper foil into a temperature-controlled washing pool with a stirring device, pour clean water into the pool until all the copper foil is submerged, heat the water in the pool to 70 °C, and wait until the carbon powder is completely removed from the copper foil. Stop stirring after washing, take out the copper foil without carbon powder attached after wet separation from the washing tank, dry and pack to complete the recovery of metal copper, at this time, the remaining material in the temperature-controlled washing tank is carbon powder ;

[0026] The above carbon powder was refluxed with 3 M nitric acid at 80°C for 10 h, and washed with water several times...

Embodiment 3

[0030]Put the waste lithium battery into the electric tank and soak it for 100 minutes to dry, then disassemble the packaged waste lithium battery by combining manual and machine methods, and disassemble the rolled lithium battery negative electrode material into strips of carbon-coated copper Foil, put the carbon-coated copper foil into a temperature-controlled water washing pool with a stirring device, pour clean water into the pool until all the copper foil is submerged, heat the water in the pool to 70°C, and wait until the carbon powder is completely removed from the copper foil Stop stirring after washing, take out the copper foil without carbon powder attached after wet separation from the washing tank, dry and pack to complete the recovery of metal copper, at this time, the remaining material in the temperature-controlled washing tank is carbon powder ;

[0031] The above-mentioned carbon powder was treated with 3 M nitric acid at 70°C for 10 h, washed with water sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com