Unsaturated polyester resin coating and preparation method thereof

A polyester resin and unsaturated technology, applied in the field of unsaturated polyester resin coatings and their preparation, can solve the problem of large curing shrinkage of unsaturated polyester resins, affecting the decorative effect and protective effect of coatings on furniture, and cracking of paint films. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

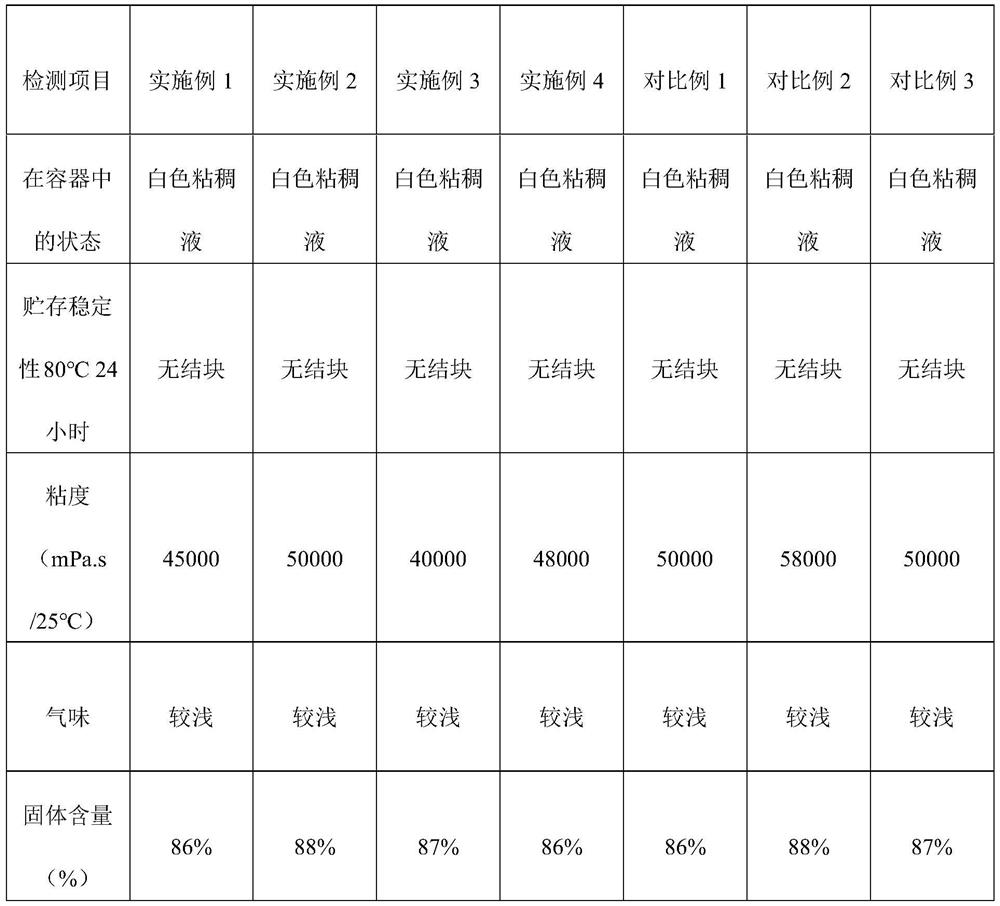

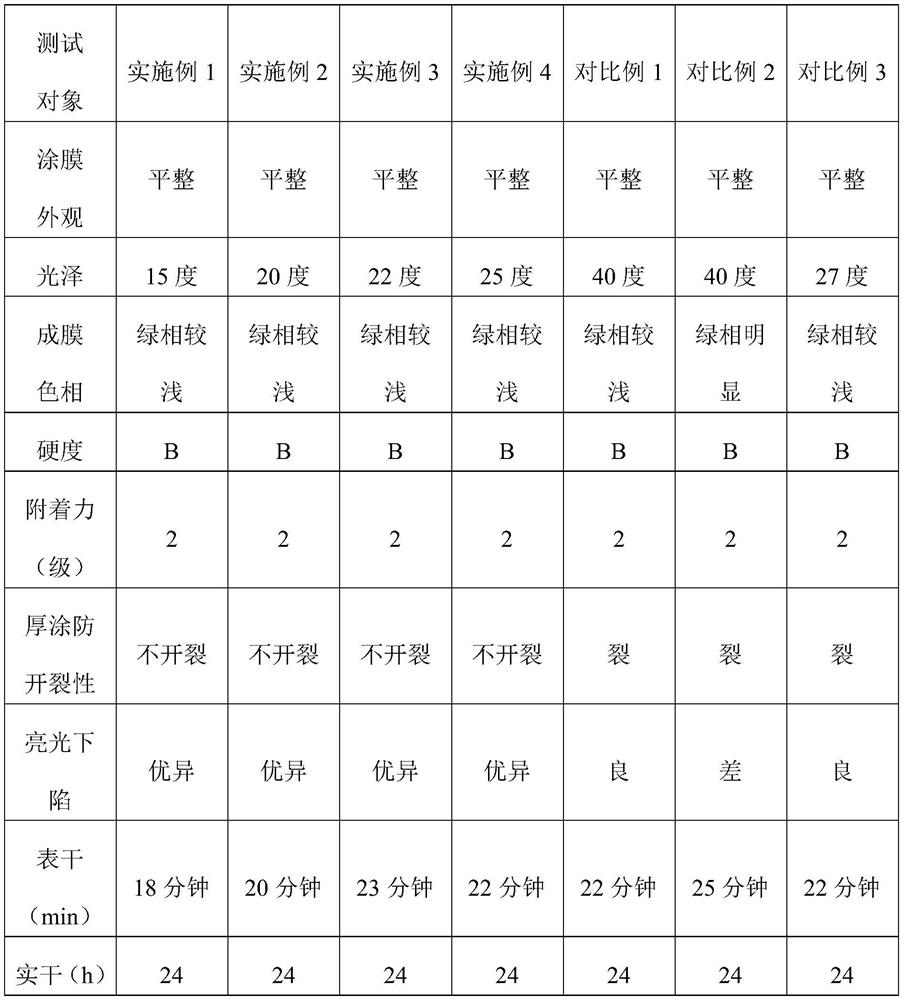

Examples

preparation example Construction

[0115] A preparation method for unsaturated polyester resin coating, comprising the following steps:

[0116] The preparation process of component A: mix the air-drying unsaturated polyester resin, thermoplastic acrylic resin, dispersant, filler, auxiliary agent and styrene under the condition of 1300 rpm-1500 rpm Stir for 10min-20min;

[0117] The preparation process of component B: mix the diluted monomer and solvent, and stir for 5min-10min under the condition of 300rpm-500rpm;

[0118] The components A, B, C and D are mixed according to the designed mass ratio and reacted.

Embodiment 1

[0131] This embodiment provides an unsaturated polyester resin coating and a preparation method thereof.

[0132] (1) The composition of unsaturated polyester resin coating 1:

[0133] The mass ratio of component A, component B, component C and component D is: 100:25:1:1.2;

[0134] Component A is prepared from the following raw materials in mass percentage: 25% of dicyclopentadiene-modified air-drying unsaturated polyester, 8% of thermoplastic acrylic resin, 0.5% of dispersant, 31% of heavy calcium carbonate, talcum powder 10%, barium sulfate 10%, titanium dioxide 10%, leveling agent 0.499%, defoamer 0.5%, anti-settling agent 0.5%, polymerization inhibitor 0.001%, zinc stearate 1% and styrene 3%;

[0135] Component B is prepared from the following raw materials in mass percentage: styrene 38.099%, xylene 31.9%, ethyl acetate 30%, polymerization inhibitor 0.001%;

[0136] C component: cobalt isooctanoate;

[0137] Component D: methyl ethyl ketone peroxide.

[0138] (2) pre...

Embodiment 2

[0143] This embodiment provides an unsaturated polyester resin coating and a preparation method thereof.

[0144] (1) The composition of unsaturated polyester resin coating 2:

[0145] The mass ratio of component A, component B, component C and component D is: 100:25:1:1.2;

[0146] Component A is prepared from the following raw materials in mass percentage: 25% of dicyclopentadiene modified air-drying unsaturated polyester, 7% of thermoplastic acrylic resin, 0.5% of dispersant, 28.2% of heavy calcium carbonate, talcum powder 15%, barium sulfate 8%, titanium dioxide 10%, leveling agent 0.299%, defoamer 0.4%, anti-settling agent 0.6%, polymerization inhibitor 0.001%, zinc stearate 1% and styrene 4%;

[0147] Component B is prepared from the following raw materials in mass percentage: styrene 38.099%, xylene 31.9%, ethyl acetate 30%, polymerization inhibitor 0.001%;

[0148] C component: cobalt isooctanoate;

[0149] Component D: methyl ethyl ketone peroxide.

[0150] (2) pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com