High temperature resistant composite silicone rubber insulator formulation

A technology for compounding silicone rubber and insulators, used in the chemical industry, can solve the problems of toxic decomposition products, long secondary vulcanization time, etc., and achieve the effects of improving processing performance, improving mechanical strength, and improving heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

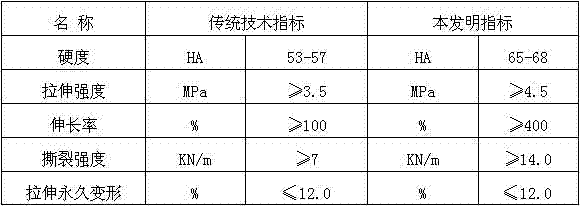

[0009] Silicone rubber insulators are widely used in high-voltage transmission lines and can be used in areas with different pollution levels. They have the characteristics of light weight, small size, unbreakable, high tensile strength and strong anti-pollution performance. Different types of silicone rubber insulators have different functions, and the structural height and creepage distance are also different. Silicone rubber insulators are mainly used in substations, with good hydrophobicity, aging resistance, tracking resistance and electrical corrosion resistance. . Through multiple tests, the present invention uses an addition vulcanization system as the vulcanizing agent before the refining (smelting temperature: room temperature-40°C), that is, before the refining, hydrogen-containing silicone oil, retarder, and platinum complex are added at one time as the vulcanizing agent. Additives, so that only one vulcanization treatment can meet the technical requirements, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com