Contamination ageing test method for silicon rubber insulator

A silicone rubber insulation and aging test technology, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of increased probability of pollution flashover accidents, surface discharge, and limited adjustment of aging conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

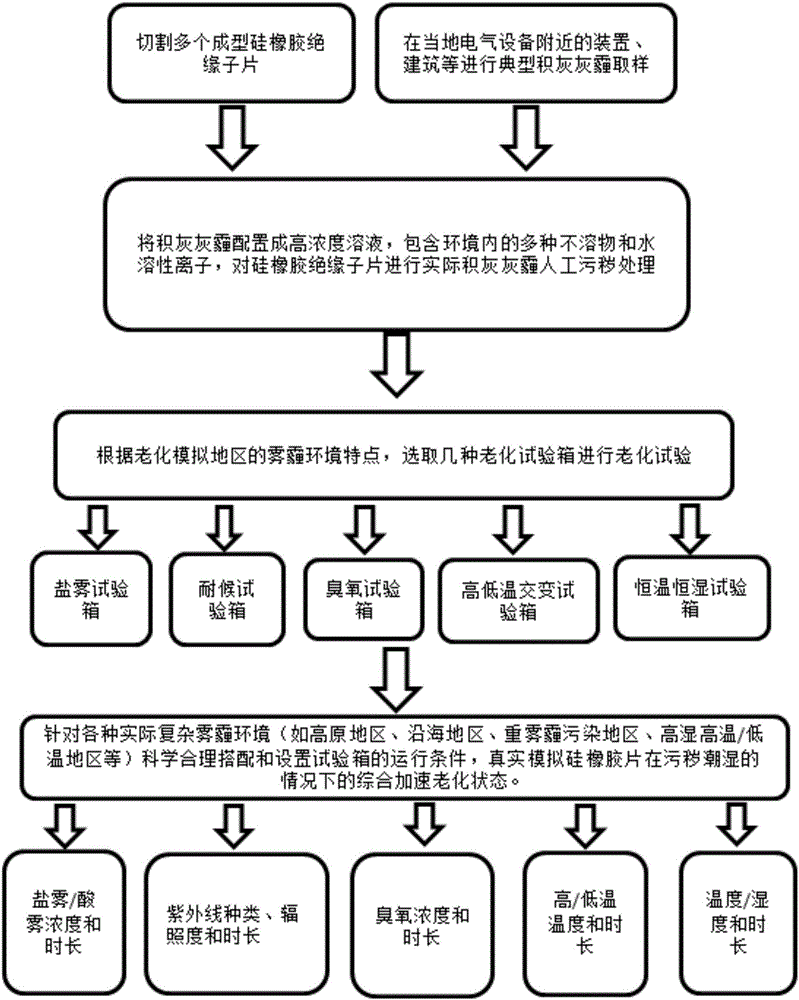

[0072] 1. Cut 60 semi-circular silicone rubber sheets from the whole string of silicone rubber insulators with a rated voltage of 220kV, with a diameter of ~17cm and a thickness of ~14mm, to ensure that the surface is dry and free of scratches;

[0073] 2. In the fog and haze environmental aging test area of a power plant in Changchun City, Jilin Province, artificial dust and haze samples were taken from the devices and buildings near the local electrical equipment to 72.5g, and put in a dry container;

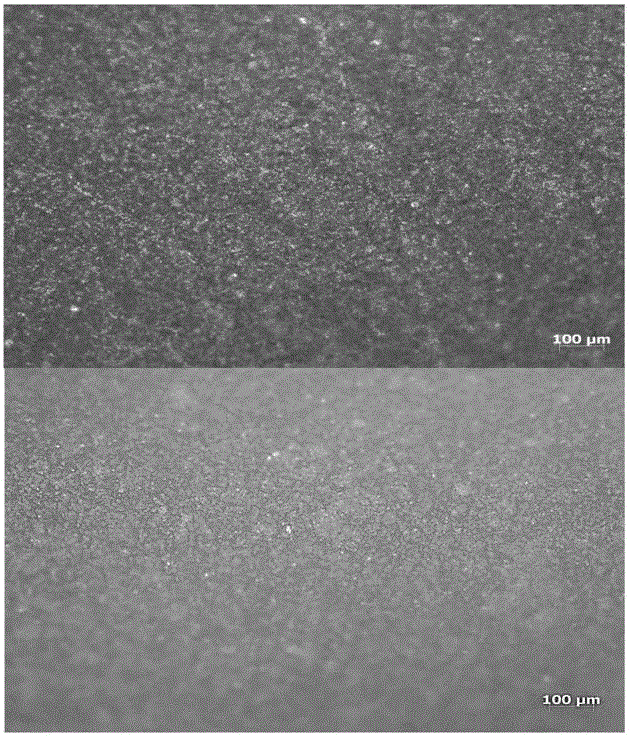

[0074] 3. Pour 40g of pure water into the obtained dust and haze, and fully stir the ~64% high-concentration haze solution evenly. The configured high-concentration haze pollution solution contains a variety of actual insoluble substances and water-soluble ions. Rotate the silicone rubber sheet in the haze solution for several weeks, then immerse it in the solution, and carry out artificial pollution treatment for 10 hours. After the pollution on the surface of the insulator...

Embodiment 2

[0085] 1. Cut 55 semi-circular silicone rubber sheets from the whole string of silicone rubber insulators with a rated voltage of 110kV, with a diameter of ~8.5cm and a thickness of ~9mm, to ensure that the surface is dry and free of scratches;

[0086] 2. In the fog and haze environment aging test area of a power plant in Dalian City, Liaoning Province, artificial dust and haze samples were collected from the devices and buildings near the local electrical equipment to 33g, and packed in a dry container;

[0087] 3. Pour 30g of pure water into the obtained dust and haze, and fully stir the ~52% high-concentration haze solution evenly. The configured high-concentration haze pollution solution contains a variety of actual insoluble substances and water-soluble ions. Rotate the silicone rubber sheet in the haze solution for several weeks, then immerse it in the solution, and carry out artificial pollution treatment for 8 hours. After the pollution distribution on the surface o...

Embodiment 3

[0097] 1. Cut 40 semi-circular silicone rubber sheets from the whole string of silicone rubber insulators with a rated voltage of 35kV, with a diameter of ~5.5cm and a thickness of ~6mm, to ensure that the surface is dry and free of scratches;

[0098] 2. In the fog and haze environmental aging test area of a power plant in Mudanjiang City, Heilongjiang Province, artificial dust and haze samples of ~30g were taken from the devices and buildings near the local electrical equipment, and put in a dry container;

[0099] 3. Pour 25g of pure water into the obtained dust and haze, and fully stir the ~50% high-concentration haze solution evenly. The configured high-concentration haze pollution solution contains a variety of actual insoluble substances and water-soluble ions. Rotate the silicone rubber sheet in the haze solution for several weeks, then immerse it in the solution, and carry out artificial pollution treatment for 6 hours. After the pollution on the surface of the insu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| irradiance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com