Structural stress checking method of steam generator

A steam generator and structural stress technology, applied to the types of heat exchangers, heat exchanger shells, indirect heat exchangers, etc., can solve the problems of one-sided, complicated and difficult to promote the verification process, and achieve comprehensive and accurate verification results. accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present application is further described in conjunction with the following examples.

[0021] 1 Case and its stress analysis ideas

[0022] 1.1 Structural decomposition

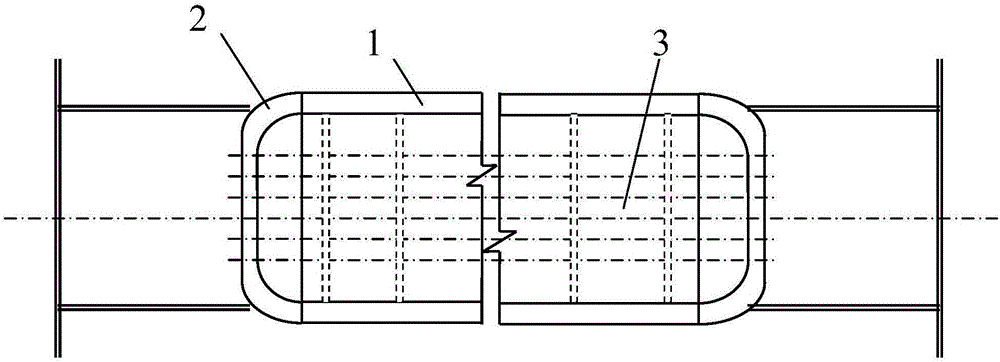

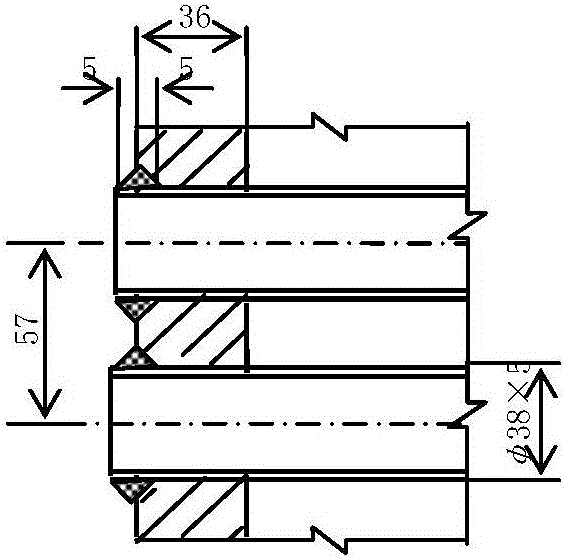

[0023] Schematic view of the main structure of the middle section of a steam generator figure 1 , ignoring the effect of the structure of the tube box at both ends, figure 1 For the connection structure between the middle flange (flexible thin tube sheet) and the shell figure 2 , the basic size is DN3400mm×68mm, and the design parameters are shown in Table 1.

[0024] Table 1 Design parameters

[0025]

[0026]

[0027] Decompose the main structure of the evaporator into four parts:

[0028] a The tube sheet 1 tube layout area supported by the tube bundle is simplified as a circular flat plate supported by the elastic foundation;

[0029] b tube bundle 3, elastic foundation;

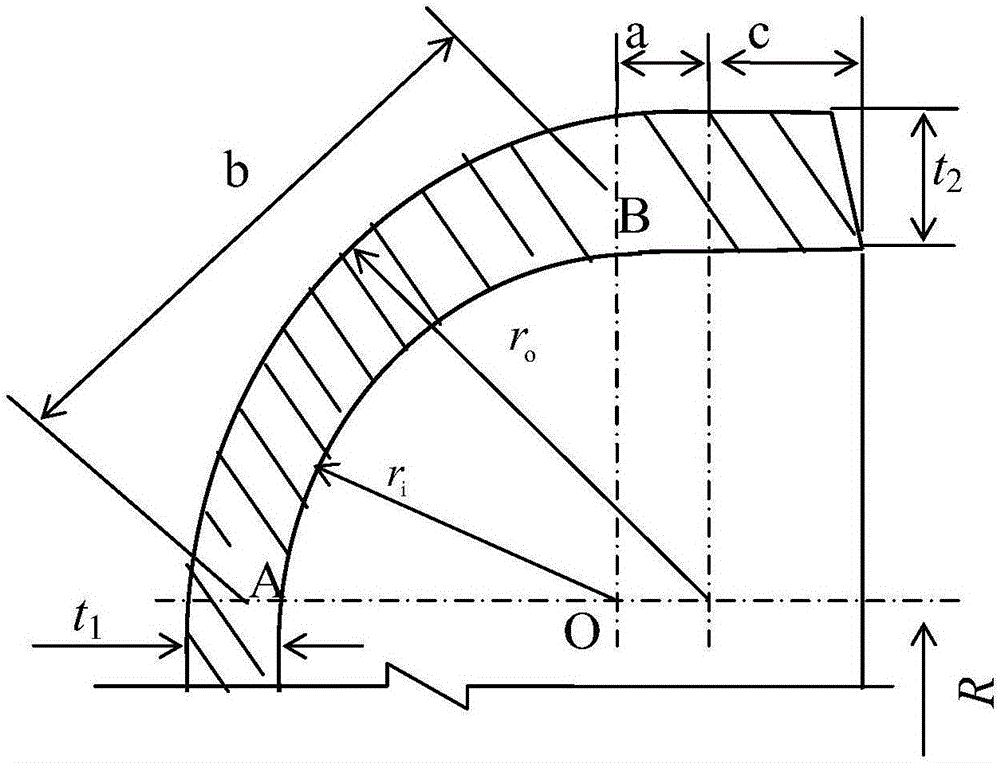

[0030] c The flange 2 transition zone around the tube sheet 1 is equivalent to a partial annular shell;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com