Hydrophobic electrical insulation epoxy resin composition

A technology of epoxy resin and composition, used in organic insulators, plastic/resin/wax insulators, etc., can solve problems such as poor hydrophobicity, improve hardness and mechanical properties, reduce curing shrinkage, and reduce industrialization costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

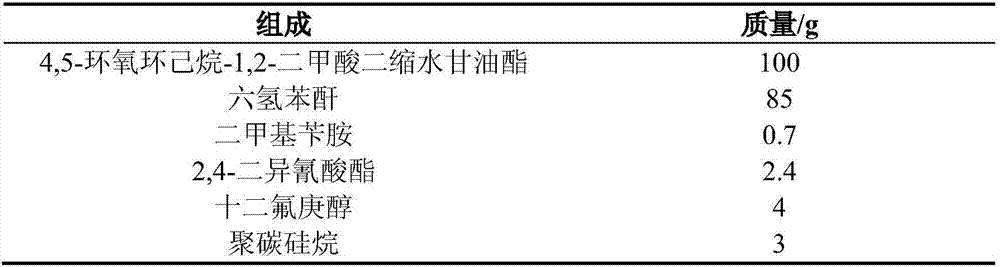

[0038] This embodiment provides a hydrophobic electrical insulating epoxy resin composition, the formula of which is as follows:

[0039]

[0040]

[0041] Preparation:

[0042] (1) Mix 2.4g of 2,4-diisocyanate and 4g of dodecafluoroheptanol in a high-speed disperser at 60°C, then add 4,5-epoxycyclohexane-1,2-dicarboxylic acid diglycidyl 100g of ester, heated up to 90°C and stirred for 2.5h, then added 1g of silane coupling agent and divinylbenzene dissolved in 3g of polycarbosilane, and continued to stir at 60°C for 2h to obtain a fluorosilicon modified epoxy resin;

[0043] (2) Add 7g of aluminum hydroxide micropowder and 43g of silicon micropowder after surface activation and drying treatment to the prepared fluorosilicone modified epoxy resin, control the system temperature at 40°C, and perform high-speed dispersion and vacuum degassing pretreatment , the treatment time is 6h, the vacuum degree is 200Pa, and component A is obtained;

[0044] (3) Mix 85g of hexahydr...

Embodiment 2

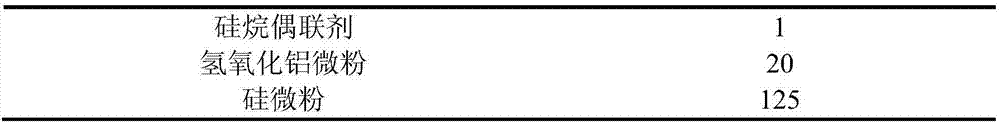

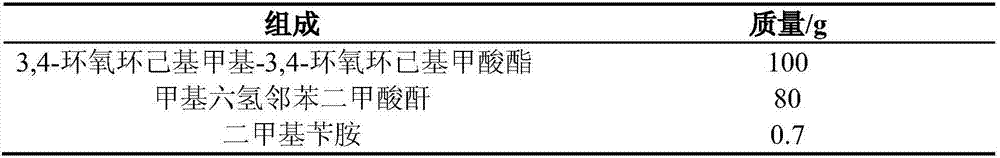

[0048] This embodiment provides a hydrophobic electrical insulating epoxy resin composition, the formula of which is as follows:

[0049]

[0050]

[0051] Preparation:

[0052] (1) Mix 2.8g of 2,4-diphenylmethane diisocyanate and 7g of hexafluoropropylene oxide dimer in a high-speed disperser at 65°C, then add 3,4-epoxycyclohexylmethyl-3 , 100g of 4-epoxy cyclohexyl carboxylate, heated up to 85°C and stirred for 2h, then added 3g of hydrogen-containing silicone oil and 1g of silane coupling agent and continued to stir for 2h at 60°C to prepare a fluorosilicone modified epoxy resin;

[0053] (2) Add 8 g of surface-activated and dried aluminum hydroxide micropowder and 40 g of silicon micropowder to the prepared fluorosilicone modified epoxy resin, control the system temperature at 40°C, perform high-speed dispersion and vacuum degassing pretreatment, and process The time is 6h, the vacuum is 200Pa, and component A is prepared;

[0054] (3) Mix 80g of methylhexahydropht...

Embodiment 3

[0058] This embodiment provides a hydrophobic electrical insulating epoxy resin composition, the formula of which is as follows:

[0059]

[0060]

[0061] Preparation:

[0062] (1) Mix 2.5g of 2,4-dimethoxybenzyl isocyanate and 5g of dodecafluoroheptanol in a high-speed disperser at 50°C, then add 100g of tetraglycidyl diaminodiphenylmethane, and heat up to 80°C Stir for 2h, then add 5g of hydrogen-containing silicone oil and 1g of silane coupling agent and continue stirring for 2h at 60°C to obtain a fluorosilicon-modified epoxy resin;

[0063] (2) Add 6 g of dry surface-activated aluminum hydroxide micropowder and 40 g of silicon micropowder to the prepared fluorosilicon-modified epoxy resin, control the system temperature at 40°C, perform high-speed dispersion and vacuum degassing pretreatment, and process The time is 6h, the vacuum is 200Pa, and component A is prepared;

[0064] (3) Mix 90 g of methyl endomethylene tetrahydrophthalic anhydride and 1 g of 2,4,6-tri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com