Patents

Literature

75 results about "Finite element algorithm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Finite Element Method Basics. The core Partial Differential Equation Toolbox™ algorithm uses the Finite Element Method (FEM) for problems defined on bounded domains in 2-D or 3-D space. In most cases, elementary functions cannot express the solutions of even simple PDEs on complicated geometries.

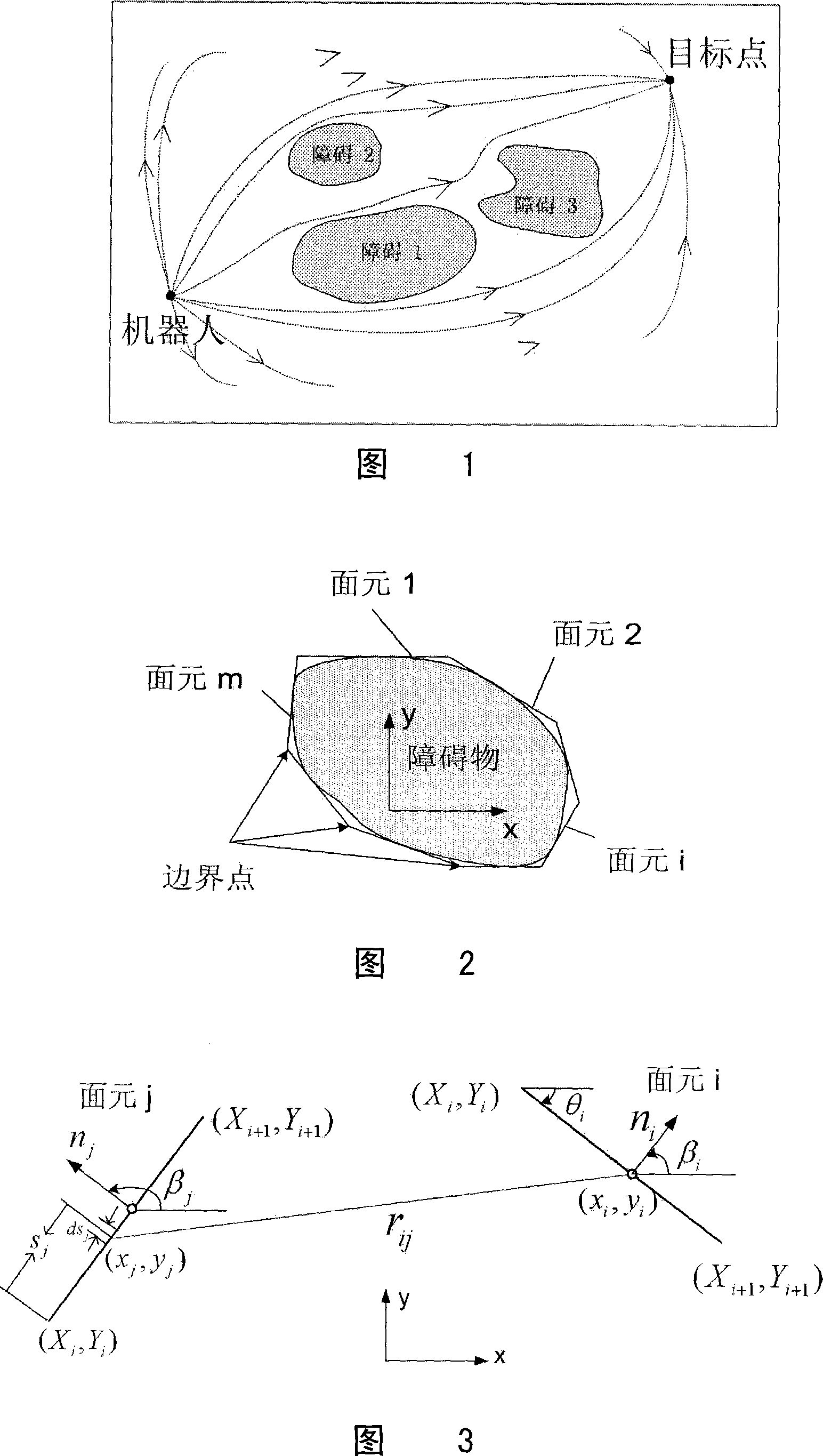

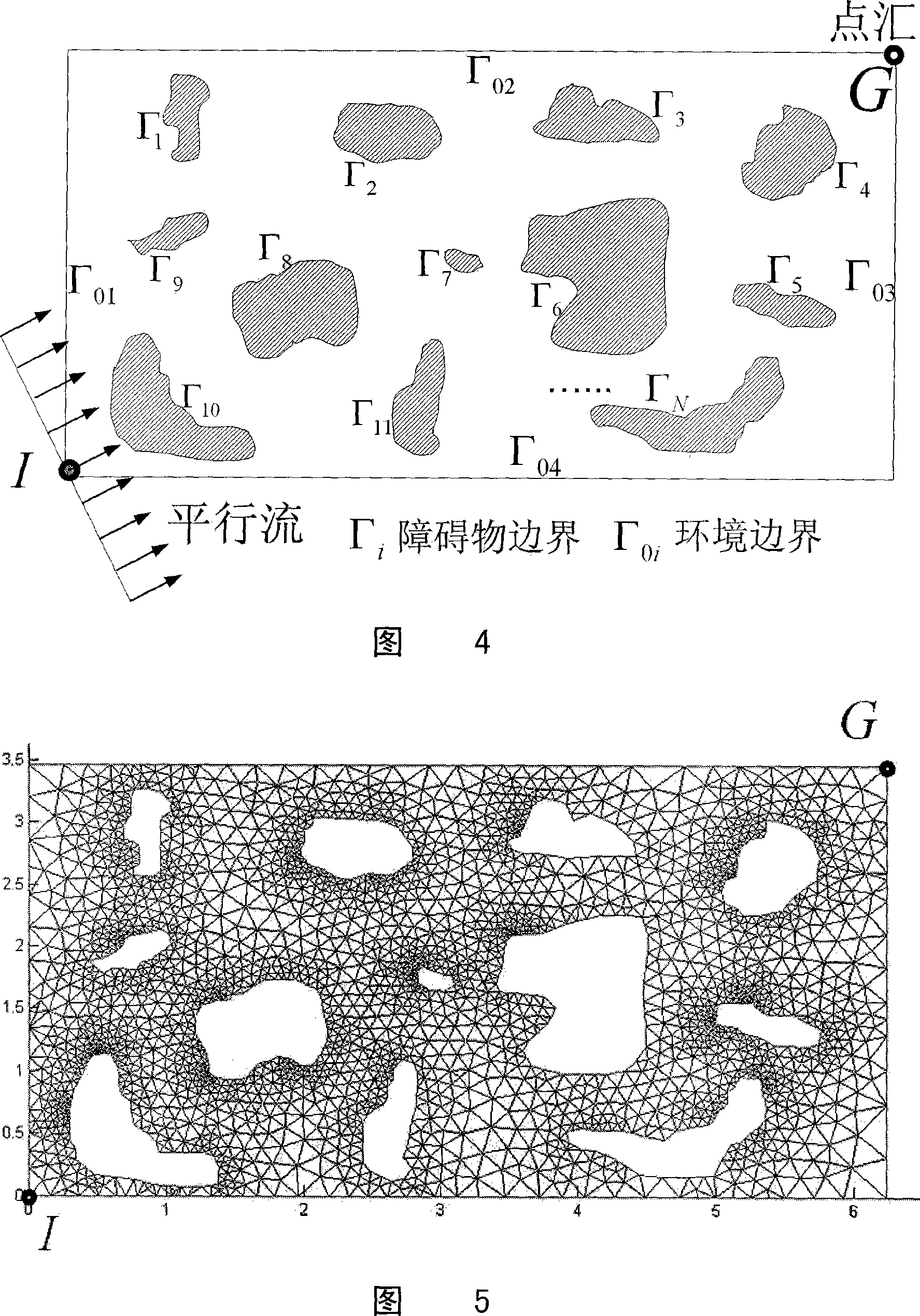

Flow field based intelligent robot obstacle-avoiding method

InactiveCN101025628ASuitable for real-time control requirementsThe solution is novel and fastTarget-seeking controlPosition/direction controlFinite element algorithmComputer science

The invention relates to an intelligent robot obstacle avoiding method based on flow field. It includes the following steps: building the center of robot as point resource, and target point as points converging, and the flow field of obstacle or building a paralleling flow from original point to target point, and adding flow field of obstacle; building the basic formula group and boundary condition that the flow satisfied; solving the flow formula to gain speed and direction of each point in flow field; selecting the speed and direction of one flow line as the input of controlling robot.

Owner:PEKING UNIV

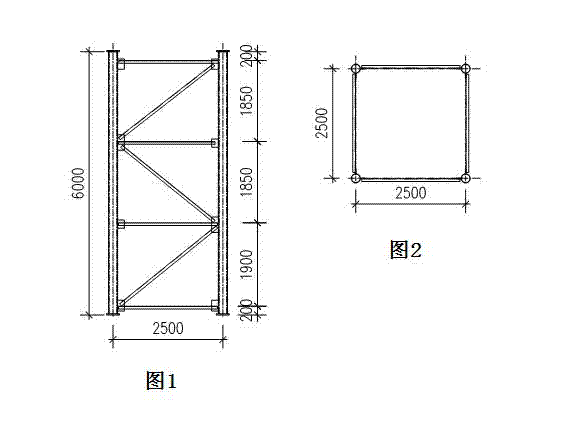

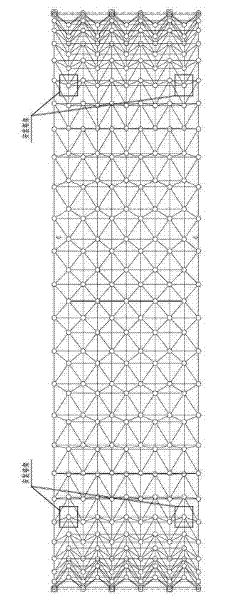

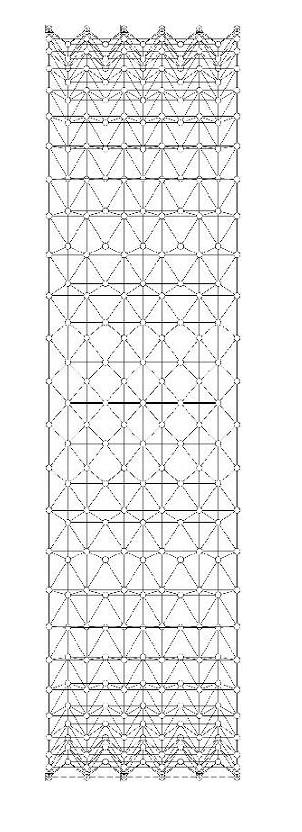

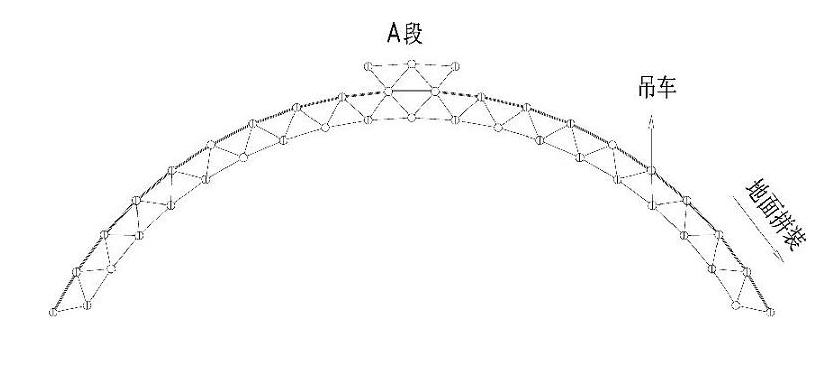

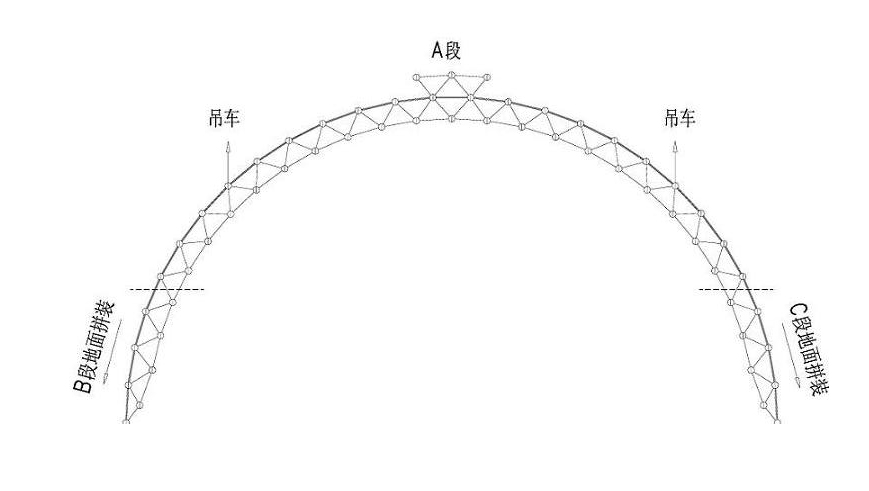

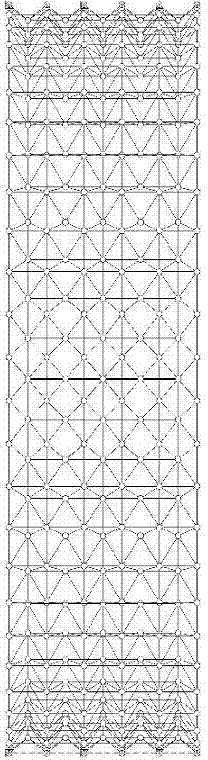

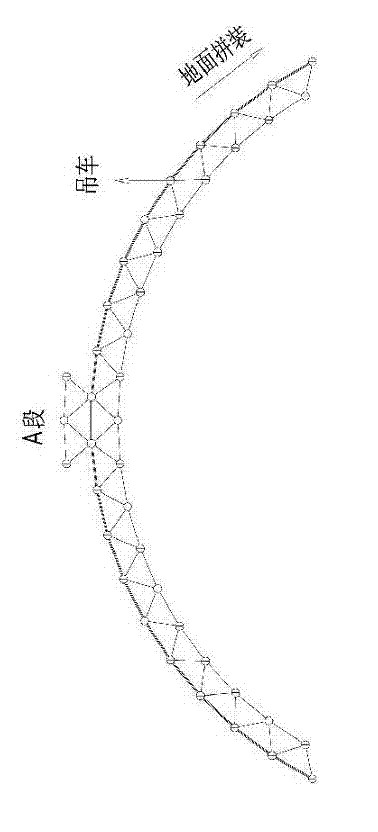

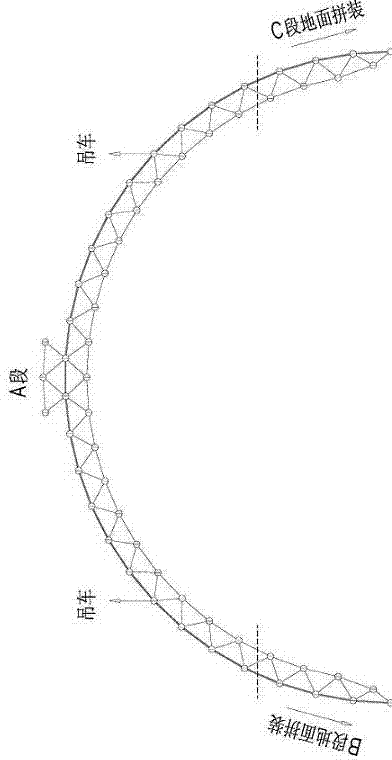

Construction process of ultra-large-span net-frame arch-shaped shed type storage silo

ActiveCN102337785AImprove accuracyShorten the timeLoad-supporting elementsBuilding material handlingFinite element algorithmEngineering

The invention relates to a construction process of an ultra-large-span net-frame arch-shaped shed type storage silo, which is characterized by comprising: obtaining dimensions of node rods of a net frame via a CFD (computational fluid dynamic) numerical wind tunnel computing technology and a finite element algorithm at first according to local weather conditions, the most adverse weather conditions and physical parameters of an arch-shaped shed, i.e. the ball head diameter of each node and geometric parameters of the rods on each node, and preparing a construction drawing, wherein the construction drawing at least comprises the serial number of each node and the number of rods on each node; and dividing construction steps into installation of basic units and installation of overhead cantilever units. Scaffolds are not needed to be erected in a whole house. The invention has the advantages that the time and materials can be saved, and the process is safe and reliable.

Owner:XUZHOU ZM BESTA HEAVY STEEL STRUCTURE

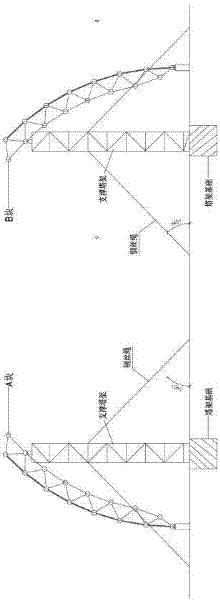

Installation construction process of bolt net rack cylindrical shell storage bin

ActiveCN102425326AImprove accuracyShorten the timeBuilding roofsBuilding material handlingFinite element algorithmStructural engineering

The invention discloses an installation construction process of a bolt net rack cylindrical shell storage bin, which is characterized by comprising the steps of: firstly, according to local meteorological conditions, obtaining sizes of net rack node rod members by adopting a CFD (Computational Fluid Dynamics) numerical value wind tunnel calculation technology and a finite element algorithm according to most disadvantageous conditions and tunnel physical parameters, namely, drawing a construction drawing by using a bulb diameter of each node and a geometric parameter of the rod members arranged on each node, wherein the construction drawing at least comprises a number of each node and the quantity of rod members of each node; and then dividing the construction step into a starting unit installation and an air overhanging unit installation. Due to no need of erecting an accomplished scaffold, the installation construction process has the characteristics of time and material saving, safety and reliability.

Owner:XUZHOU ZM BESTA HEAVY STEEL STRUCTURE

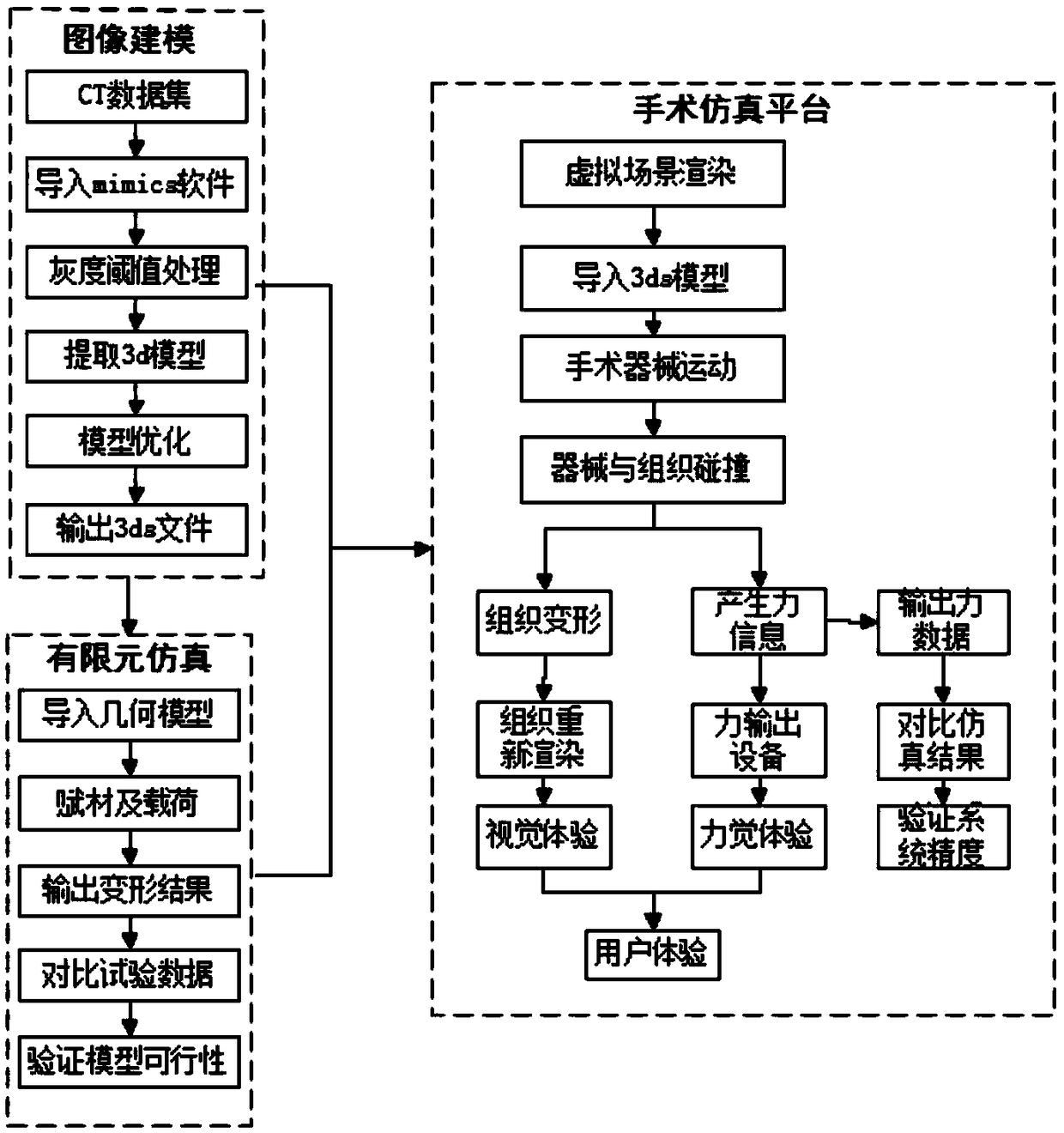

A training method of soft tissue minimally invasive surgery based on virtual reality

PendingCN109308739AGuaranteed accuracyGuaranteed force experience3D modellingFinite element algorithmVoxel

The invention discloses a soft tissue minimally invasive surgical training method based on virtual reality, which can enable a user to operate a force feedback device to perform minimally invasive puncture or forceps pulling on the soft tissue, comprising the following steps: 1, reverse modeling the abdominal CT image of a patient; 2, optimize that model; 3, carry out finite element puncture simulation on that model; 4, that finite element simulation result are processed in Matlab software to verify the correctness of the model by compare with the experimental results; 5. Complete the module design of model import, scene rendering, collision detection, deformation algorithm, data input and output of force feedback device in Microsoft Visual Studio 2013 software, and realize the function ofinteraction between user and virtual scene through force feedback device. The invention can improve the system accuracy through modeling and simulation, adopt voxel octree and finite element algorithm, improve the collision and deformation accuracy and real-time, accurately perceive the virtual force through the external force feedback device, and effectively enhance the immersion feeling.

Owner:NANJING INST OF TECH

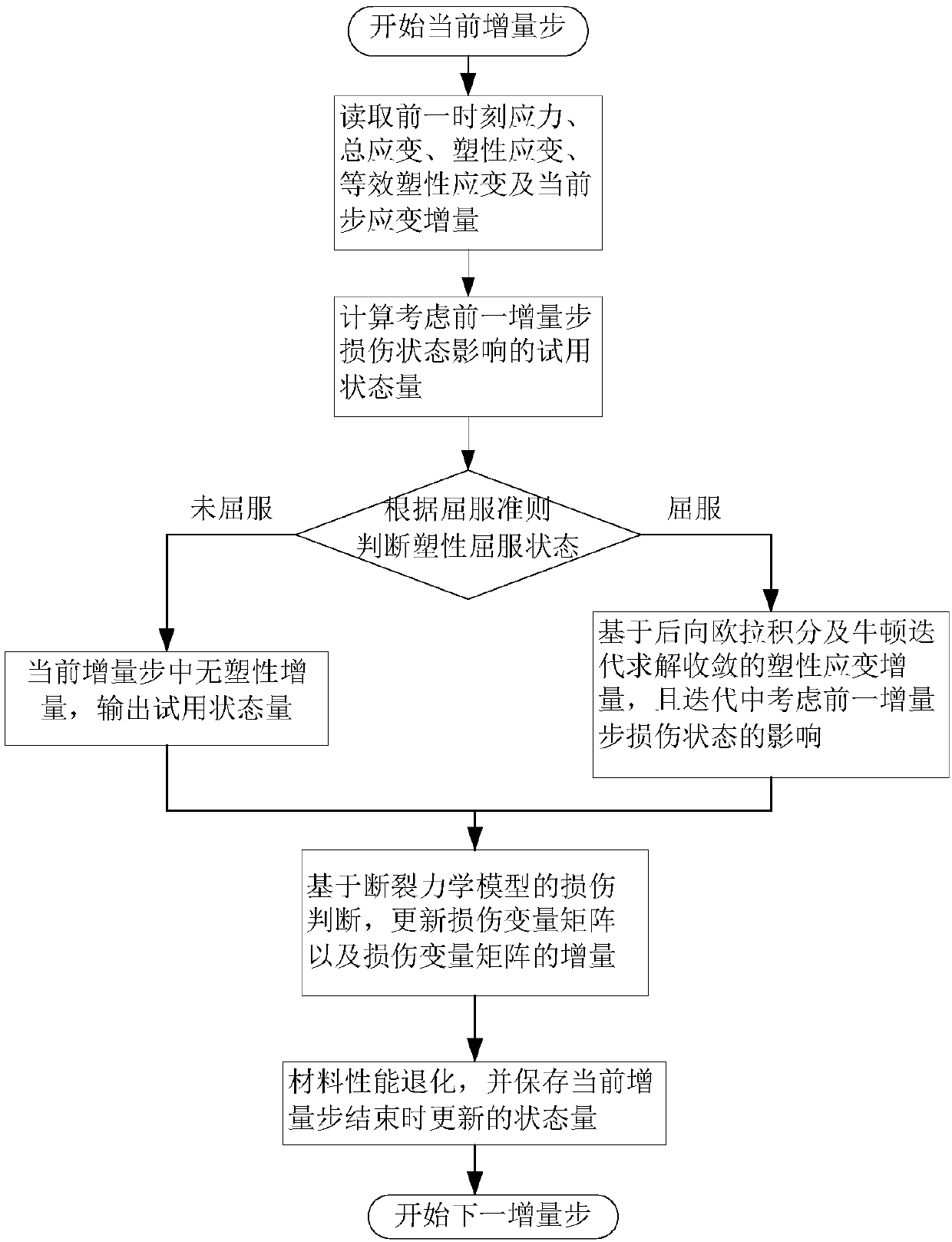

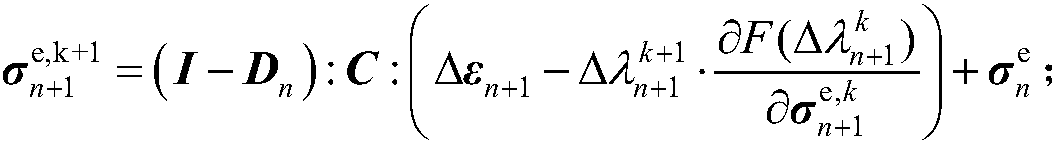

Elastoplastic-damage finite-element algorithm of considering elastoplasticity and damage coupling of composite material

ActiveCN108416084APredicting Elastic-Plastic Damage Coupled BehaviorMaterial strength using tensile/compressive forcesDesign optimisation/simulationFinite element algorithmPlastic yielding

The invention discloses an elastoplastic-damage finite-element algorithm of considering elastoplasticity and damage coupling of a composite material, and belongs to the field of finite-element analysis of mechanical properties of composite materials. On the basis of a model of carrying out solving of elastoplastic damage of composite materials on the basis of a backward Euler integral rule and Newton iteration, softening influences which are of damage state quantity in a previous incremental step and on current stress are all considered when solving of elastic stress is carried out in initialsolving of trial stress and plastic yielding iteration, thus damage degradation action is considered in an elastoplasticity solving process, and an interaction relationship between plastic behaviors and the damage of the resin matrix composite-material under complex loading conditions is more truly reflected. The algorithm can effectively describe a coupling action relationship between the elastoplasticity and the damage of resin matrix composite-material, and can be applied to the technical fields of scientific research and engineering such as development of elastoplastic-damage constitutive-models of the composite materials in finite-element software, research of mechanical properties of novel resin matrix composite-materials and related refined modeling analysis of engineering structures of the composite materials.

Owner:NANJING UNIV OF SCI & TECH

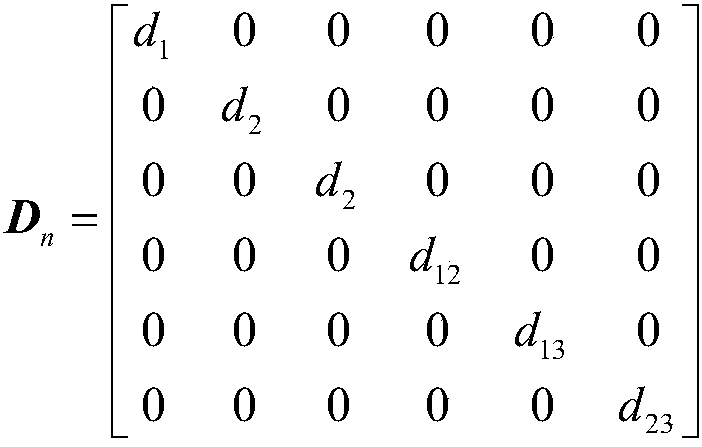

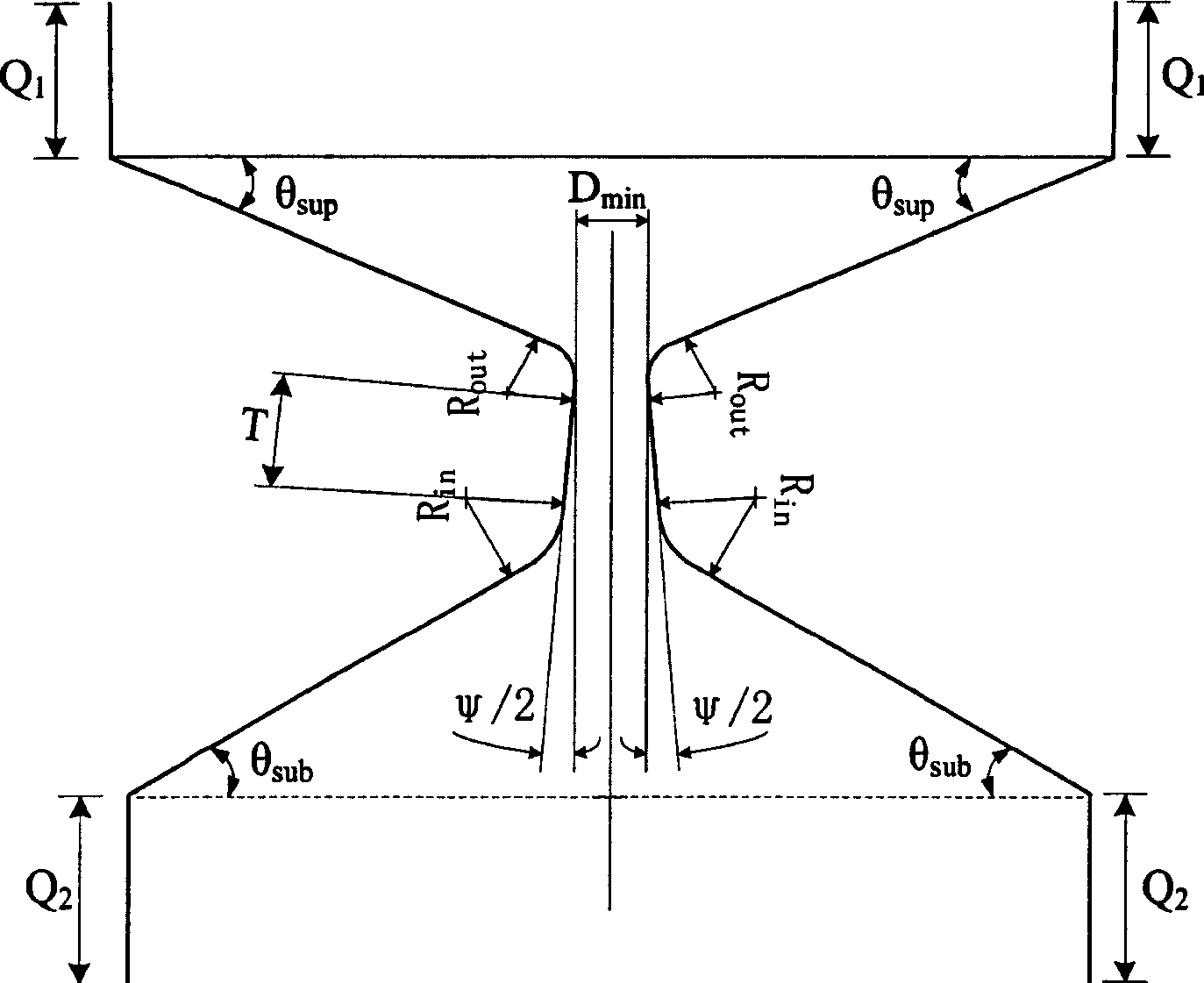

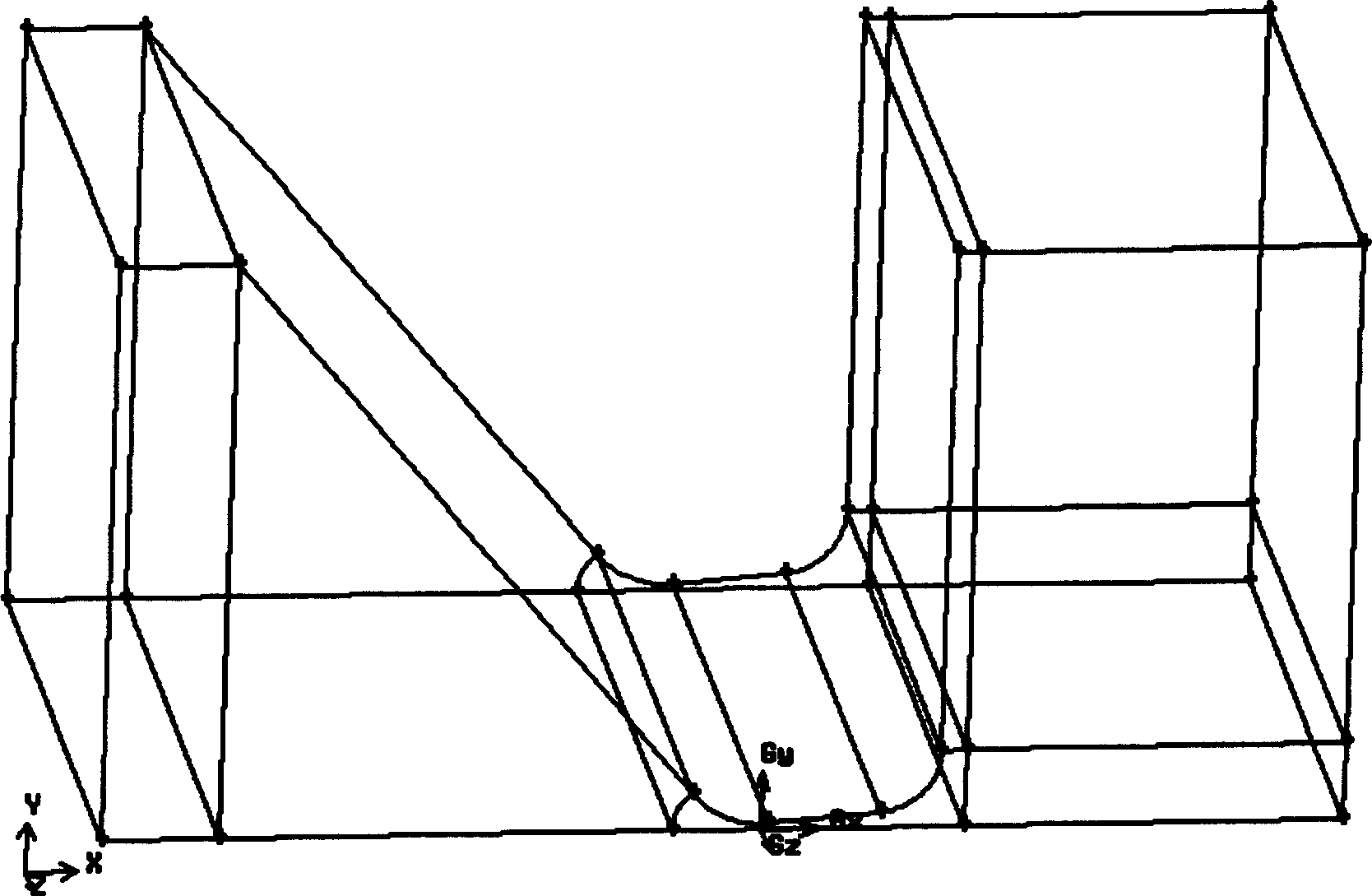

A method for obtaining subglottic pressure value and calculating phonation efficiency

The invention discloses the glottal pressure and computational sounding efficiency and aerodynamics parameter value on the base of aerodynamics modeling technology. The method comprises as follows: providing the method of defining vocal fold three-dimensional geometrical form characteristic value; offering the vocal fold surface three-dimensional reconstruction method; providing the aerodynamics modeling method which is based on three-dimensional finite element algorithm; providing the method of getting glottal pressure and computational sounding efficiency. The method is used to auxiliary diagnose throat, and has significant meaning in sounding function evaluation, sounding physiology, basic research, artistic noise, phonetic science, speech signal processing and linguistic science.

Owner:XI AN JIAOTONG UNIV

Method for inverting dam foundation restrained deformation based on dam in-situ displacement monitoring data

ActiveCN106960116AReasonably reflect the role of rigid supportAccurately judge the actual work performanceMeasurement devicesDesign optimisation/simulationFinite element algorithmMechanical models

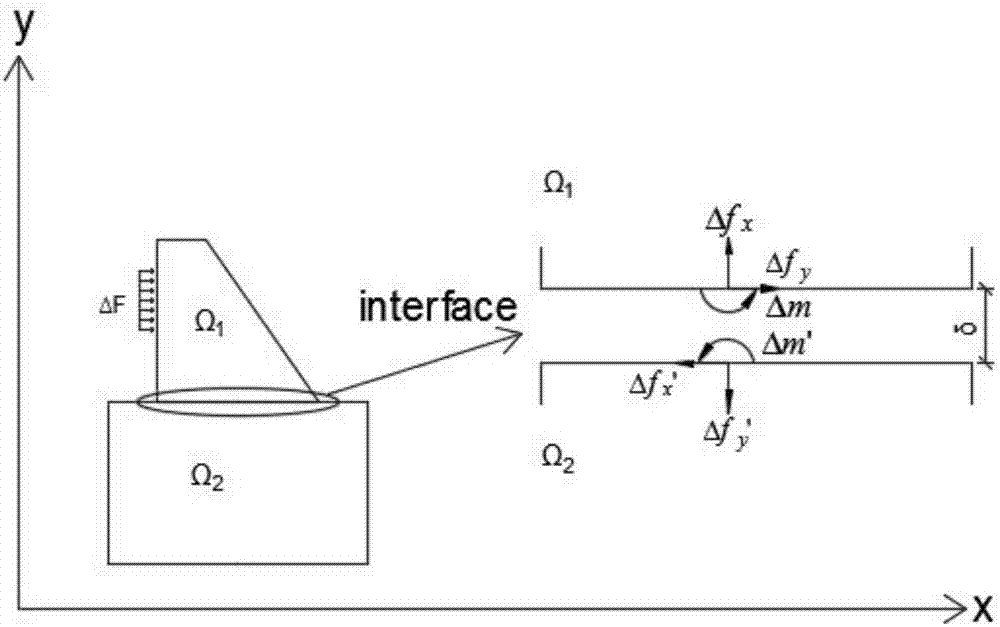

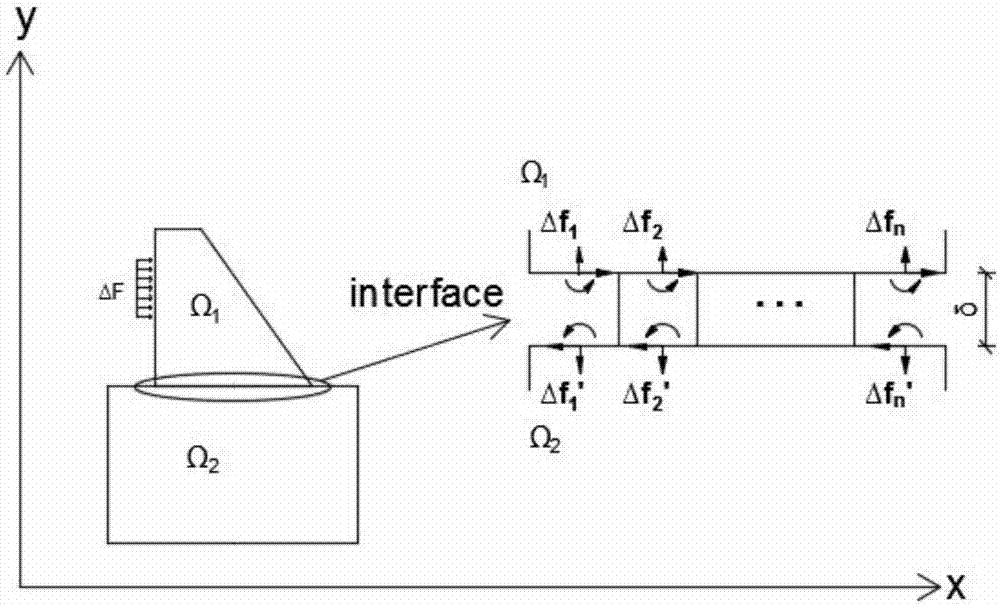

The invention discloses a method for inverting dam foundation restrained deformation based on dam in-situ displacement monitoring data. The method is characterized in that a novel dam-dam foundation interaction mechanical model is provided; the action on a dam body is simplified into the distributive restraining or concentrated restraining (including unknown restraining counter-force and unknown displacement) on the bottom of the dam body according to the model; a method for distinguishing between finite element and block interfacial element and hybrid-solving is carried out to directly invert to obtain the restrained deformation of a dam foundation; on that basis, a finite element algorithm is adopted to count to obtain the displacement value of each point of the dam body, and thus the safe running state of the dam can be reasonably evaluated.

Owner:HOHAI UNIV

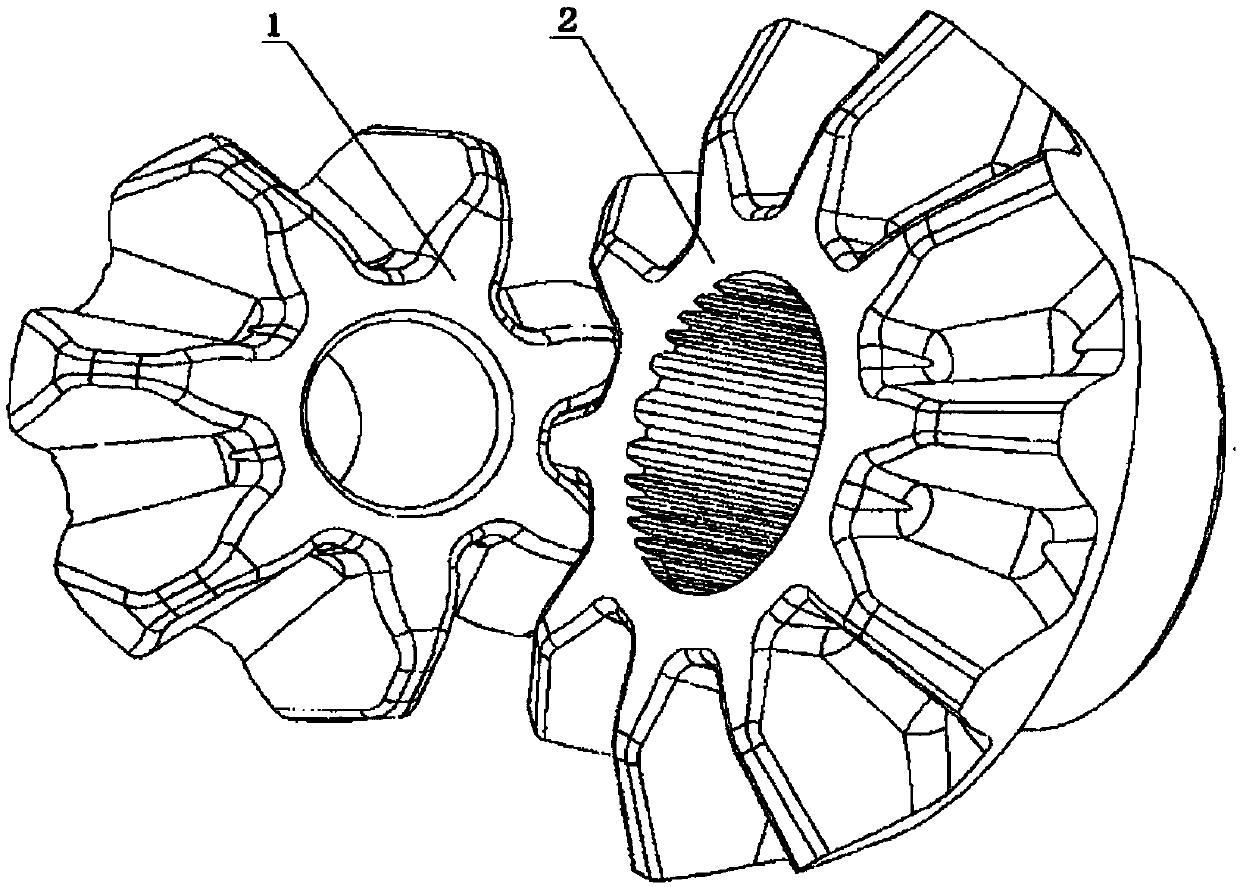

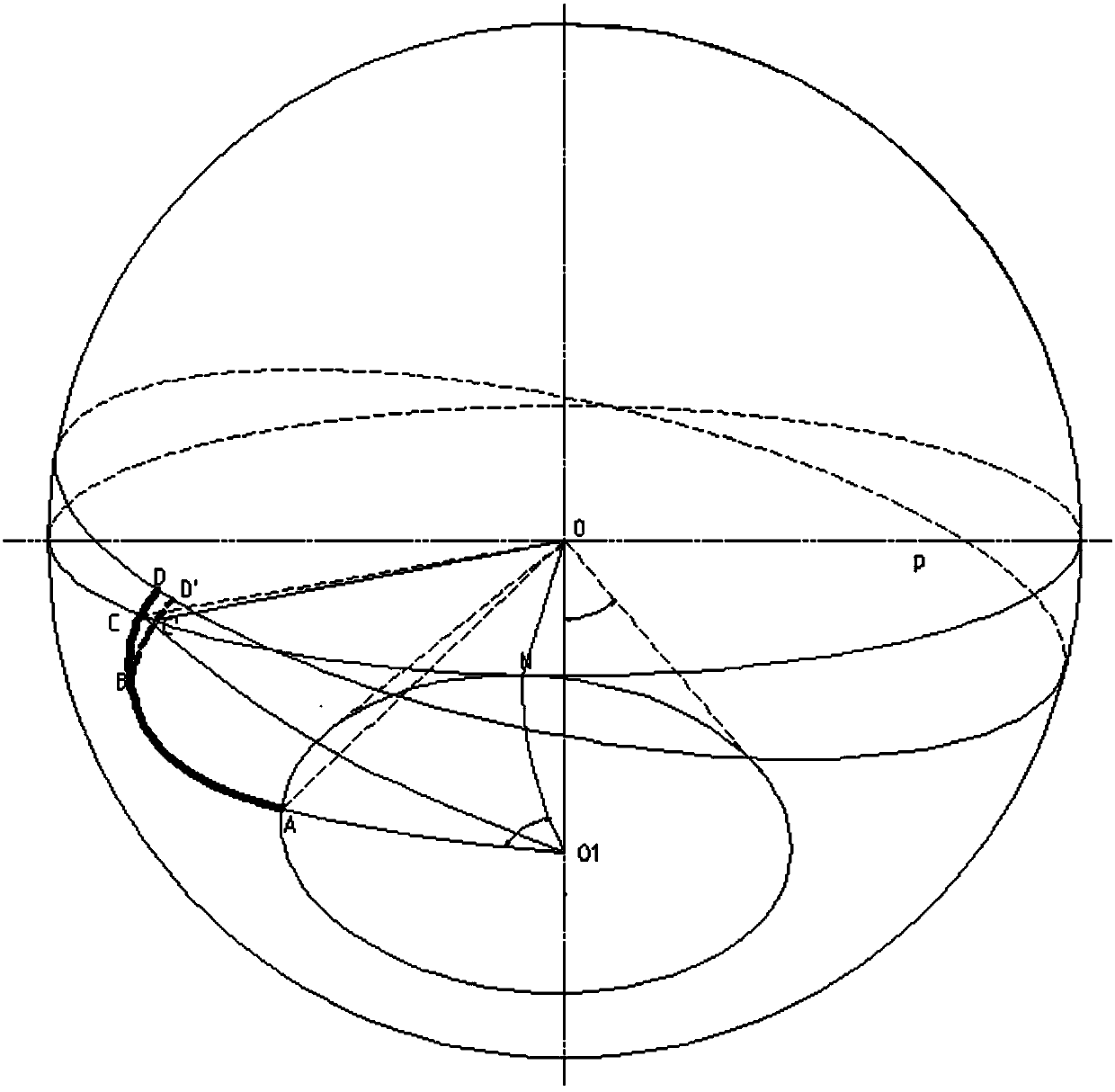

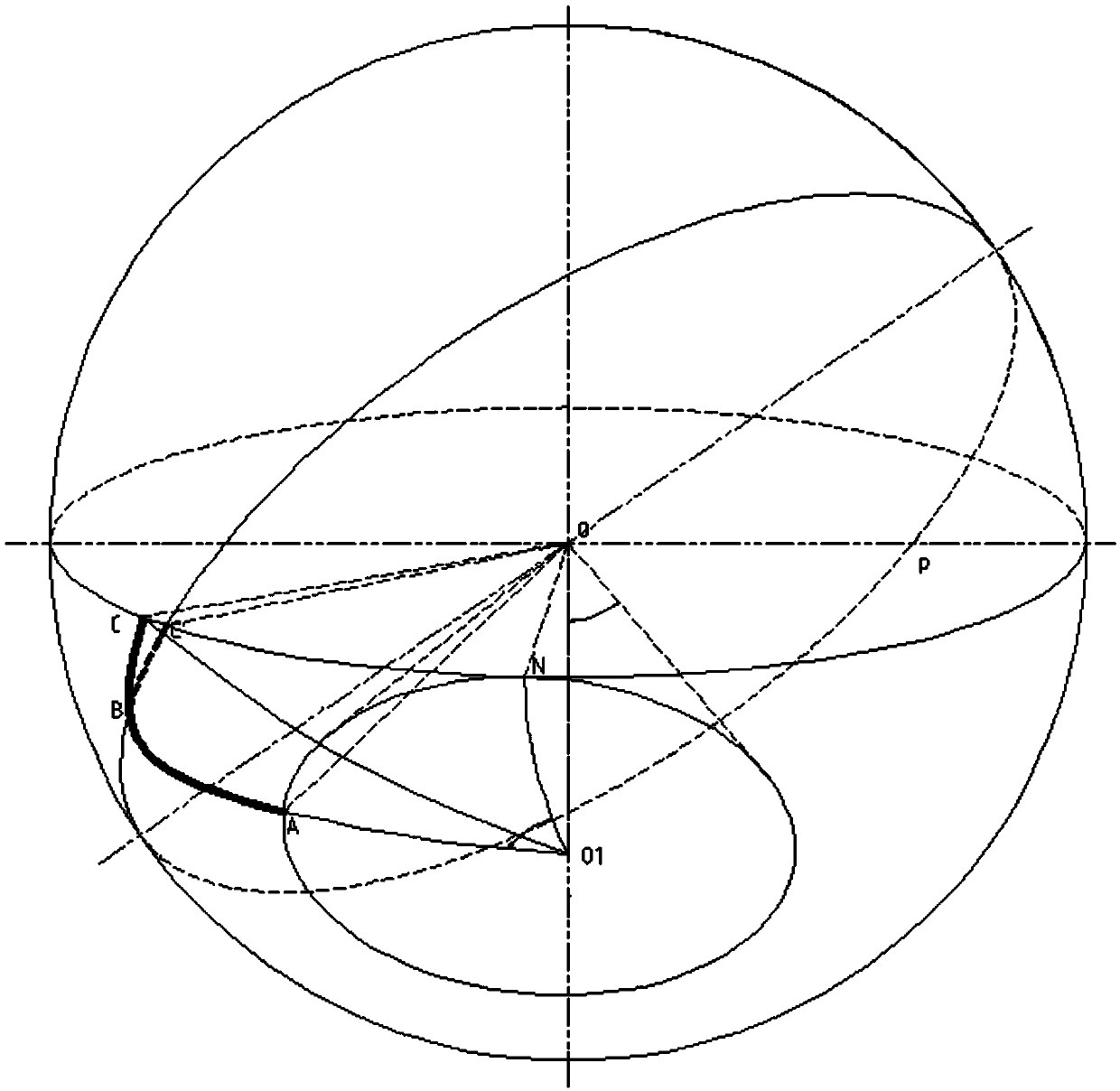

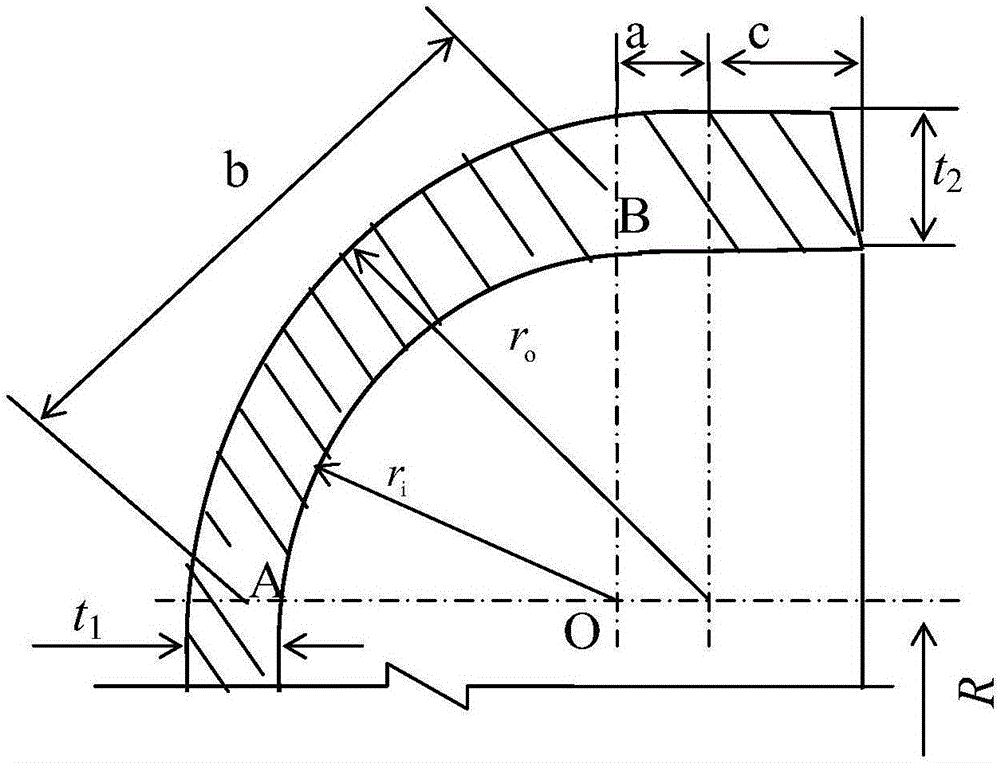

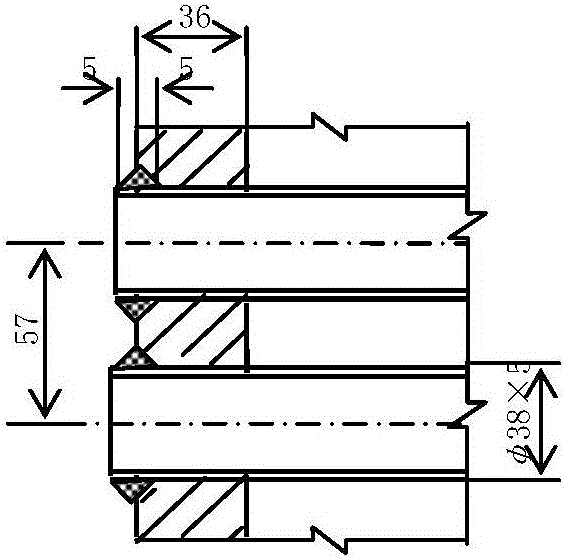

Spherical involute straight-tooth bevel gear pair and tooth profile modification method thereof

ActiveCN108679196AReduce bitingLess bite out shockPortable liftingGearing elementsFinite element algorithmInvolute

The invention discloses a spherical involute straight-tooth bevel gear pair and a tooth profile modification method thereof. The spherical involute straight-tooth bevel gear pair comprises a driving gear and a driven gear, wherein the driving gear meshes with the driven gear, and the tooth profile of each gear is divided into two segments, an AB segment is a theoretical spherical involute, a BD' segment is a spherical surface modification curve, and a B point is the modification starting point. The tooth profile modification method of the gear pair includes the following steps of software modeling, manufacturing of a profile modification mold and mass production. According to the spherical involute straight-tooth bevel gear pair, tooth profile modification of the driving gear and the driven gear adopts the method of tooth top profile modification at the same time; and the profile modification curve is a curve on the spherical surface on which the spherical involute lies, the profile modification direction is the direction of the spherical involute normal line, the profile modification starting point and the profile modification quantity can be optimized and obtained according to the finite element algorithm, the engaging-in and engaging-out impacts of the gears are reduced, vibration and noise are reduced, the meshing quality the gear pair is improved and the service life of the gear pair is prolonged.

Owner:JIANGSU PACIFIC GEAR DRIVE CO LTD +1

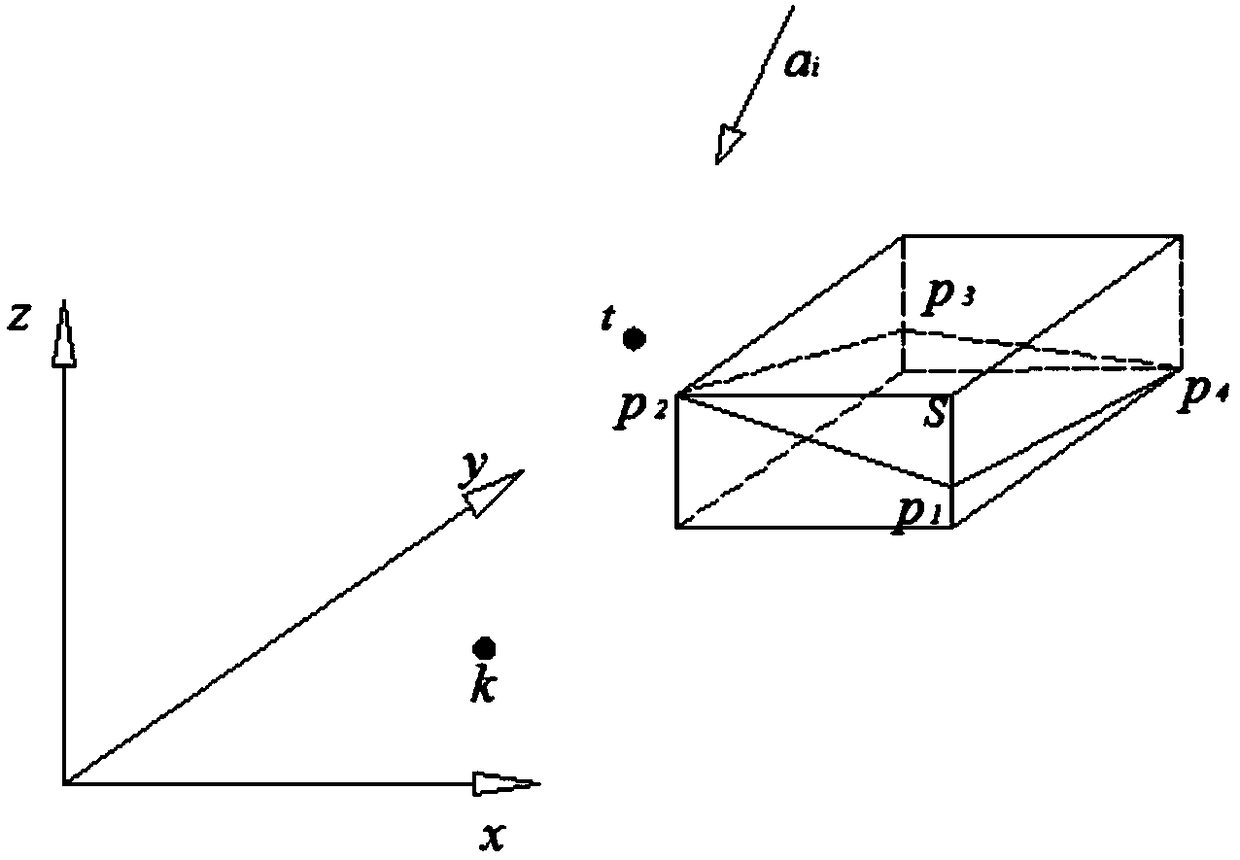

Particle movement driving finite element algorithm applied to PIC

ActiveCN108416107AImprove calculation accuracyGrid fittingDesign optimisation/simulationSpecial data processing applicationsNumerical stabilityFinite element algorithm

The invention belongs to the field of particle-in-cell numerical simulation, and particularly relates to a particle movement driving finite element algorithm applied to PIC. A non-structured grid is used; the grid can better fit the shape of a model boundary, so that the particle movement driving algorithm for the PIC has higher calculation precision; a particle movement driving FEM is combined with a typical PIC method, and while excellent characteristics of calculation simplicity and quickness of the typical PIC method are kept, higher finite element calculation precision is obtained by utilizing the FEM; and the FEM not only can well match the complex boundary but also can use a non-uniform grid according to a simulation need and is not limited by a numerical stability condition, so that under the condition of keeping the calculation precision, a spatial grid and a time step length can be optimized, and the simulation efficiency is greatly improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

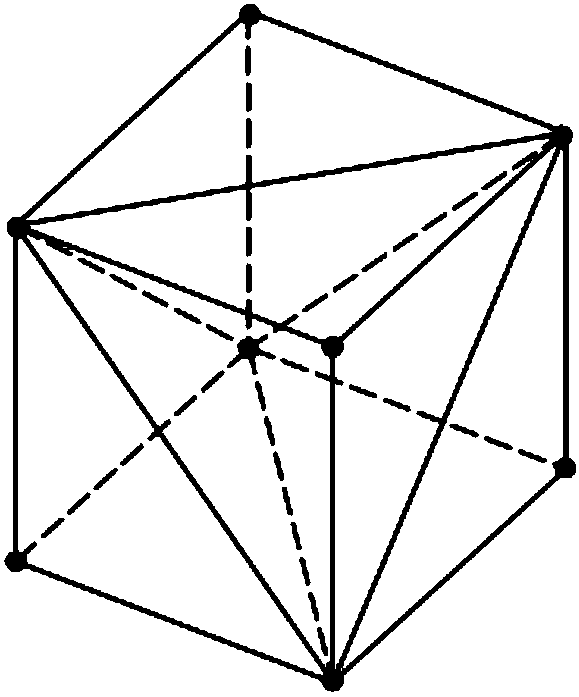

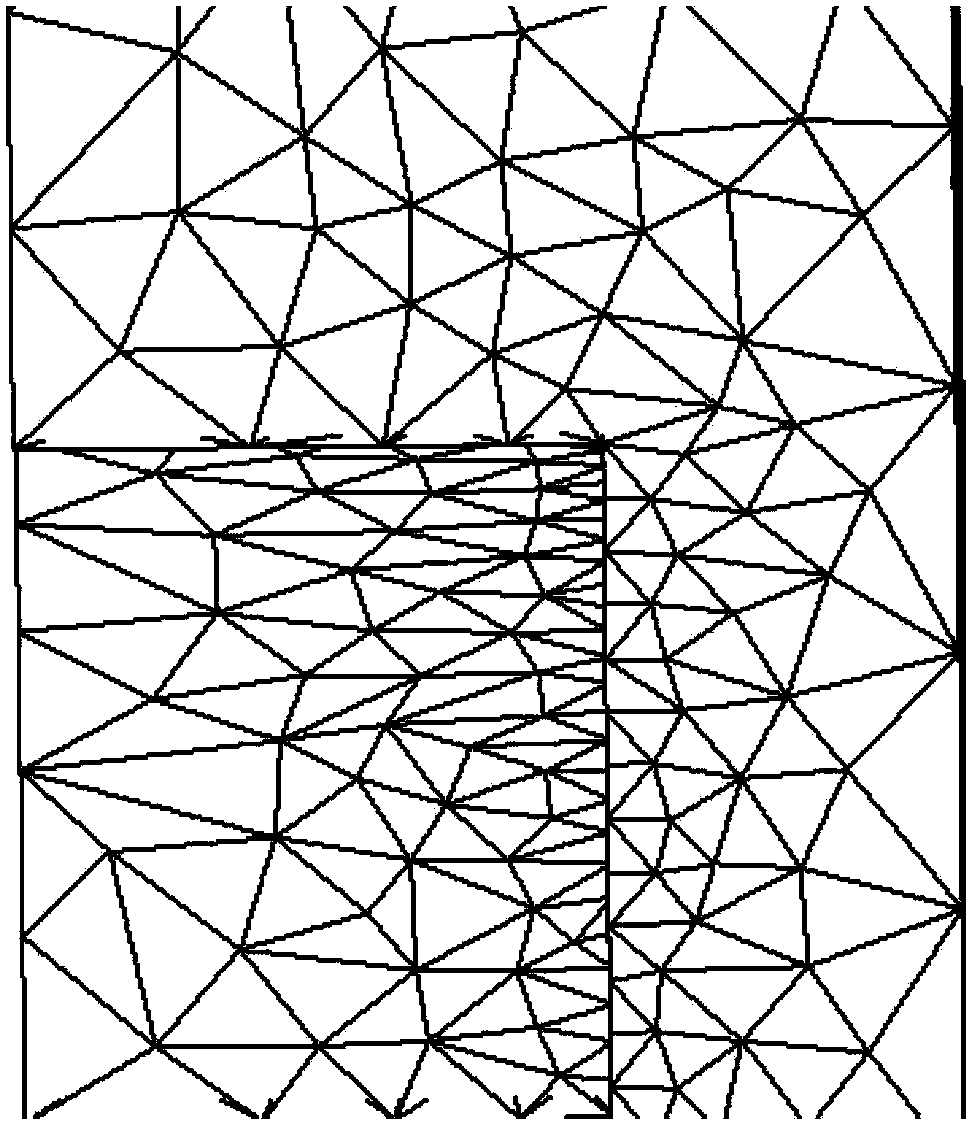

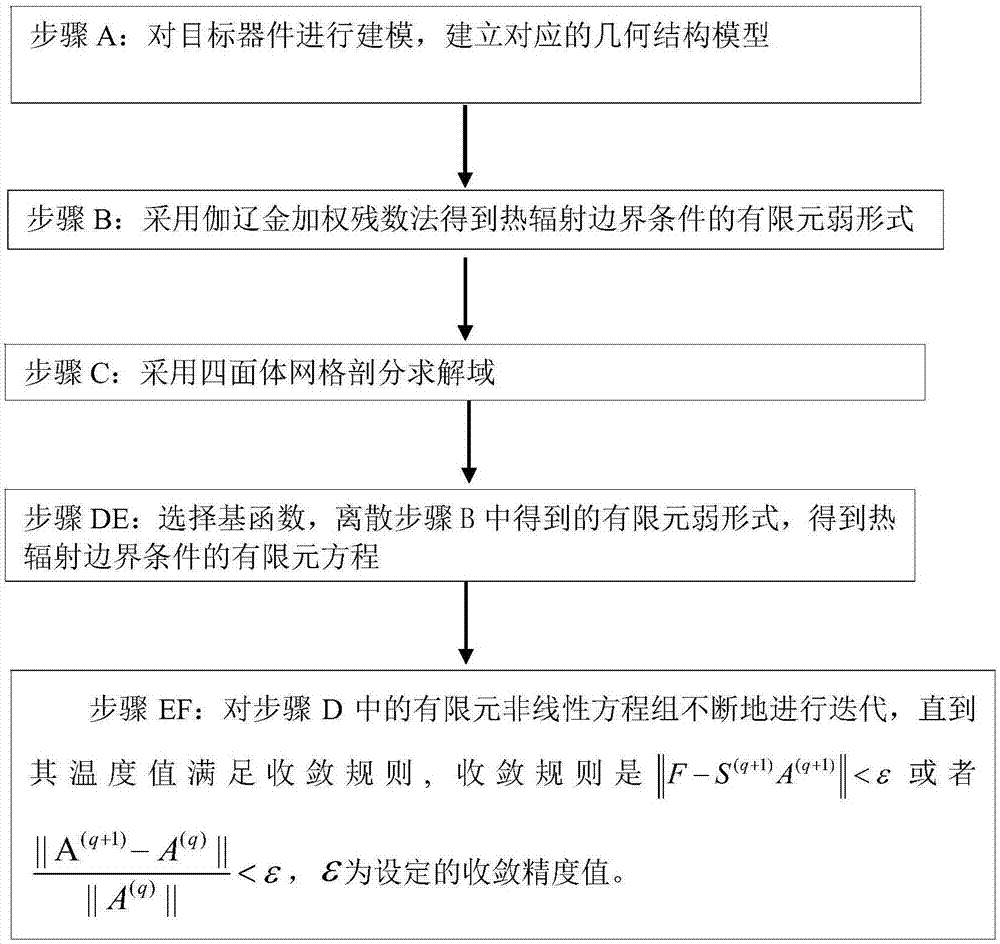

Three-dimensional finite element simulation method based on heat radiation boundary conditions

ActiveCN107577857AAccurate solutionQuick solveSpecial data processing applications3D modellingFinite element algorithmRadiation boundary conditions

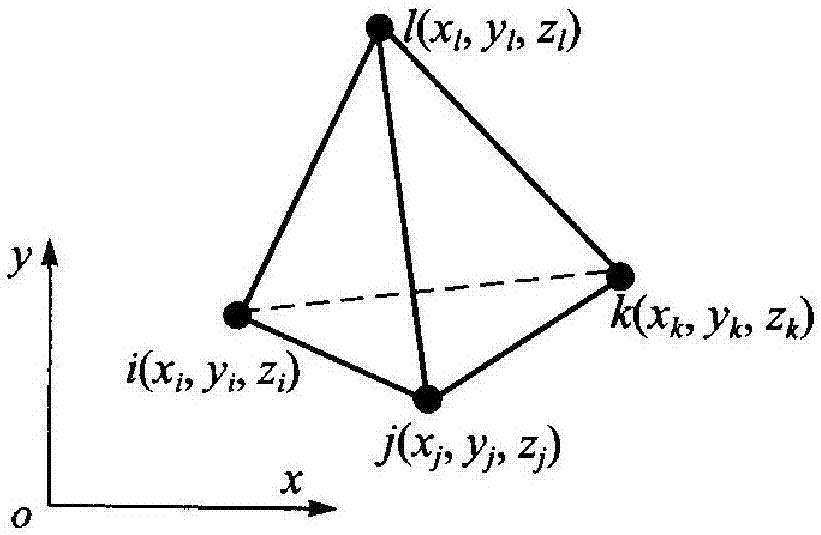

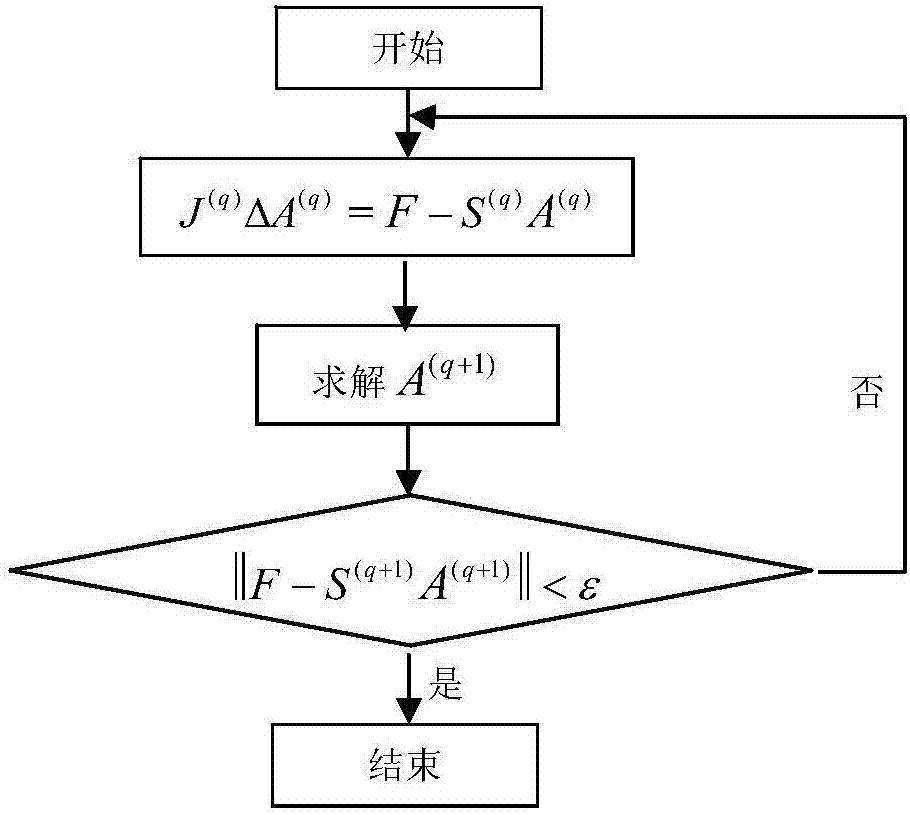

The present invention belongs to the technical field of numerical analysis of three-dimensional thermal analysis and relates to a three-dimensional finite element simulation method based on heat radiation boundary conditions. The method comprises: carrying out modeling on a device to be subjected to the thermal analysis, introducing radiation boundary conditions into the heat conduction problem, and obtaining the finite element weak form of the heat radiation boundary conditions by adopting the method of Galerkin residual weighting; using the tetrahedral meshed model to select the second-orderlaminated basis function and the discrete finite element weak form equation, obtaining a finite element matrix and aright-end vector by cooperating with the Newton-Raphson iteration method, and integrating the final equation; and finally, by using the scientific nonlinear convergence criteria, through continuous iteration, quickly and accurately obtaining final numerical results.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

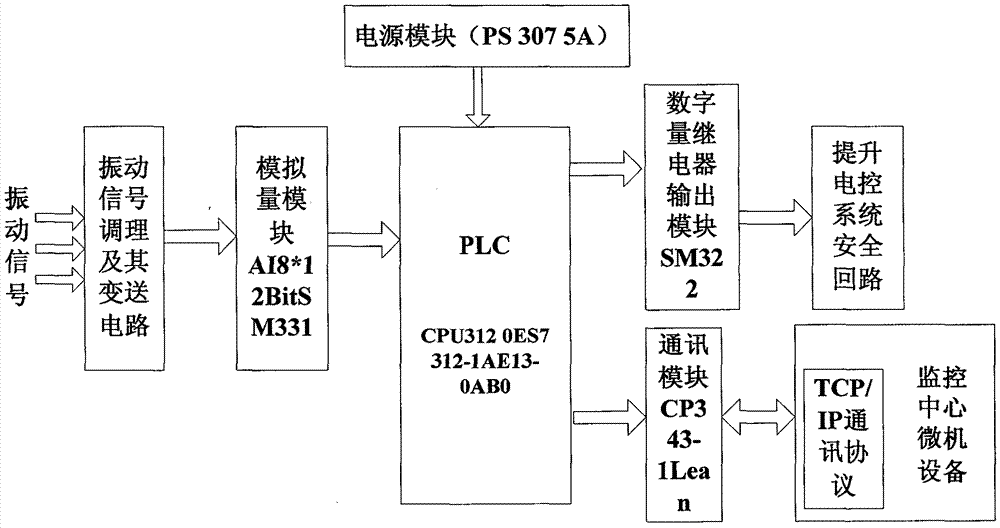

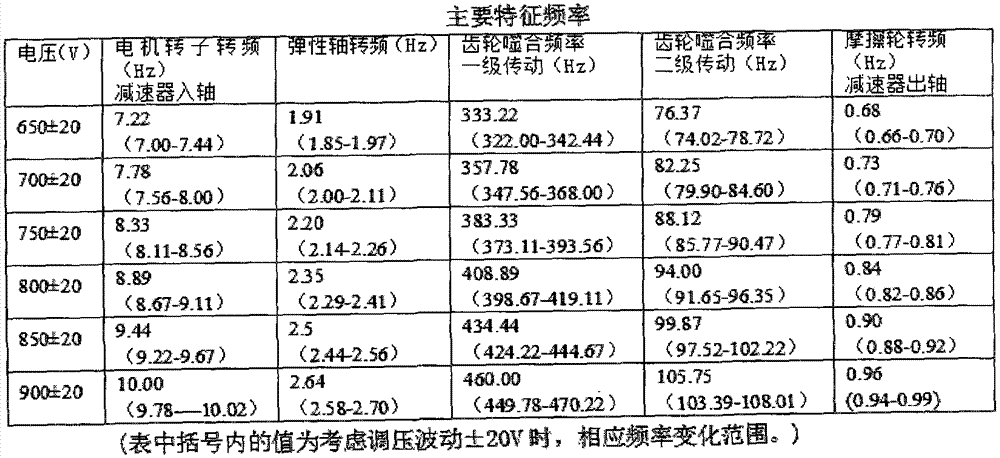

Vertical shaft hoist main shaft vibration detection method based on finite element analysis method

InactiveCN103712682AEnsure safetyTimely warning repairSubsonic/sonic/ultrasonic wave measurementFinite element algorithmVibratory signal

The invention discloses a vertical shaft main shaft vibration detection method based on a finite element analysis method. According to the special structure of a vertical shaft hoist, an integrated vibration transmitter is adopted to detect data of the vibration frequency amplitude of a hoist main shaft, the transmitter is adopted to convert a vibration signal to a 4-20MA analog signal to be transmitted to a field S7-300PLC, then after processing through the PLC, an RS485 bus is adopted to convert the processed signal to a TCP / IP Ethernet signal which can be recognized on a PC through a CP343-1LEAN bus converter, the signal is further transmitted to an upper computer located inside a monitoring room through an underground ring network, received by Kingview software in the upper computer and then transmitted to a finite element algorithm model with built-in MATLAB software, relatively accurate early warning of a future development tread is obtained through calculation, data are displayed on the upper computer in real time, and safe operation of the hoist is monitored in real time through a PC of the monitoring room, so that safety and stability of coalmine production are ensured. The vertical shaft main shaft vibration detection method based on the finite element analysis method starts from safety of the vertical shaft hoist, in combination with the actual situation of daily running, and makes full use of the advantages of the finite element algorithm to predict the running state of the hoist, so as to realize timely warning and repair when an accident does not happen, and thus ensure the safety of underground workers.

Owner:安徽恒源煤电股份有限公司

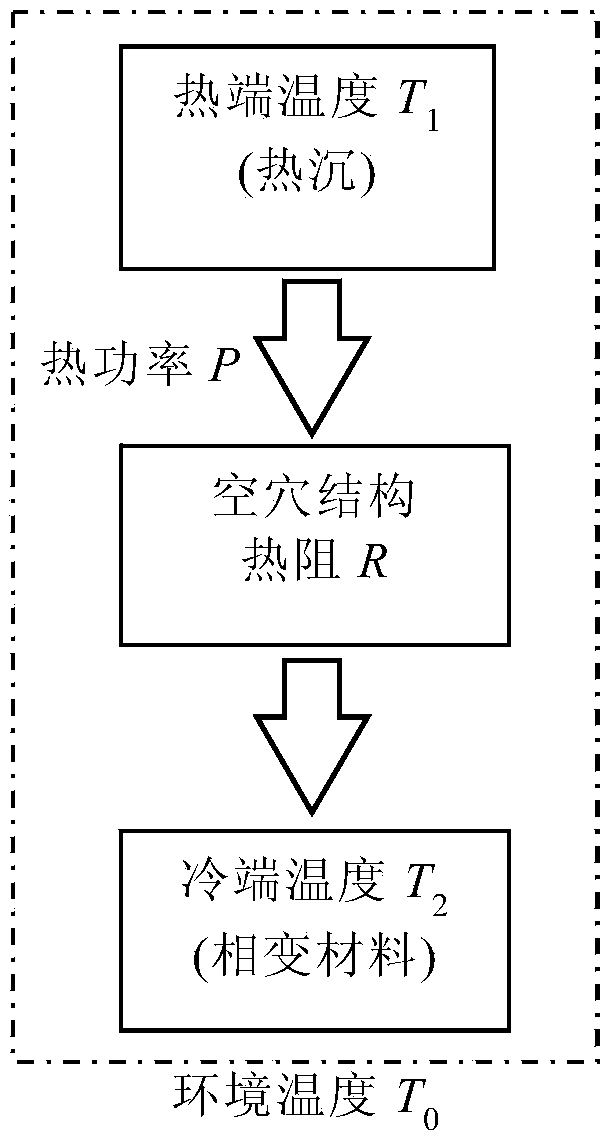

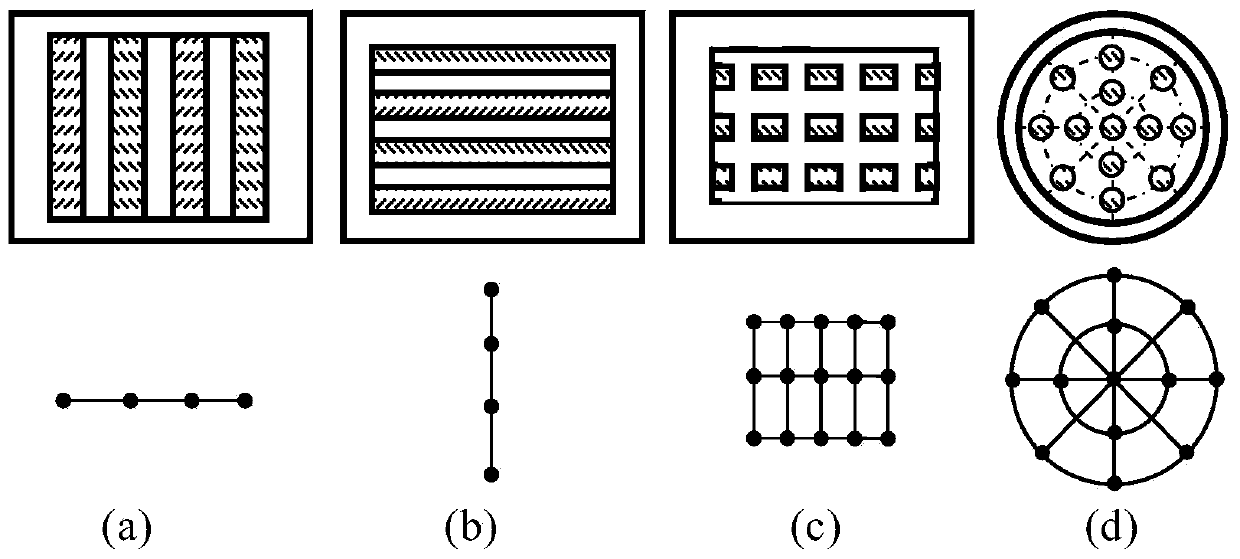

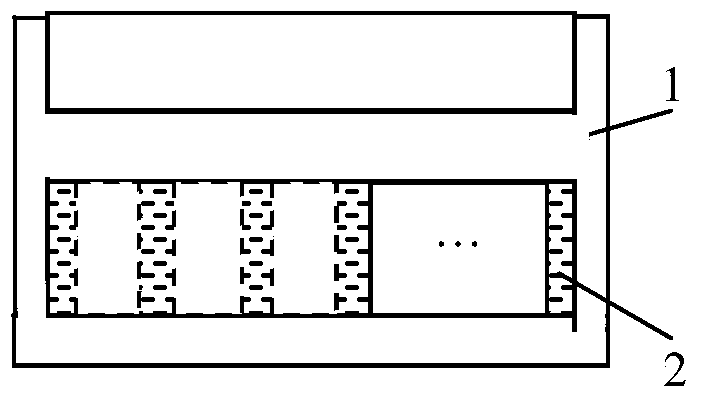

Phase change material thermal buffering device and method for dissipating heat of high-power device

ActiveCN103700638APromote absorptionIncrease heat conduction areaSemiconductor/solid-state device detailsSolid-state devicesFinite element algorithmWorking temperature

The invention discloses a phase change material thermal buffering device and method for dissipating heat of a high-power device. A phase change material is taken as a heat conduction cold end T2 since the phase change material has the characteristic of constant phase change heat absorption temperature, a certain temperature difference is formed between the heat conduction cold end T2 and a heat sink T1 of equipment, heat dissipated by a heat-end device is introduced into a phase change energy-storing substance in time, and the temperature T1 of the device is kept within an allowed working temperature range in the working time t of the heat-end device. The phase change material thermal buffering device consists of a heat sink, a honeycomb structure etched at the bottom of the heat sink, and a phase change material filled into honeycomb cavities. The effectiveness of the phase change material thermal buffering device can be evaluated via the temperature distribution of the device after the working time t under thermal power P or adjusted according to a calculation result. Temperature indexing can be obtained via an established thermal buffering process model or calculating with a finite element algorithm. By adopting the buffering device and the buffering method, the heat conduction area is increased, and the heat conduction efficiency is increased. Moreover, the heat sink and the thermal buffering device are integrated, so that the space is saved.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

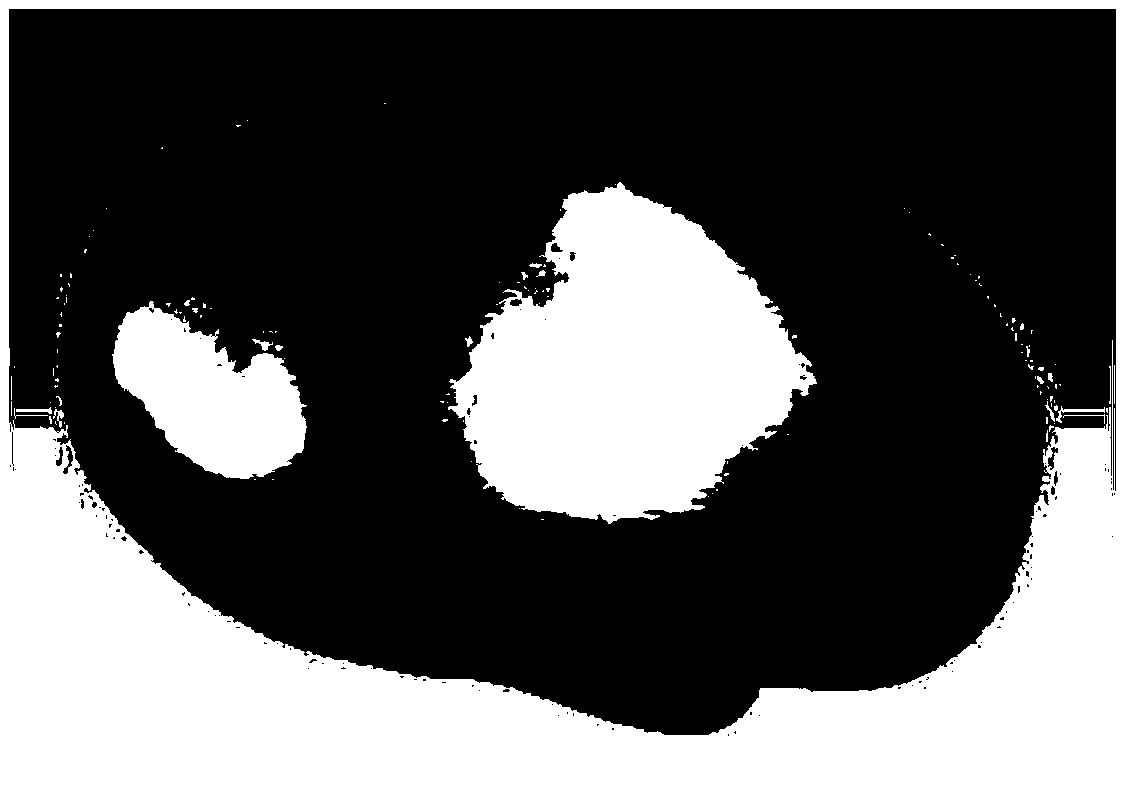

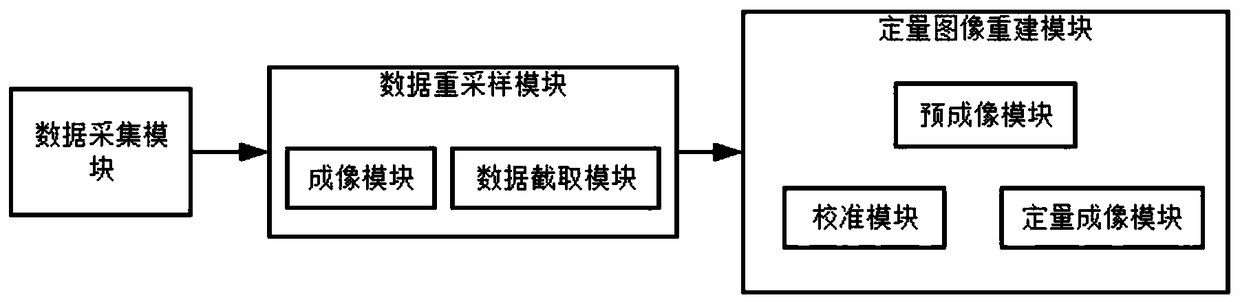

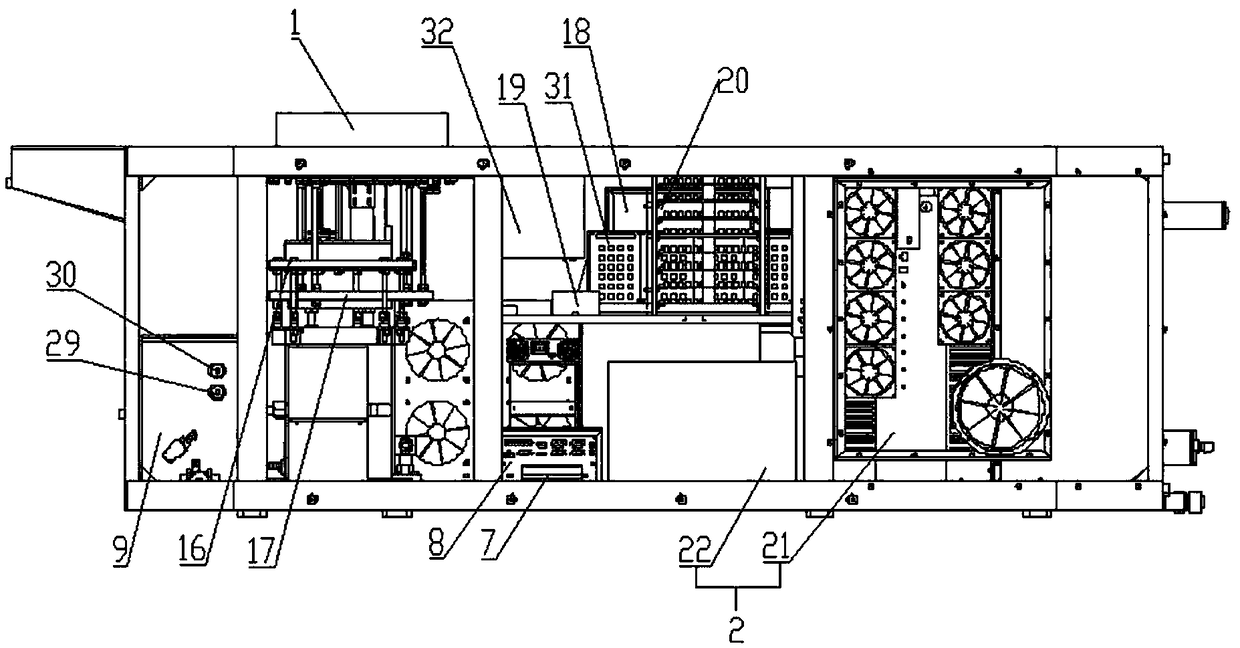

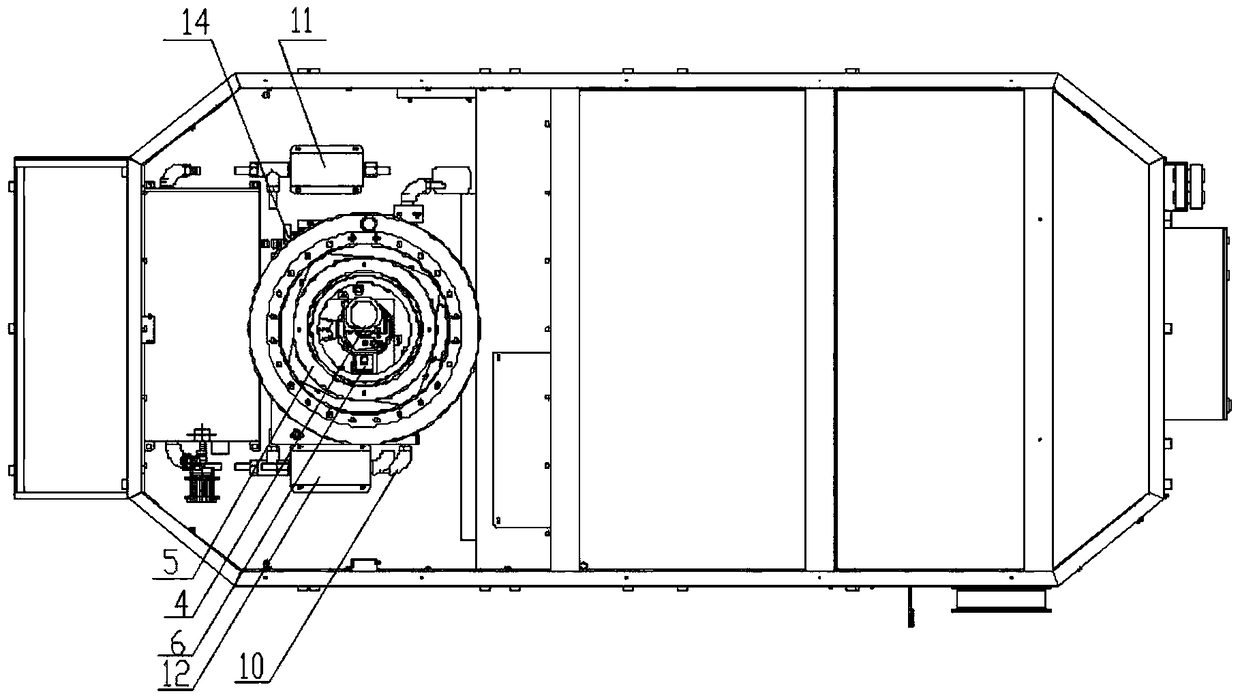

Finite-element quick image reestablishment system and method for optoacoustic mammary gland imager

ActiveCN108814555AFast imagingGuaranteed speedDiagnostic signal processingSensorsFinite element algorithmMammary gland structure

The invention discloses a finite-element quick image reestablishment system and method for an optoacoustic mammary gland imager. The system comprises a data collection module, a data resampling moduleand a quantitative image reestablishment module. The data collection module is used for conducting data collection on the mammary gland of the human body through the optoacoustic mammary gland imager; the data resampling module is used for conducting quick imaging on data collected by the data collection module, observing whether or not a suspected focus exists in an illumination area according to an imaged graph and intercepting data with the suspected focus to obtain valid data of a laser radiation area; the quantitative image reestablishment module is used for conducting quantitative imaging on output data of the data resampling module through a finite element algorithm and reestablishing hemoglobin concentration and oxygen saturation images of the suspected focus and the periphery ofthe suspected focus. According to the system, when the focus is analyzed, the images are cut through the quick image reestablishment system, the illumination area with the diameter of 5 cm is cut, sothat the grid diameter becomes extremely small when the finite-element algorithm is conducted, the imaging precision is guaranteed, and the imaging speed is also guaranteed.

Owner:中川新迈科技有限公司

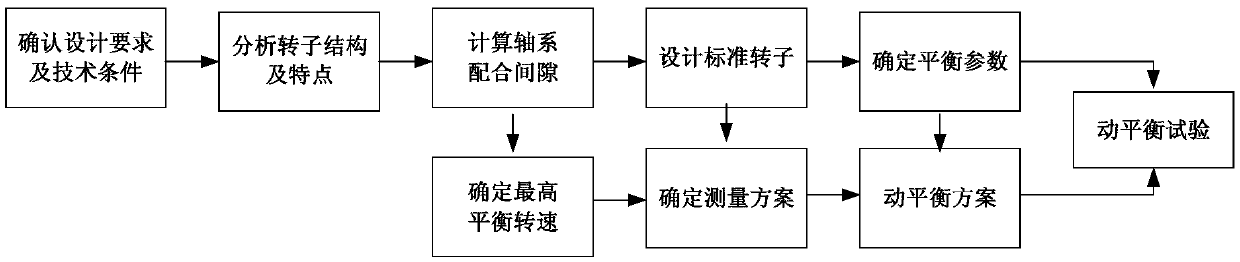

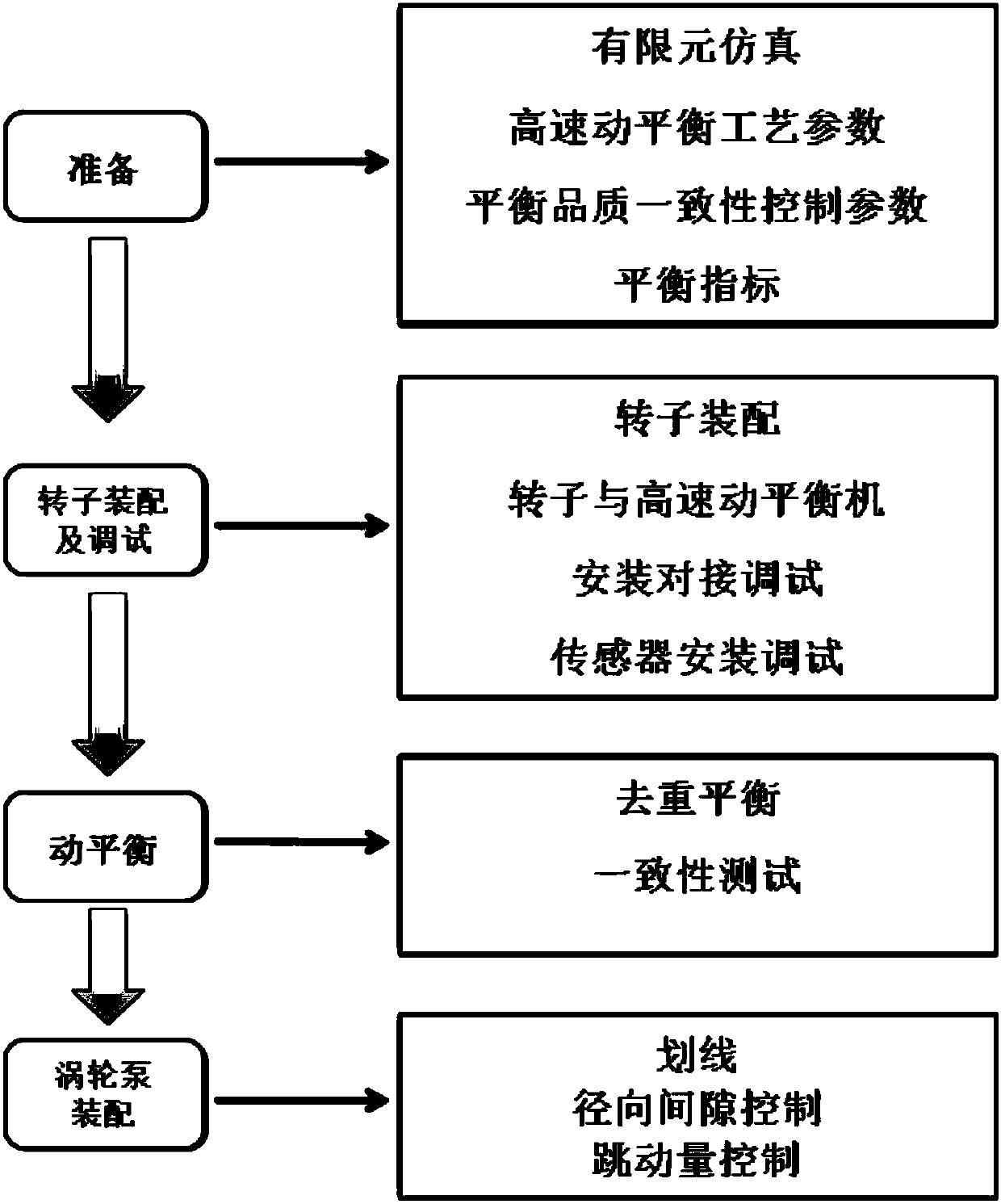

High-speed dynamic balancing method satisfying assembly and usage of rocket engine turbopump

ActiveCN107702854AMeet the test run vibration level requirementsHigh balance qualityStatic/dynamic balance measurementFinite element algorithmConsistency test

A high-speed dynamic balancing method satisfying the assembly and usage of a rocket engine turbopump comprises the following steps of 1 utilizing a finite element method to calculate the dynamic characteristics of a turbopump flexible rotor, and combining a high-speed dynamic balancing quality consistency control method to determine the high speed dynamic balancing parameters and indexes of the turbopump flexible rotor; 2 assembling the turbopump flexible rotor, installing the turbopump flexible rotor on a high speed dynamic balancing machine, and installing and debugging a displacement sensor; 3 carrying out the repeated assembly and disassembly consistency tests of the de-weight balancing and high speed dynamic balancing effects on the turbopump flexible rotor; 4 according to the test results in the steps 1 to 3, assembling the turbopump. The high-speed dynamic balancing method of the present invention solves the problem that other high-speed dynamic balancing methods and precisionsare not suitable for the turbopump assembly and usage conditions.

Owner:BEIJING AEROSPACE PROPULSION INST

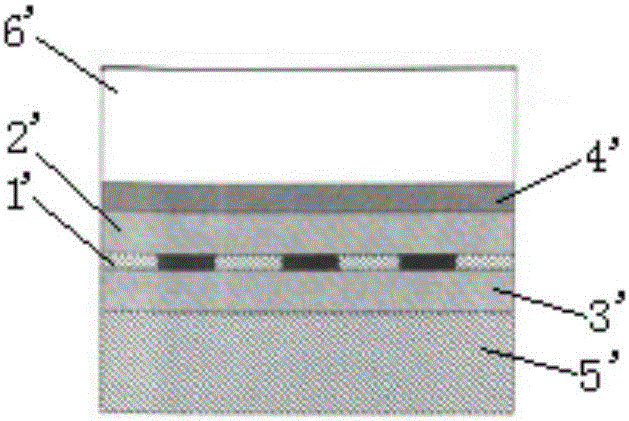

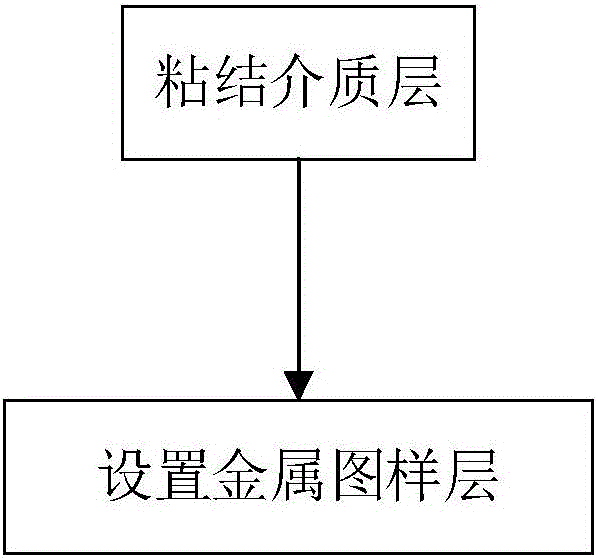

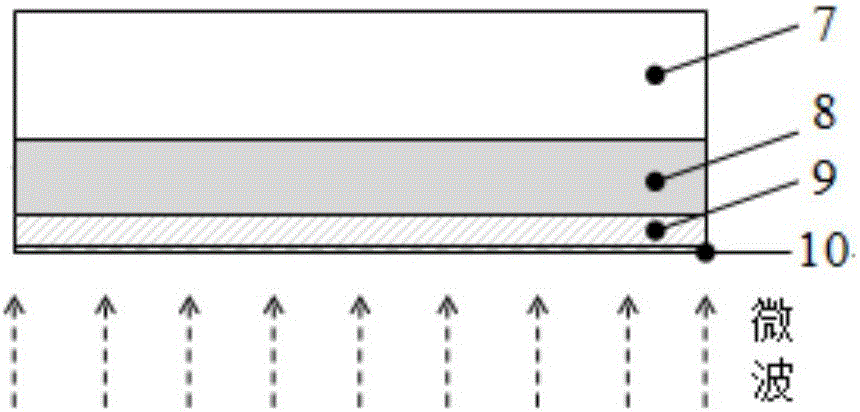

Airplane metamaterial skin used for microwave heating ice prevention and removal and manufacturing method of airplane metamaterial skin

ActiveCN106081054AReduce complexityReduce thicknessFuselage bulkheadsMetal layered productsFinite element algorithmMicrowave

The invention provides an airplane metamaterial skin used for microwave heating ice prevention and removal. An FR4 material or a polyimide material serves as a dielectric layer, various parameters of the dielectric layer and a metal pattern layer are determined through the finite element method, the dielectric layer and metal patterns are sequentially arranged on the inner side face of a metal skin, then the skin can completely absorb microwaves at a specific frequency point and convert the microwaves into the heat on the surface of the skin, and accordingly ice layers on the surface of the skin can be melted and removed. By the adoption of the airplane metamaterial skin, the heat consumed on the ice prevention and removal skin is reduced, and the heat transmission efficiency and the heat utilization ratio are improved.

Owner:NAT UNIV OF DEFENSE TECH

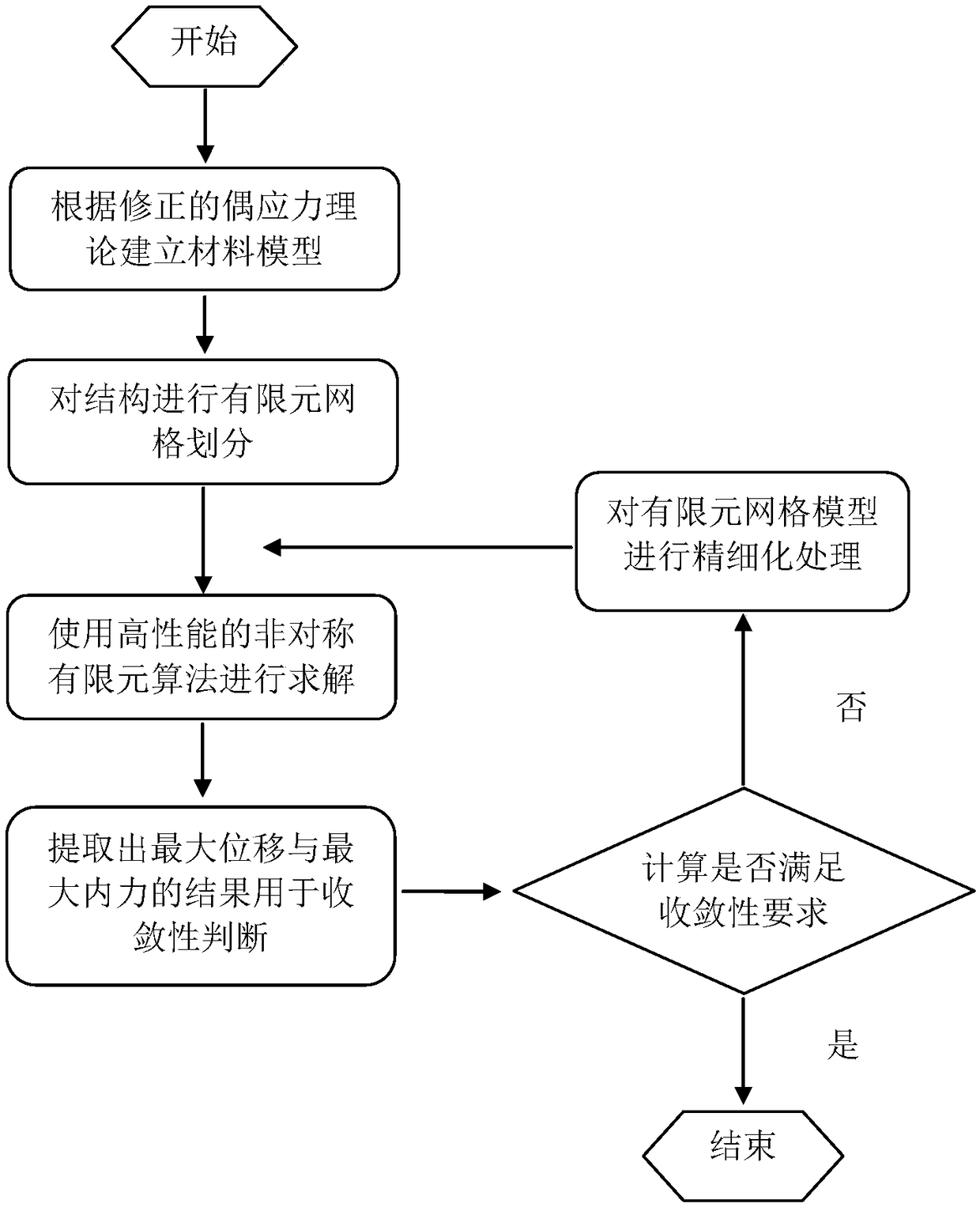

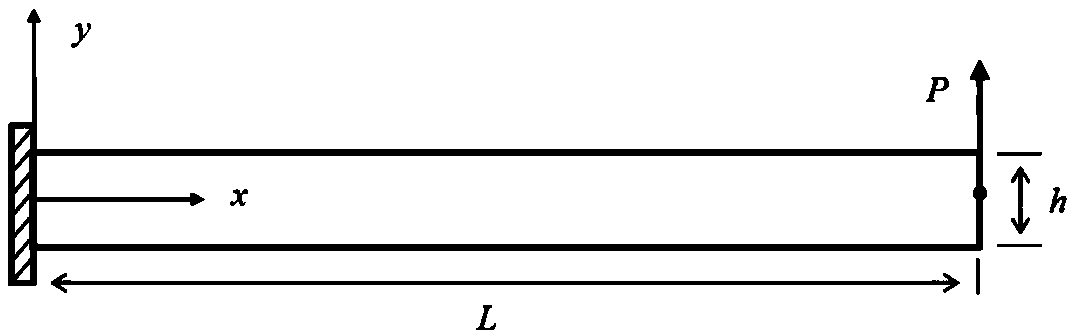

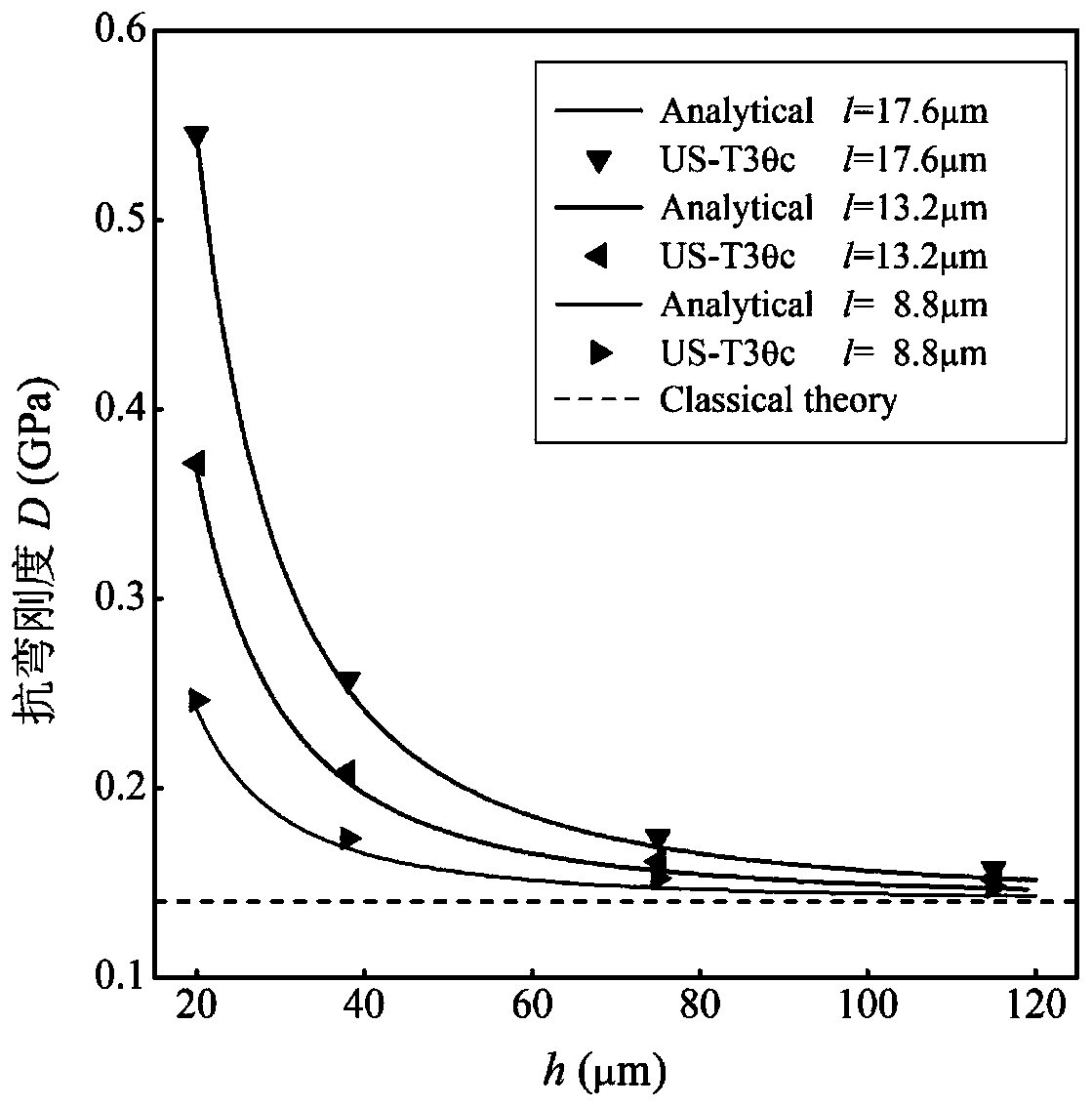

A material scale effect analysis method based on asymmetric finite element algorithm

ActiveCN109271655AHigh precisionImprove performanceDesign optimisation/simulationSpecial data processing applicationsFinite element algorithmNon symmetric

The invention discloses a material scale effect analysis method based on an asymmetric finite element algorithm, belonging to the field of CAE simulation and mechanical analysis and calculation, including: 1) establishing a constitutive model of a material based on a modified couple stress theory; 2) carrying out finite element mesh division on the structure to obtain a finite element mesh model;3) using high-performance asymmetric finite element algorithm to solve numerically, and extracting the maximum displacement value and the maximum stress value; 4) after refining that finite element mesh model, repeating the operation of step 3, and judging whether the reference index can meet the convergence condition or the precision requirement. The invention solves the problems of low efficiency and insufficient precision in analyzing the scale effect of the material by the conventional finite element method. The method also has better flexibility and applicability, and can be embedded intothe existing commercial finite element software, so it can be used to solve a wider range of engineering structures.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Structural stress checking method of steam generator

InactiveCN106123649AAvoid the problem of overly complicated calibration processThe verification results are comprehensive and accurateHeat exchanger casingsStationary tubular conduit assembliesFinite element algorithmDecomposition

The invention belongs to the technical field of steam generators in mechanical equipment engineering and particularly relates to a structural stress checking method of a shell and tube type steam generator. According to the structural stress checking method of the shell and tube type steam generator, the structure of the steam generator is decomposed into four parts, and individual stress analysis and connection edge stress analysis are conducted on each part of the four parts; in this way, a targeted algorithm can be adopted for each part, and the problem that in the prior art, a finite element method is individually adopted so that a checking process is too complicated is avoided; and besides, through the decomposition, the conditions of all the structures of the steam generator can be fully reflected, and therefore a checking result is guaranteed to be complete and accurate.

Owner:THE CHALLENGE PETROCHEM MACHINERY CORP

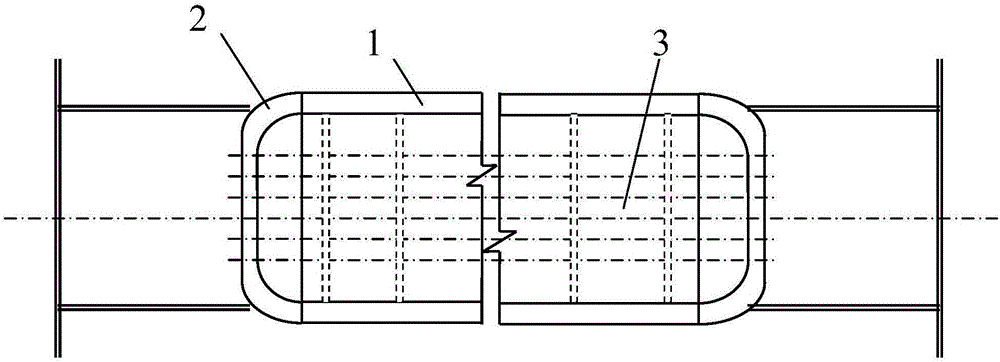

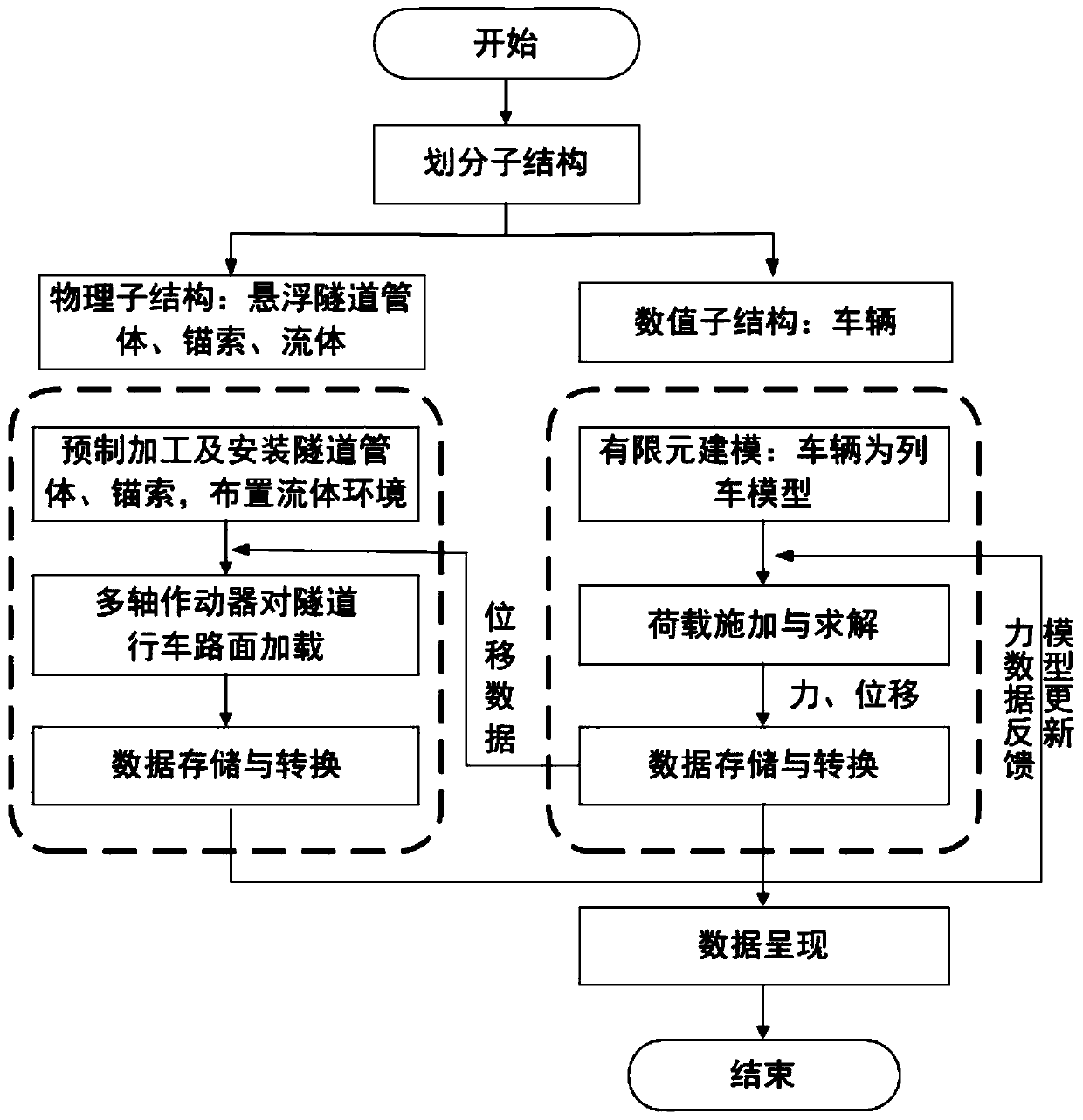

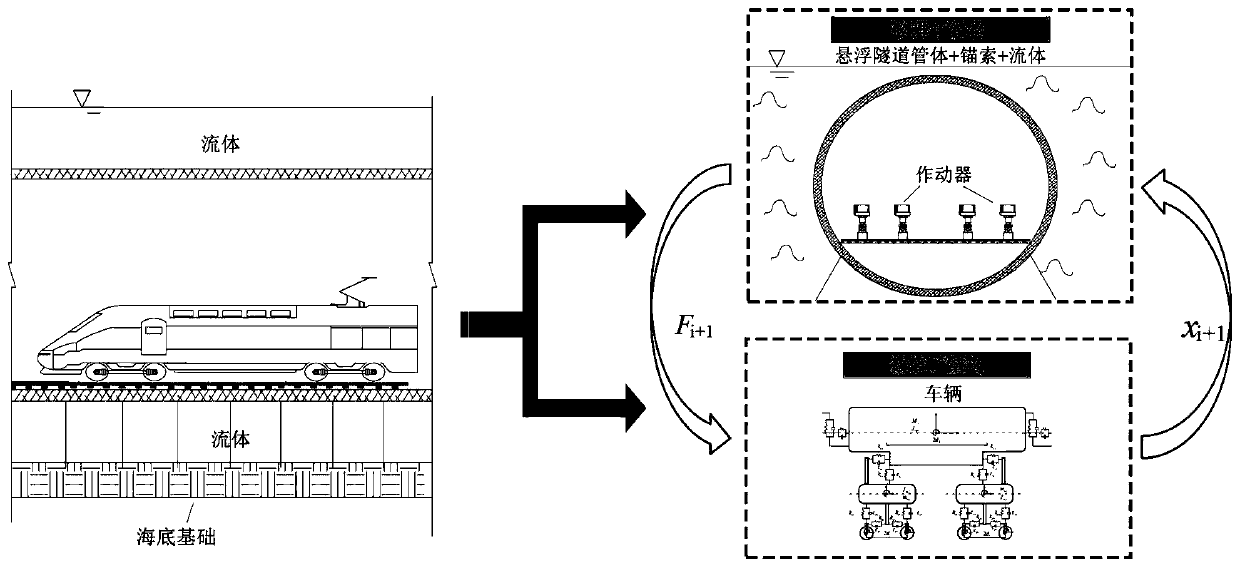

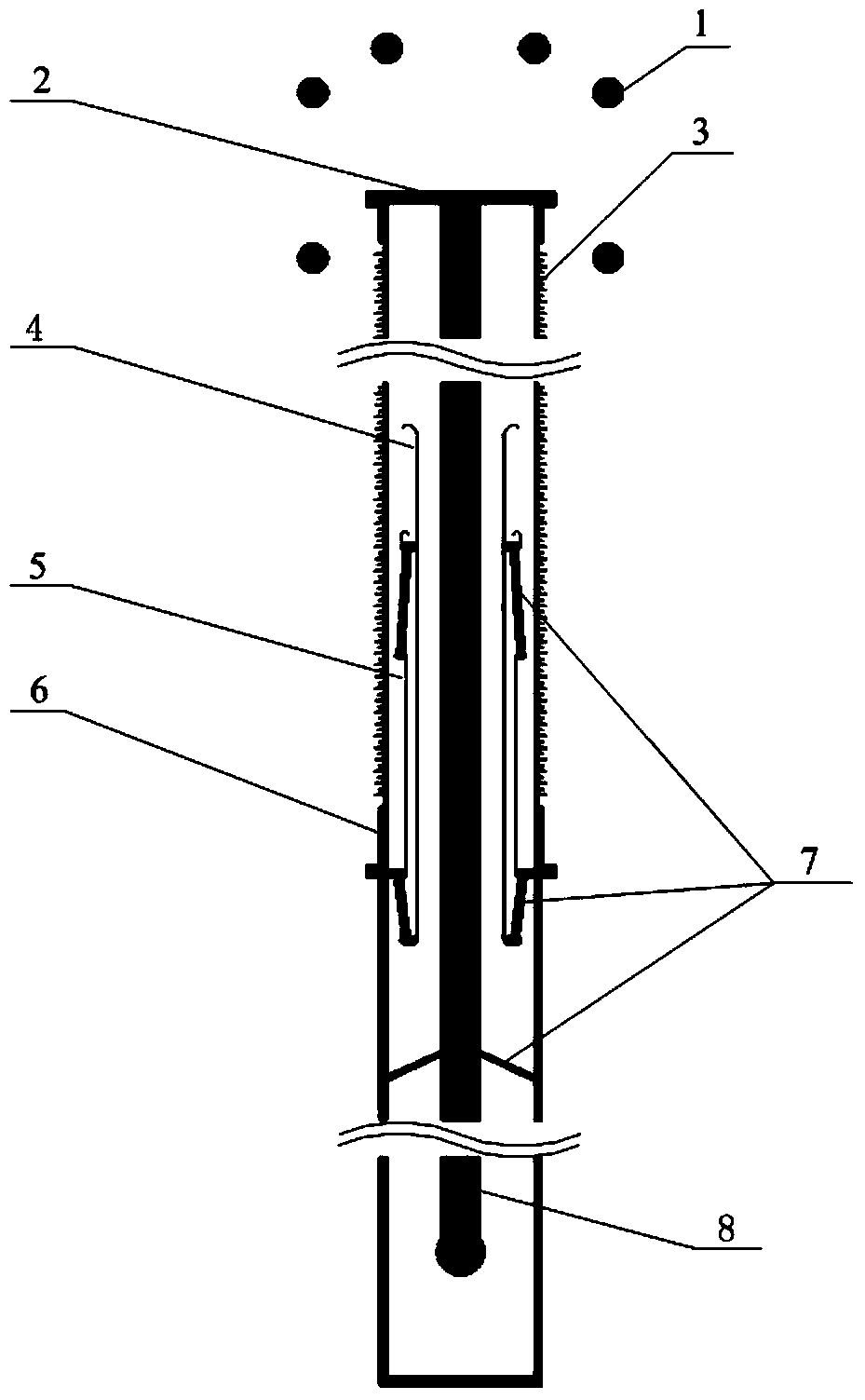

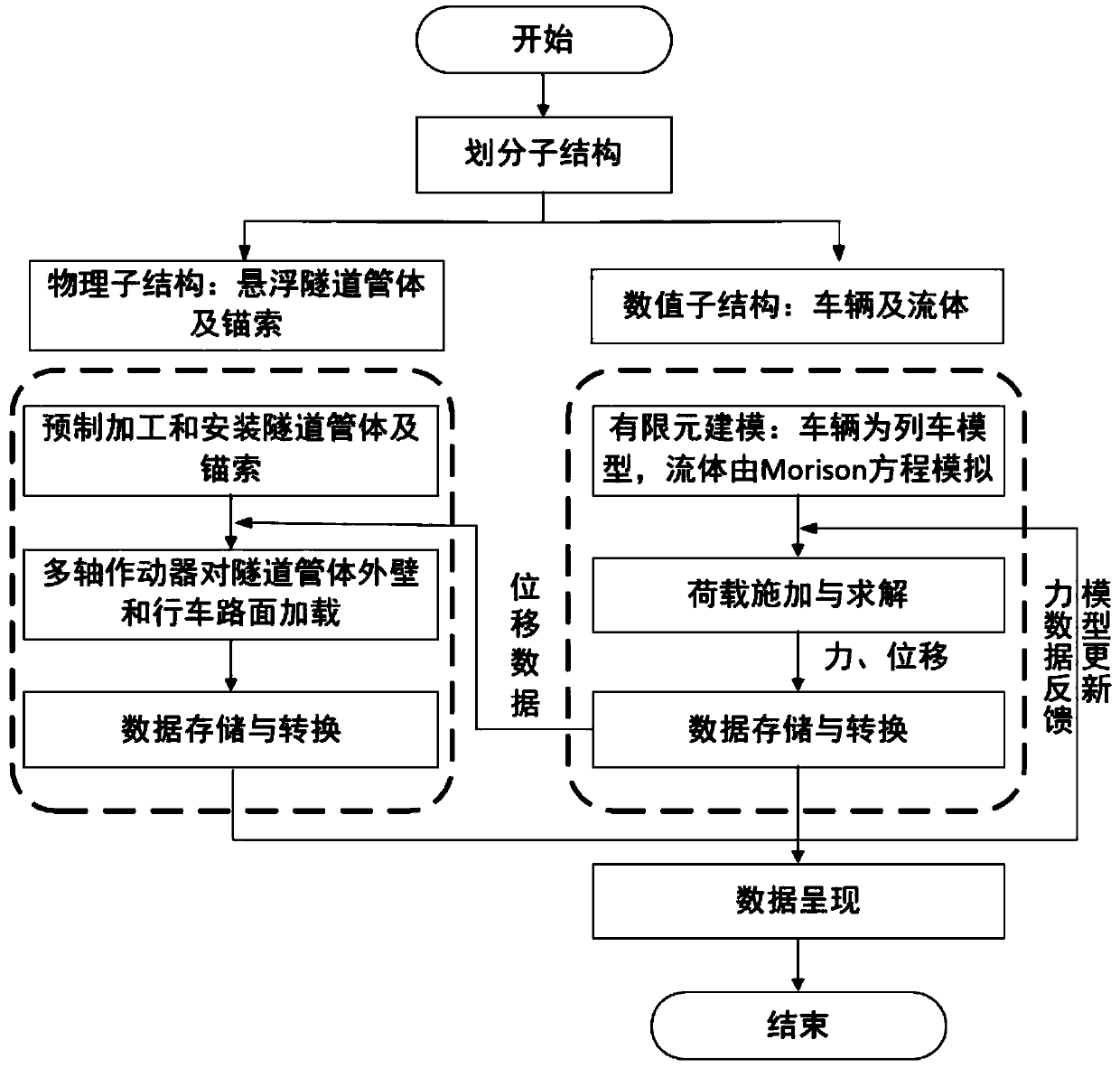

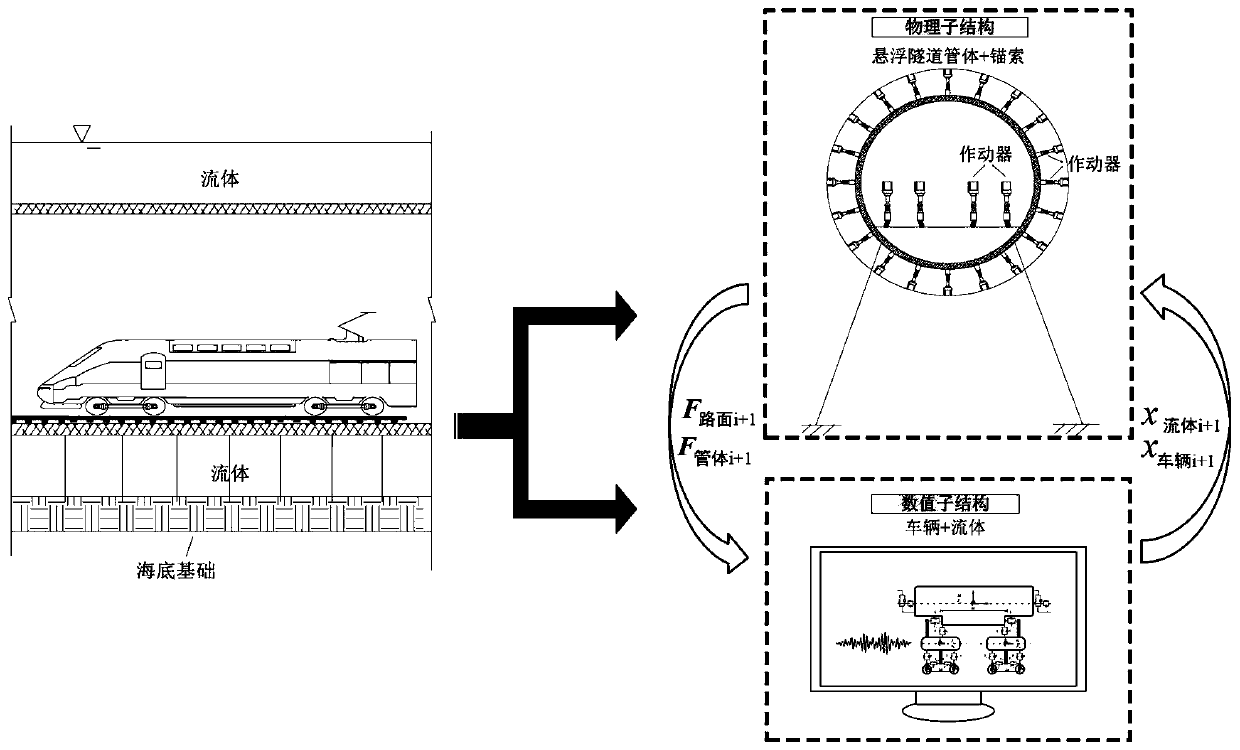

Floating tunnel vehicle-tunnel dynamic coupling hybrid simulation test method and device

ActiveCN110261141AModeling implementationReduce size requirementsRailway vehicle testingFinite element algorithmInteraction systems

The invention discloses a floating tunnel vehicle-tunnel dynamic coupling hybrid simulation test method and device. The method is used to analyze and research a dynamic characteristic of a floating tunnel in a vehicle-tunnel coupling problem. The method comprises the following steps of for different research emphases, dividing a floating tunnel, a vehicle, a fluid and the like into different physical substructures and numerical substructures; based on a finite element algorithm or related software, establishing a numerical simulation model for the numerical substructures; prefabricating, processing and installing the physical substructures; through a data interaction system and a data acquisition system, completing loading control of the physical substructures by calculation information of the numerical substructures, and model updating of the numerical substructures by measurement information of the physical substructures; and finally, monitoring and extracting the required information through a visual interface. A pure numerical simulation method is difficult to accurately simulate and has low calculating efficiency when a structure is complex or a complex nonlinear behavior exists. In the invention, the above disadvantages are avoided. For problems that a traditional structural test can not capture a dynamic characteristic of the structure or a size is limited, use and maintenance costs are high and so on, a sub-structure technology advantage of a hybrid simulation test is used and the method and the device can be widely applied to nonlinear dynamic characteristic analysis of complex structure objects such as the floating tunnel and the like.

Owner:ZHEJIANG UNIV

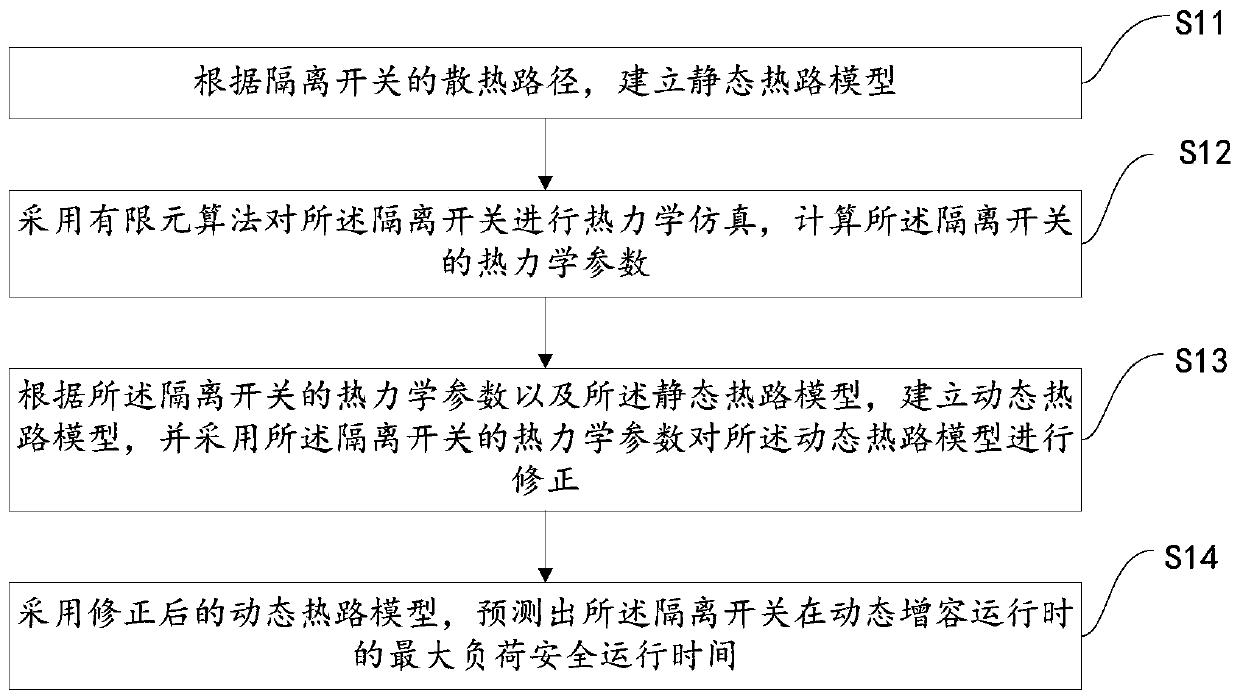

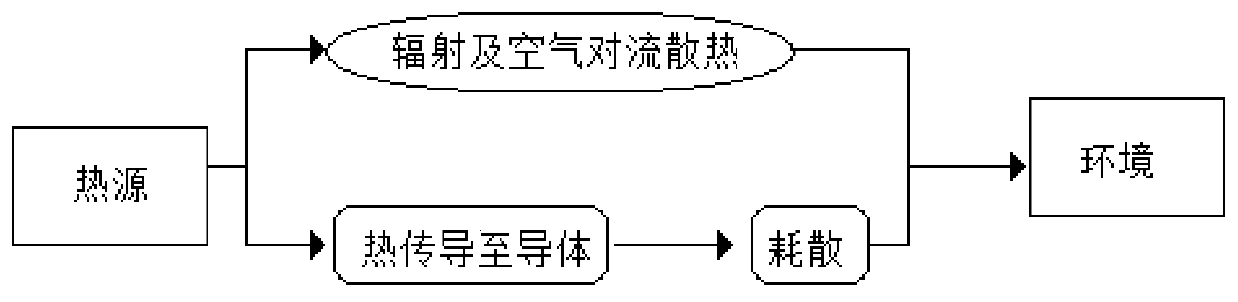

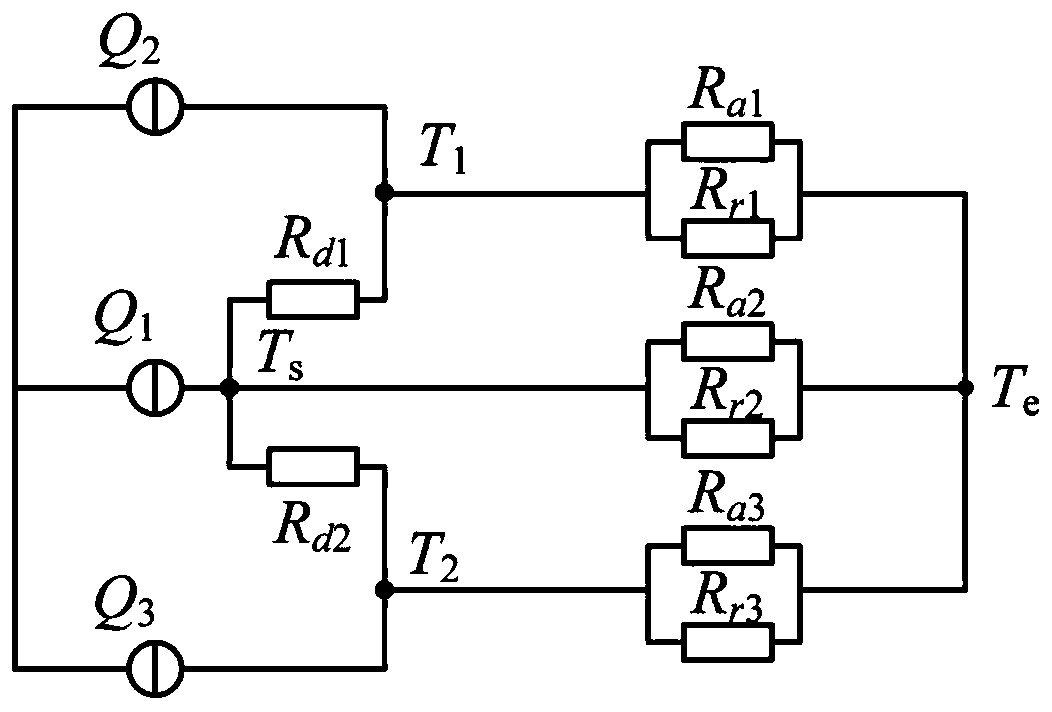

Isolating switch dynamic capacity-increasing operation prediction method and device, apparatus and storage medium

ActiveCN110197000AQuick calculationImprove calculation accuracyDesign optimisation/simulationSpecial data processing applicationsThermodynamic simulationFinite element algorithm

The invention discloses an isolating switch dynamic capacity-increasing operation prediction method and device, an apparatus and a storage medium, wherein the method comprises the steps of building astatic thermal circuit model according to a heat dissipation path of an isolating switch; performing thermodynamic simulation on the isolating switch by adopting a finite element algorithm, and calculating the thermodynamic parameters of the isolating switch; correcting the dynamic thermal circuit model according to the thermodynamic parameters of the isolating switch; predicting the maximum loadsafe operation time of the isolating switch during dynamic capacity-increasing operation by adopting the corrected dynamic thermal circuit model; adopting a thermal circuit model, and combining the finite element simulation to carry out the numerical calculation on the thermodynamic parameters during the heat generation, heat conduction and heat dissipation processes of the isolating switch, so that the thermal circuit model is corrected, the calculation accuracy of the thermal circuit model is greatly improved, the calculation is quick, and the dynamic capacity-increasing safe operation timeof the isolating switch is accurately predicted.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

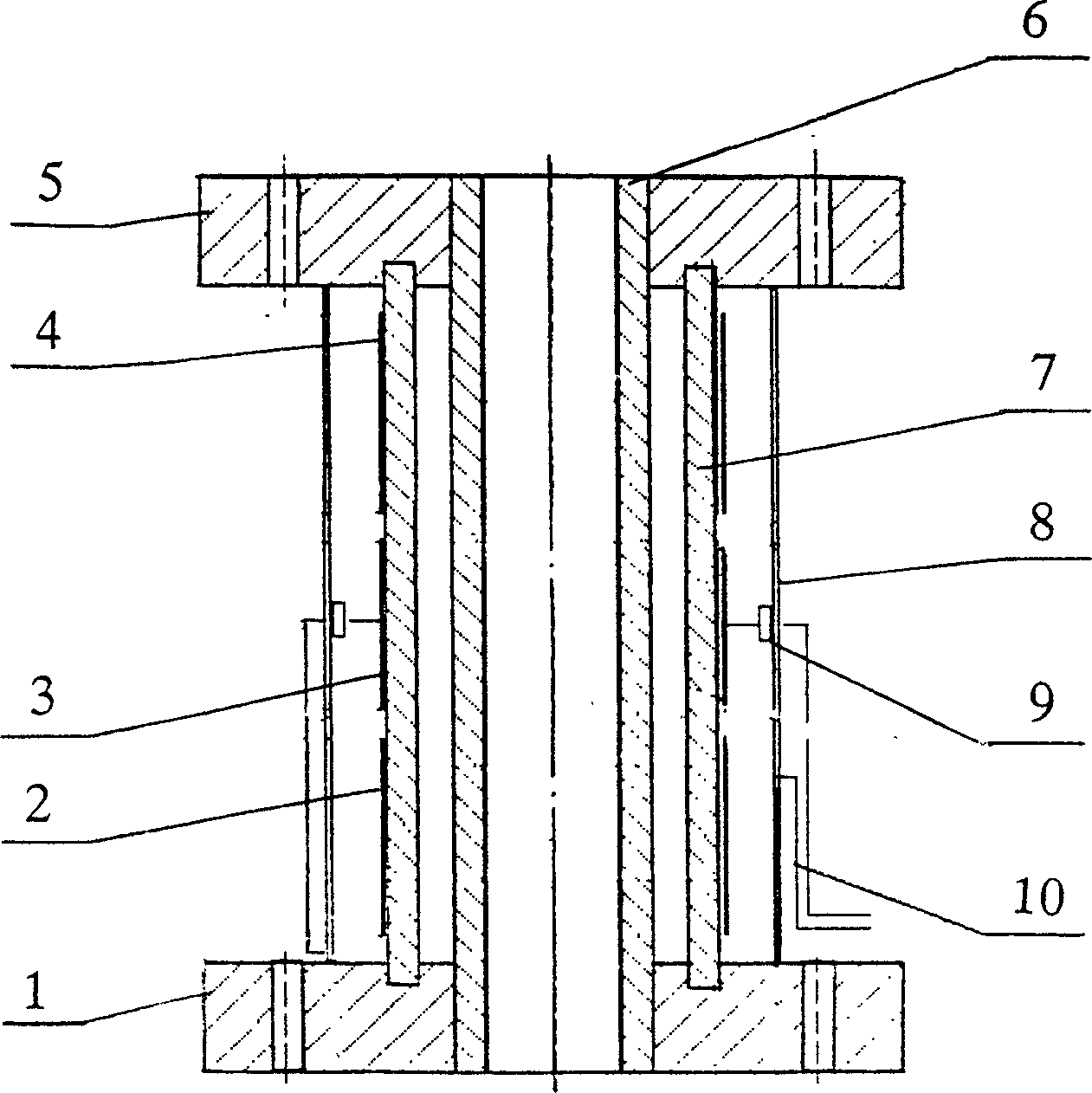

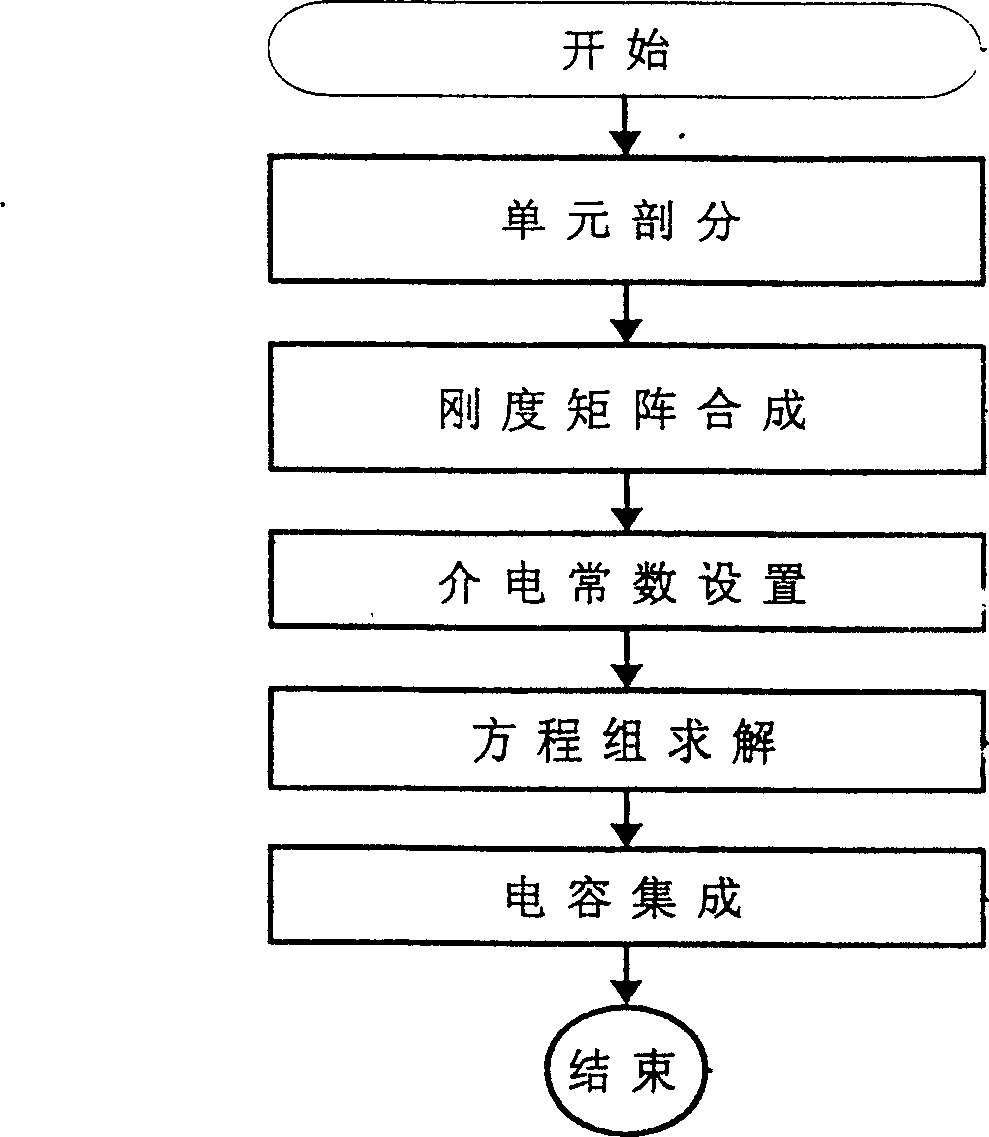

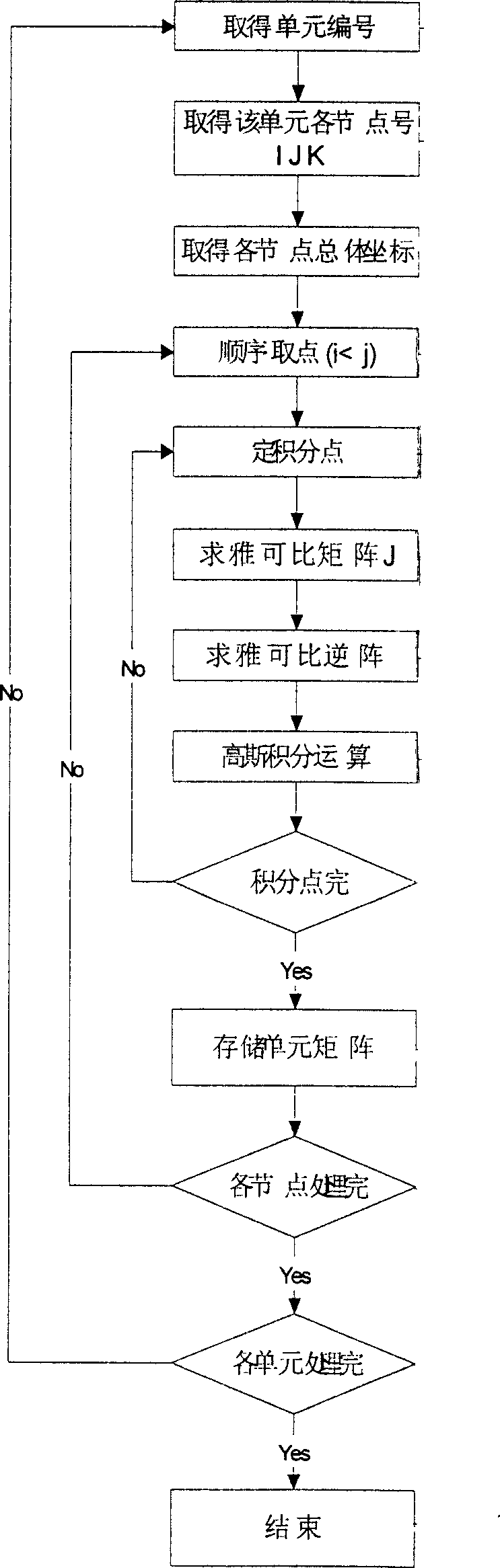

Solution to edge effect of two-phase gas-liquid flow capacitive sensor

InactiveCN1487288AAccurate measurementSimple structureMaterial capacitanceFinite element algorithmEdge effects

The present invention is solution to edge effect of two-phase gas-liquid flow capacitive sensor. The two-phase gas-liquid flow capactitive sensor is provided with protecting pole plates of optimal length L. The increase of length results in decreased influence of the edge effect but increased volume of the sensor, and the angle of the arced pole plate is 120-140 deg. The protecting plate length L and the angle of the arced pole plate, as the main parameters, are obtained via 3D electromagnetic field equi-parameter finite element algorithm including the steps of: start, unit separating, dielectric constant setting, rigid matrix synthesis, solving coupled equations and capacitor integration. The method of the present invention has simple structure, low cost, long life, high sensitivity and capacity of measuring flow rate, phase density and sliding ratio, and other advantages. The present invention is suitable for non-invasion measurement of two-phase gas-liquid flow in oil pipeline.

Owner:沈阳工业学院

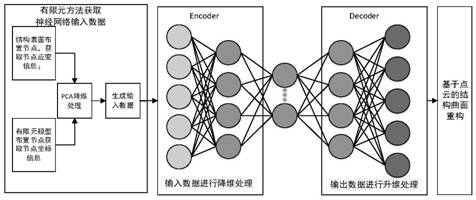

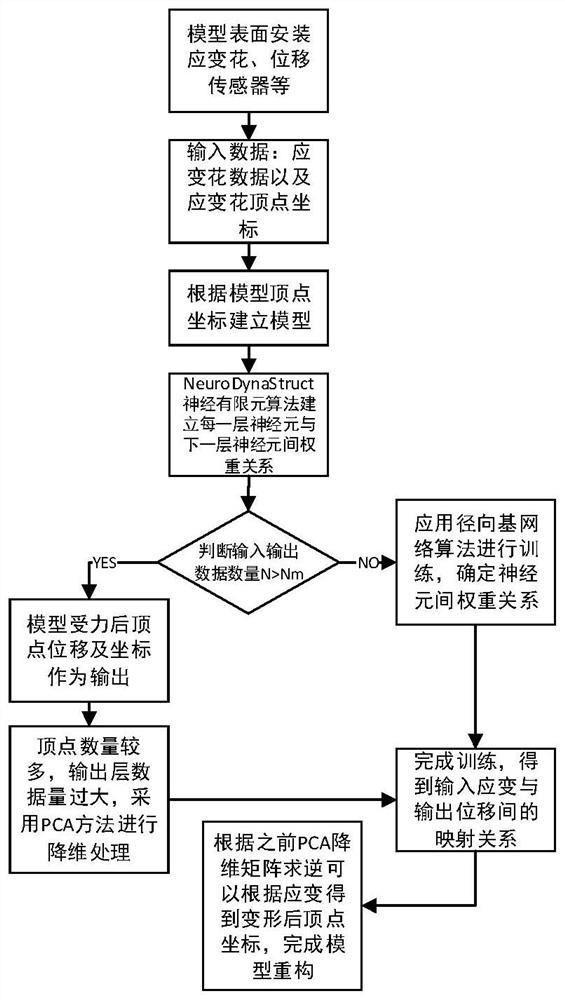

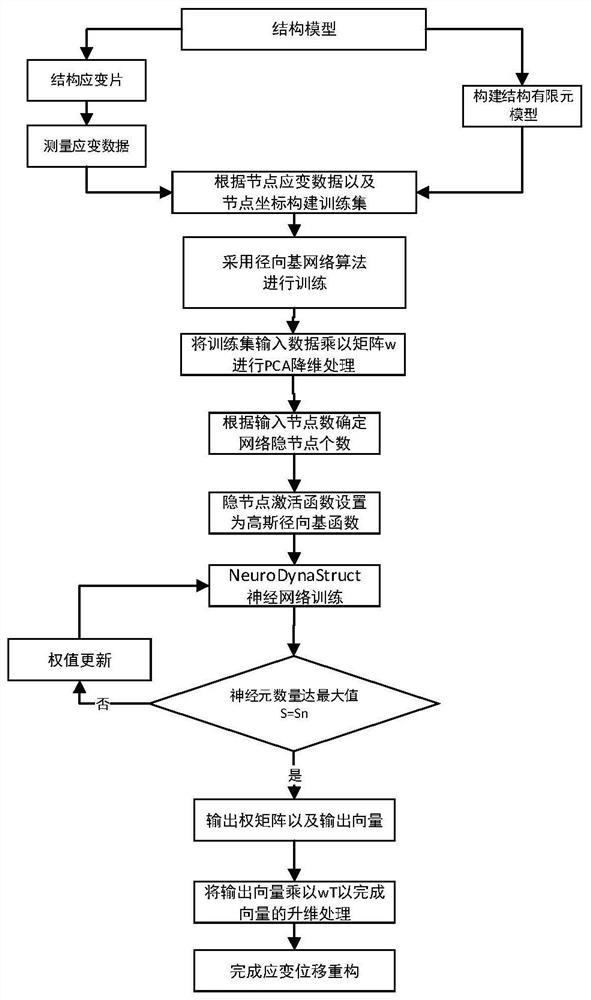

Strain-displacement reconstruction method of finite element model structure

PendingCN114169383ACharacter and pattern recognitionNeural architecturesFinite element algorithmElement model

The invention discloses a strain-displacement reconstruction method of a finite element model structure, particularly relates to a method for constructing a strain-displacement relationship by adopting a NeuroDynaStract neural network based on a finite element structure, and belongs to the field of finite element displacement reconstruction. The method is used for performing strain-displacement reconstruction on a finite element model based on a NeuroDynaStructure neural network architecture, and comprises the following steps: fitting measured strain and measured displacement through an established NeuroDynaStructure neural finite element algorithm by adopting a finite element method based on basic measured data, constructing a training set, and performing training by adopting a radial basis network algorithm, in the training process, a principal component analysis (PCA) method is used for carrying out dimension reduction processing, the operand is reduced, and a correction strain-correction displacement relation is obtained. The method is used for reconstructing deformation of the real-time nonlinear finite element simulation model, the finite element model and the neural network are combined together, a novel method for obtaining the strain-displacement relation based on the finite element model and test data is provided, and the structural reconstruction precision can be improved while the neural network architecture is simplified.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

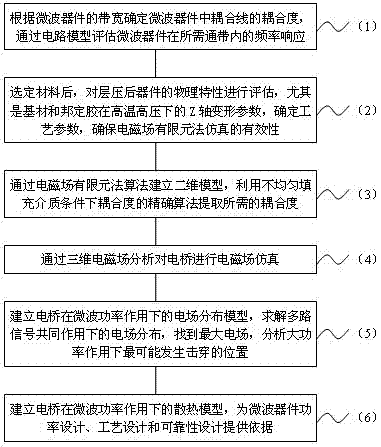

Method of simulation design for surface-mounted microwave devices

ActiveCN103049616AReduce design difficultyImprove design efficiencySpecial data processing applicationsFinite element algorithmCoupling

The invention discloses a method of simulation design for surface-mounted microwave devices. The method includes: determining coup0ling degree of coupling lines in a microwave device according to bandwidth of the microwave device, and estimating frequency response of the microwave device within the required bandwidth through a circuit model; after materials are selected, estimating physical properties of the laminated device to determine process parameters and ensure effectiveness of simulation by electromagnetic field finite element method; establishing a two-dimensional model by electromagnetic field finite element algorithm, and precisely extracting the required coupling degree; performing electromagnetic field simulation to a bridge by three-dimensional electromagnetic field analysis; establishing an electric field distribution model of the bridge under the action of microwave power and electric field distribution under the coaction of multiple signals, locating a largest electric field, and analyzing a most possible breakdown position under the action of high power; and establishing a radiating model of the bridge under the action of microwave power. The method enables design to be greatly easier, design labor to be reduced and design cost to be lowered, and assists in improving accuracy and reliability in microwave device design.

Owner:成都泰格微电子研究所有限责任公司

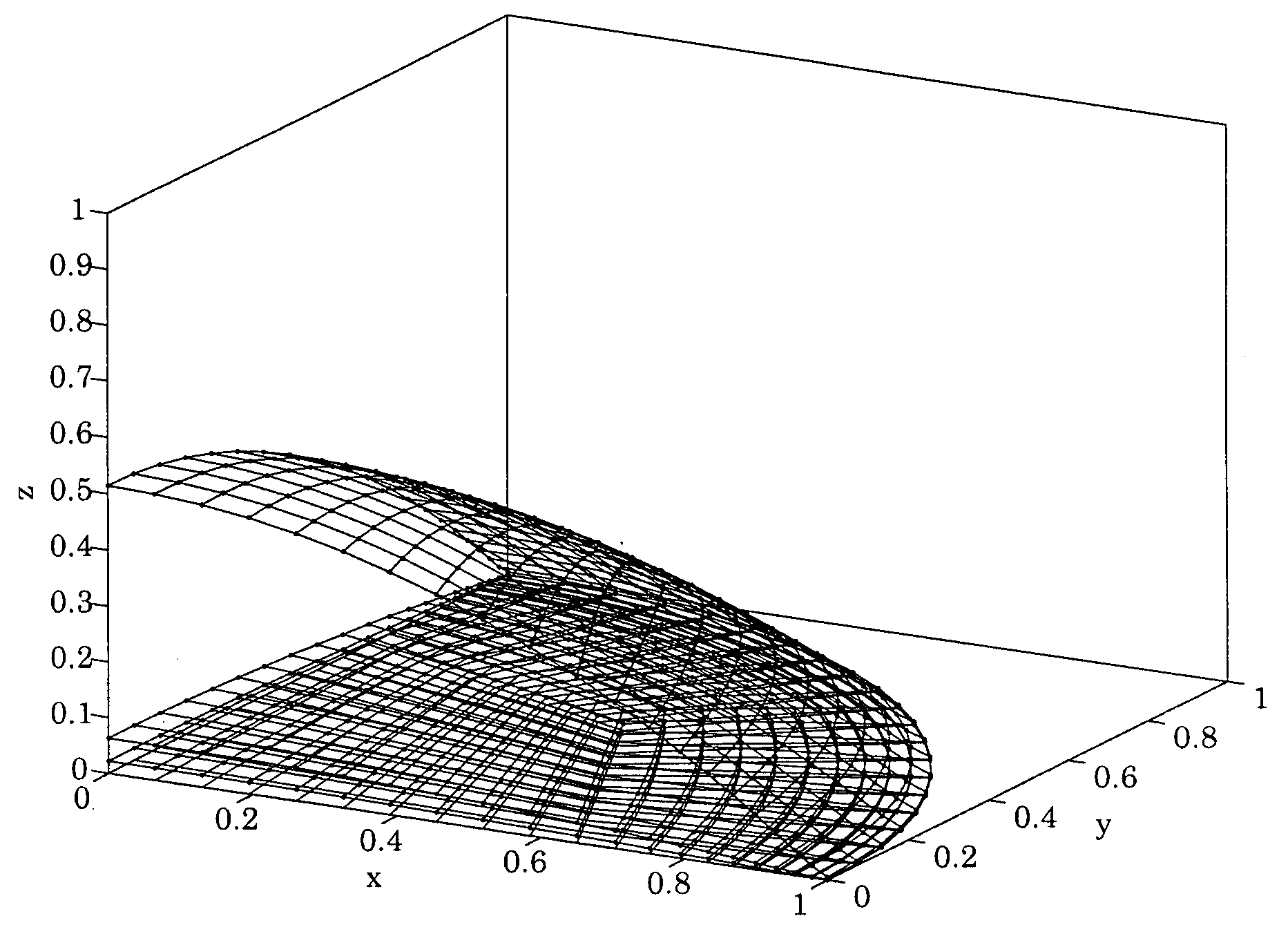

Finite Element Algorithm for Solving a Fourth Order Nonlinear Lubrication Equation for Droplet Evaporation

InactiveUS20100250203A1Computation using non-denominational number representationDesign optimisation/simulationFinite element algorithmDifferential function

The present invention is directed towards systems, methods and a computer-readable medium for simulating the evolution of a height of an evaporating droplet. The simulation includes a simulation space with boundary conditions. The simulation includes generating a height function that is representative of the height of the droplet at a first point in time at a plurality of points in the simulation space based upon a lubrication equation that is a differential function describing variation of the height function over time. The simulation determines the height function at a second point in time by finding an approximate solution that satisfies the lubrication equations and boundary conditions.

Owner:SEIKO EPSON CORP

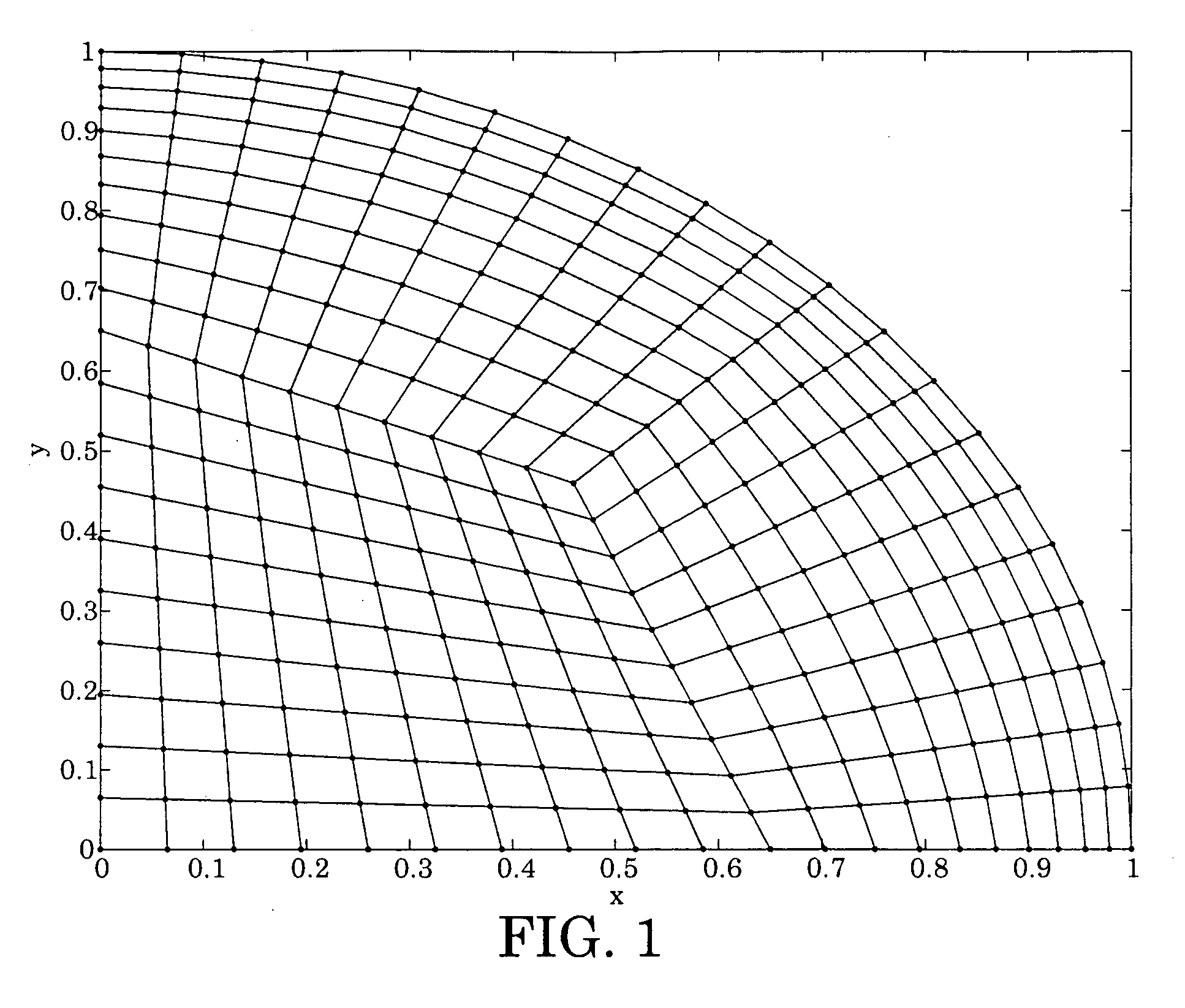

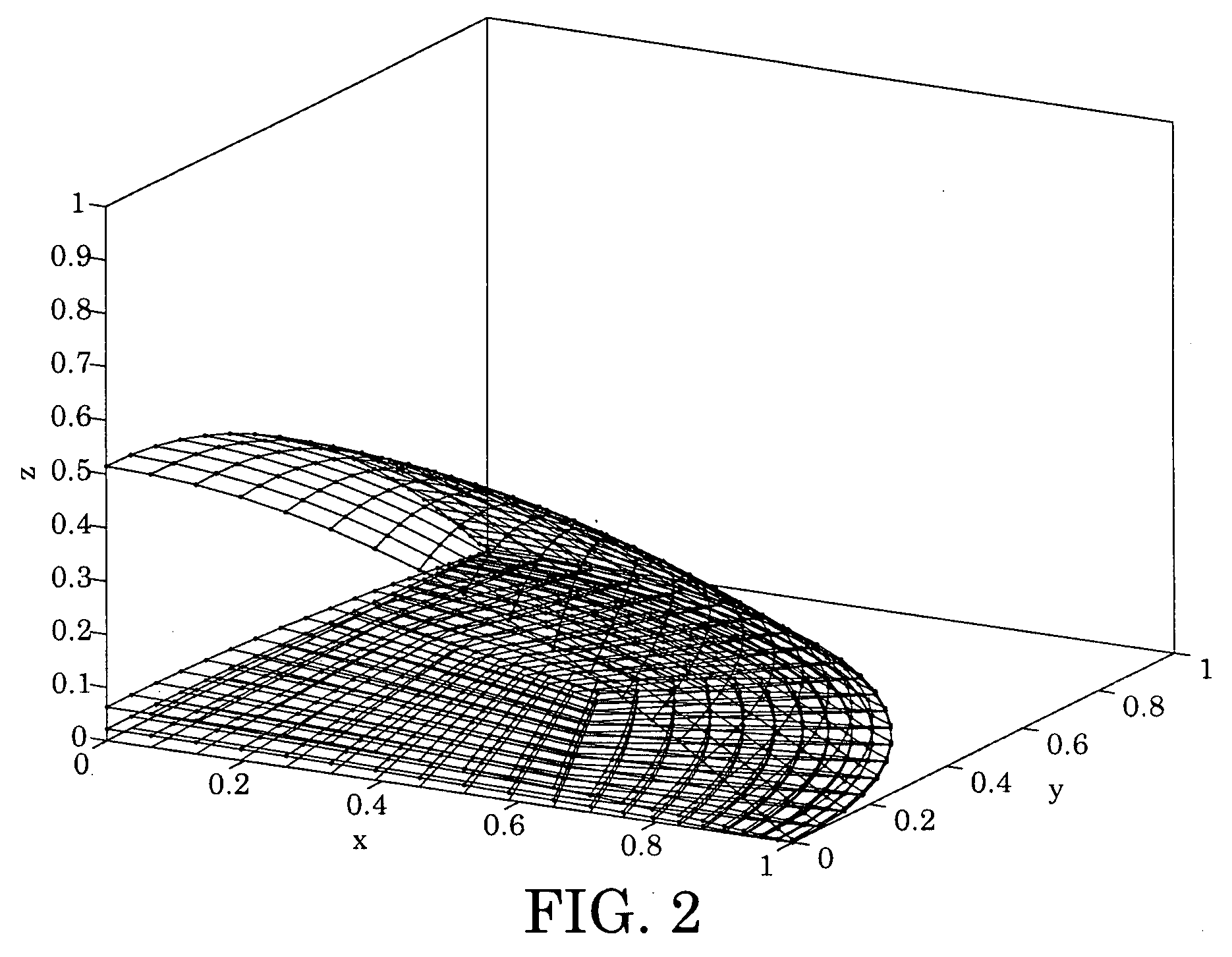

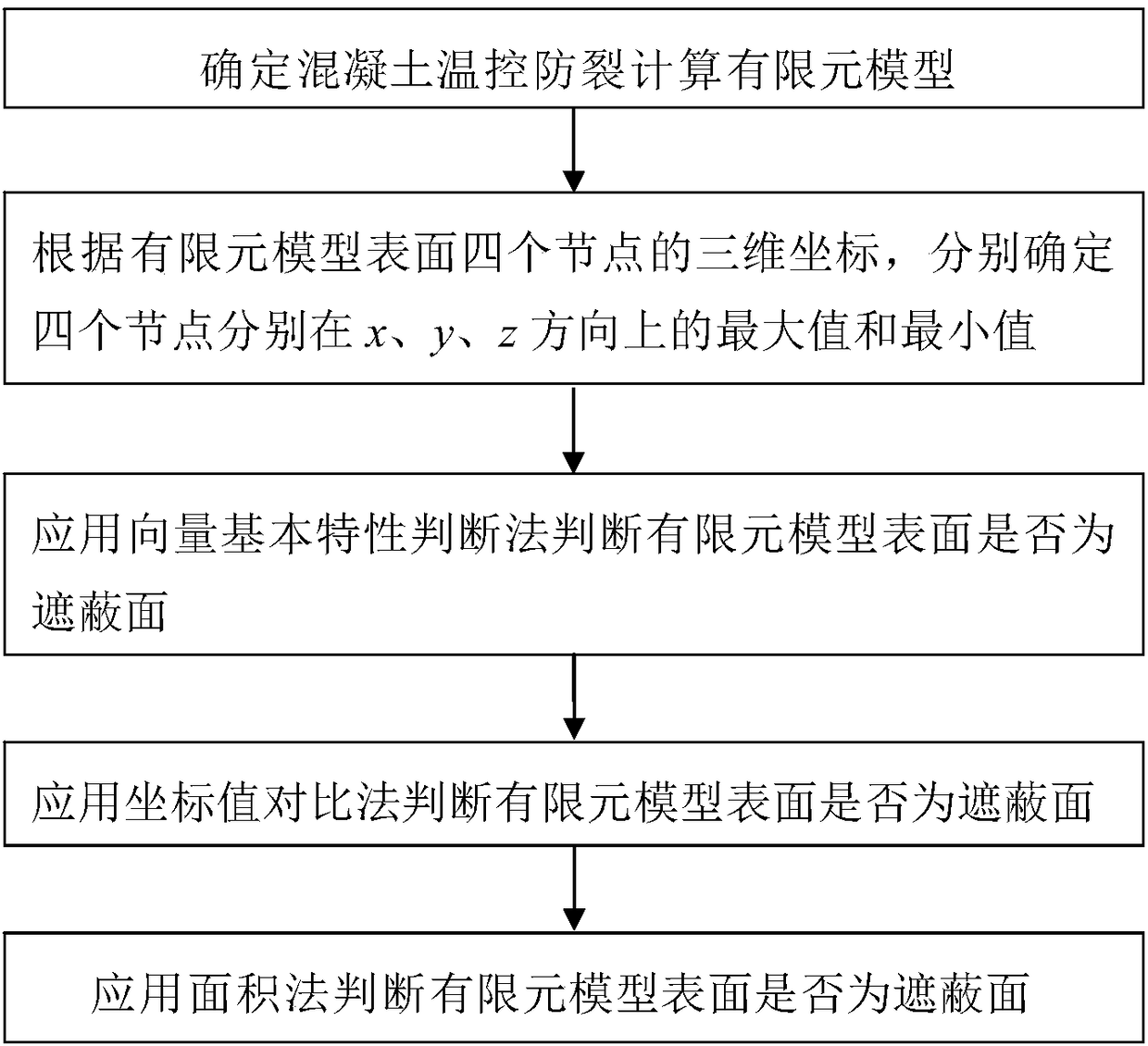

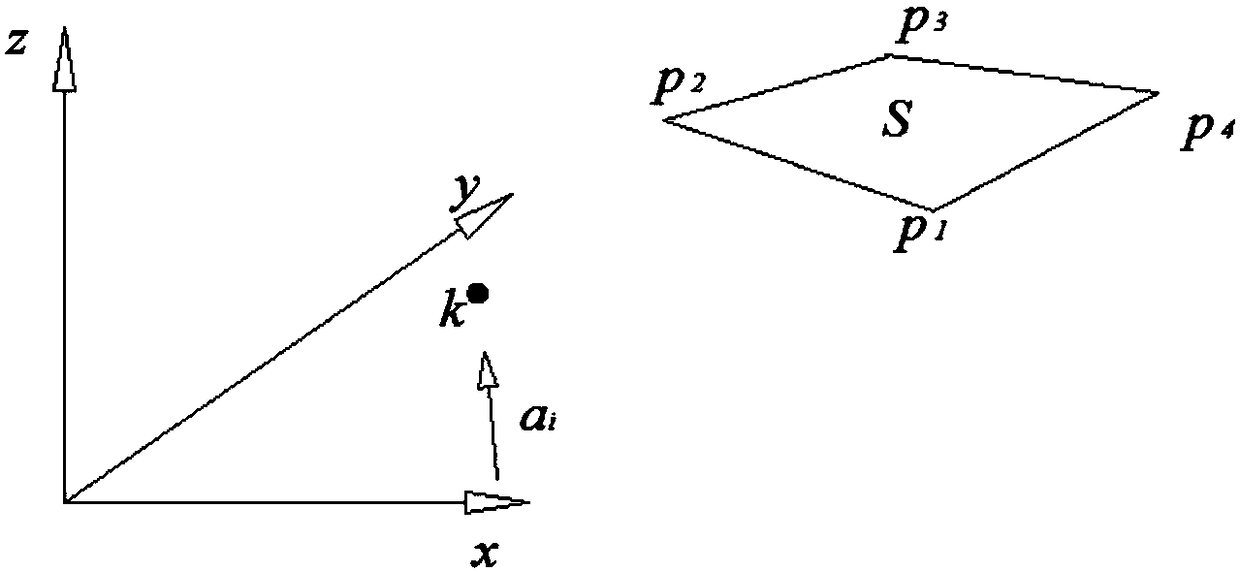

Finite-element-simulation solar ray shading computing method

ActiveCN108319792AEasy to implementComputationally efficientDesign optimisation/simulationSpecial data processing applicationsFinite element algorithmTemperature control

The invention provides a finite-element-simulation solar ray shading computing method. On the basis of the traditional shading algorithm, combined with the characteristics of the finite element algorithm, whether light rays which are emitted by finite element nodes and are same as angles of solar rays and are opposite to the direction of the solar rays are shaded by buildings or not is judged withthe screening excluding method, thus whether all the finite element nodes on the surfaces of a finite element model are irradiated by the sun or not is computed, it is achieved that judgment is carried out with the vector basic characteristic judgment method, the coordinate value correlation method and the area method in sequence, and whether all the surfaces of the finite element model are shading faces or not is screened. According to the finite-element-simulation solar ray shading computing method, finite element grids are fully combined, particularly, characteristics of high-arch-dam temperature control and crack prevention model grids are fully combined, the influence of solar radiation can be rapidly solved, the algorithm is easily achieved, computing is efficient, and the practicability is high; the finite-element-simulation solar ray shading computing method is applied to correlation computation of practical engineering, simulation computation is accurate, and the finite-element-simulation solar ray shading computing method can provide a scientific and reasonable data supporting basis for engineering application.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

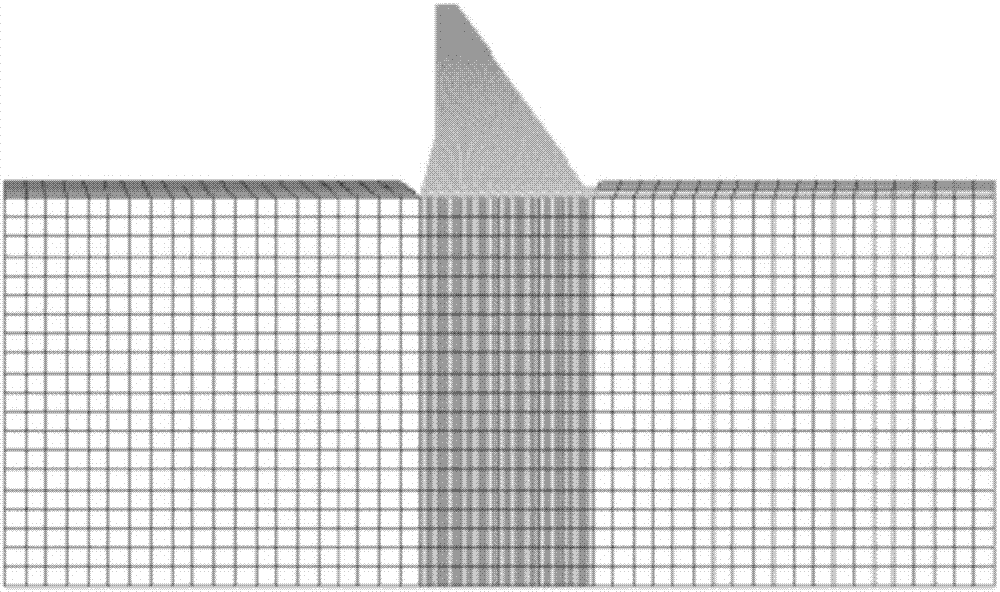

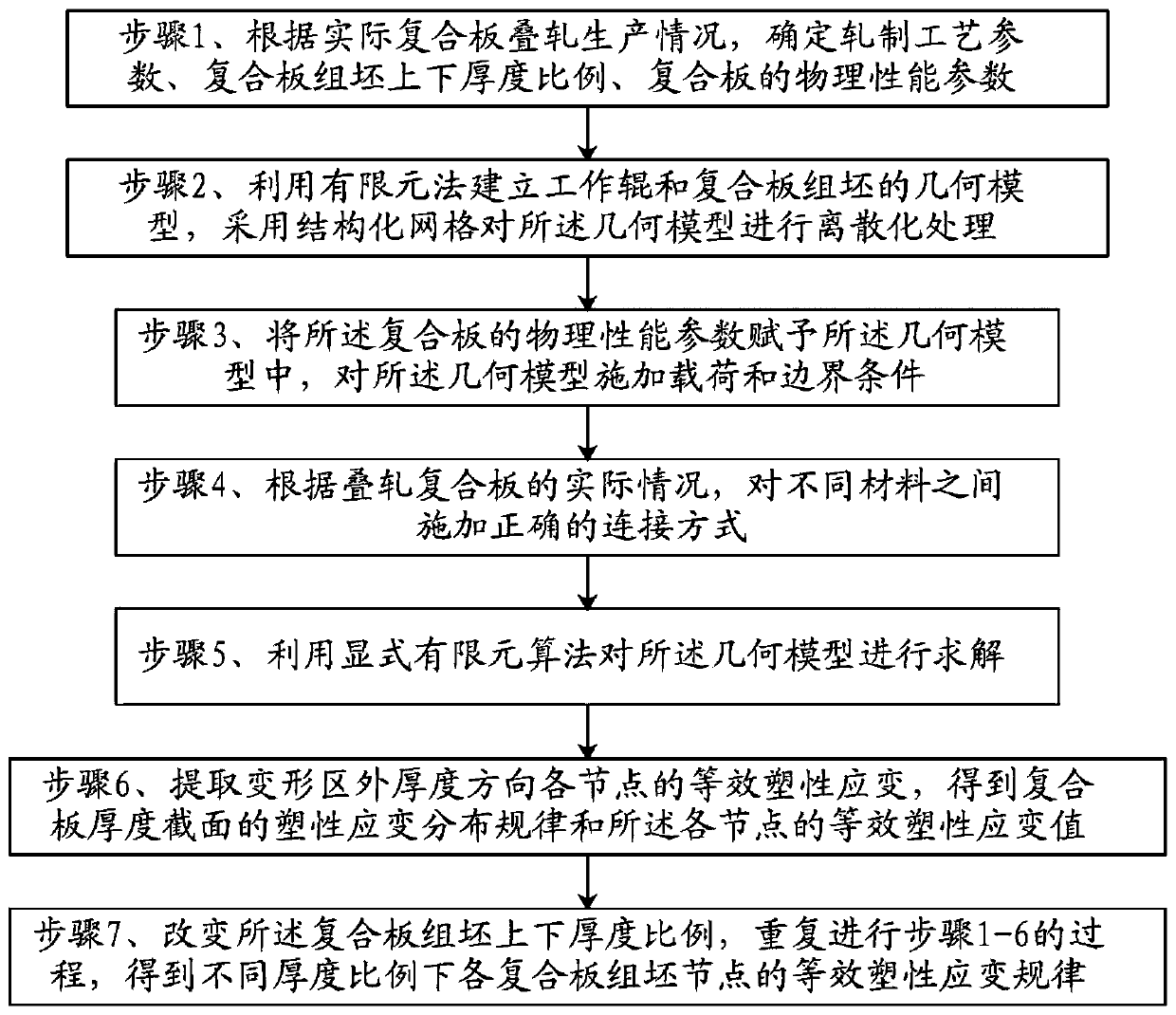

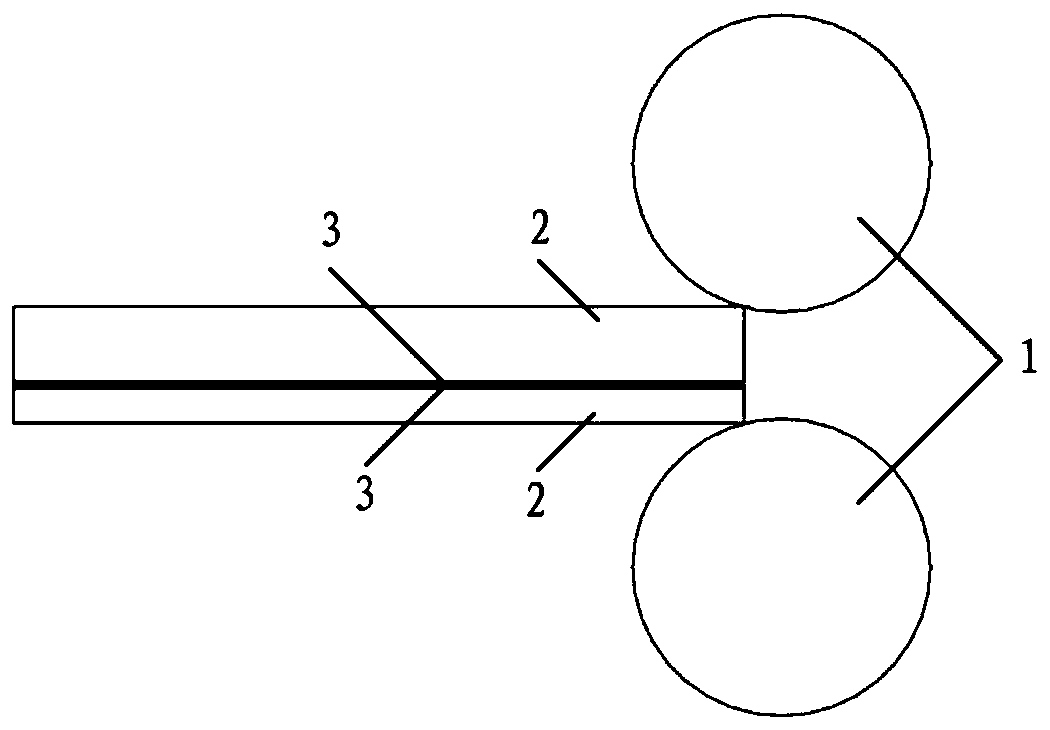

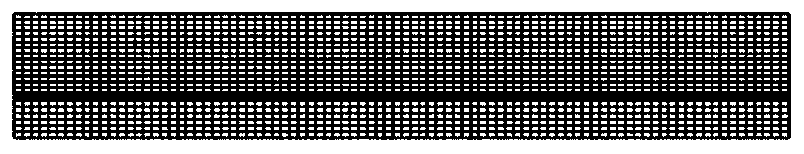

Method for predicting deformation penetration at bonding surface of asymmetric assembling rolling composite plate

ActiveCN110814028ASolve the technical problem of whether the deformation penetration is sufficient and difficult to predictTo achieve deformation penetration effectTemperature control deviceMetal rolling arrangementsFinite element algorithmGeometric modeling

The embodiment of the invention provides a method for predicting deformation penetration at a bonding surface of an asymmetric assembling rolling composite plate. The method comprises the following steps that performance parameters of the composite plate is determined according to actual conditions; a geometric model is established and subjected to discretization processing; the parameters are substituted into the model, and load and boundary conditions are applied to the model; a connection mode is selected according to the actual conditions; the model is solved through a finite element algorithm; a plastic strain distribution rule and a plastic strain value of each node are extracted; and a thickness ratio of the upper to lower of the composite plate is changed, and the above steps are repeated to obtain a plastic strain rule. The technical problem that in the prior art, the plate shape, the thickness uniformity and whether deformation penetration at the bonding surface is sufficiently are difficult to predict are solved. By adopting the finite element numerical simulation technology, the deformation penetration at the bonding surface of the asymmetric assembling rolling composite plate is subjected to regularity study, and the technical effect that whether the deformation penetration effect is achieved under the condition of assembling with different thickness proportions can be predicted is achieved.

Owner:SHOUGANG CORPORATION

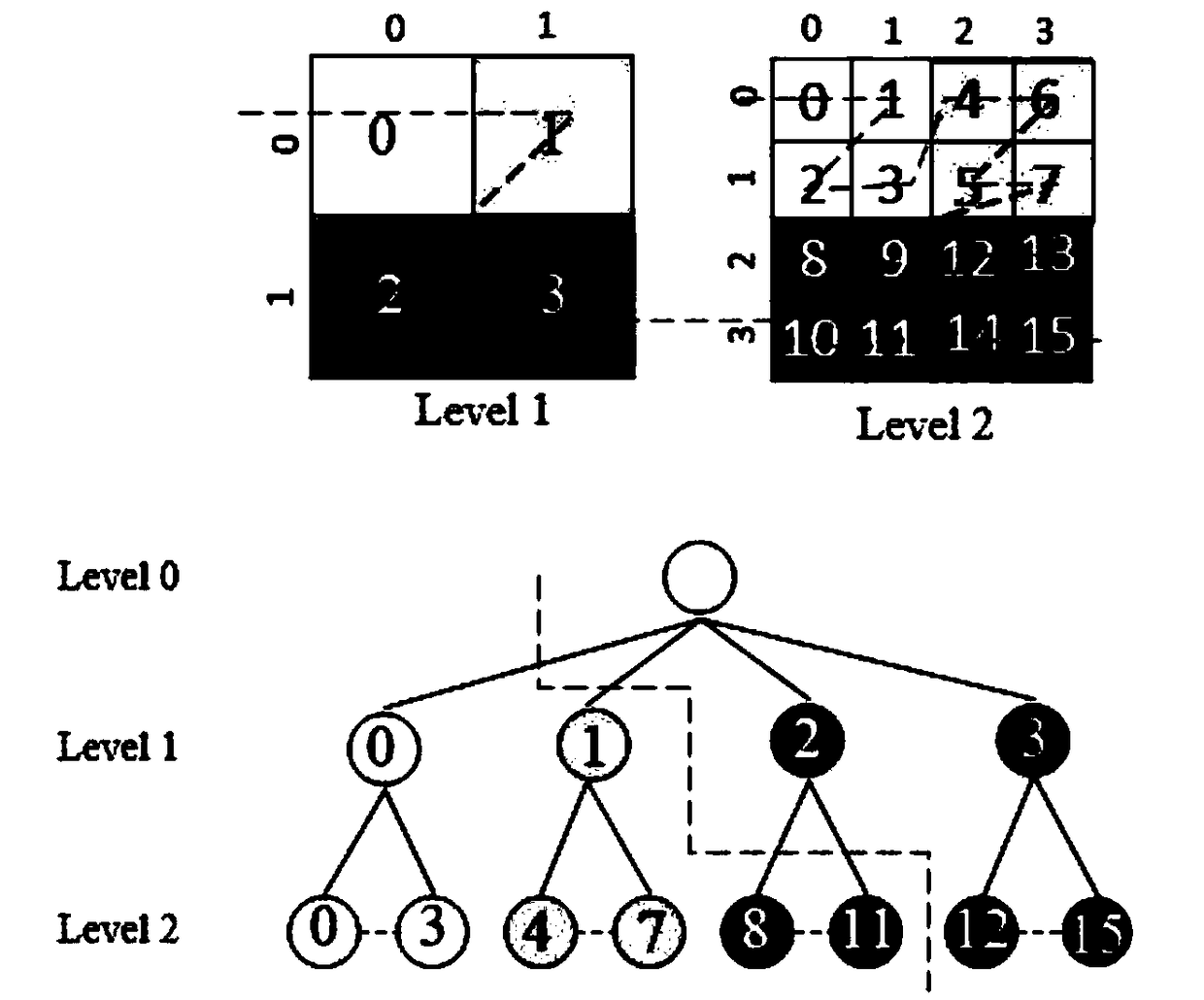

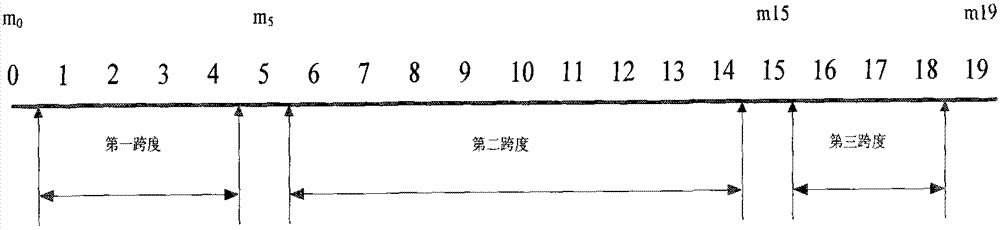

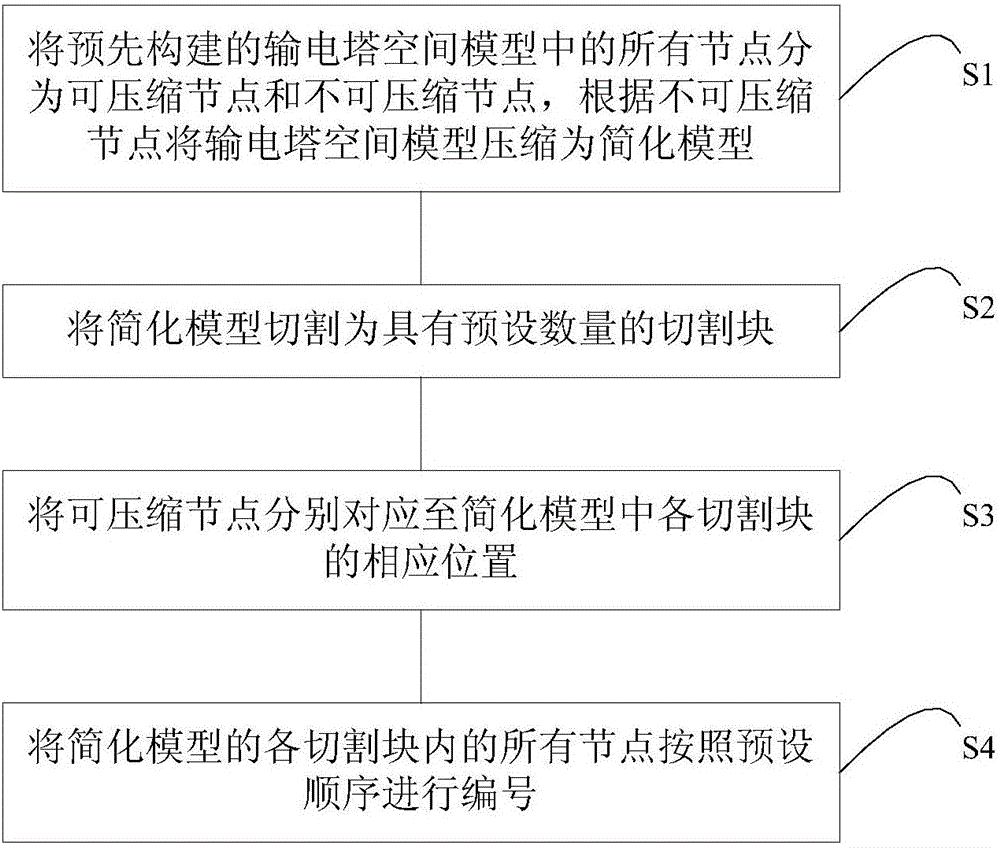

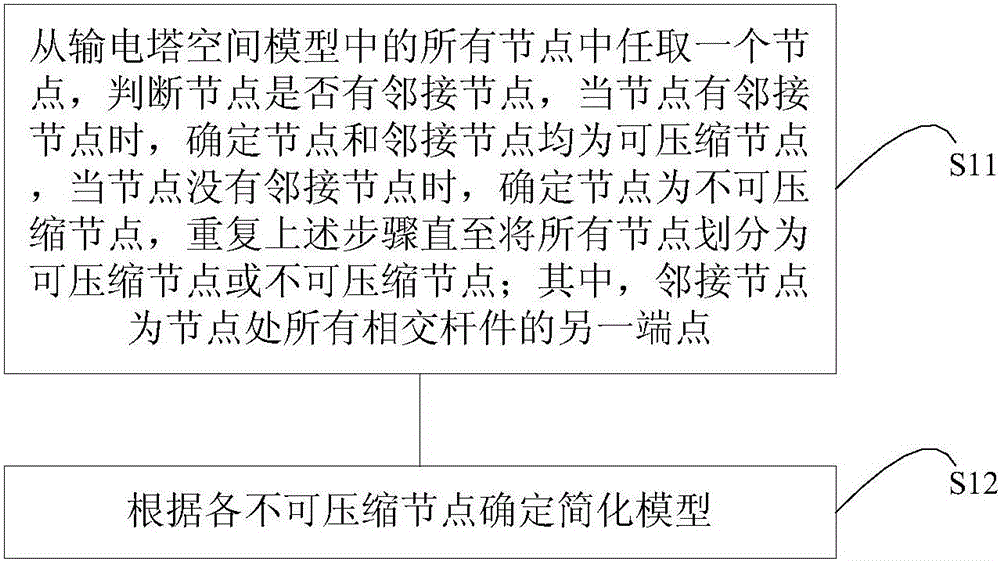

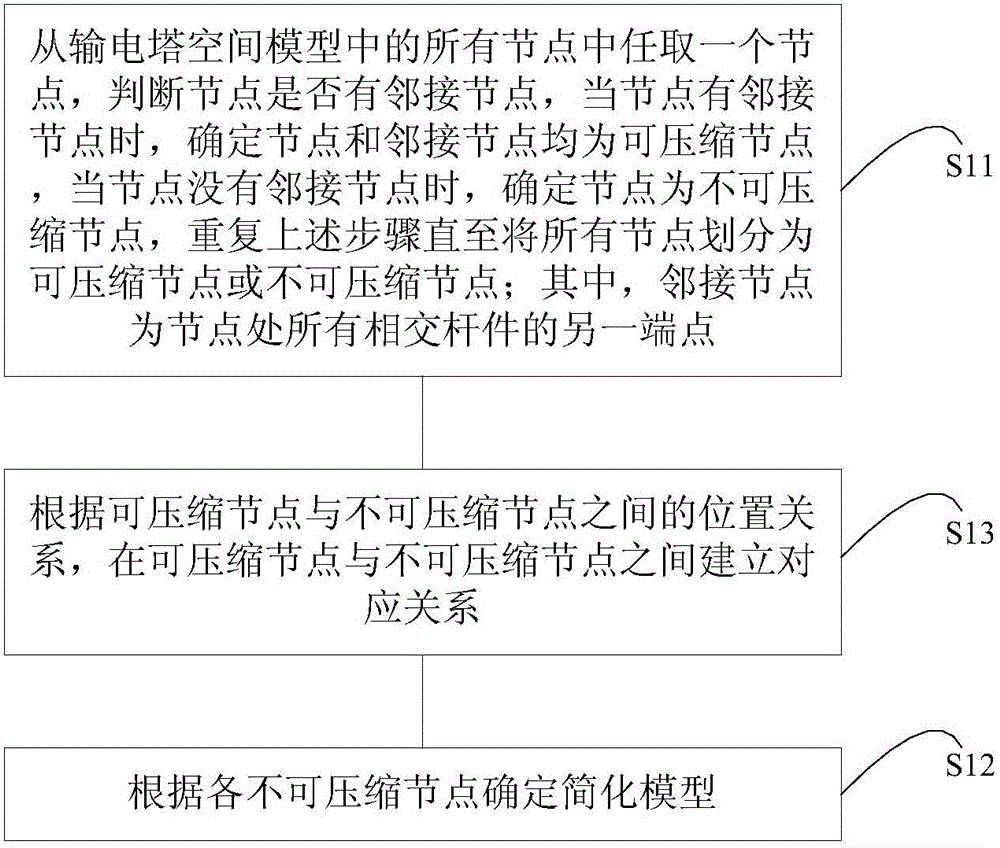

A power transmission tower node numbering method and device

ActiveCN106021657ASolve the problem that cannot be calculated normallyReduce workloadData processing applicationsDesign optimisation/simulationFinite element algorithmEngineering

The invention provides a power transmission tower node numbering method and device. The method comprises: a simplified model determining step: dividing all nodes in a power transmission tower space model established in advance into compressible nodes and incompressible nodes, and compressing the power transmission tower space model into a simplified model according to the incompressible nodes; a partitioning step: cutting the simplified model into cutting blocks with a preset number; a restoring step: making the compressible nodes correspond to the corresponding positions of the cutting blocks in the simplified model separately; a numbering step: number all the nodes in the cutting blocks of the simplified model according to a preset order. The method can meet the requirement for numbering differences in the finite element algorithm, guarantees the normal calculation of the finite element algorithm, is simple and practical, and can prevent mistakes and reduce the workload of checking; the partitioning is performed on the simplified model, so that the number of cut rod members of cutting surfaces during partitioning is small and the workload of the finite element algorithm is greatly reduced.

Owner:CHINA ELECTRIC POWER RES INST +2

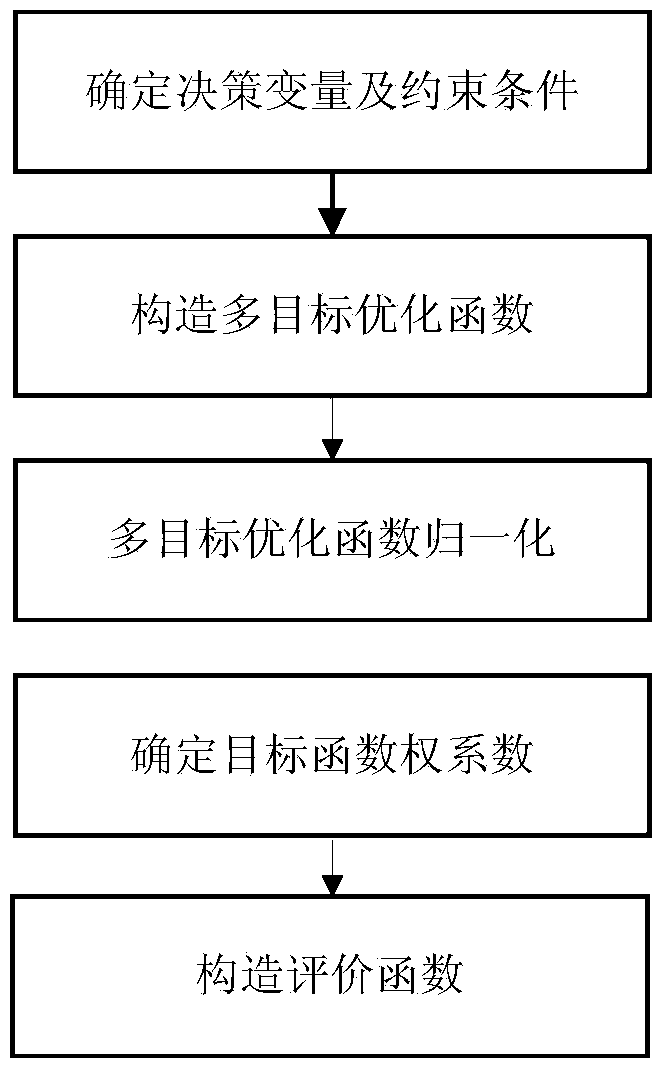

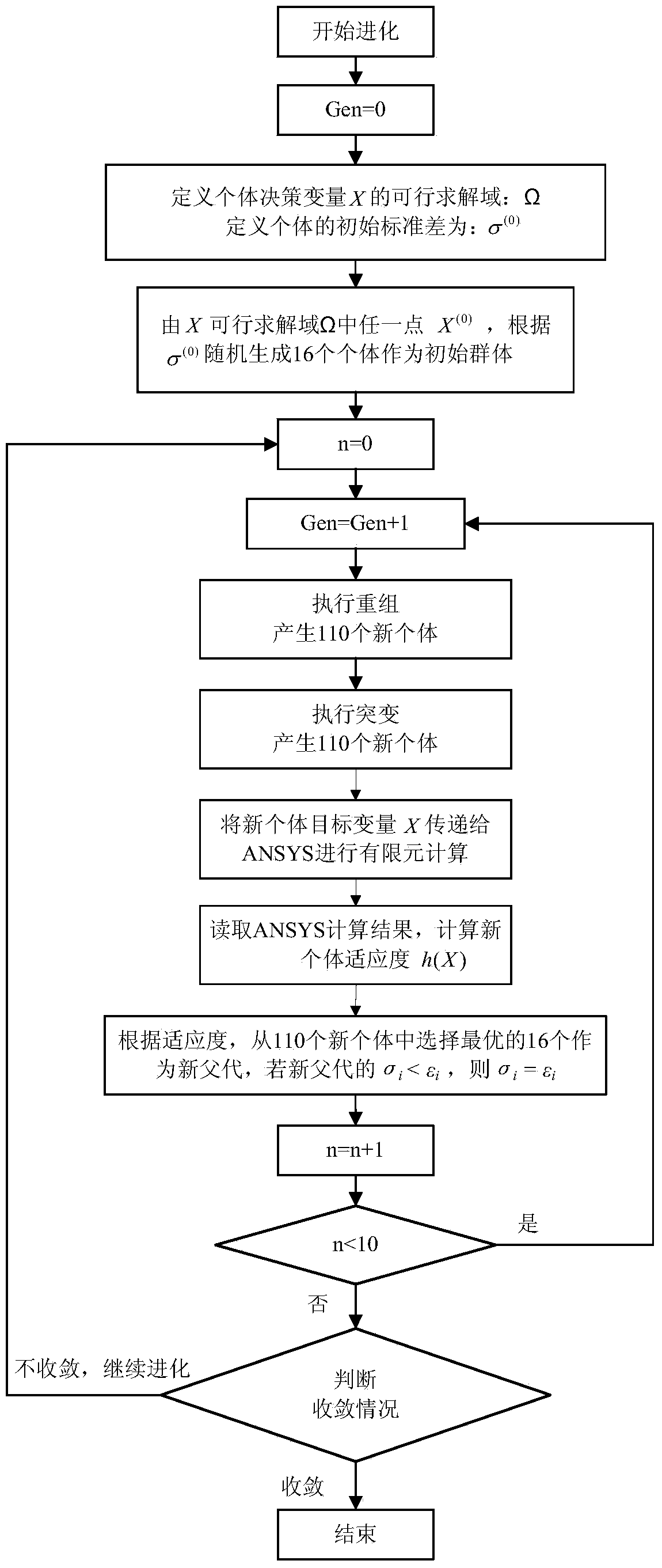

Multi-objective optimum design method of gas insulating bush based on evolutionary strategy

ActiveCN104112075AImprove insulation performanceIncrease flexibilitySpecial data processing applicationsFinite element algorithmEngineering

The invention discloses a multi-objective optimum design method of a gas insulating bush based on an evolutionary strategy. The method comprises the following steps of determining the decision variable and constraint condition of multi-objective optimization design of the gas insulating bush, and building an insulating structure to design a multi-objective optimization function, building evaluation functions of an insulating optimum structural design of the gas insulating bush; initializing evolutionary parental groups of the evaluation functions; generating offspring groups for the parental groups by recombination and mutation; invoking a finite element algorithm to calculate and compare the fitness of the evaluation functions of the offspring groups, and selecting to generate new parental groups; repeatedly iterating to generate new parental groups and offspring groups until the prescribed iteration times can be achieved; and calculating a convergence criterion to determine whether the iteration is continued, and outputting results if the iteration can be stopped. According to the method provided by the invention, a global optimal design scheme can be determined for the gas insulating bush structure, the optimal design level of the gas insulating bush structure can be greatly improved, and wide practicality can be realized.

Owner:XI AN JIAOTONG UNIV

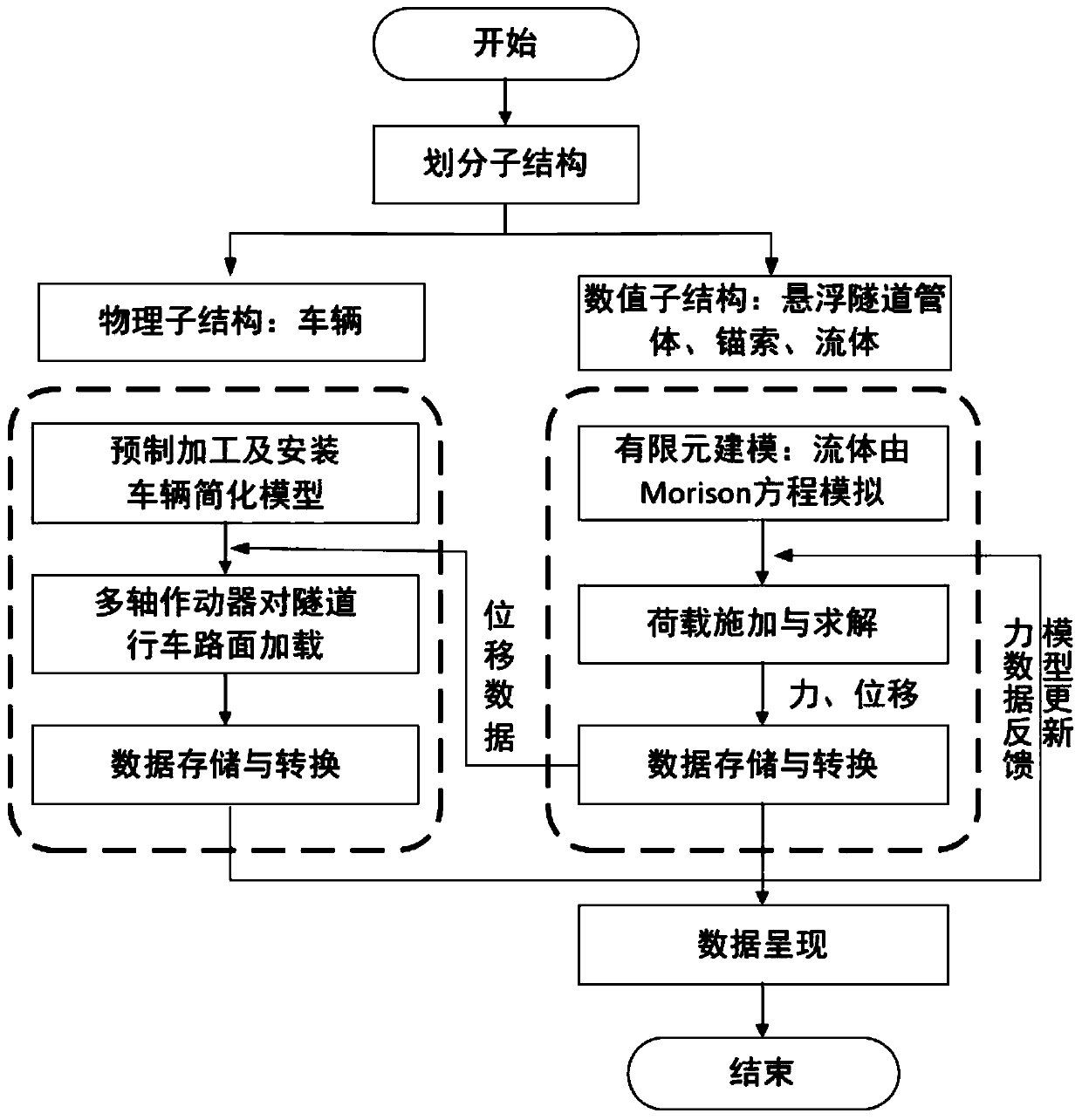

Suspension tunnel pipeline performance hybrid simulation test method and device

ActiveCN110263359AAvoid Modeling DifficultiesRelieve stressDesign optimisation/simulationSpecial data processing applicationsInteraction systemsScale model

The invention discloses a suspension tunnel pipeline performance hybrid simulation test method and device. The method is used for analyzing and researching dynamic characteristics of a suspension tunnel pipe body under vehicle-fluid action. The method comprises the following specific steps: dividing an integral structure into a physical substructure and a numerical substructure; based on a finite element algorithm or related software, establishing a numerical simulation model for the numerical substructure; prefabricating and installing the physical substructure according to a full-scale model or a reduced scale model; through a control system, a data interaction system and a data acquisition system, completing loading control on the physical substructure by the calculation information of the numerical substructure, and updating a model of the numerical substructure by the measurement information of the physical substructure; and finally, extracting required information through visual interface monitoring. The method solves the problem that the pure numerical algorithm is difficult to simulate the dynamic characteristics of the suspension tunnel under the action of complex loads, and also reduces the cost of the test technology and the requirements of site equipment and the like.

Owner:ZHEJIANG UNIV

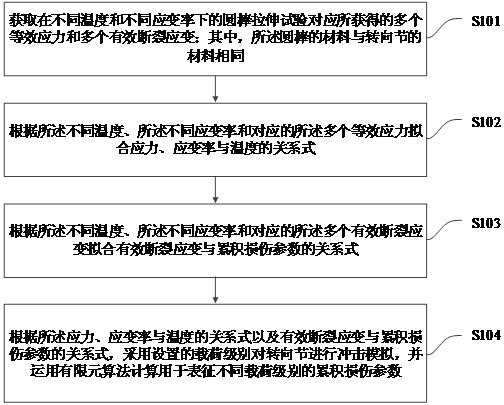

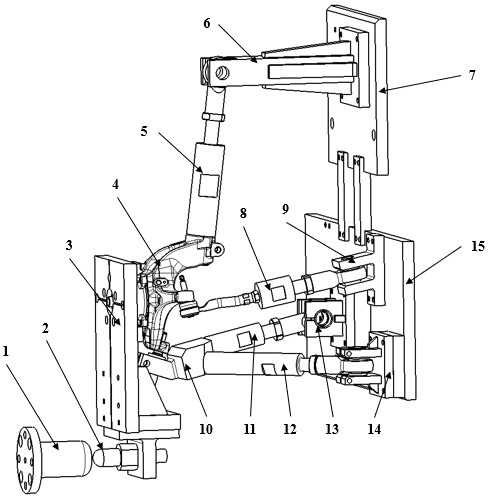

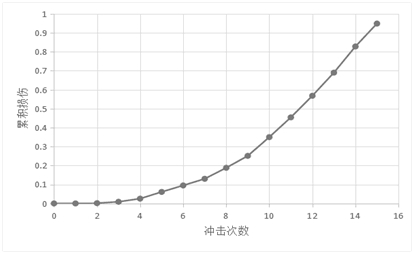

Dynamic load checking method and device for steering knuckle and computer storage medium

PendingCN111931410AAccurate response to damage accumulation fracture behaviorAccurately predict impact resistanceDesign optimisation/simulationSpecial data processing applicationsFinite element algorithmEngineering

The invention discloses a dynamic load checking method of a steering knuckle. The method comprises the following steps: acquiring a plurality of equivalent stresses and a plurality of effective fracture strains correspondingly acquired by round bar tensile tests at different temperatures and different strain rates; fitting a relational expression of the stress, the strain rate and the temperatureaccording to different temperatures, different strain rates and a plurality of corresponding equivalent stress; fitting a relational expression between the effective fracture strain and the accumulated damage parameter according to different temperatures, different strain rates and a plurality of corresponding effective fracture strains; and according to the relational expression of the stress, the strain rate and the temperature and the relational expression of the effective fracture strain and the accumulated damage parameter, adopting the set load level to perform impact simulation on the knuckle, and adopting a finite element algorithm to calculate the accumulated damage parameter used for representing different load levels. According to the dynamic load checking method and device forthe steering knuckle and the computer storage medium, the impact resistance of the steering knuckle can be accurately predicted, and the risk position can be found in advance to provide help for optimization design.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Installation construction process of bolt net rack cylindrical shell storage bin

ActiveCN102425326BImprove accuracyShorten the timeBuilding roofsBuilding material handlingFinite element algorithmStructural engineering

The invention discloses an installation construction process of a bolt net rack cylindrical shell storage bin, which is characterized by comprising the steps of: firstly, according to local meteorological conditions, obtaining sizes of net rack node rod members by adopting a CFD (Computational Fluid Dynamics) numerical value wind tunnel calculation technology and a finite element algorithm according to most disadvantageous conditions and tunnel physical parameters, namely, drawing a construction drawing by using a bulb diameter of each node and a geometric parameter of the rod members arranged on each node, wherein the construction drawing at least comprises a number of each node and the quantity of rod members of each node; and then dividing the construction step into a starting unit installation and an air overhanging unit installation. Due to no need of erecting an accomplished scaffold, the installation construction process has the characteristics of time and material saving, safety and reliability.

Owner:XUZHOU ZM BESTA HEAVY STEEL STRUCTURE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com