Application of aromatic amine hydrochloride serving as shale inhibitor for drilling fluid

A technology of aromatic amine hydrochloride and shale inhibitor, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., to achieve the effects of inhibiting shale dispersion, inhibiting clay hydration expansion, and excellent inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

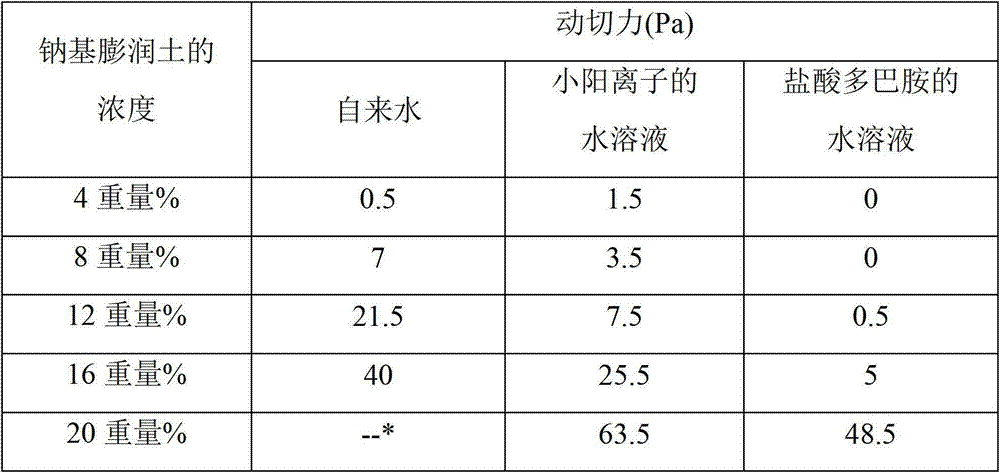

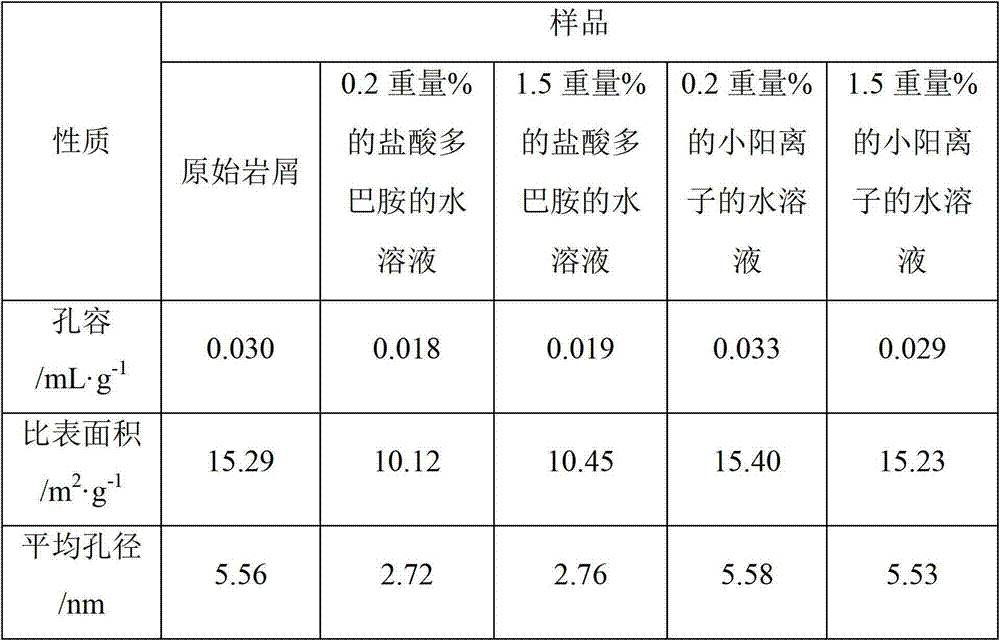

[0031] The dopamine hydrochloride prepared in the preparation example was dissolved in tap water to prepare an aqueous solution of dopamine hydrochloride with a concentration of 1% by weight. Five parts of 300 mL of 1% by weight dopamine hydrochloride aqueous solution were respectively selected for the determination of inhibitory effect evaluation.

Embodiment 2

[0045] The dopamine hydrochloride prepared in the preparation example was dissolved in tap water to prepare 0.2% by weight, 1.0% by weight and 1.5% by weight of dopamine hydrochloride aqueous solutions respectively. 300mL samples of each concentration were selected for the determination of inhibitory effect evaluation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com