High-strength insulating support beam and preparation method thereof

An insulating support and high-strength technology, which is applied in the field of high-strength insulating support beams and its preparation, can solve the problems of tracking resistance, arc resistance, poor flame retardancy, increased weight of insulating boards, and inconvenient transportation, etc., to achieve excellent resistance. Flammability, excellent tracking resistance, and easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

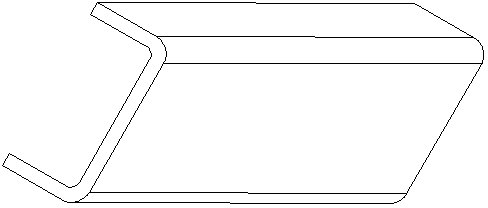

[0065] A high-strength insulating support beam, the preparation method of which comprises the following steps:

[0066] (1) Preparation of flame retardant epoxy resin glue solution: prepare materials according to the above raw materials, first add solvent, flame retardant epoxy resin, curing agent, curing agent accelerator and stir evenly, and the stirring time is 30-60 minutes. Then add organic and inorganic flame retardants, and stir for 1 to 3 hours, take a sample to test the molding time of the glue, and the molding time is between 180 and 600 seconds.

[0067] (2) Preparation of glass cloth prepreg: the glass cloth soaked in the grease glue solution in step (1) is passed through a vertical dipping machine to obtain glass cloth prepreg;

[0068] (3) Compression molding: use a mold to press the glass cloth prepreg into a hot press or a vacuum hot press.

[0069] Further, the step of cutting glass cloth (cutting to the size required for processing) is also included ...

Embodiment 1

[0081] In terms of solid parts by weight of flame-retardant epoxy resin (the following examples are based on parts by weight of solid parts of flame-retardant epoxy resin or ordinary epoxy resin):

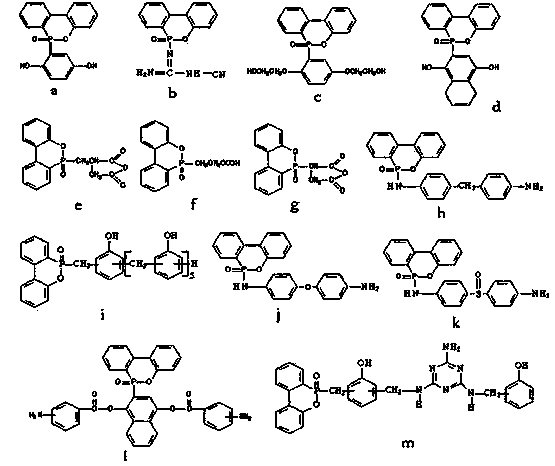

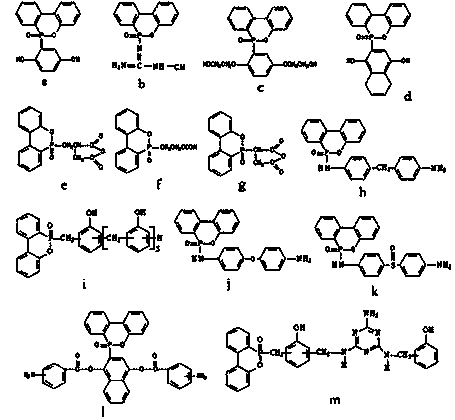

[0082] After 100 parts of phosphorus-containing epoxy resin (structural formula (1)), 3 parts of ethylenediamine, 0.01 part of 2-methylimidazole and 50 parts of toluene, stir for 40 minutes and stir evenly, then add organic flame retardant (structural formula (a )) 10 parts, and then stirred for 2 hours, using the knife method to test the molding time of the glue solution was 200s, and the flame retardant epoxy resin glue solution was prepared.

[0083] Glass cloth impregnated with flame-retardant epoxy resin glue is passed through a vertical impregnation machine, and the glass cloth prepreg (semi-cured) sheet is prepared by controlling the extrusion roller speed, line speed, wind temperature and furnace temperature conditions.

[0084] Cut the prepreg into the required size, lay i...

Embodiment 2

[0088] 100 parts of phosphorus-containing epoxy resin (structural formula (2)), 10 parts of 4,4′ diaminodiphenylmethane, 5 parts of 2-ethyl-4-methylimidazole, 80 parts of ethanol, organic phosphorus flame retardant (structural formula (b) 40 copies.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com