Polystyrene sheet and preparation method thereof

A polystyrene sheet, polystyrene technology, applied in the field of polystyrene sheet and its preparation, can solve the problems of sacrificing material rigidity and heat resistance, achieve easy stacking, increase toughness, and good light transmittance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

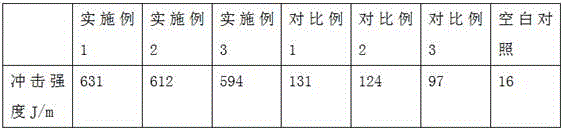

Examples

Embodiment 1

[0018] A polystyrene sheet, the raw material composition of the polystyrene sheet includes by weight: 90 parts of polystyrene, 9 parts of black masterbatch, 9 parts of filler, 8 parts of toughening agent, 1 part of dispersant part, 0.1 part of antistatic agent; the toughening agent is ABS, SBS, and talcum powder mixed in a weight ratio of 4:3:1; the particle diameter of the talcum powder is 50nm.

[0019] A preparation method for a polystyrene sheet, specifically comprising the steps of:

[0020] (1) Fully stir all the raw materials according to the stated weight parts to obtain a mixture, and dry the mixture;

[0021] (2) Feed the dried mixture in step (1) into the extruder, melt and extrude through the extruder, and control the melting temperature at 150°C;

[0022] (3) After the impurities are filtered out by the filter, the molten material in step (2) is sent to the die for extrusion, and cast into a thick sheet, and the temperature in the die is controlled at 180°C;

[...

Embodiment 2

[0027] A polystyrene sheet, the raw material composition of the polystyrene sheet includes by weight: 88 parts of polystyrene, 8 parts of black masterbatch, 8 parts of filler, 7 parts of toughening agent, 0.8 parts of dispersant part, 0.1 part of antistatic agent; the toughening agent is ABS, SBS, and talcum powder mixed in a weight ratio of 4:3:1; the particle diameter of the talcum powder is 80nm.

[0028] A preparation method for a polystyrene sheet, specifically comprising the steps of:

[0029] (1) Fully stir all the raw materials according to the stated weight parts to obtain a mixture, and dry the mixture;

[0030] (2) Feed the dried mixture in step (1) into the extruder, melt and extrude through the extruder, and control the melting temperature at 160°C;

[0031] (3) After the impurities are filtered out by the filter, the molten material in step (2) is sent to the die for extrusion, and cast into a thick sheet, and the temperature in the die is controlled at 190°C; ...

Embodiment 3

[0036] A polystyrene sheet, the raw material composition of the polystyrene sheet includes by weight: 85 parts of polystyrene, 7 parts of black masterbatch, 7 parts of filler, 6 parts of toughening agent, 0.5 parts of dispersant part, 0.1 part of antistatic agent; the toughening agent is ABS, SBS, and talcum powder mixed in a weight ratio of 4:3:1; the particle diameter of the talcum powder is 100nm.

[0037] A preparation method for a polystyrene sheet, specifically comprising the steps of:

[0038] (1) Fully stir all the raw materials according to the stated weight parts to obtain a mixture, and dry the mixture;

[0039] (2) Feed the dried mixture in step (1) into the extruder, melt and extrude through the extruder, and control the melting temperature at 180°C;

[0040] (3) After the impurities are filtered out by the filter, the molten material in step (2) is sent to the die for extrusion, and cast into a thick sheet, and the temperature in the die is controlled at 200°C; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com