A kind of thermal diaphragm preforming method

A technology of preforming and thermal diaphragm, which is applied in the field of composite material preforming, which can solve the problems affecting the forming accuracy and quality, the position deviation of prepreg sheets, and the difficulty of precise positioning, so as to ensure the forming quality and avoid position deviation. The effect of shifting and fiber angle deviation and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical solutions of the present invention more obvious and easy to understand, specific embodiments are given and described in detail below with reference to the accompanying drawings.

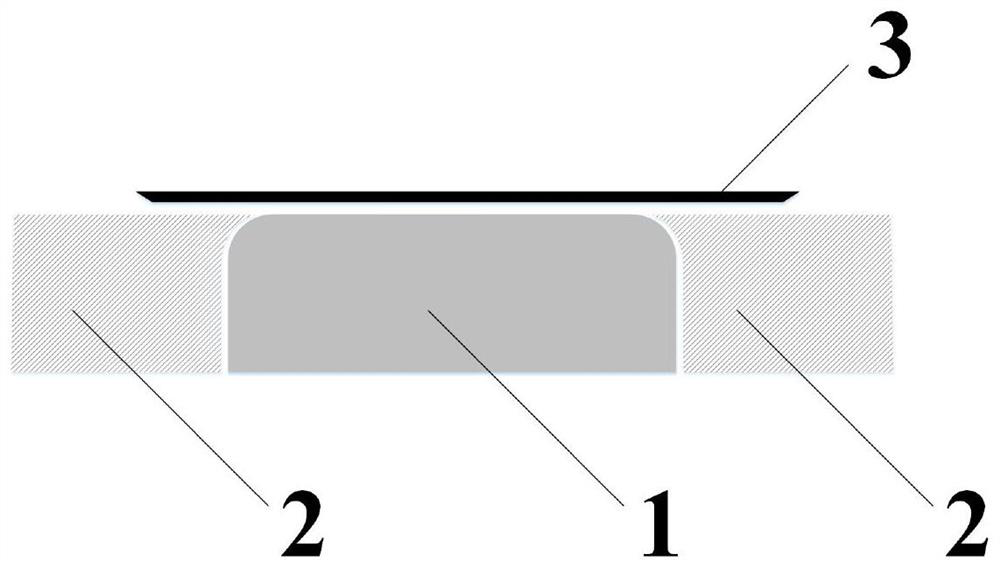

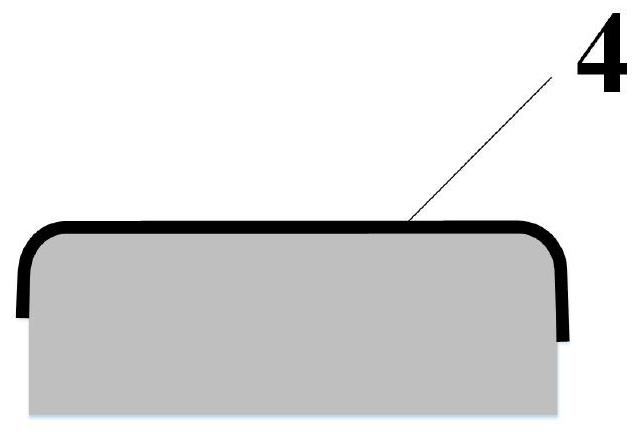

[0020] The invention discloses a thermal diaphragm preforming method which can eliminate the transfer process of uncured prepregs. The specific process includes five steps: 1. the combination of pre-formed tools; 2. the laying of prepregs and the Pre-compaction; 3. Removal of auxiliary paving tooling; 4. Pre-forming of thermal diaphragm; 5. Subsequent operation of pre-formed body.

[0021] 1. Combination of preformed tooling

[0022] Preformed tooling includes preformed main tooling and auxiliary paving tooling matching its profile. The preformed main body tooling profile includes but is not limited to L-shape, C-shape, Z-shape, Ω-shape, etc., and its materials include but are not limited to steel, aluminum alloy, wood, carbon fiber composite material, glass fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com