Contact synchronous belt conveying device of circuit breaker assembling equipment and method

A technology for assembling equipment and conveying devices, which is applied to chemical instruments and methods, accessories of shearing machines, and cleaning methods using tools, etc., can solve problems such as low contact conveying efficiency, improve overall processing efficiency, and save equipment space. , The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

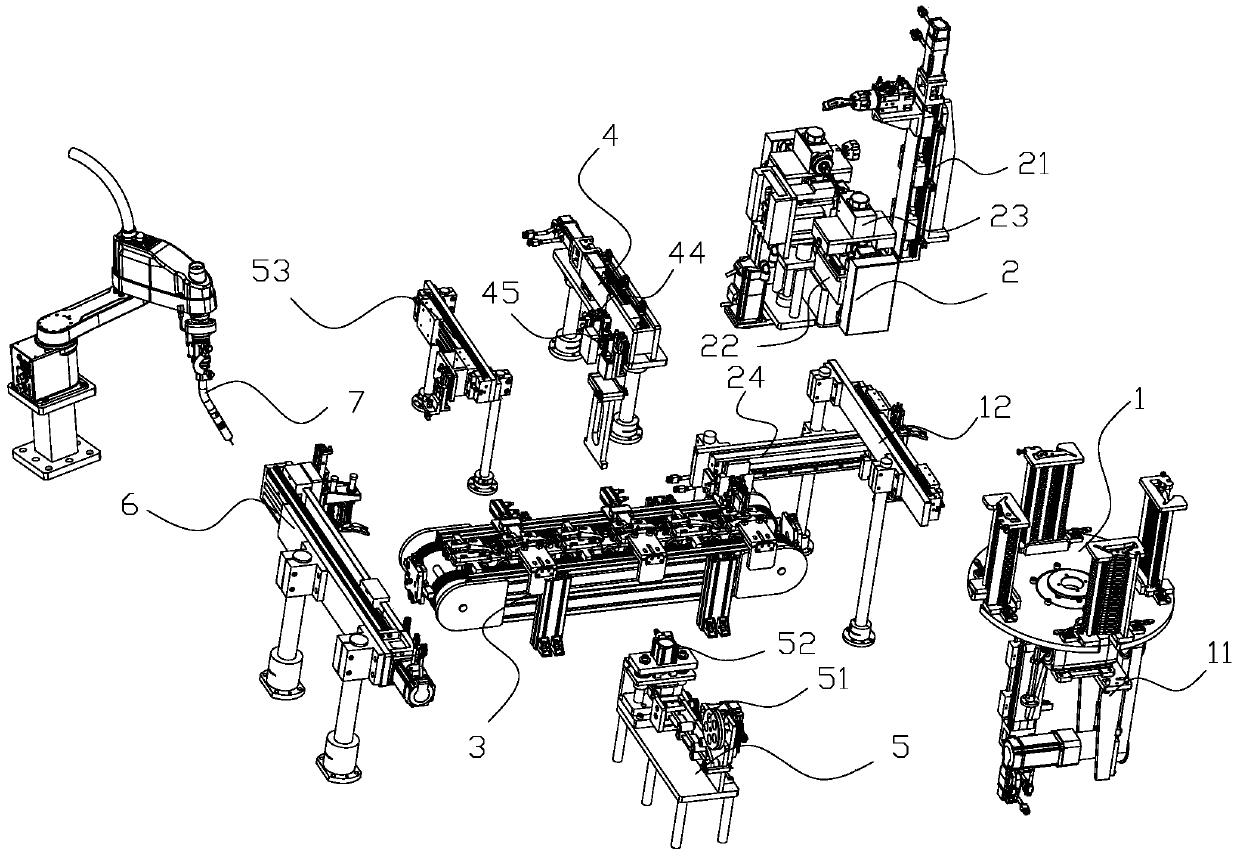

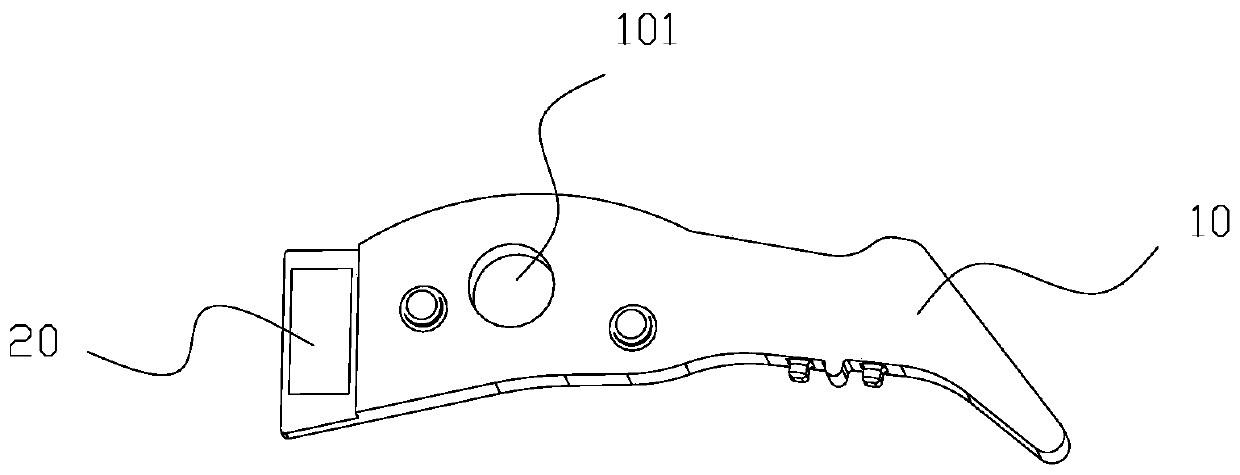

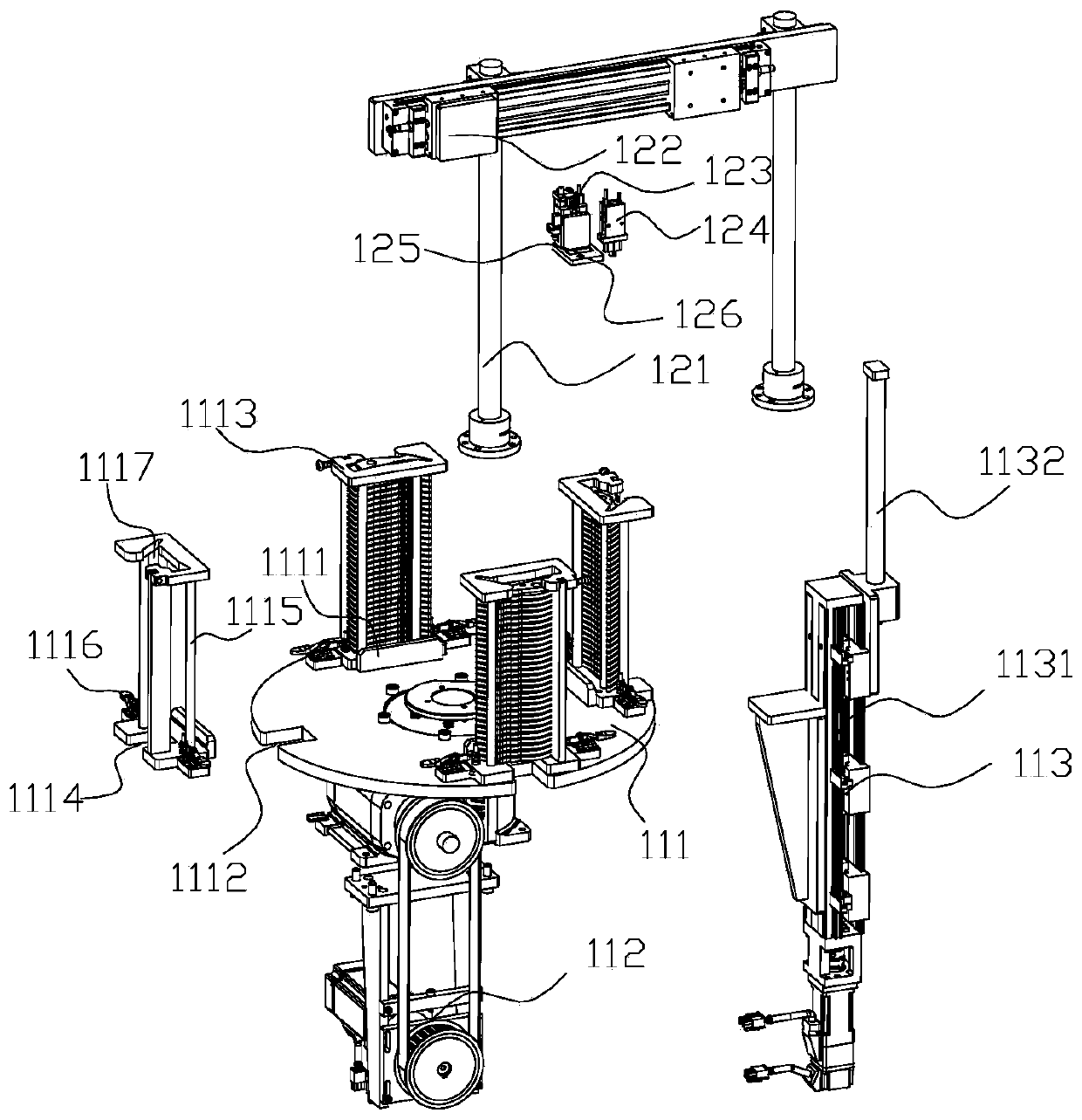

[0030] like figure 1 As shown, a circuit breaker assembly equipment, the equipment includes the frame and the contact conveying transfer device 1 on it, the contact deburring device 2, the contact synchronous belt conveying device 3, the contact cleaning coating device 4, copper Chip assembly device 5, discharge device 6 and welding device 7; contact conveying transfer device 1 is used to transport the contacts to the contact deburring device 2, and the contact deburring device 2 is used to remove the burrs on both sides of the contacts Remove and transfer to the contact synchronous belt conveying device 3; the contact synchronous belt conveying device 3 is used to sequentially transport the contacts to the contact cleaning coating device 4 and the copper sheet assembly device 5, and the contact cleaning coating device 4 It is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com