Soft ultra-wearproof cable for new-energy automobile

A new energy vehicle, ultra-wear-resistant technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve electrical safety hazards and other problems, achieve the effect of improving temperature resistance and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

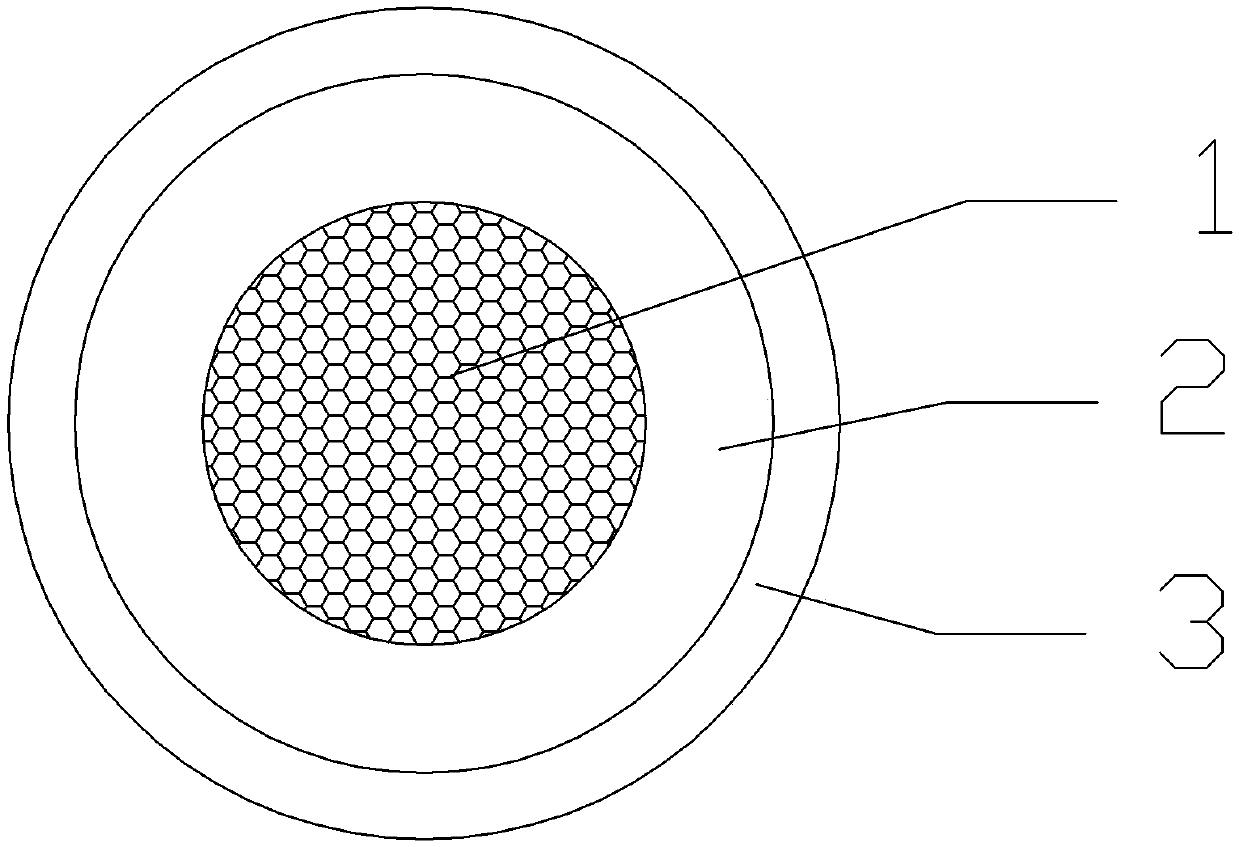

[0018] A kind of flexible super wear-resistant cable for new energy vehicles, see figure 1 : It includes a conductor 1, an insulating layer 2 and a sheath 3, and the conductor 1, insulating layer 2 and sheath 3 in the cross-sectional state are arranged radially from the inside to the outside in sequence, and the conductor 1 is an annealed bare copper conductor or tinned annealed Copper conductor, insulation layer 2 adopts high temperature silicon rubber insulator, insulation layer 2 is tightly extruded on conductor 1.

[0019] The material of the sheath 3 is polyether polyurethane elastomer, and the sheath 3 is tightly extruded on the insulating layer 2;

[0020] Conductor 1 adopts a cross regular twisted structure of ultra-fine copper wire multi-element small-pitch conductors.

[0021] In the specific embodiment, the conductor 1 is a Class 6 annealed bare copper conductor that meets the requirements of GB / T3956, the insulating layer 2 is made of high-temperature silicone rub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com