Phase change material thermal buffering device and method for dissipating heat of high-power device

A phase-change material and high-power technology, applied in electric solid devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of high heat flux density, low operating temperature, small size, etc. Improve thermal conductivity and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

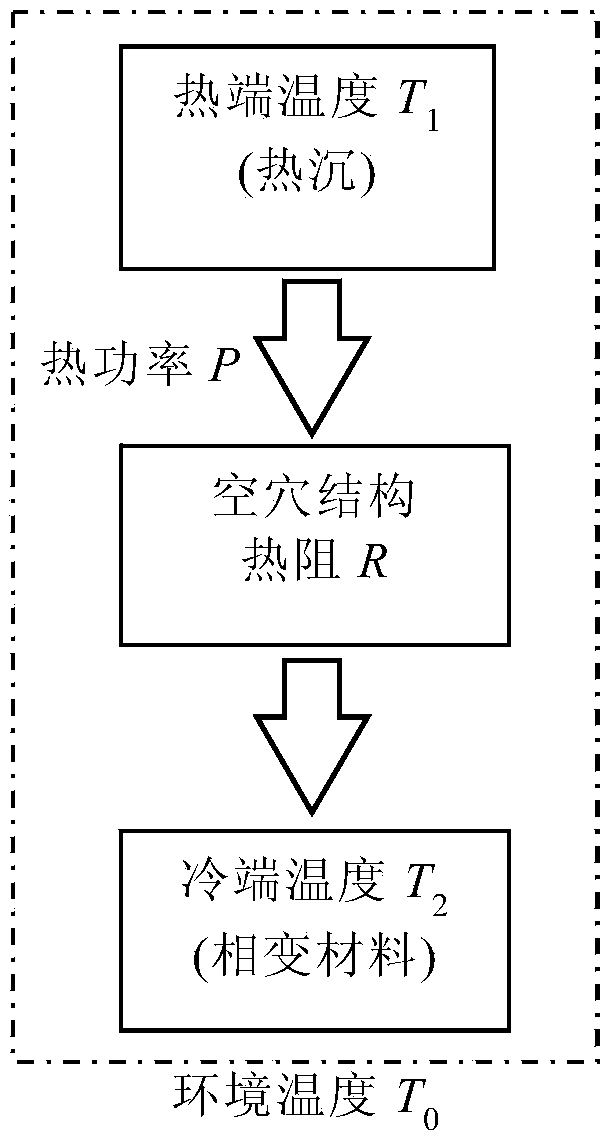

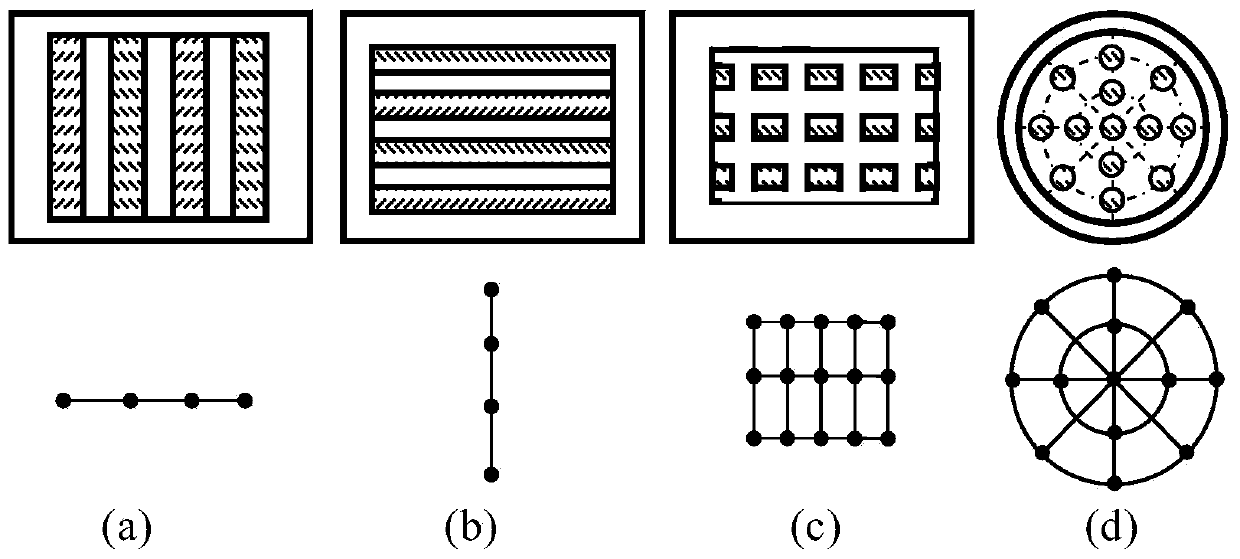

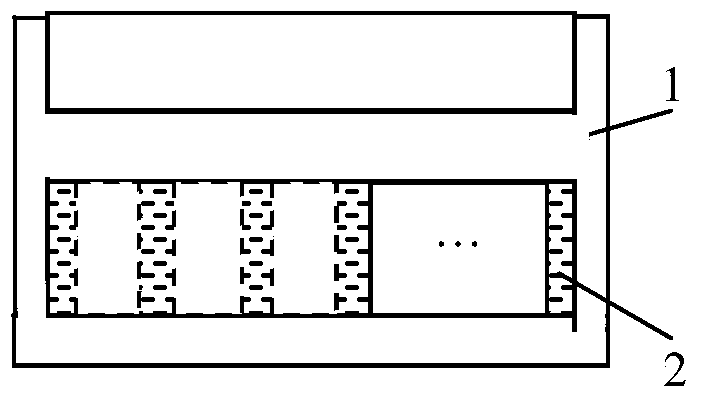

[0024] The method and device for thermal buffering of phase change materials according to the present invention will be described in detail below in conjunction with specific embodiments. Multiple LD pump sources of high-power lasers generate 2500W thermal power and work continuously for 3 minutes. The uniform arrangement of all LDs results in uniform heating of the circular heat sink with a diameter of 400 mm. The working temperature of LD is 20~30℃, and the working environment temperature is 0℃. It is required to keep the LD temperature within the normal working range within 3 minutes, and the total height of the thermal buffer device of the equipment should not exceed 40mm.

[0025] The heat P generated by the high-power laser is 2500W, and the working time t is 3min. The thermal power is too high, both air cooling and water cooling methods are difficult to export in time, a large amount of heat energy accumulated in the thermal diffusion device causes the LD temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com