A kind of rare earth aluminum alloy production device for metallurgy

An aluminum alloy and rare earth technology, applied in the direction of metal rolling, etc., can solve the problems that the continuous production of rare earth aluminum alloys cannot be realized, and the rare earth aluminum alloys are not suitable for the metallurgical industry, etc. It is easy to implement, simple in principle and structure, and overcomes oxidation phenomena Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

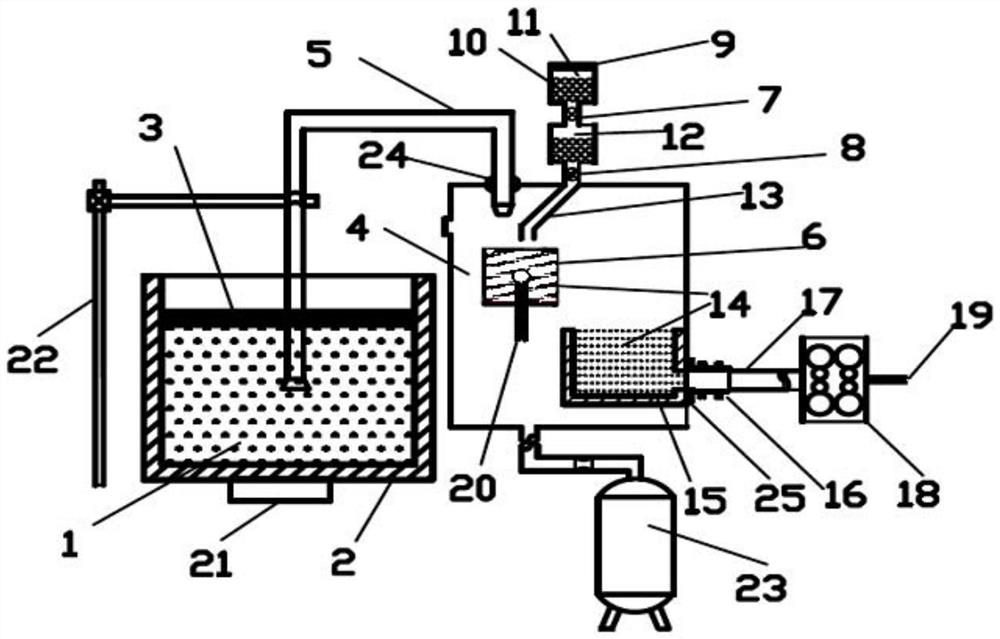

[0037] A rare earth aluminum alloy production device for metallurgy, comprising an aluminum bag 2 and a vacuum chamber 4 connected in sequence, wherein the aluminum liquid 1 is stored in the aluminum bag 2, the guide tube 5 communicates with the aluminum liquid 1 and the vacuum chamber 4, and the vacuum chamber 4 An electromagnetic induction heating container 6 is provided, and a feeding bin for rare earth bulk materials is provided above the vacuum chamber 4. A continuous casting buffer container 15 is provided at the outlet of the electromagnetic induction heating container 6 in the vacuum chamber 4, and the continuous casting buffer container 15 is sequentially It is connected with the continuous casting machine 16 and the rolling unit 18 outside the vacuum chamber 4 .

[0038] The upper layer of the aluminum liquid 1 is a covering agent 3 (also known as mold slag), one end of the guide tube 5 is located in the aluminum liquid 1 below the covering agent 3, and the other end ...

Embodiment 2

[0043] A method for producing rare earth aluminum alloys for metallurgy, comprising the following steps:

[0044] ①Adding aluminum: molten aluminum (1) enters the electromagnetic induction heating container (6) in a decompression and cooling environment;

[0045] ② Rare earth addition: Add rare earth bulk material (10) into the electromagnetic induction heating container (6) in a vacuum environment;

[0046] ③ Alloy homogenization: through electromagnetic induction heating, the rare earth bulk material (10) is gradually melted, the aluminum liquid (1) is mixed with the rare earth bulk metal, and finally an alloy liquid (14) with a relatively uniform composition is formed;

[0047] ④ The alloy liquid is poured into the continuous casting buffer container (15) from the electromagnetic induction heating container (6) at one time, and the alloy liquid (14) is formed into a trapezoidal cross-section aluminum rod through the continuous casting machine, or rolled into a cross-section...

Embodiment 3

[0050] A specific operation method for the production of rare earth aluminum alloys for metallurgy, comprising the following steps:

[0051] ① Aluminum liquid 1 is stored in aluminum bag 2. In the aluminum package 2, the lower layer is the aluminum liquid 1, and the upper layer is the covering agent 3. When the vacuum chamber 4 reaches a certain degree of vacuum, the aluminum liquid 1 is transferred to the vacuum chamber 4 through the guide tube 5, and enters the electromagnetic induction heating container 6. After the aluminum liquid in the electromagnetic induction heating container 6 reaches a certain volume, the aluminum ladle is moved The lifting device 21 and the guide tube supporting device 22 adjust the relative positions of the aluminum bag 2 and the guide tube 5, and stop adding the aluminum liquid 1.

[0052] ② When both the silo valve 7 and the feeding vacuum valve 8 are closed, open the feeding cover 9 and put the rare earth bulk material 10 into the upper feedin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com