Steam Condensing Heat Conduction Pipe For Air Cooling Steam Condensing Plant

A steam condensing, air-cooling technology, applied in heat exchange equipment, lighting and heating equipment, tubular components, etc., can solve problems such as unusable and easily damaged products, reduce corrosion, save material costs, and be beneficial to capillary phenomenon. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In the following, the configuration and functions of the embodiments of the present invention will be described in detail in conjunction with the accompanying drawings. In the process, the size and shape of components shown in the drawings may be exaggerated for the sake of concise and clear description. In addition, from the perspective of the configuration and function of the present invention, the terms specifically defined may be different according to the user's or implementer's intention or practice. The definitions of these terms must be interpreted in a manner consistent with the technical field, technical problems, technical solutions and beneficial effects of the present invention based on the entire content of this specification.

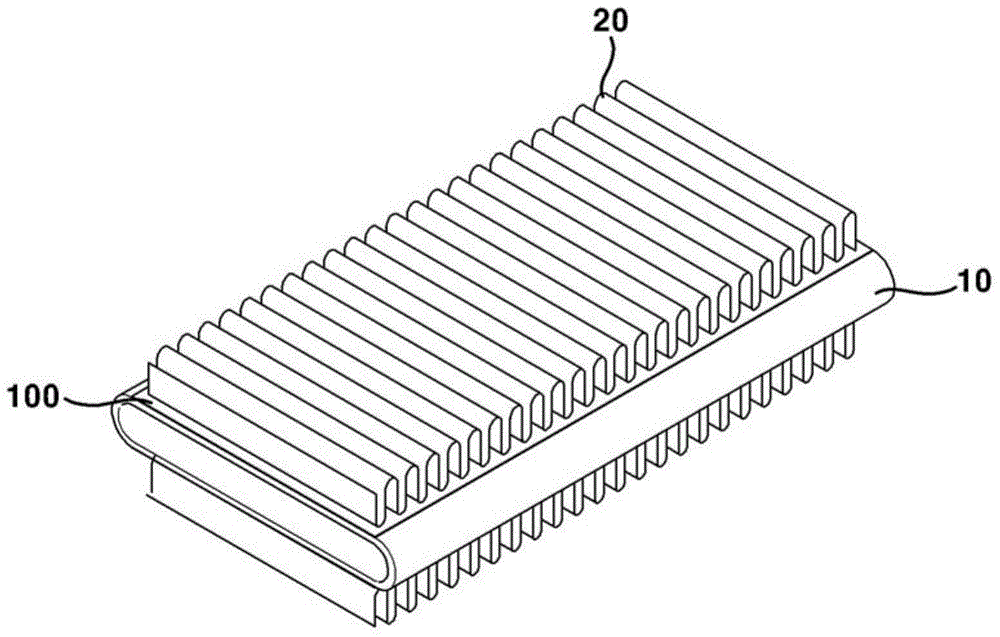

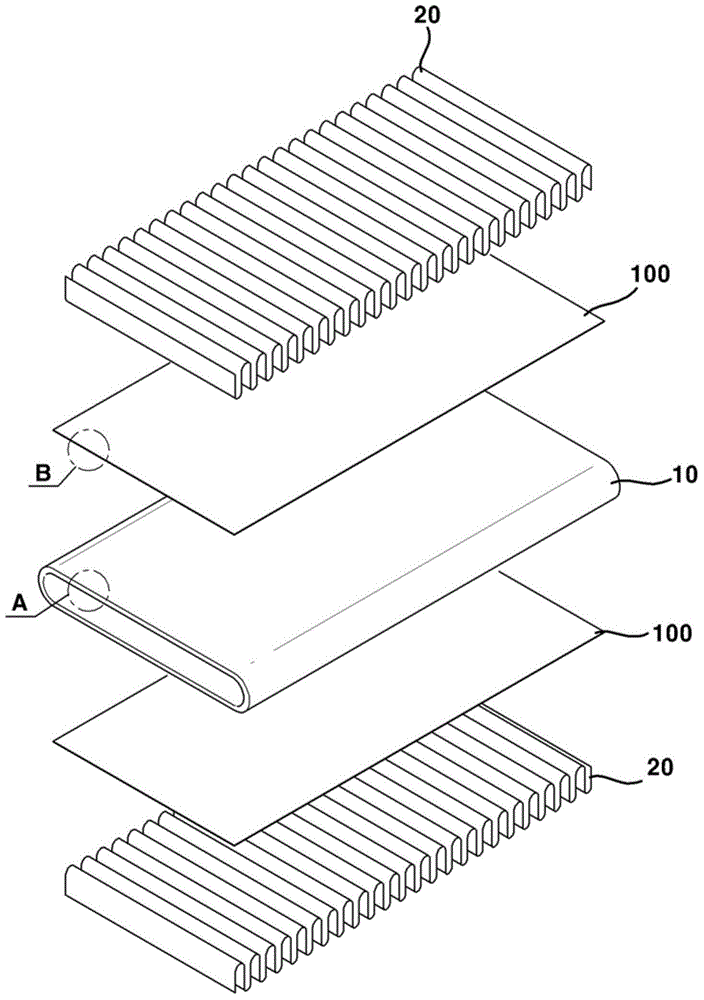

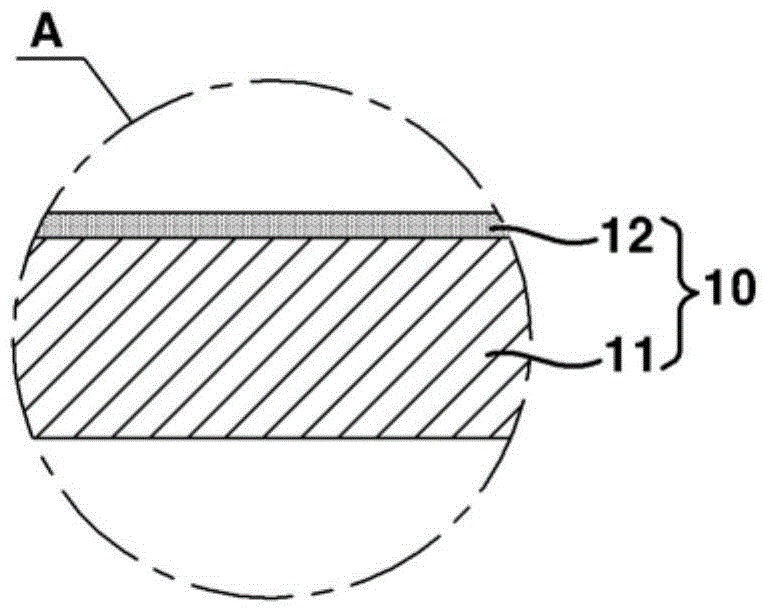

[0049] figure 1 It is a perspective view of a steam condensing heat pipe for an air-cooled steam condensing device according to the first embodiment, figure 2 for figure 1 assembly diagram, image 3 for figure 2 An enlarged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com