Exhaust gas recirculation (EGR) cooler

An EGR cooler and cylinder technology, which is applied to machines/engines, adding non-fuel substances to fuel, internal combustion piston engines, etc., can solve problems such as poor structural strength, low production efficiency, and low stability, and achieve easy maintenance, The effect of high production efficiency and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

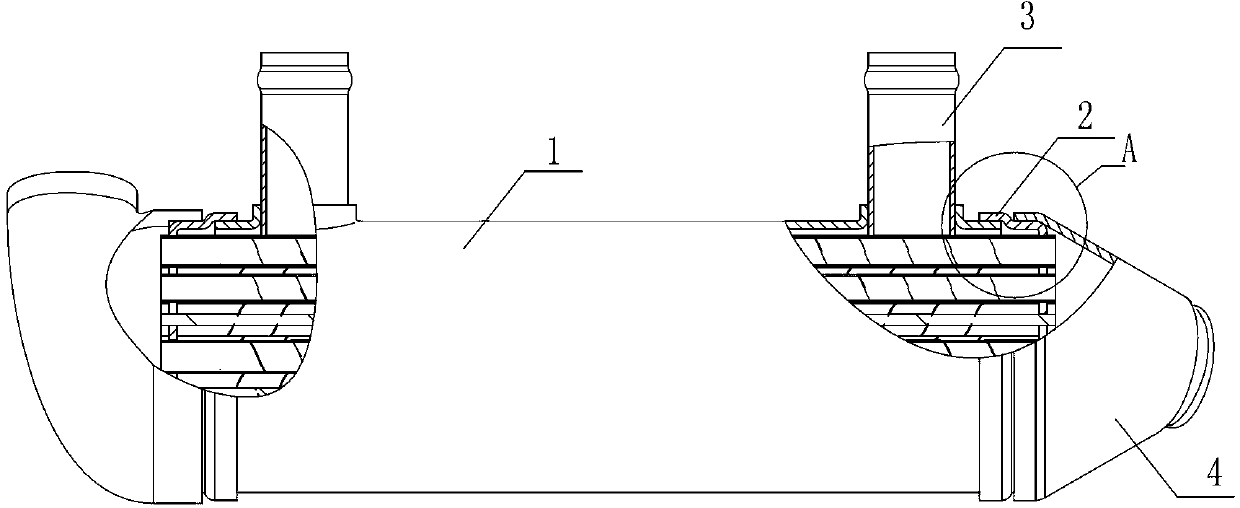

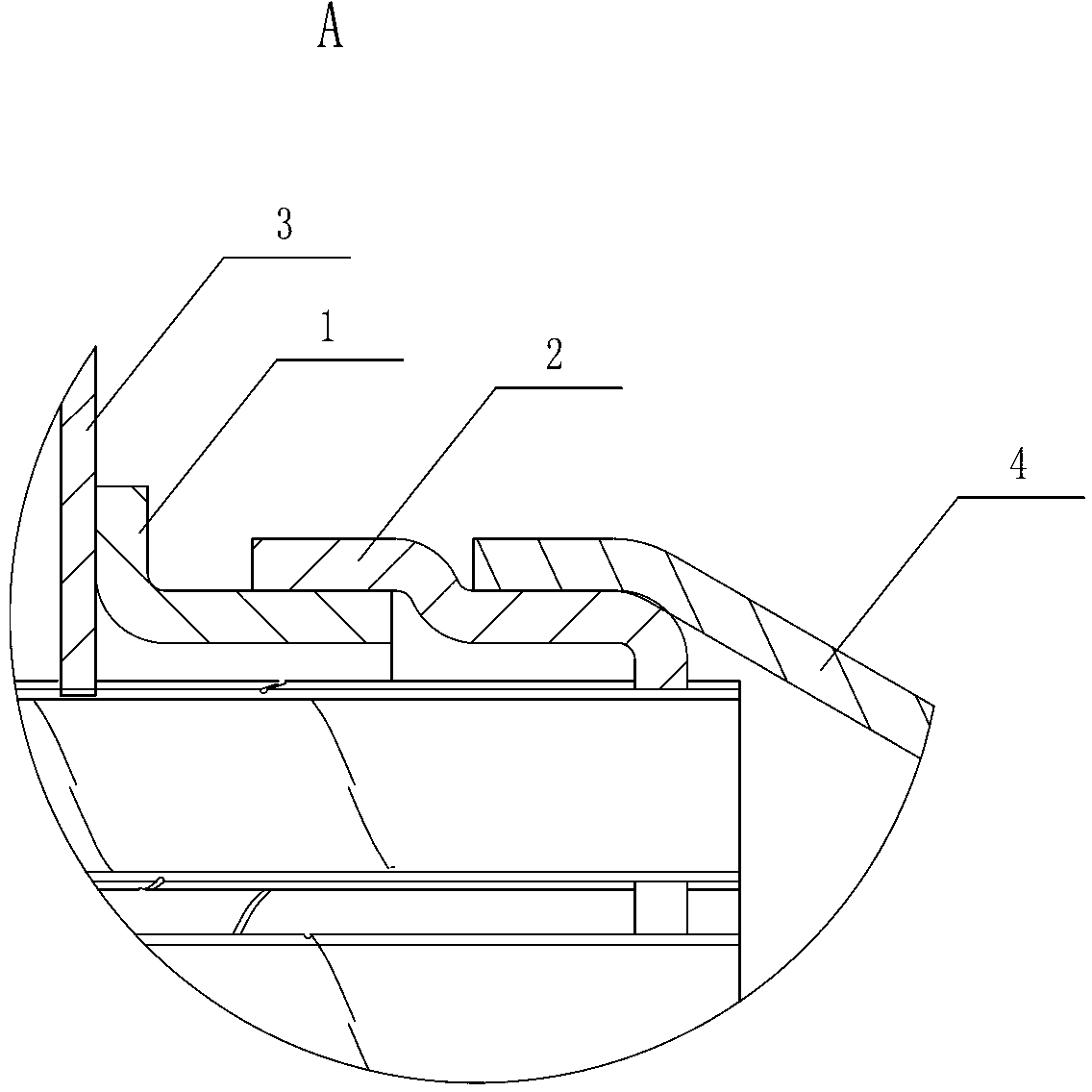

[0013] figure 1 , 2 , including cylinder 1, fixed plate 2, water pipe 3, end cap 4 and so on.

[0014] Such as figure 1 , 2 As shown, the present invention is an EGR cooler, including a water pipe 3 welded on the cylinder body 1, a fixing plate 2 installed at both ends of the cylinder body 1, an end cover 4 fixedly installed on the fixing plates 2 at both ends of the cylinder body 1, The connection between the cylinder body 1 and the water pipe 3 has a flanging structure, and the edge of the fixing plate 2 is bent into a stepped structure.

[0015] The bending angle of the step structure on the edge of the fixing plate 2 is 90°, and the step structure has two steps, the outer step cooperates with the cylinder body 1, and the inner step cooperates with the end cover 4, and the length of the inner step is equal to the wall thickness of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com