Bore machining cutter head and bore machining cutting tool

A technology of cutter heads and tools, which is applied in the field of cutting tools for inner diameter processing, can solve the problems of reduced brazing area, reduced brazing strength, and peeling of cutting edges, and achieves the effects of suppressing peeling, low-cost manufacturing, and high brazing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

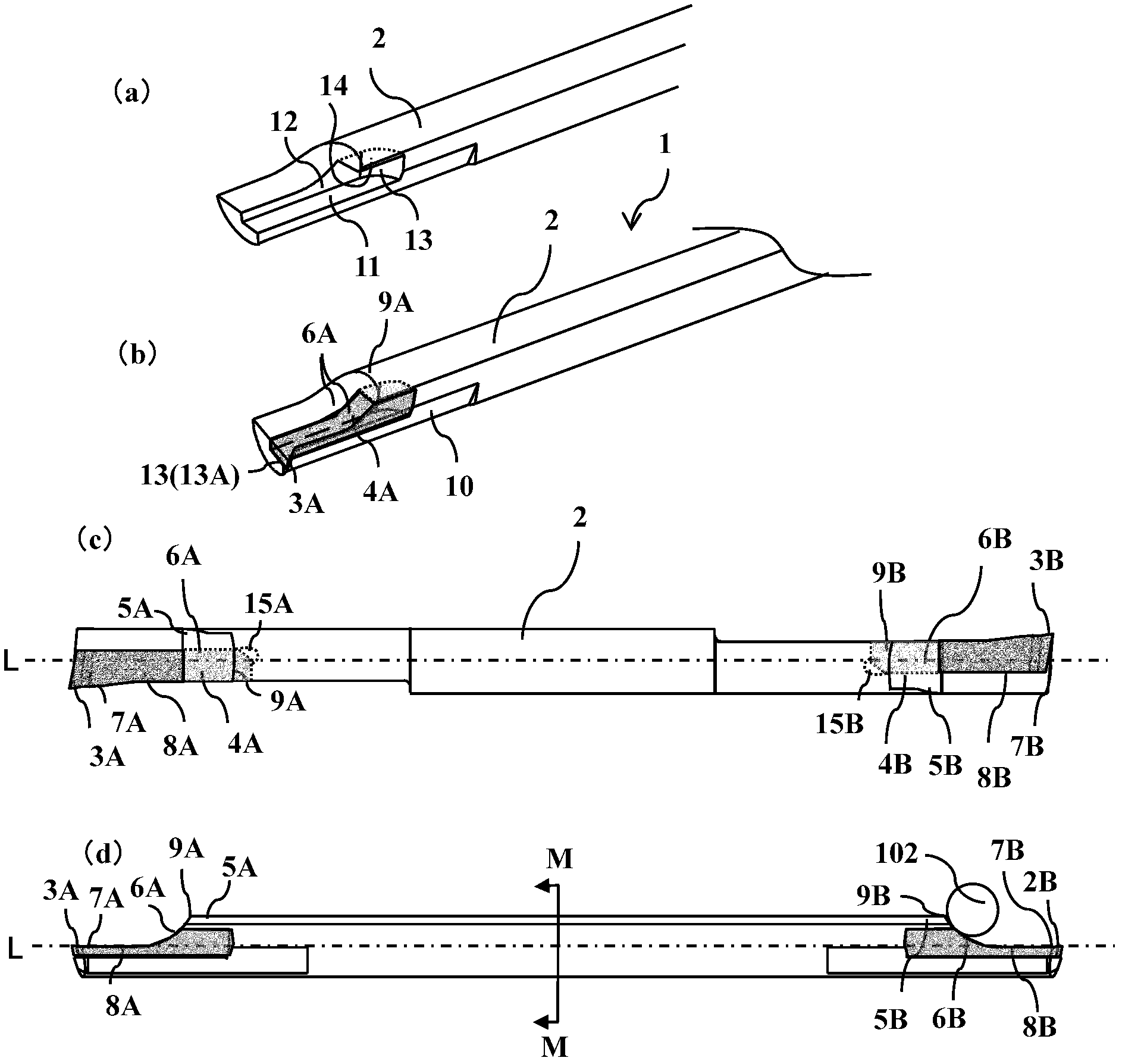

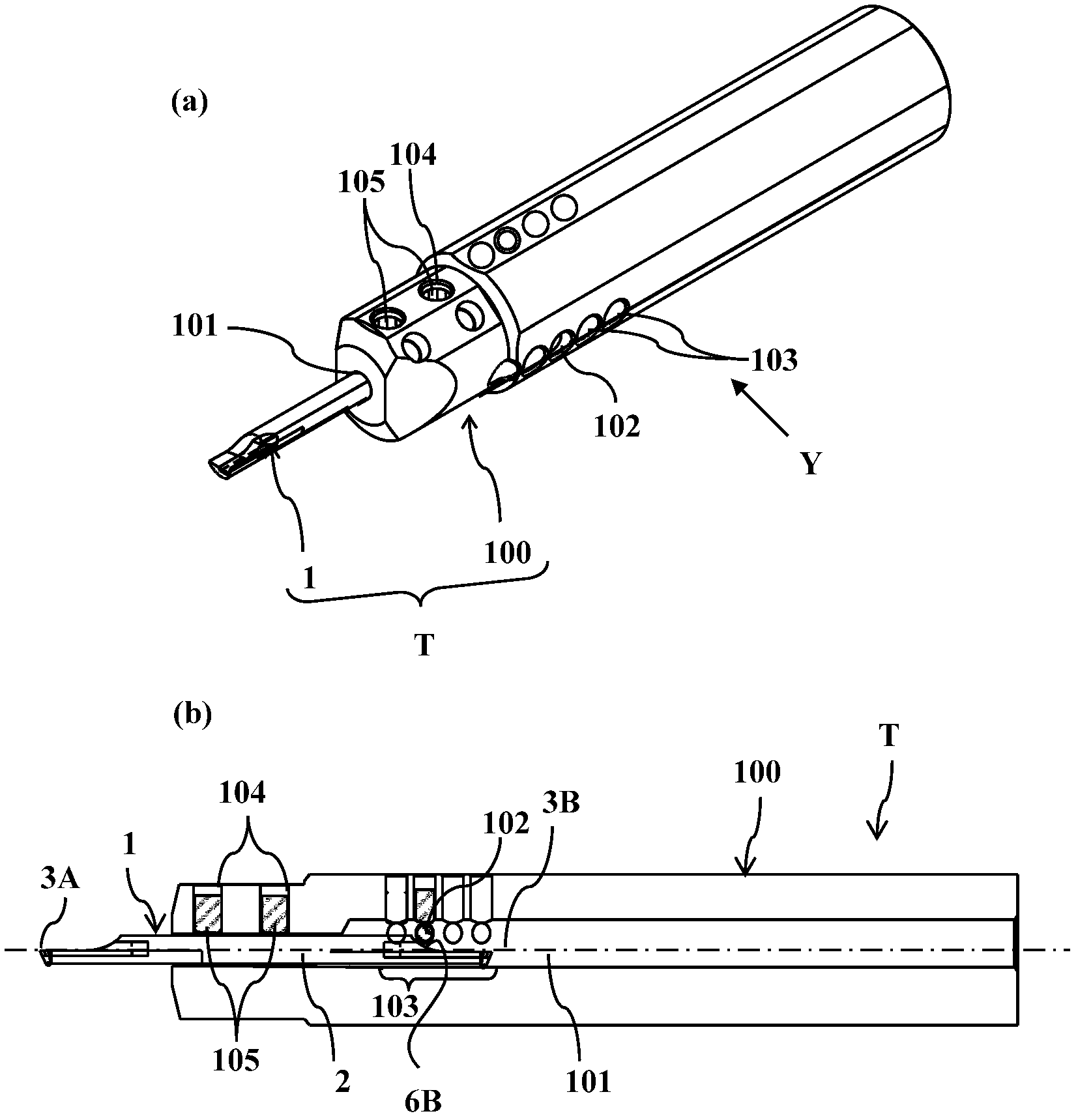

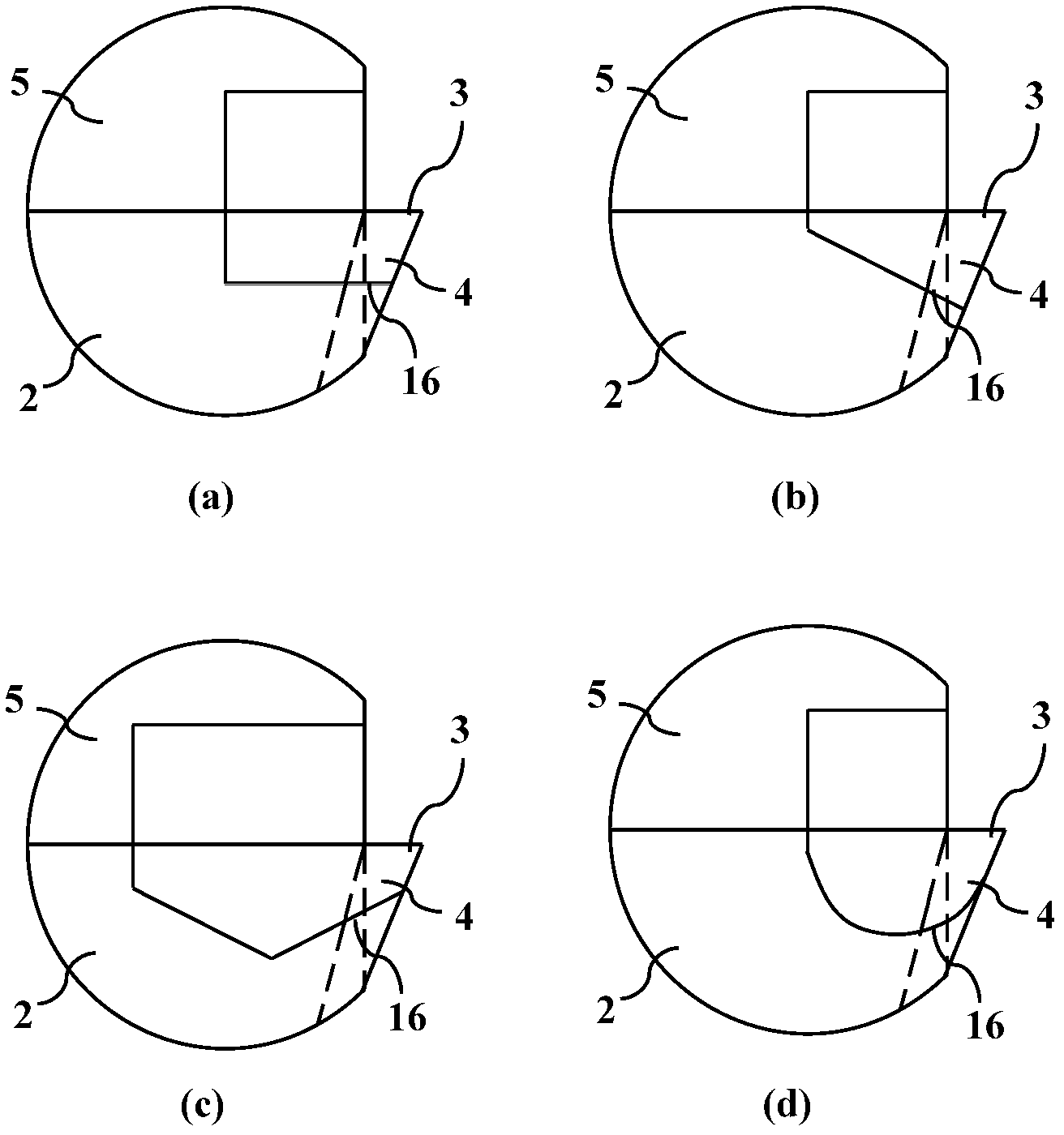

[0043] Below, use Figure 1 ~ Figure 4 Next, a cutting tool T for inner diameter machining that is used by attaching an inner diameter machining tip (hereinafter, sometimes referred to as a tip) 1 according to an embodiment of the present invention to an arbor 100 will be described. exist figure 1 Among them, (a) is a perspective view of the tool body before inserting the cutting edge bit of the inner diameter machining bit, (b) is a perspective view of main parts, (c) is a plan view, and (d) is a side view. figure 2 An example of the cutting tool for inner diameter processing in which the tip 1 is attached to the holder 100 is shown, (a) is a perspective view, and (b) is a side view. image 3 It shows the front end view of the cutting tool for inner diameter machining which attached the bit for inner diameter machining to the holder, and is a figure to which the tip for inner diameter machining of the bottom surface shape of (a)-(d) is attached. Figure 4 An example of a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com