Method for remarkably improving surface hydrophobicity of silicone rubber

A silicone rubber, hydrophobic technology, applied in the field of material surface modification, can solve the problems of reduced hydrophobic recovery ability, loss, insufficient hydrophobicity or surface energy of silicone rubber, and achieves the effect of simple process and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0024] The method of significantly improving the surface hydrophobicity of silicone rubber includes the following two processes:

[0025] 1) In a closed reaction chamber, carry out fluorination treatment to silicone rubber products or articles covered with a silicone rubber layer;

[0026] 2) In a temperature-controlled furnace, heat-crosslink the fluorinated silicone rubber product or the item covered with the silicone rubber layer.

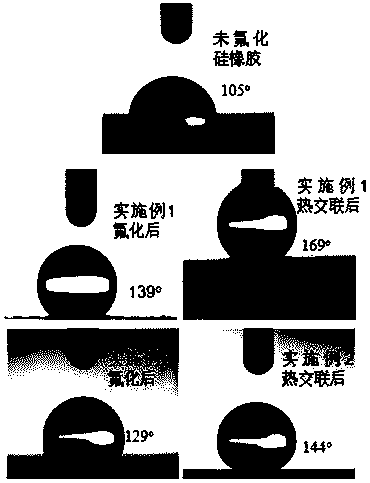

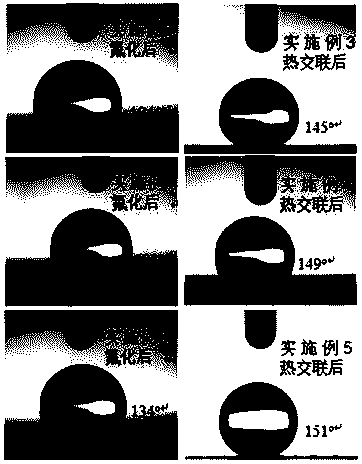

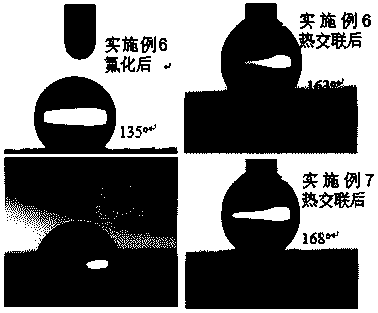

[0027] see Figure 1 ~ Figure 3 . The wettability of a material depends on its surface chemistry and surface topography. Surface chemistry determines its intrinsic surface wettability, and surface roughness amplifies surface wettability, making a hydrophobic or hydrophilic surface more hydrophobic or hydrophilic. The first step of fluorination treatment makes the fluorine atoms replace or partially replace the hydrogen atoms in the silicone rubber, causing surface chemical changes to form a fluorinated surface layer. The second step of therm...

Embodiment 1

[0030] The fluorination treatment conditions of silicone rubber: the temperature is 55°C, the volume concentration of fluorine gas in the fluorine gas / nitrogen gas mixture is 12.5%, the pressure of the reaction gas is 1 bar, and the fluorination treatment time is 30 minutes. Thermal crosslinking conditions of fluorinated silicone rubber: 150°C, 60min. After the above-mentioned fluorination treatment and further thermal crosslinking, the water contact angles of silicone rubber are 139° and 169° respectively (due to superhydrophobicity, water droplets can only be maintained on the surface of silicone rubber through the liquid supply needle), such as Figure 4 shown.

Embodiment 2

[0032] The fluorination treatment conditions of silicone rubber: the temperature is 25°C, the volume concentration of fluorine gas in the fluorine gas / nitrogen gas mixture is 50%, the pressure of the reaction gas is 0.2 bar, and the fluorination treatment time is 60 minutes. Thermal crosslinking conditions of fluorinated silicone rubber: 180°C, 30min. After the above fluorination treatment and further thermal crosslinking, the water contact angles of silicone rubber are 129° and 144° respectively, as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com