Composite insulator hydrophobicity grade determination method based on a water drop offset distance

A composite insulator and offset distance technology, which is applied in the field of image processing, can solve the problems of hydrophobic performance affecting the insulation performance of composite insulators, the shed aging of composite insulators, and increasing flashover phenomena, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

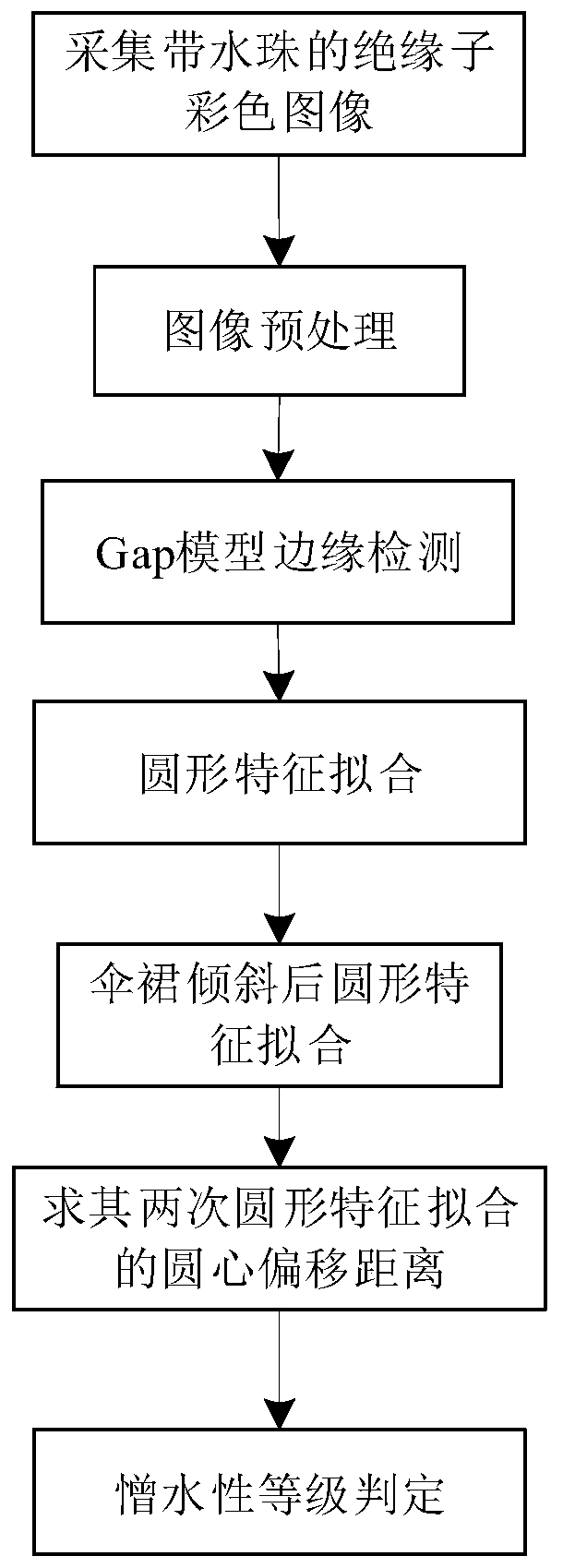

[0071] A method for judging the hydrophobicity level of composite insulators based on the offset distance of water droplets in the present invention, such as figure 1 As shown, the specific steps are as follows:

[0072] Step 1. Obtain the original color image of the silicone rubber insulator with water droplets, such as figure 2 shown;

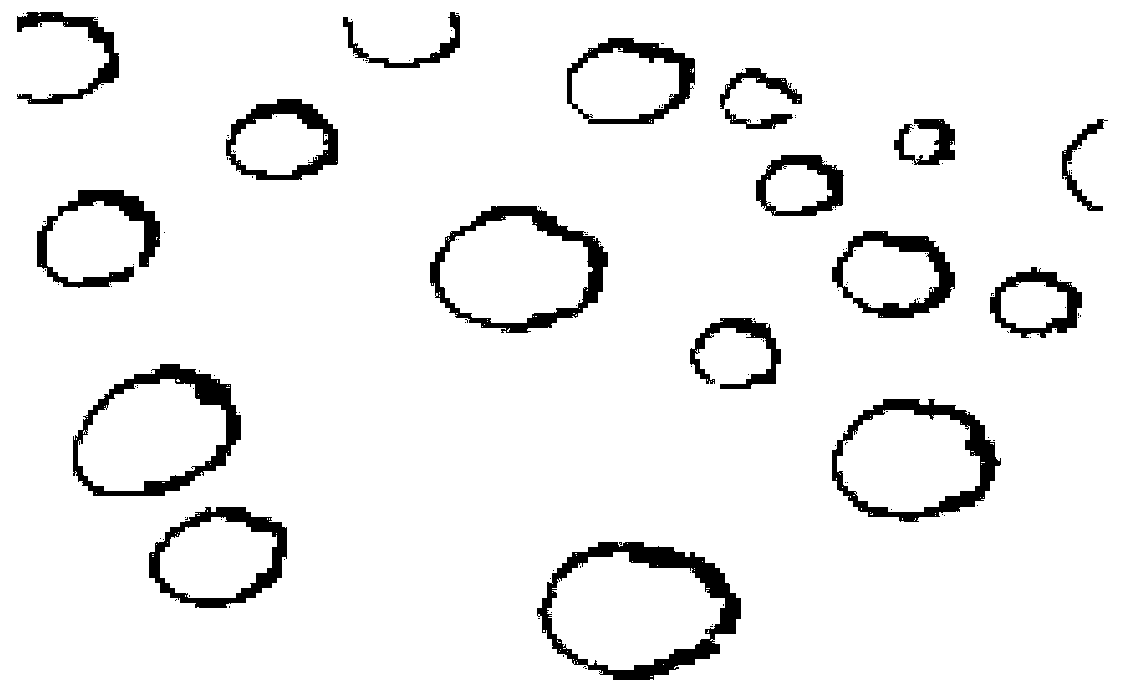

[0073] Step 2. Carry out grayscale processing and image filtering processing on the color image obtained in step 1 to improve the contrast of the image and remove image interference noise, as follows:

[0074] Step 2.1, image grayscale processing, the grayscale formula is:

[0075] Y=0.299R+0.587G+0.114B (1)

[0076] Wherein, Y is the brightness calculated according to the relationship between the R, G, and B color components and the brightness signal Y in the color coding method YUV, and R, G, and B re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com