CVD (chemical vapor deposition) diamond brazing nickel-based alloy brazing sheet and preparation method thereof

A nickel-based alloy and diamond technology, which is applied in the field of nickel-based alloy brazing filler metal for CVD diamond brazing and its preparation, can solve the problem that it is difficult to realize the connection between the brazing filler metal and the CVD diamond surface, the Ni-Cr brazing filler metal has a high melting point, and the Ag-based filler metal is difficult to achieve. The problem of high cost of brazing material, to achieve the effect of good plasticity, easy brazing, and improving the strength of the brazing material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

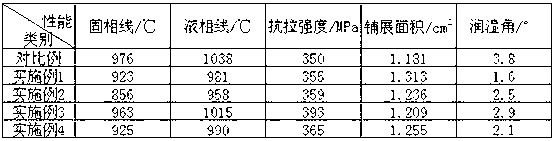

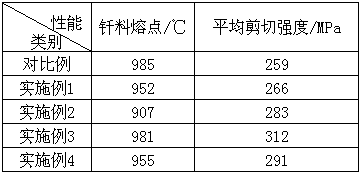

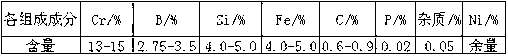

Examples

Embodiment 1

[0018] Weigh the components according to the ratio in Table 1, mix the weighed lanthanum and neodymium metal with 9 times the mass of Sn, and add them to the intermediate frequency induction melting furnace, set the temperature in the intermediate frequency induction melting furnace to 600 ° C, vacuum The degree is 1×10 -2 Pa, after heating for 30 minutes, the master alloy was prepared; put all the remaining raw materials in Table 1 into a non-consumable vacuum electric arc furnace, then add the above-mentioned master alloy, and set the temperature in the non-consumable vacuum electric arc furnace to 1700°C , after all the raw materials are melted into a melt, stir 3 times, each stirring time is 2min, then keep warm at 1700°C, stop heating after 25min, let the melt cool naturally with the furnace; wait for the melt to cool down to 1250°C Finally, use a vacuum pouring machine to pour the cooled melt into a graphite mold, and take it out after cooling to below 150°C to obtain a ...

Embodiment 2

[0022] Weigh the components according to the ratio in Table 2, mix the weighed lanthanum and neodymium metal with 9 times the mass of Sn, and add them to the intermediate frequency induction melting furnace, set the temperature in the intermediate frequency induction melting furnace to 500 ° C, vacuum The degree is 1×10 -3 Pa, master alloy was prepared after heating for 40 minutes; put all the remaining raw materials in Table 1 into a non-consumable vacuum electric arc furnace, then add the above-mentioned master alloy, and set the temperature in the non-consumable vacuum electric arc furnace to 1800°C , after all the raw materials are melted into a melt, stir 3 times, each stirring time is 1.5min, then keep warm at 1800°C, stop heating after 20min, let the melt cool naturally with the furnace; wait until the melt cools to 1200 After ℃, use a vacuum pouring machine to pour the cooled melt into a graphite mold, and take it out after cooling below 150°C to obtain a brazing alloy...

Embodiment 3

[0026] Weigh the components according to the ratio in Table 3, mix the weighed lanthanum and neodymium metal with 9 times the mass of Sn, and add them to the intermediate frequency induction melting furnace, set the temperature in the intermediate frequency induction melting furnace to 650 ° C, vacuum The degree is 5×10 -3 Pa, after heating for 20 minutes, the master alloy was prepared; put all the remaining raw materials in Table 1 into the non-consumable vacuum electric arc furnace, then add the above-mentioned master alloy, and set the temperature in the non-consumable vacuum electric arc furnace to 1600°C , after all the raw materials are melted into a melt, stir 4 times, each stirring time is 1min, then keep warm at 1600°C, stop heating after 30min, let the melt cool down naturally with the furnace; wait for the melt to cool down to 1300°C Finally, use a vacuum pouring machine to pour the cooled melt into a graphite mold, and take it out after cooling to below 150°C to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com