Coated tio 2 Graphite dual-ion battery composite cathode material and preparation method thereof

A composite cathode material, battery cathode technology, applied in battery electrodes, graphite, secondary batteries, etc., can solve the problems of electrolyte viscosity increase, affecting the fast charge and discharge performance of dual-ion batteries, etc., to improve cycle stability, excellent High current charge and discharge performance, reducing the effect of crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

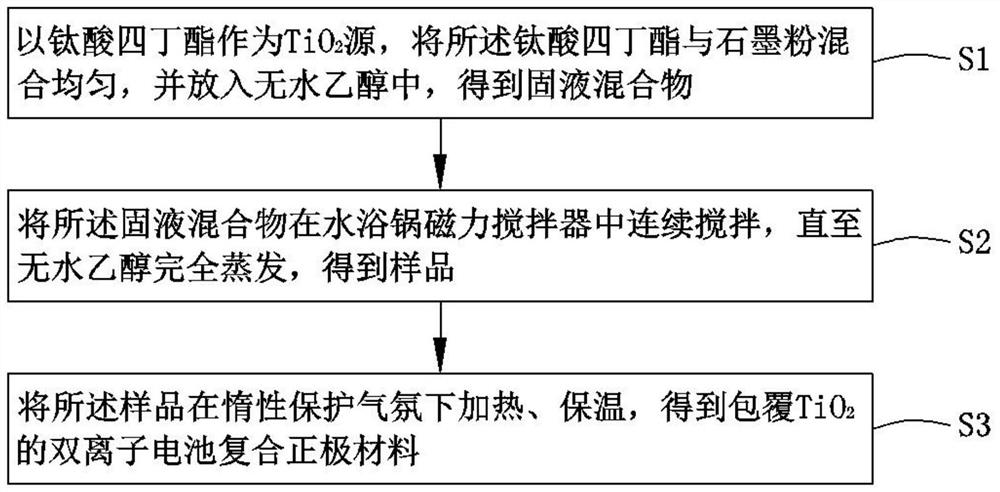

[0031] See figure 1 The present invention provides a coating TiO in the present invention. 2 The graphite double ion battery composite positive material preparation method, including the steps of:

[0032] S1: Tetanyl titanate as TiO 2 The source, the titanate tetrabutyate is mixed with graphite powder and placed in anhydrous ethanol to obtain solid-liquid mixture;

[0033] S2: The solid solution mixture was stirred in a water bath magnetic stirrer until anhydrous ethanol was completely evaporated to give a sample;

[0034] S3: Heat the sample under an inert protective atmosphere to obtain a coating TiO 2 Graphite Double Ion Battery Composite Positive Material.

[0035] Preferably, the mass ratio of tetutyl titanate and graphite powder is (0.05-0.15): 1.

[0036] Preferably, the water bath in the step S2 is 40-70 ° C.

[0037] Preferably, the heating temperature in the step S4 is 400 ° C to 600 ° C, and the holding time is 3-6 hours.

[0038] The present invention also provides a ...

Embodiment 1

[0040] The titanate tetrabutyate and graphite powder were mixed with a mass ratio of 0.15: 1 and placed in an appropriate amount of anhydrous ethanol, which was placed in a 60 ° C water bath, and the continuous magnetic stirring was stirred until there was all evaporation of no water ethanol; The sample was carbonized at 600 ° C for 3 hours at an argon atmosphere, which was obtained by coating TiO. 2 Graphite Double Ion Battery Composite Positive Material.

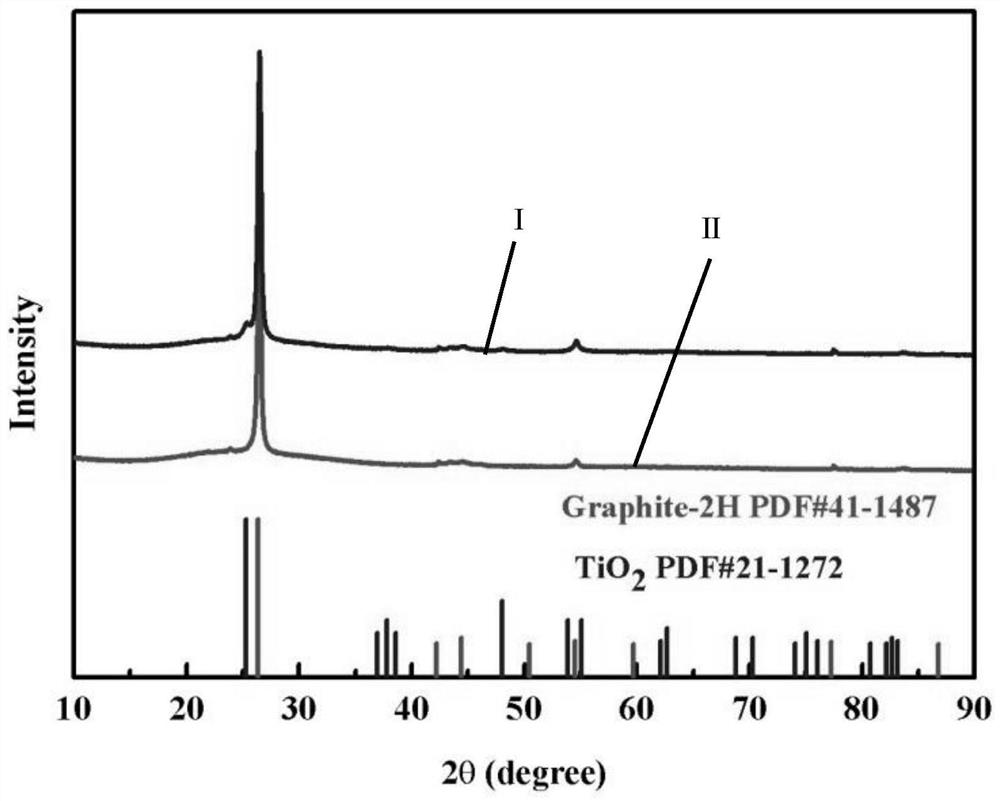

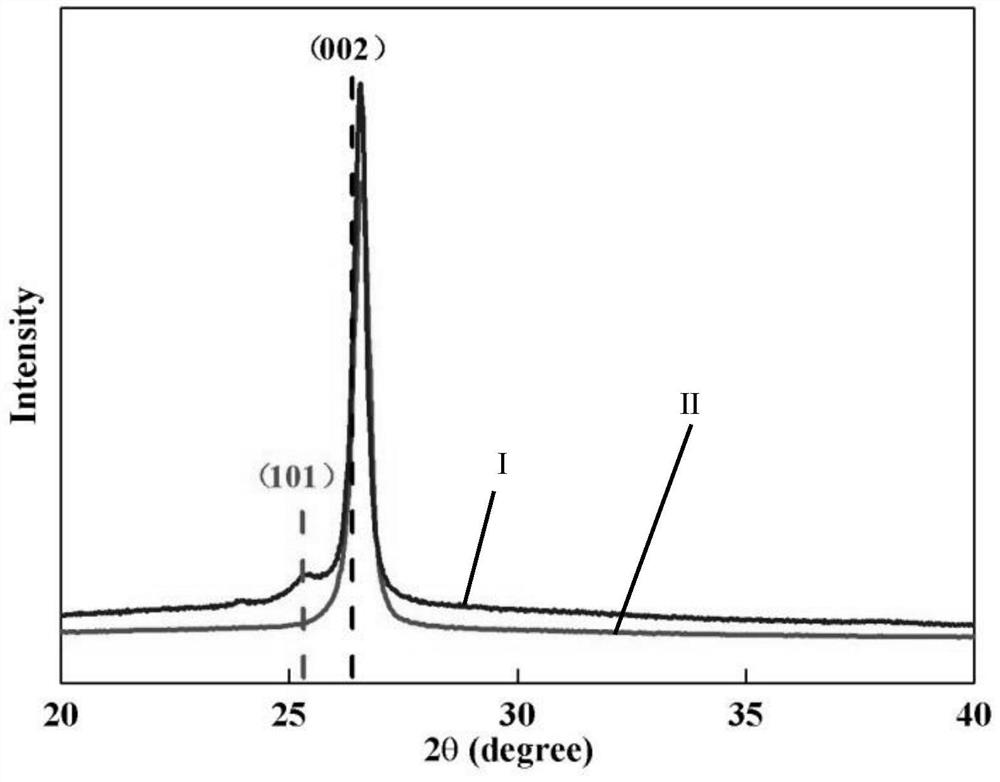

[0041] Figure 2 (a) is a covering TiO 2 Graphite double ion battery composite positive material and uncoated TiO 2 X-ray diffraction spectrum (XRD) comparison diagram of graphite double ion battery positive electrode material, where the graph I is a coating TiO 2 X-ray diffraction spectrum (XRD) of graphite double ion battery composite positive material; graph II is uncoated TiO 2 X-ray diffraction spectrum (XRD) of graphite dual ion battery positive electrode material. Unclosed Tio 2 The graphite double ion battery positive m...

Embodiment 2

[0047] The titanate tetrabutyate and graphite powder were mixed with a mass ratio of 0.05: 1 and placed in an appropriate amount of anhydrous ethanol, which was placed in a 40 ° C water bath, until there was all evaporation of water absorbed ethanol; The sample was carbonized at 400 ° C for 6 hours at an argon atmosphere, which was obtained by coating TiO. 2 Graphite Double Ion Battery Composite Positive Material.

[0048] Figure 3 (a) is a covering TiO 2 Graphite double ion battery composite positive material SEM topography, TiO 2 The nanoparticles are evenly covered in the surface of the graphite. Figure 3 (b) is a covering TiO 2 Cycle performance diagram of graphite double ion battery composite positive electrode material at a current density of 2C, wherein the graph I is a coating TiO 2 Graphic efficiency graph of graphite double ion battery composite positive material; graph II is a coating TiO 2 Charlan Double Ion Battery Composite Positive Material Charging Capacity Diston;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com