Graphene-containing water-borne epoxy resin emulsion and preparation method thereof

A water-based epoxy resin, epoxy resin technology, applied in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve problems such as poor compatibility and difficult dispersion of graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

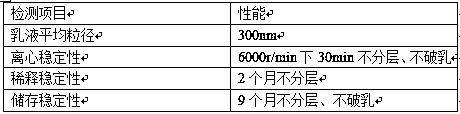

Embodiment 1

[0024] (1) Preparation of polyethylene glycol / graphene composites

[0025] Put 0.1mol ethylene glycol, 0.2g graphene powder, and 0.02mol sodium hydroxide into the high-pressure reactor, mix and stir evenly, pass high-purity nitrogen to replace 3~5 times, and then vacuumize to -0.1MPa, Raise the temperature to 110°C, slowly feed 9mol of ethylene oxide into the reactor, keep the temperature in the reactor at 130°C, control the reaction pressure to 0.35MPa, and completely pass through the ethylene oxide. Keeping the reaction temperature for decompression aging, degassing treatment after aging, neutralization with citric acid after degassing, adsorption, dehydration, filtration, and drying to obtain a polyethylene glycol / graphene composite material with a molecular weight of about 4000;

[0026] (2) Preparation of water-based epoxy resin emulsifier

[0027] Mix 400g polyethylene glycol / graphene composite material and 400g epoxy resin E-44 uniformly at 70°C, add 2g potassium persu...

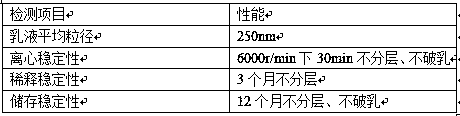

Embodiment 2

[0032] (1) Preparation of polyethylene glycol / graphene composites

[0033]Put 0.1mol ethylene glycol, 0.2g graphene oxide powder, and 0.02mol sodium hydroxide into the high-pressure reactor, mix and stir evenly, pass high-purity nitrogen gas for replacement 3~5 times, and then vacuumize to -0.1MPa , heat up to 110°C, slowly feed 9mol ethylene oxide into the reactor, keep the temperature in the reactor at 130°C, control the reaction pressure to 0.35MPa, and pass through all the ethylene oxide. Keeping the reaction temperature for decompression aging, degassing treatment after aging, neutralization with citric acid after degassing, adsorption, dehydration, filtration, and drying to obtain a polyethylene glycol / graphene oxide composite material with a molecular weight of about 4000;

[0034] (2) Preparation of water-based epoxy resin emulsifier

[0035] Mix 400g of polyethylene glycol / graphene oxide composite material and 400g of epoxy resin E-44 uniformly at 70°C, add 2g of pot...

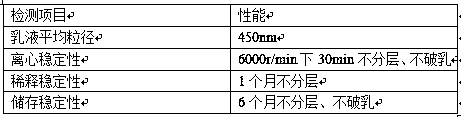

Embodiment 3

[0040] (1) Preparation of polyethylene glycol / graphene composites

[0041] Put 0.1mol ethylene glycol, 0.2g functionalized graphene powder, and 0.02mol sodium hydroxide into the high-pressure reactor, mix and stir evenly, pass high-purity nitrogen gas for replacement 3~5 times, and then vacuumize to -0.1 MPa, raise the temperature to 110°C, slowly feed 9mol ethylene oxide into the reactor, keep the temperature in the reactor at 130°C, control the reaction pressure to 0.35MPa, and completely pass through the ethylene oxide. Keeping the reaction temperature for decompression aging, degassing treatment after aging, neutralization with citric acid after degassing, adsorption, dehydration, filtration, and drying to obtain a polyethylene glycol / functionalized graphene composite material with a molecular weight of about 4000;

[0042] (2) Preparation of water-based epoxy resin emulsifier

[0043] Mix 400g of polyethylene glycol / functionalized graphene composite material and 400g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com