Plasma processing device, annular element and plasma processing method

A ring-shaped component and plasma technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, gaseous chemical plating, etc., can solve problems such as hindering the common use of processing chambers, increasing operating costs, and difficulty in shrinking, and achieving the effect of common use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

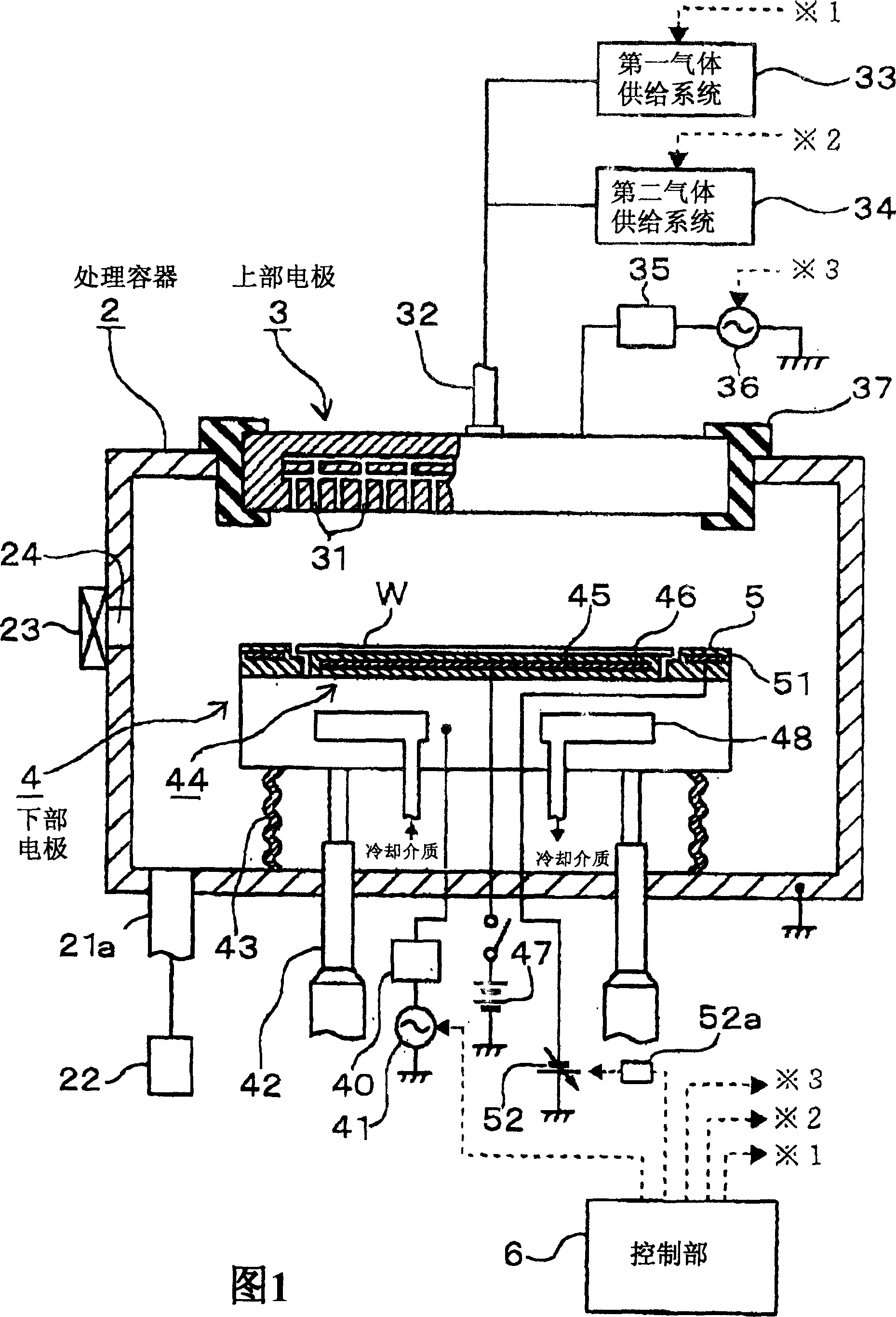

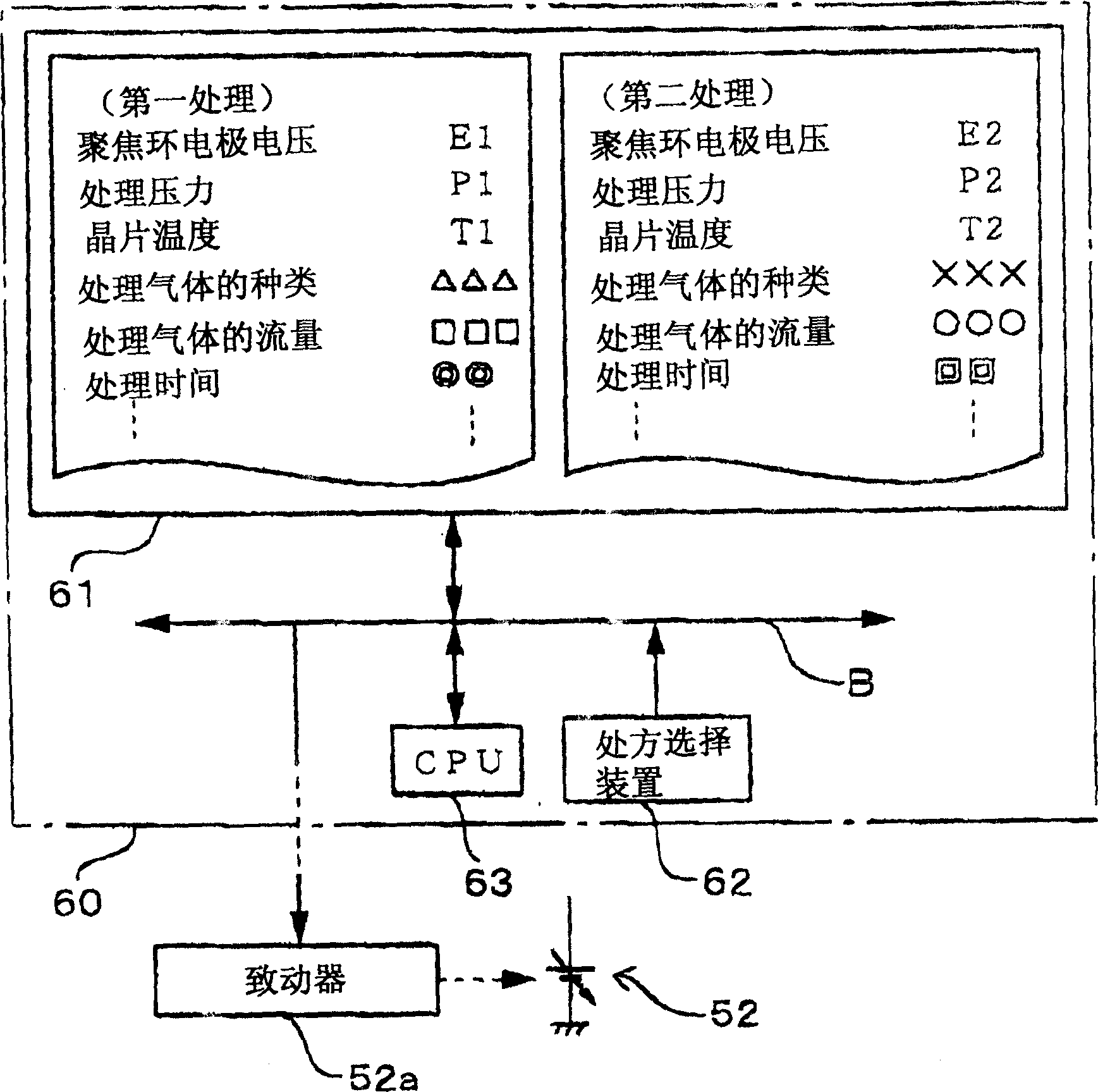

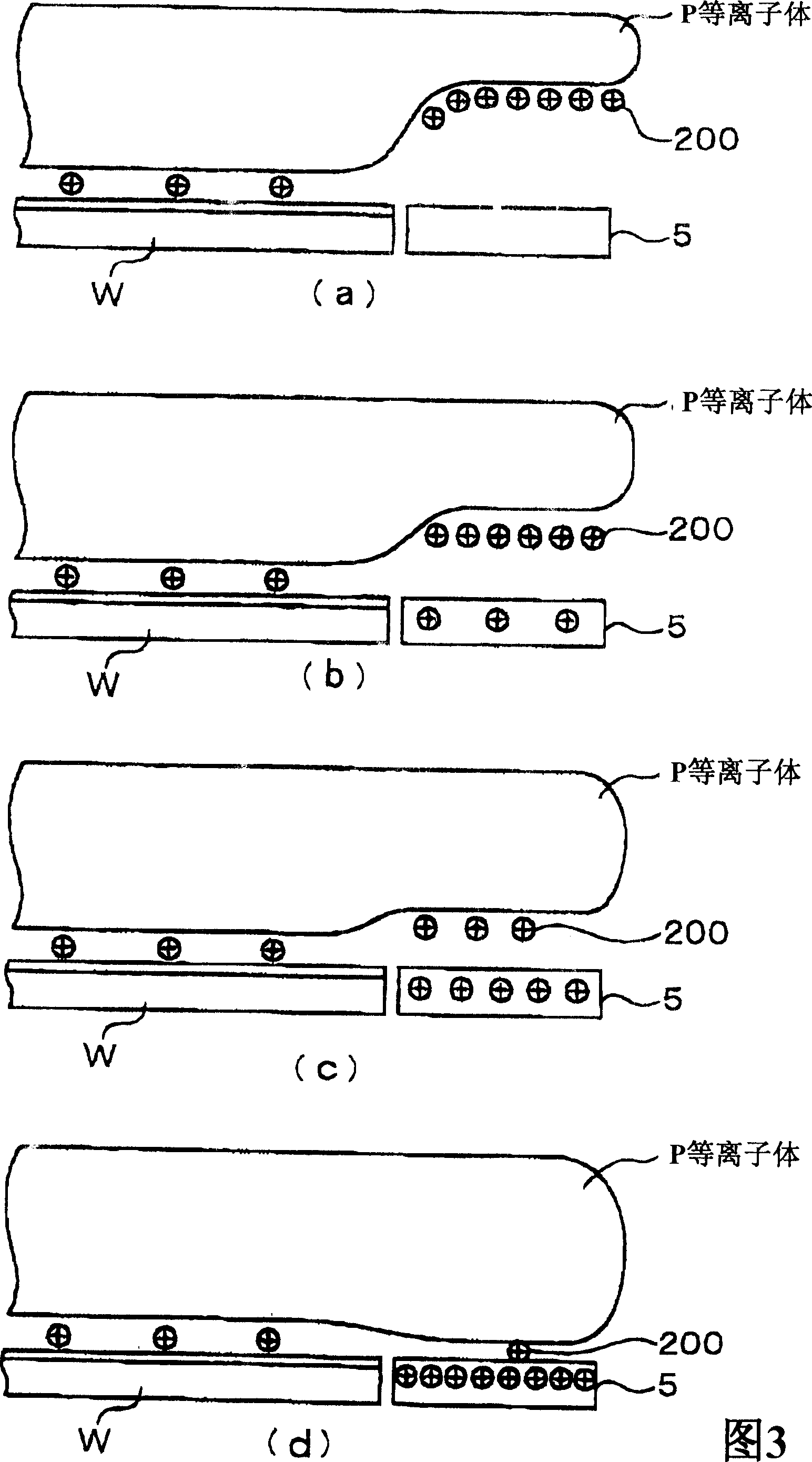

[0085] An embodiment of a plasma processing apparatus according to the present invention will be described with reference to FIG. 1 . figure 2 The processing container 2 is an airtight processing container made of a conductive member such as aluminum, and the processing container 2 is grounded. In the processing container 2, an upper electrode 3 serving as a gas shower head for introducing a specific processing gas such as an etching gas, and a lower electrode 4 serving as a substrate stage for carrying a substrate to be processed such as a wafer W are opposed to each other. set up. In addition, an exhaust port 21 is provided at the bottom of the processing container 2, and a vacuum exhaust device such as a vacuum pump 22 such as a turbomolecular pump and a dry pump is connected to the exhaust port 21 through an exhaust passage 21a. In addition, a freely openable valve 23 is provided on the side wall of the processing container 2, and an opening 24 for carrying in or carryin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com