Method for predicting deformation penetration at bonding surface of asymmetric assembling rolling composite plate

A technology for rolling clad and clad plates, which is applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., and can solve the problems of sufficient deformation penetration and unpredictability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

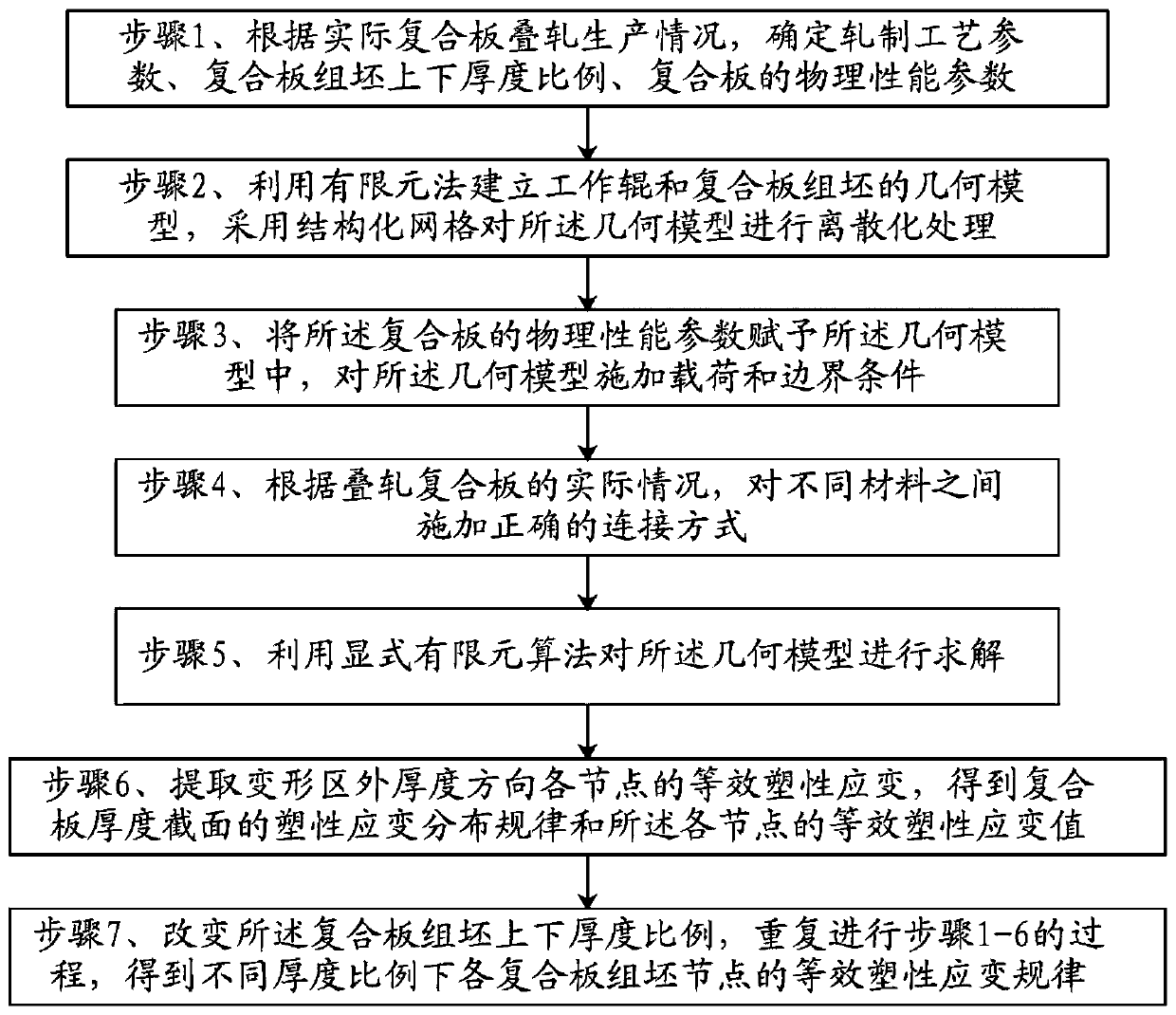

[0028] The embodiment of the present invention provides a method for predicting the deformation and penetration of the joint surface of the asymmetric billet rolled clad plate, please refer to Figure 1~6 , the method includes:

[0029] Step 1. Determine the rolling process parameters, the ratio of the upper and lower thicknesses of the composite slab blanks, and the physical performance parameters of the composite slab according to the actual composite slab stack rolling production situation;

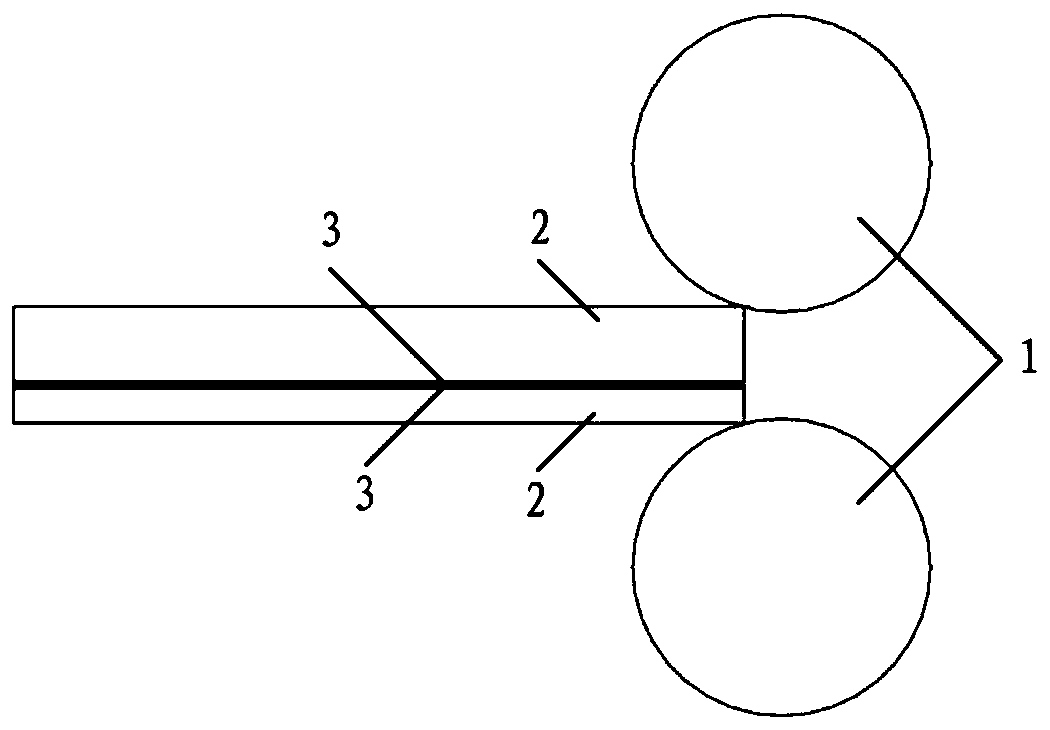

[0030] Specifically, the composite rolling process parameters include the billet size of the composite plate group, the total thickness of the rolling target, the diameter of the roll 1 of the rolling mill, the length of the roll 1, the quality of the roll 1, the speed of the track, the rotation speed of the roll 1, etc., and determine the composite The ratio of the upper and lower thicknesses of the panel blanks, the specifications of the composite board substrate 2 and the doubler bo...

Embodiment 1

[0058] Regarding the first embodiment, the embodiment of the present application also provides an implementation method for predicting the deformation penetration at the joint surface of the asymmetric billet rolled clad plate, which specifically includes:

[0059] If measured, the billet size of the composite plate assembly is: 2700mm (length) × 2400mm (width) × 430mm (thickness); the rolling target total thickness is 100mm. The roll diameter of the rolling mill: Ф1120mm, the roll length: 4600mm; the mass of a single roll is 124t, the track speed is 1.2m / s, and the roll speed: 20.8r / min, the process parameters are as follows:

[0060] Table 1 The ratio of the upper and lower thicknesses of the composite panel blanks, the specifications of the composite panel substrate and doubler panels

[0061]

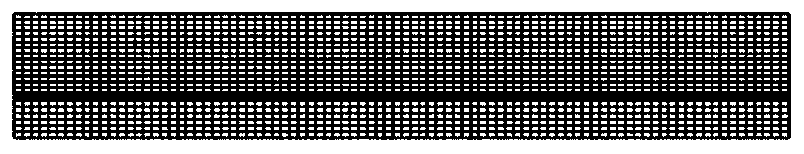

[0062] Using the finite element method to establish a 2D geometric model of the composite plate assembly, such as figure 2 , the finite element model after discretization of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com