Highly hydrophobic outdoor strain insulator

A technology of tensile insulators and hydrophobicity, applied in the direction of insulators, suspension/strain insulators, electrical components, etc., can solve the problems of poor tensile performance and damage of insulators, and achieve good durability, high stability and reliability, The effect of excellent strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

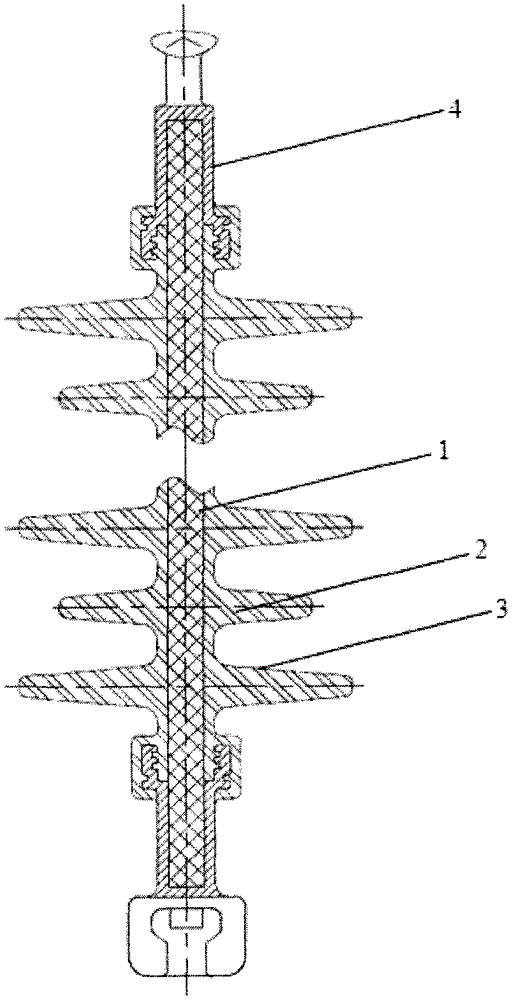

[0026] Such as figure 1 As shown, a highly hydrophobic outdoor tension insulator includes a core rod 1, a shed 2 arranged outside the mandrel, a coating 3 coated on the surface of the shed, and end components crimped to both ends of the mandrel 1 4. The shed 2 is made by molding high weather resistance epoxy resin onto the mandrel 1 by APG molding process; the coating 3 is a highly hydrophobic fluorocarbon coating.

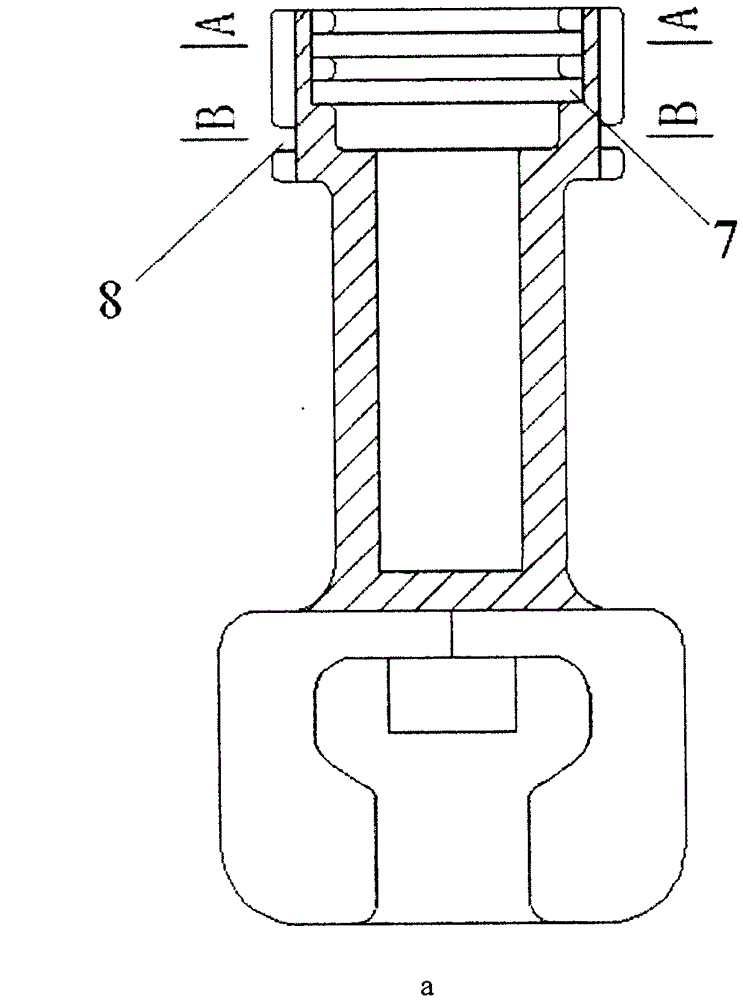

[0027] Such as figure 2 As shown, the surface of the end assembly 4 in contact with the resin is sandblasted, and the inner and outer reinforcement grooves 7 and 8 are respectively provided on the inner and outer sides. The reinforcement groove is an annular groove with rounded corners, which can strengthen the ring Oxygen resin bonding, and has a waterproof effect.

[0028] In this embodiment, the end assembly 4 is provided with an inner reinforcement groove 7 and an outer reinforcement groove 8 . The direction of the reinforcing groove is perpendicular to th...

Embodiment 2

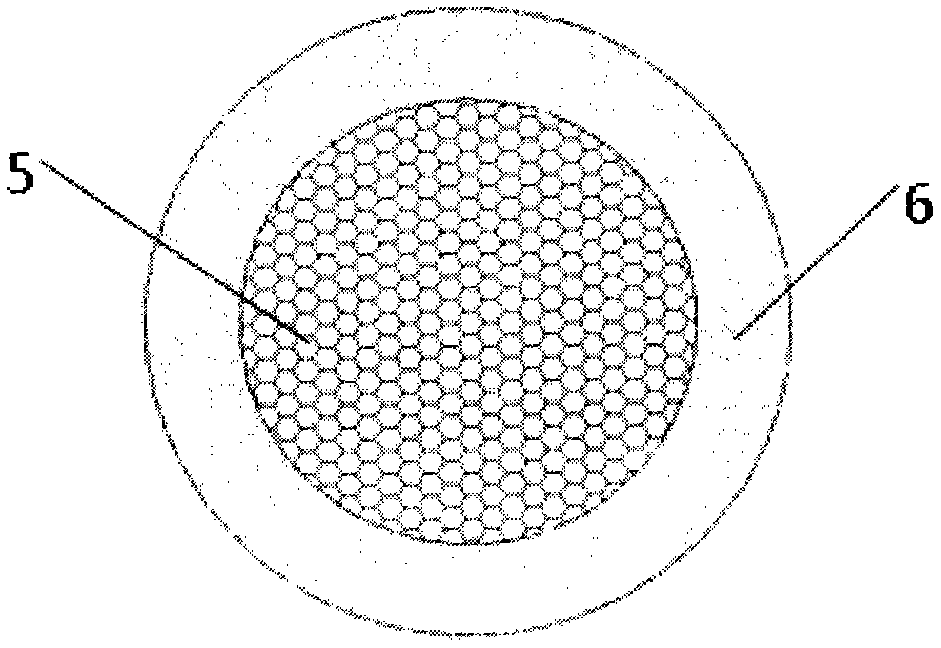

[0035]In this embodiment, the mandrel 1 formed by the pultrusion process is a hybrid reinforced epoxy resin-based composite material of oriented aramid fiber 5 and alkali-free glass fiber 6, the aramid fiber 5 is located inside the reinforcement, and the alkali-free glass fiber 6 is located The periphery of the aramid fiber bundle is covered with the aramid fiber bundle, and the volume ratio of the aramid fiber 5 and the alkali-free glass fiber 6 is 3:1.

[0036] In this example, if figure 2 The end assembly 4 is provided with two inner reinforcement grooves 7 and one outer reinforcement groove 8 .

[0037] In this embodiment, the highly hydrophobic fluorocarbon coating 3 on the surface of the shed 2 is pre-sprayed on the surface of the mold cavity coated with a release agent, and the wet film thickness of the coating 3 is 230-250 μm.

[0038] In the actual production of this embodiment, during the actual production of the highly hydrophobic outdoor tension insulator, firstl...

Embodiment 3

[0040] In this embodiment, the mandrel 1 formed by the pultrusion process is a hybrid reinforced epoxy resin-based composite material of oriented aramid fiber 5 and alkali-free glass fiber 6, the aramid fiber 5 is located inside the reinforcement, and the alkali-free glass fiber 6 is located The periphery of the aramid fiber bundle is covered with the aramid fiber bundle, and the volume ratio of the aramid fiber 5 to the alkali-free glass fiber 7 is 2.5:1.

[0041] In this example, if figure 2 The end assembly 4 is provided with three inner reinforcement grooves 7 and one outer reinforcement groove 8 .

[0042] In this embodiment, the highly hydrophobic fluorocarbon coating 3 on the surface of the shed 2 is pre-sprayed on the surface of the mold cavity coated with a release agent, and the wet film thickness of the coating 3 is 210-230 μm.

[0043] In the actual production of this embodiment, during the actual production of the highly hydrophobic outdoor tension insulator, fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com