Vertical shaft hoist main shaft vibration detection method based on finite element analysis method

A technology of finite element and hoist, applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve problems such as low efficiency and inability to realize real-time monitoring, and achieve simple circuit, friendly interface, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

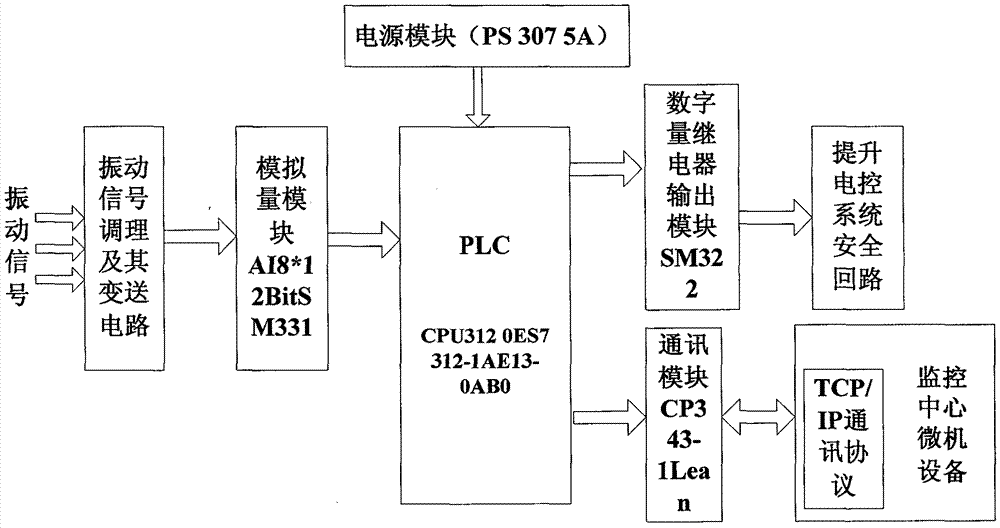

[0019] like figure 1 As shown, first, according to the special structure of the shaft hoist, an integrated vibration transmitter is used to detect the vibration frequency and amplitude of the main shaft of the hoist, and the transmitter is used to convert the vibration signal into a 4-20MA analog signal and send it to the S7- 300PLC, and after being processed by the PLC, the RS485 bus is converted into a TCP / IP Ethernet signal that can be recognized by the PC through the CP343-1LEAN bus converter, and then sent to the upper computer in the monitoring room through the underground ring network, and the upper computer in the upper computer The Kingview software receives and transmits to the finite element algorithm model of the built-in MATLAB software, obtains more accurate early warning of future development trends through calculation, and displays the data on the host computer in real time, and monitors the safety of the hoist in real time through the PC in the monitoring room ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com