Copper, aluminium, stainless steel composite brazing method

A technology of stainless steel and stainless steel sheets, applied in welding equipment, high-frequency current welding equipment, metal processing equipment, etc., can solve problems such as not being able to meet the use requirements, and achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

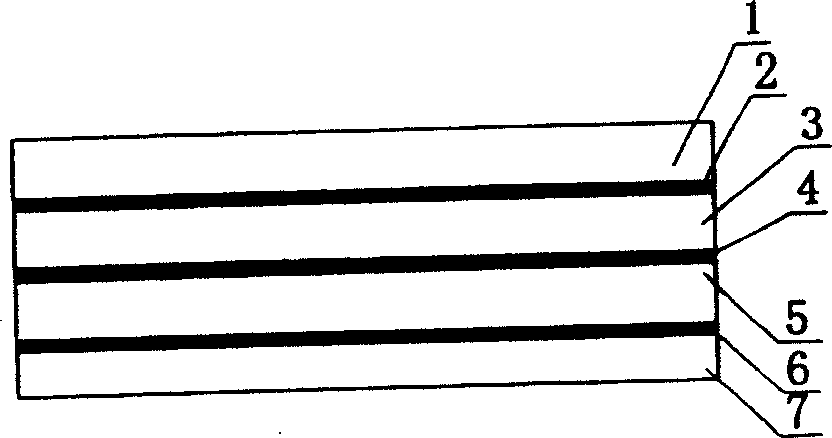

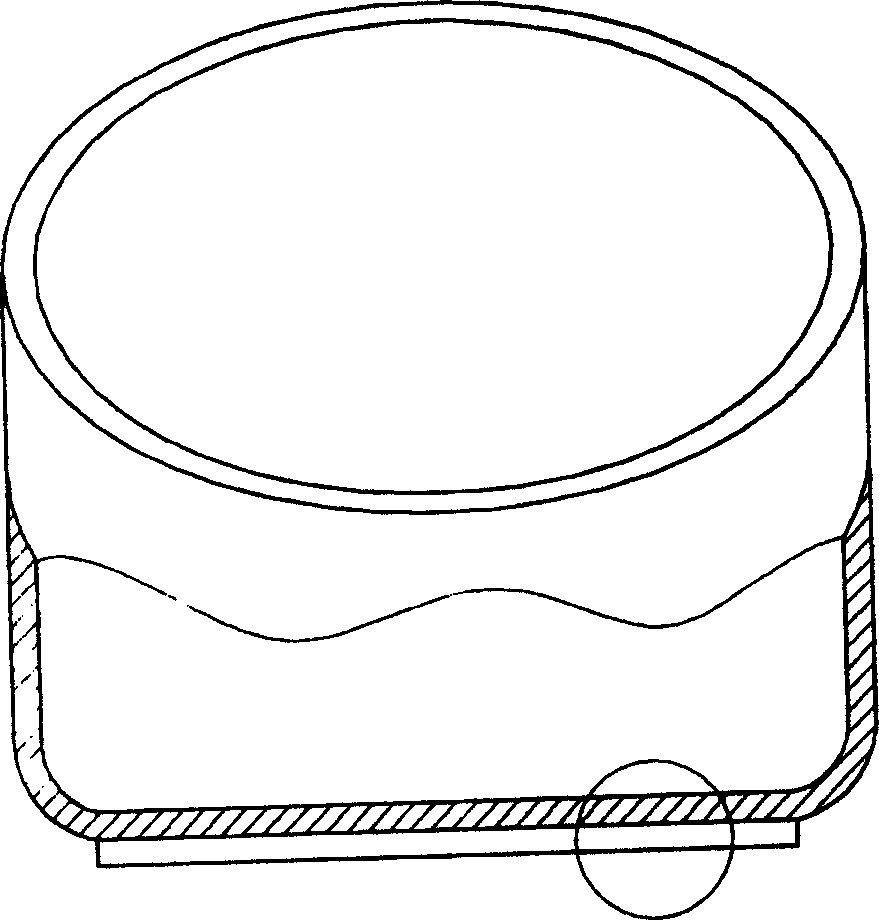

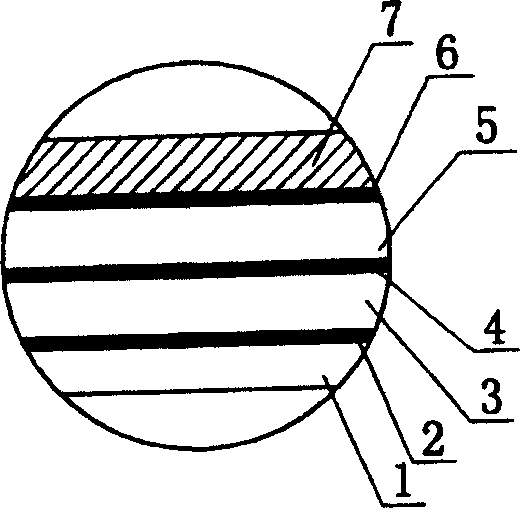

[0022] Using the present invention as figure 2 , image 3 As shown, 0.2mm stainless steel sheet is used as the transition layer, the thickness of the brazing copper sheet is 0.5mm, the thickness of the aluminum sheet is 3mm, and 200 stainless steel sandwich pans with a thickness of 0.5mm and a diameter of 180mm. The post-welding visual inspection and percussion inspection are all qualified. All dry firing tests were done, 1 weld was cracked, and 199 were qualified. The pass rate is not less than 99%. (The pass rate requirement for brazing stainless steel-aluminum-stainless steel sandwich pans is not less than 98%)

Embodiment 2

[0024] Using the present invention as figure 2 , image 3 As shown, use 0.2mm stainless steel sheet as the transition layer, brazing copper sheet thickness 0.6mm, aluminum sheet thickness 2.4mm, 200 stainless steel sandwich pans with a thickness of 0.6mm and a diameter of 280mm. The post-welding visual inspection and percussion inspection are all qualified. All dry firing tests were done, 2 welds were cracked, and 198 were qualified. The pass rate is not less than 99%.

Embodiment 3

[0026] Adopt the present invention, use 0.3mm stainless steel bottom sheet to make transition layer, brazing copper sheet bag bottom sheet thickness 0.6mm, aluminum plate thickness 3mm, thickness 0.6mm diameter is 200 stainless steel bottom pans of 240mm. After welding, the visual inspection was all qualified, and one product was found to be defective by knocking inspection. 199 workpieces were dry-fired, 3 welds were cracked, and 196 were qualified. The pass rate is not less than 96%. (The qualification rate of the brazing stainless steel-aluminum-stainless steel clad bottom pan is not less than 98%).

[0027] The present invention adopts the transition layer of stainless steel sheets arranged between copper and aluminum, which can complete the brazing of multiple different metals at one time, with high controllability of product quality and a yield of more than 98%. The cost can be reduced, and the appearance quality of the product can be ensured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com