Halogen-free resin composition and copper-clad plate prepared by using composition

A resin composition and composition technology, applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., can solve the problem of decreased processability of copper clad laminates, poor tracking resistance, heat resistance and resistance Problems such as poor alkalinity, to achieve the effect of avoiding processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

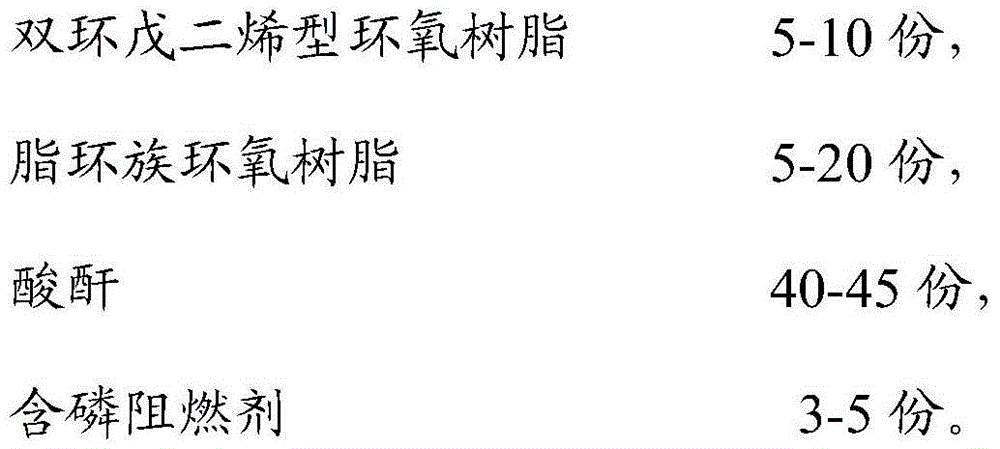

[0026] A kind of total amount is the resin composition of 100 parts, comprises each component of following parts by weight: 25 parts of phosphorus-containing epoxy resins (Dow Chemical, XZ92530), dicyclopentadiene type epoxy resins (Dainippon Ink Co., Ltd., HP7200H) 5 parts, cycloaliphatic epoxy resin (Dow Chemical, ERL-4221D) 20 parts, acid anhydride (Kray Willy, SMAEF-40) 45 parts, phosphorus-containing flame retardant (Clariant, EXOLIT OP935) 5 parts share.

[0027] The method for preparing a copper-clad laminate with the above-mentioned resin composition comprises the following steps:

[0028] 1) Weigh each component according to the formula and mix well;

[0029] 2) Add an accelerator and an organic solvent to the composition to form a glue solution, stir and mix evenly, and coat it on an electronic grade glass cloth, and then bake it in an oven at 155°C for 5 minutes to remove the solvent to obtain a prepreg; The prepregs are stacked together, covered with an electroly...

Embodiment 2

[0031] A kind of total amount is the resin composition of 100 parts, comprises each component of following parts by weight: 35 parts of phosphorus-containing epoxy resins (Dow Chemical, XZ92530), dicyclopentadiene type epoxy resins (Dainippon Ink Co., Ltd., HP7200H) 10 parts, cycloaliphatic epoxy resin (Dow Chemical, ERL-4221D) 10 parts, acid anhydride (Kray Willy, SMAEF-40) 42 parts, phosphorus-containing flame retardant (Clariant, EXOLIT OP935) 3 share.

[0032] The method for preparing a copper-clad laminate with the above-mentioned resin composition comprises the steps of:

[0033] 1) Weigh each component according to the formula and mix well;

[0034] 2) Add an accelerator and an organic solvent to the composition to form a glue solution, stir and mix evenly, and coat it on an electronic grade glass cloth, and then bake it in an oven at 155°C for 5 minutes to remove the solvent to obtain a prepreg; The prepregs are stacked together, covered with an electrolytic copper f...

Embodiment 3

[0036] A kind of total amount is the resin composition of 100 parts, comprises each component of following parts by weight: 45 parts of phosphorus-containing epoxy resins (Dow Chemical, XZ92530), dicyclopentadiene type epoxy resins (Dainippon Ink Co., Ltd., HP7200H) 7 parts, cycloaliphatic epoxy resin (Dow Chemical, ERL-4221D) 5 parts, acid anhydride (Kray Willy, SMAEF-40) 40 parts, phosphorus-containing flame retardant (Clariant, EXOLIT OP935) 3 parts share.

[0037] The method for preparing a copper-clad laminate with the above-mentioned resin composition comprises the following steps:

[0038] 1) Weigh each component according to the formula and mix well;

[0039] 2) Add an accelerator and an organic solvent to the composition to form a glue solution, stir and mix evenly, and coat it on an electronic grade glass cloth, and then bake it in an oven at 155°C for 5 minutes to remove the solvent to obtain a prepreg; The prepregs are stacked together, covered with an electrolyt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com