Flame-retardant reinforced warping-resistance PBT/PTT (polybutylene terephthalate/polytrimethylene terephthalate) alloy material and preparation method thereof

An alloy material and warping technology, applied in the field of polymer composite materials, can solve the problems that affect the performance of PBT/PTT alloy materials, PTT is easily warped when heated, and has a low tracking resistance index, and achieves high flame retardancy. high CTI value, smooth surface without warping, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

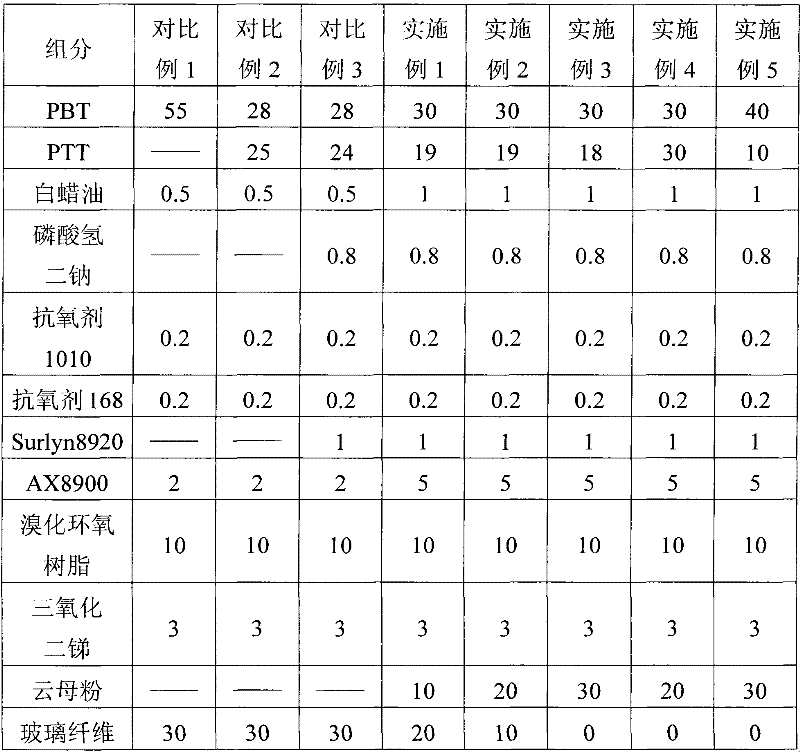

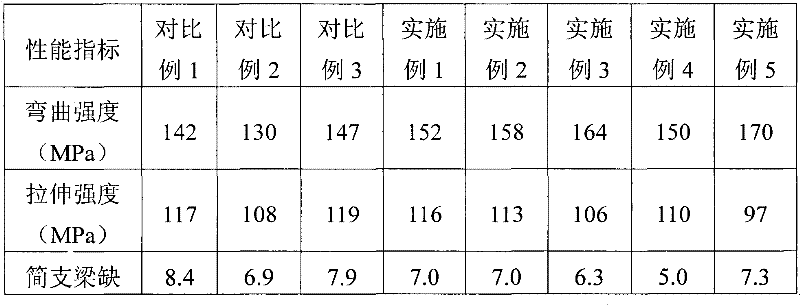

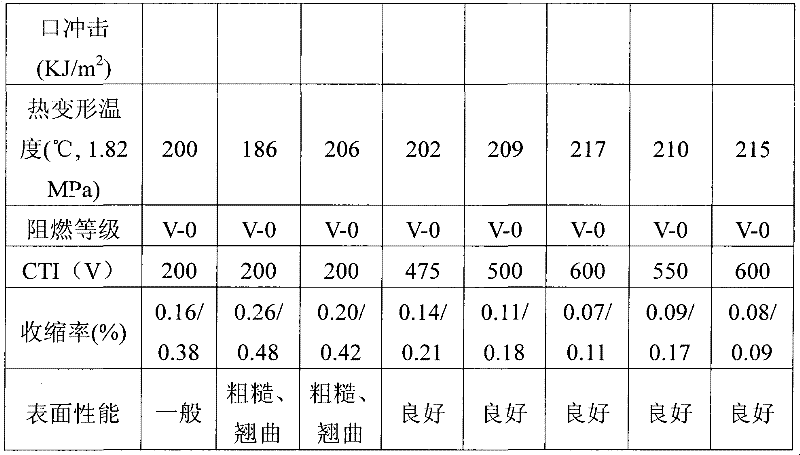

Examples

Embodiment 6

[0042] A method for preparing a flame-retardant reinforced warpage-resistant PBT / PTT alloy material, comprising the following steps:

[0043] PBT and PTT were air-dried at 130°C for 3 hours, the intrinsic viscosity of PBT was 0.7dL / g, and the density was 1.30g / cm 3 , the viscosity of PTT is 0.7dL / g, and the density is 1.33g / cm 3 ; Take by weight proportion dry good PBT30 weight portion, PTT30 weight portion, lubricant silicone oil 0.3 weight portion, transesterification inhibitor triphenyl phosphite 0.1 weight portion, antioxidant 1010 0.3 weight portion, nucleating agent surlyn 8920 0.5 parts by weight, 5 parts by weight of flame retardant decabromodiphenyl ether, 1 part by weight of flame retardant synergist sodium antimonate, 2 parts by weight of toughening agent AX89002, mica powder ( The particle size is 800 mesh) and 10 parts by weight are uniformly mixed in a high-speed mixer; the uniformly mixed material is blended with 5 parts by weight of alkali-free glass fibers co...

Embodiment 7

[0045] A method for preparing a flame-retardant reinforced warpage-resistant PBT / PTT alloy material, comprising the following steps:

[0046] PBT and PTT were air-dried at 130°C for 3 hours, the intrinsic viscosity of PBT was 1.3dL / g, and the density was 1.35g / cm 3 , the viscosity of PTT is 1.0dL / g, and the density is 1.37g / cm 3 ; Take dry PBT40 weight part, PTT10 weight part, lubricant white wax oil 1 weight part, transesterification inhibitor disodium hydrogen phosphate 0.8 weight part, antioxidant 1680.8 weight part, nucleating agent Aclyn 2855 by weight proportion Parts by weight, 10 parts by weight of flame retardant brominated epoxy resin, 5 parts by weight of antimony oxide of flame retardant synergist, 10 parts by weight of toughening agent AX8900, the mica powder (particle size is 600 orders) that carries out surface treatment through silane coupling agent ) 30 parts by weight are uniformly mixed in a high-speed mixer; the homogeneously mixed material is blended with...

Embodiment 8

[0048] A method for preparing a flame-retardant reinforced warpage-resistant PBT / PTT alloy material, comprising the following steps:

[0049] PBT and PTT were air-dried at 130°C for 3 hours, the intrinsic viscosity of PBT was 1.2dL / g, and the density was 1.31g / cm 3 , the viscosity of PTT is 0.8dL / g, and the density is 1.36g / cm 3; Weigh dry PBT32 parts by weight, PTT22 parts by weight, lubricant silicone oil 0.3 parts by weight, white wax oil 0.2 parts by weight, transesterification inhibitor triphenyl phosphite 0.2 parts by weight, disodium hydrogen phosphate 0.2 parts by weight parts, 10100.2 parts by weight of antioxidant, 1680.3 parts by weight of antioxidant, 2.5 parts by weight of ionomer nucleating agent, 5 parts by weight of flame retardant decabromodiphenyl ether, 3 parts by weight of brominated epoxy resin, flame retardant association 1 part by weight of antimony antimonate, 1 part by weight of antimony oxide, 7 parts by weight of toughening agent AX8900, 22 parts by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com