Detection method for ageing degree of silicone rubber composite insulator

A technology of composite insulator and aging degree, which is applied in the field of power equipment, can solve the problems of inability to explain the aging of insulators, and cannot reflect the polarity change of the insulator surface, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Detection method of aging degree of silicone rubber composite insulator

[0031] A method for detecting the aging degree of a silicone rubber composite insulator, comprising the following steps:

[0032] (1) Randomly select 9 parts of unused silicone rubber composite insulators, and irradiate 0h, 48h, 96h, 144h, 192h, 240h, 480h, 720h under the ultraviolet radiation of UV-A with a center wavelength of 340nm , 880h;

[0033] (2) Cut a small piece from the high-voltage side shed of each silicone rubber composite insulator in step (1) as a test sample, and cut out a piece of the upper surface that is not less than 4cm×4cm. Uniform thickness does not affect the shooting effect of projection;

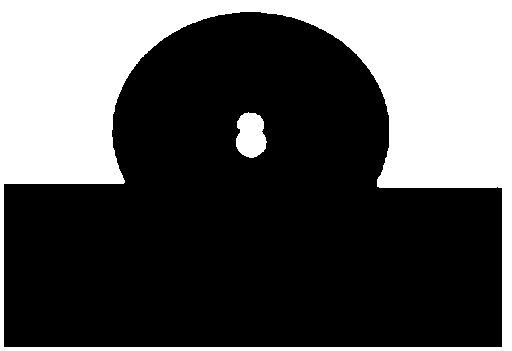

[0034] (3) Place the test sample in the test area of the GBX contact angle meter, select the free energy test mode, adjust the focus of the sample, and adjust the focus of the test sample. It is observed that the needle is rectangular, and the droplet appears until the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com