Collected heat type high efficient and energy-saving burning Chinese food frying-oven

A high-efficiency, energy-saving, Chinese food technology, applied in burners, combustion methods, heating fuels, etc., can solve the problems of shortening the service life of the stove, increasing the temperature of the kitchen environment, and failing to achieve comprehensive energy saving, reducing heat Loss, reducing the impact of the kitchen environment, the effect of preventing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

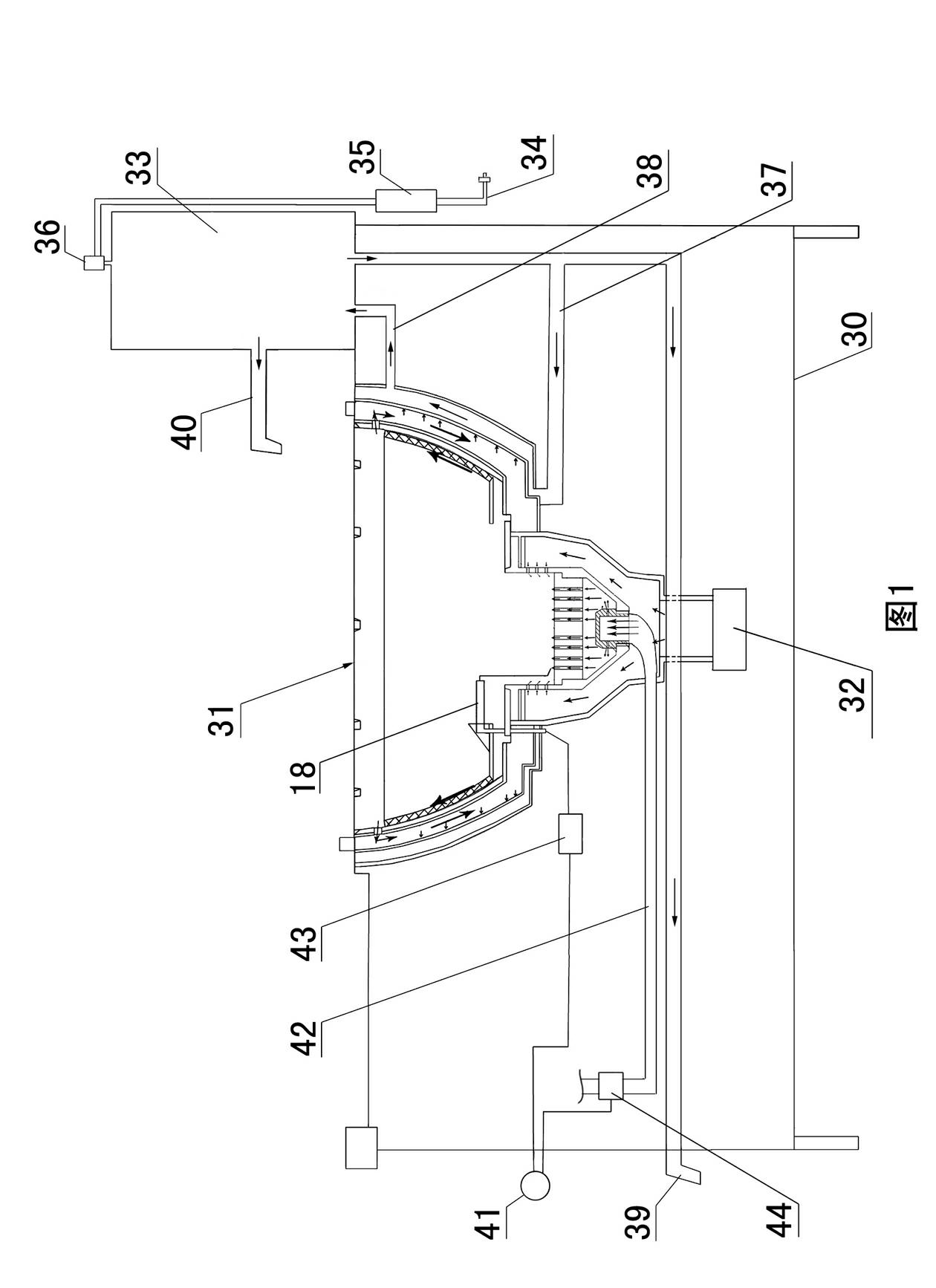

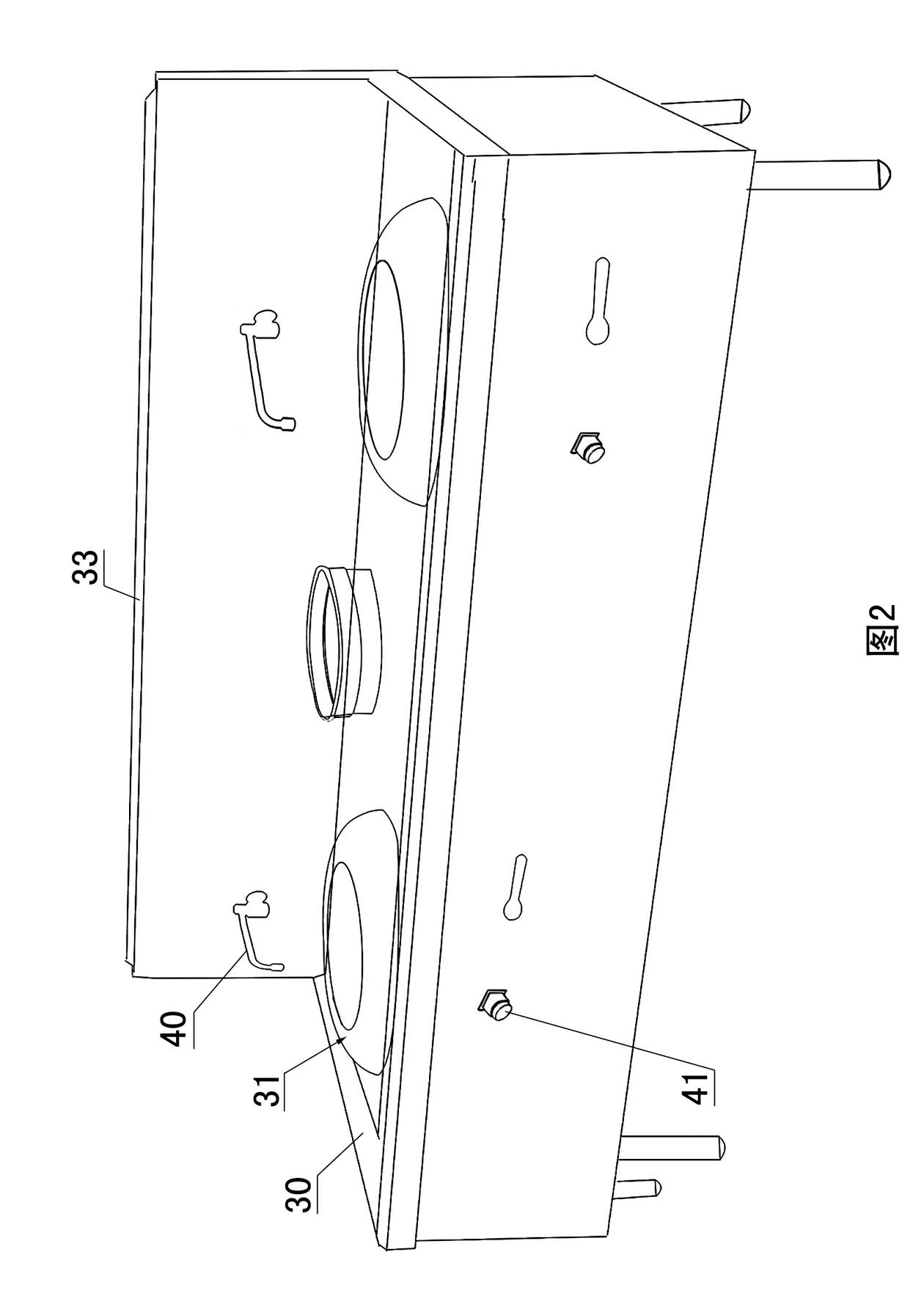

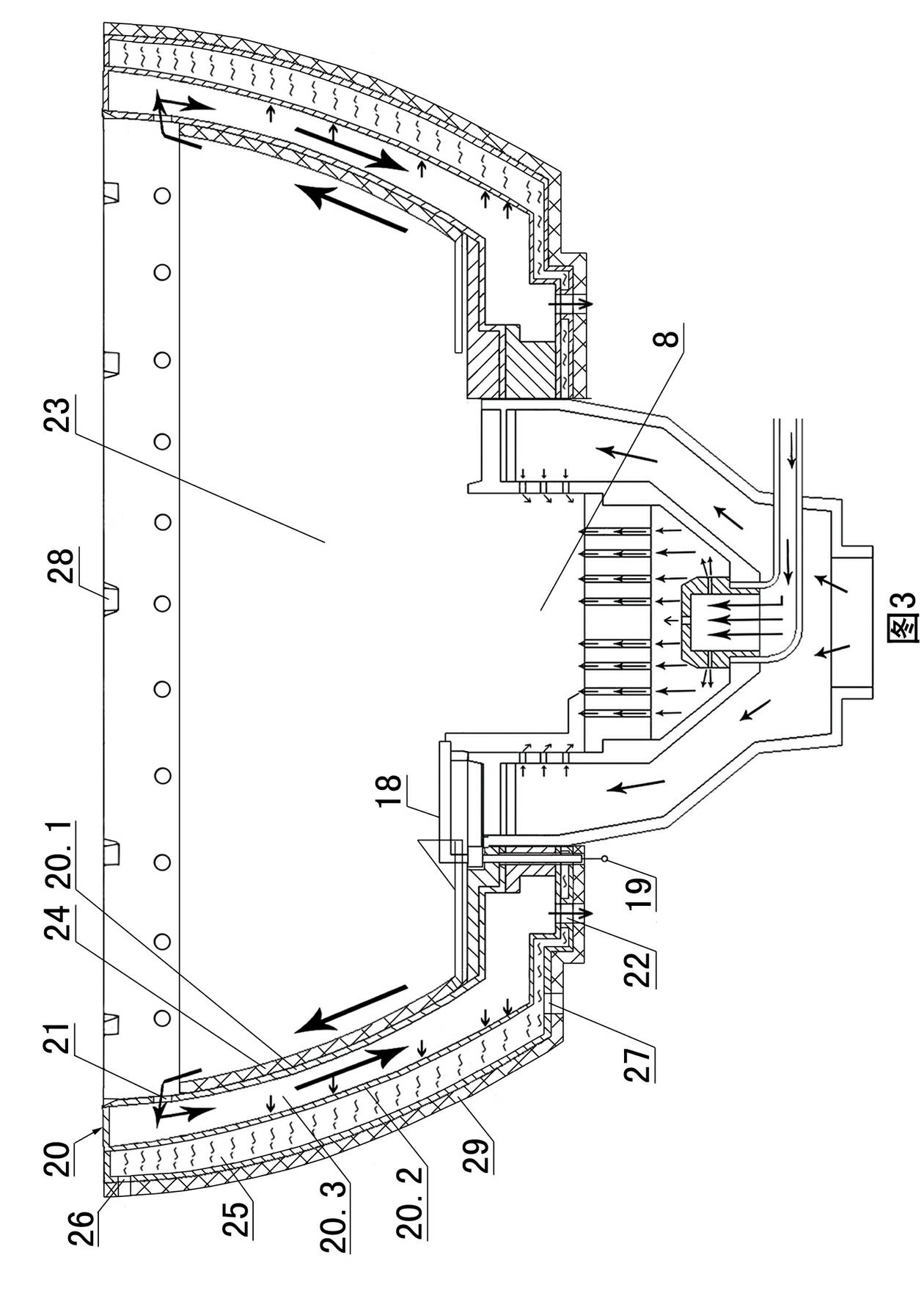

[0030] Examples see figure 1 , figure 2 As shown, this heat-collecting high-efficiency energy-saving combustion Chinese cooking stove includes a stove 30 and a burner assembly 31 placed on the stove, a blower 32, a water storage tank 33, and an electronic ignition device. The burner assembly 31 includes a burner and a furnace, the water storage tank 33 is connected with a swinging hot water faucet 40, and the water storage tank 33 is also connected with a water tap 39, and the water storage tank 33 communicates with the running water pipe 34 through the automatic water supply valve 36 and the magnetizer 35. In this embodiment, there are two stove mouths and a water storage tank 33 on the stove 30, the burner assembly is placed on the stove mouth, and two water outlet valves are opened on the water storage tank 33, that is, a water tap 39 and a swing hot water tap 40, and the swing hot water faucet 40 is connected above the burner assembly 31 and on the front of the water sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com