Construction process of ultra-large-span net-frame arch-shaped shed type storage silo

A construction process and storage bin technology, applied in the field of logistics equipment manufacturing, can solve the problems of large steel consumption, complex process, long cycle, etc., and achieve the effect of saving steel consumption, simplifying construction procedures and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

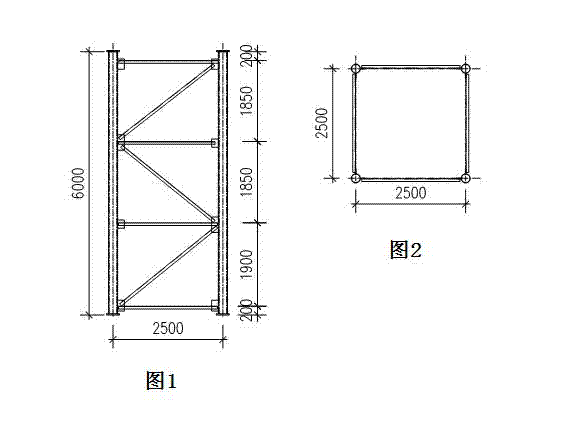

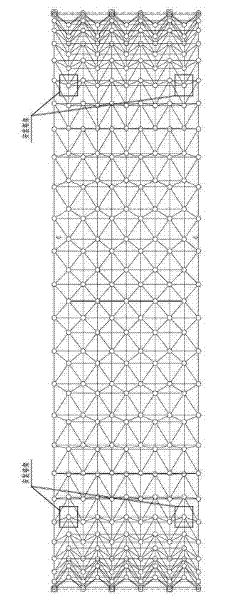

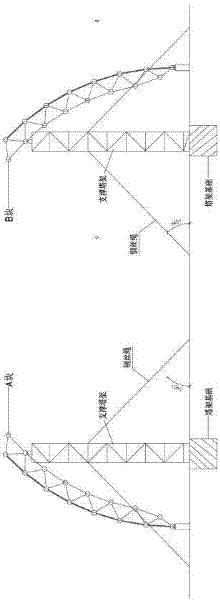

[0045] As shown in Figure 1-13.

[0046] A construction process for a super-large-span grid arch shed storage silo, which includes the following steps:

[0047] First, according to the local meteorological conditions, according to the most unfavorable meteorological conditions and the physical parameters of the shed, the span is more than 100 meters, the height is 60 meters, and the storage capacity is 80,000 tons. The size of the grid node rods is obtained by using CFD numerical wind tunnel calculation technology and finite element algorithm. , that is, the diameter of the ball head of each node and the geometric parameters of the rods installed on it, draw the construction drawings, which should at least include the number of each node and the number of rods at each node; the specific calculation method can be used The calculation method of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com