Electrolyte suitable for silicon-carbon negative electrode material

A technology of negative electrode material and electrolyte, applied in the electrolyte field of silicon carbon negative electrode material, can solve the problems of unsatisfactory battery cycle performance and rate performance, poor volume expansion conductivity, etc., achieve SEI film optimization, increase conductivity, increase rate performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

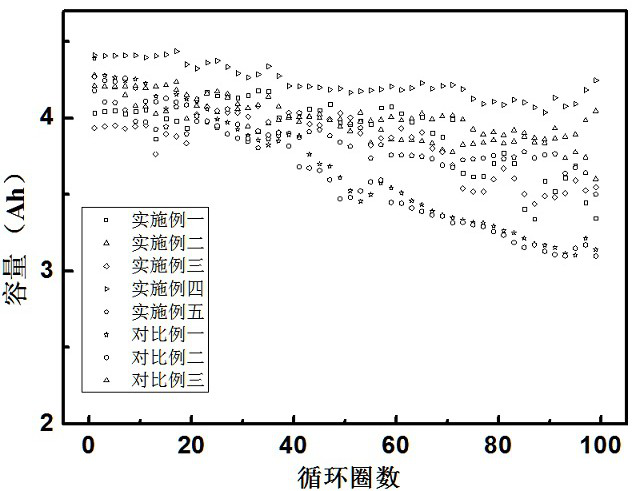

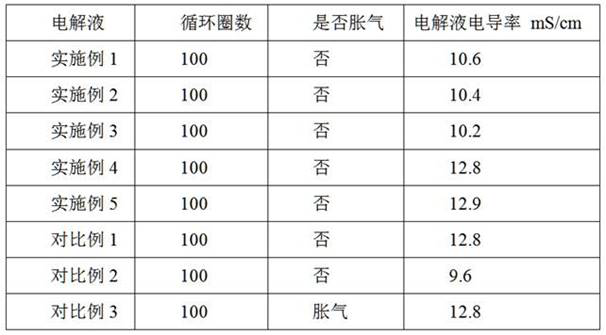

Embodiment 1

[0019] An electrolyte suitable for silicon-carbon anode materials of lithium-ion batteries, comprising the following raw materials: ethylene carbonate 30 g, diethyl carbonate 30 g, dimethyl carbonate 30 g, 15 crown ether-5 0.6 g, perfluoro 0.6 g of n-butylsulfonyl, 4.8 g of fluoroethylene carbonate, and 12 g of lithium hexafluorophosphate. According to the above quality, these raw materials were prepared and stirred in a glove box, and the conductivity of the electrolyte was measured to be 10.6 mS / cm by a conductivity meter.

[0020] Inject the prepared electrolyte into LiNi 0.8 co 0.1 mn 0.1 o 2 In the / SiC soft-pack battery, the design capacity of the soft-pack battery is 4.5 Ah. After the liquid injection is completed, packaging, shelving, formation, aging, secondary packaging, and capacity separation are performed to obtain a lithium-ion battery with a silicon-carbon negative electrode.

Embodiment 2

[0022] An electrolyte suitable for silicon-carbon anode materials of lithium-ion batteries, comprising the following raw materials: ethylene carbonate 30 g, diethyl carbonate 30 g, dimethyl carbonate 30 g, 15 crown ether-5 0.6 g, perfluoro 1.2 g of n-butylsulfonyl, 4.8 g of fluoroethylene carbonate, and 12 g of lithium hexafluorophosphate. According to the above quality, these raw materials were prepared and stirred in the glove box, and the conductivity of the electrolyte was measured by a conductivity meter to be 10.4 mS / cm.

[0023] Inject the prepared electrolyte into LiNi 0.8 co 0.1 mn 0.1 o 2 In the / SiC soft-pack battery, the design capacity of the soft-pack battery is 4.5 Ah. After the liquid injection is completed, packaging, shelving, formation, aging, secondary packaging, and capacity separation are performed to obtain a lithium-ion battery with a silicon-carbon negative electrode.

Embodiment 3

[0025] An electrolyte solution suitable for silicon-carbon negative electrode materials for lithium-ion batteries, comprising the following raw materials: 30 g of ethylene carbonate, 30 g of diethyl carbonate, 30 g of dimethyl carbonate, 0.6 g of 15 crown ether-5, and 0.6 g of perfluorinated 2.4 g of n-butylsulfonyl, 4.8 g of fluoroethylene carbonate, and 12 g of lithium hexafluorophosphate. According to the above quality, these raw materials were prepared and stirred in a glove box, and the conductivity of the electrolyte was measured by a conductivity meter to be 10.2 mS / cm.

[0026] Inject the prepared electrolyte into LiNi 0.8 co 0.1 mn 0.1 o 2 In the / SiC soft-pack battery, the design capacity of the soft-pack battery is 4.5 Ah. After the liquid injection is completed, packaging, shelving, formation, aging, secondary packaging, and capacity separation are performed to obtain a lithium-ion battery with a silicon-carbon negative electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com