A kind of zirconium-containing mullite composite phase material and preparation method thereof

A zirconium-mullite and raw material technology, applied in the field of zirconium-containing mullite composite materials and its preparation, can solve the problems of unfavorable industrial production, complex production process, high cost, etc., and achieve the convenience of industrial production, simple production process, and improved The effect of using the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A zirconium-containing mullite composite phase material and a preparation method thereof. First mix waste molding sand and bauxite as raw materials, and the Al in the raw materials 2 o 3 : SiO 2 The mass ratio is (2.6~2.8)︰1; add 40~45wt% water and 2~3wt% polyvinyl alcohol of the raw materials, and ball mill for 8~10h; then the ball milled slurry is spray granulated, machine pressed Molding, the molded green body is kept at 1600~1650°C for 3~4 hours, and cooled naturally to obtain the zirconium-containing mullite composite material.

[0020] In the present embodiment: the Al of the waste molding sand 2 o 3 Content 30~32wt%, SiO 2 Content 58~60wt%, ZrO 2 Content 5.8 ~ 6.1wt%; Al of the bauxite 2 o 3 Content 80~83wt%, SiO 2 The content is 11~13wt%; the pressure of machine pressing is 70~80MPa.

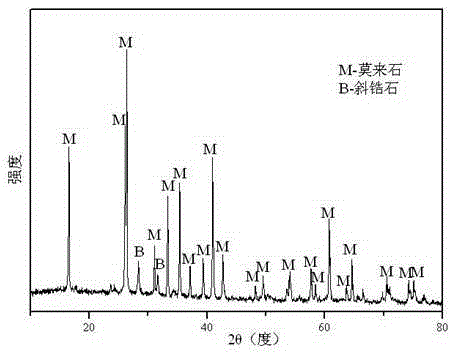

[0021] The zirconium-containing mullite composite material prepared in this example is analyzed by X-ray diffraction: the main crystal phase is mullite; the secondary ...

Embodiment 2

[0023] A zirconium-containing mullite composite phase material and a preparation method thereof. First mix waste molding sand and bauxite as raw materials, and the Al in the raw materials 2 o 3 : SiO 2 The mass ratio is (2.6~2.8)︰1; add 45~50wt% water and 2~3wt% polyvinyl alcohol of the raw materials, and ball mill for 8~10h; then the ball milled slurry is spray granulated, machine pressed Molding, the formed green body is kept at 1600~1650°C for 4~5 hours, and cooled naturally to obtain the zirconium-containing mullite composite material.

[0024] In the present embodiment: the Al of the waste molding sand 2 o 3 Content 32~35wt%, SiO 2 Content 55~58wt%, ZrO 2 Content 5.8 ~ 6wt%; Al of the bauxite 2 o 3 Content 80~82wt%, SiO 2 The content is 10~13wt%; the pressure of machine pressing is 60~70MPa.

[0025] The zirconium-containing mullite composite material prepared in this example is analyzed by X-ray diffraction: the main crystal phase is mullite; the secondary cr...

Embodiment 3

[0027] A zirconium-containing mullite composite phase material and a preparation method thereof. First mix waste molding sand and bauxite as raw materials, and the Al in the raw materials 2 o 3 : SiO 2 The mass ratio is (2.6~2.8)︰1; add 45~50wt% water and 3~4wt% polyvinyl alcohol of the raw materials, and ball mill for 7~9h; then the slurry after ball milling is spray granulated, machine pressed Molding, the molded green body is kept at 1650~1700°C for 3~4 hours, and cooled naturally to obtain the zirconium-containing mullite composite material.

[0028] In the present embodiment: the Al of the waste molding sand 2 o 3 Content 35~38wt%, SiO 2 Content 52~55wt%, ZrO 2 Content 6 ~ 6.3wt%; Al of the bauxite 2 o 3Content 78~80wt%, SiO 2 The content is 13~15wt%; the pressure of machine pressing is 80~90MPa.

[0029] The zirconium-containing mullite composite material prepared in this example is analyzed by X-ray diffraction: the main crystal phase is mullite, and the sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com