Intelligent mechanical clamping device

A technology of mechanical clamps and clamping seats, which is applied in the direction of workpiece clamping devices and manufacturing tools, can solve the problems of reducing clamping efficiency, clamping parts can only go straight up or down, and difficulty in clamping workpieces, so as to achieve precise control of clamping positional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

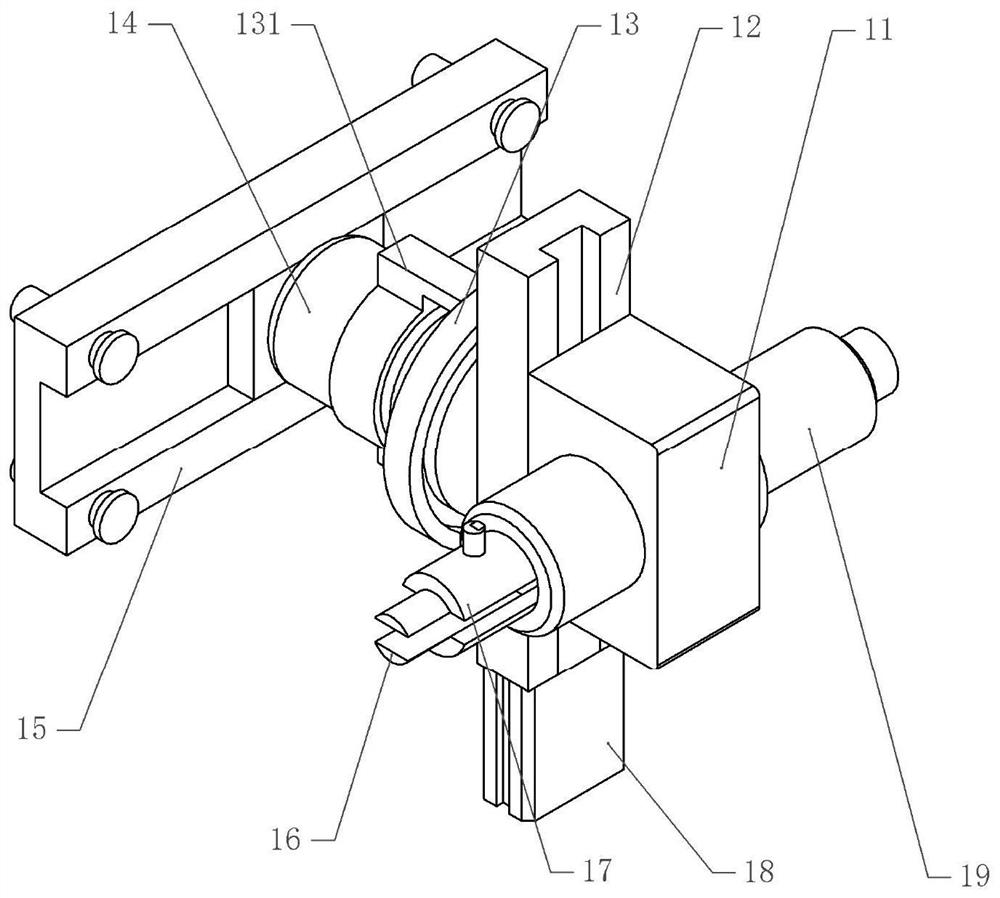

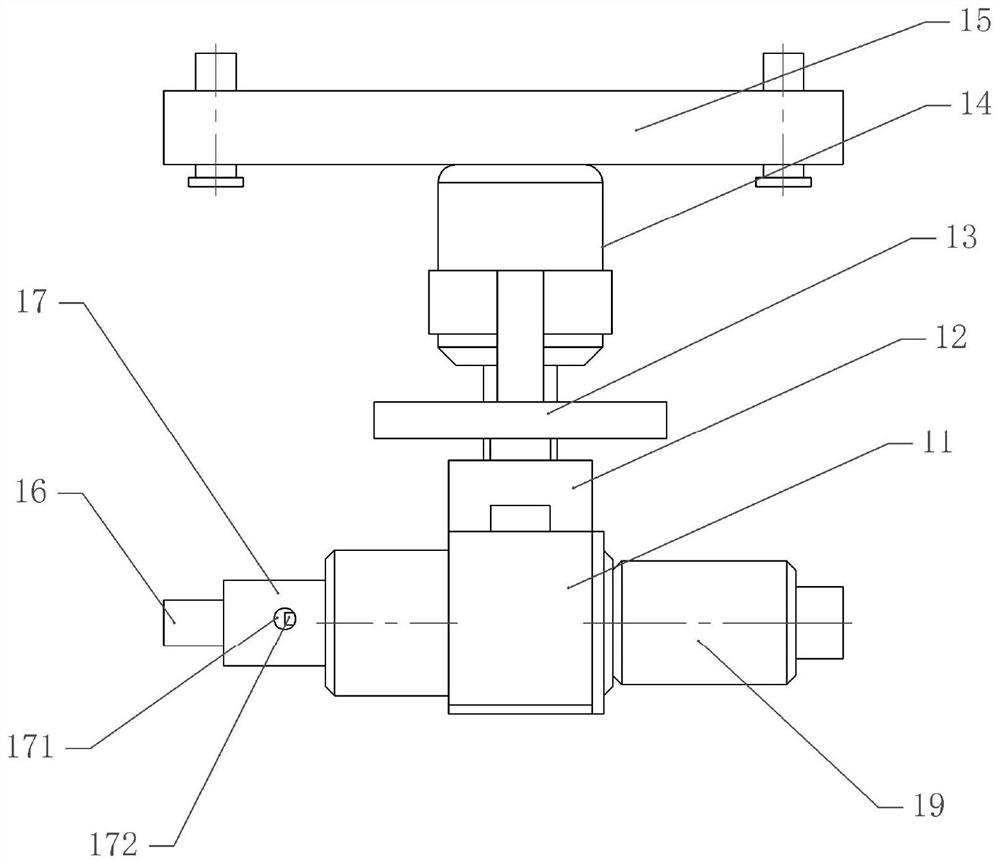

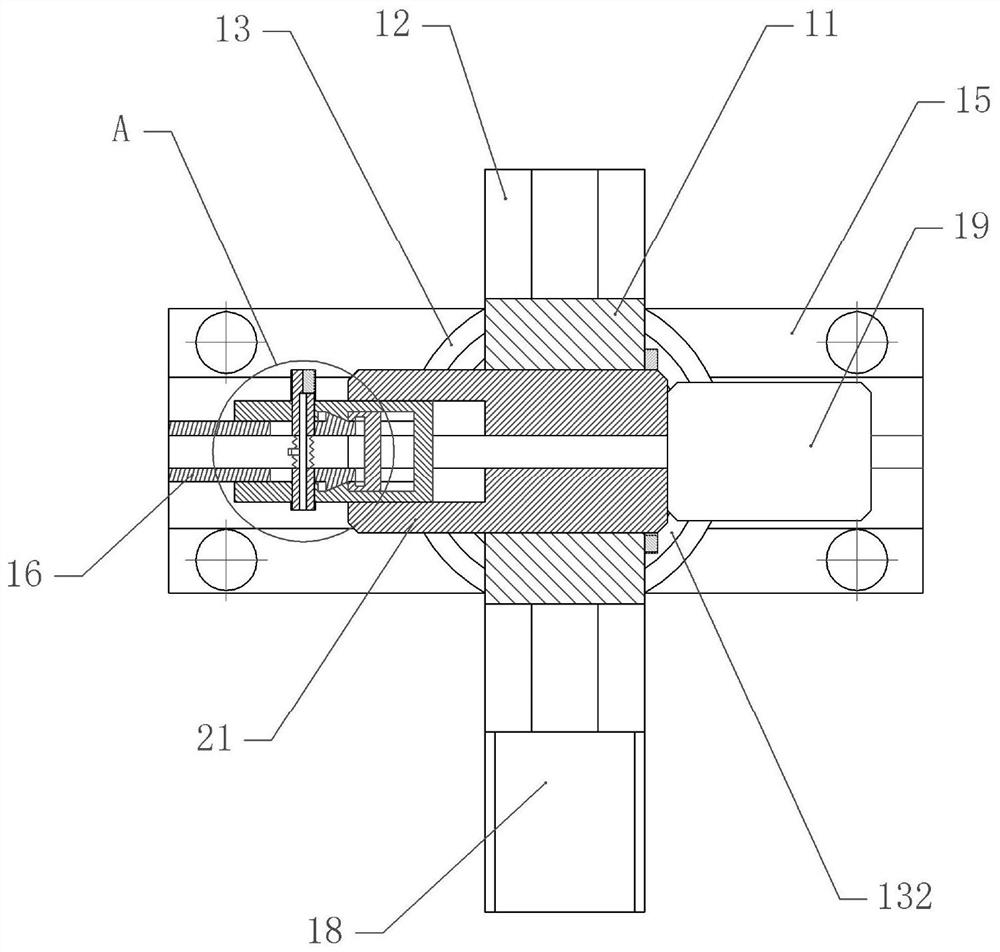

[0040] Basic as attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 Shown: an intelligent mechanical clamping device, including a frame, a first adjustment mechanism is installed on the frame, the first adjustment mechanism is a linear motor module 15, and the output end of the linear motor module 15 is fixed with a drive member, The driving part is a servo motor 14, and the linear motor module 15 drives the servo motor 14 to move laterally, that is, to move horizontally.

[0041] The output shaft of the servo motor 14 is coaxially rotatably connected with a circular angle plate 13, the angle plate 13 is provided with a support 131 fixedly connected with the servo motor 14 shell, and the angle plate 13 is provided with scale marks (not shown in the figure). Out), the output shaft of the servo motor 14 is fixed with a second adjustment mechanism, the second adjustment mechanism in this embodiment includes an adjustment plate 12 and an output pie...

Embodiment 2

[0049] The difference between embodiment two and embodiment one is that, as attached image 3 And attached Figure 5 As shown, a first cavity is formed between the clamping seat 191 and the inner sleeve 17, and an air hole 192 is opened on the clamping seat 191, and the air hole 192 communicates with the first cavity.

[0050] In this embodiment, the first electric control cylinder 19 drives the clamping seat 191 to move towards the inner sleeve 17 until it is against the inner sleeve 17. During this process, the clamping seat 191 will squeeze the gas in the inner sleeve 17 and pass through the The air hole 192 blows to the workpiece to blow away impurities (such as dust) on the workpiece to achieve the purpose of cleaning the workpiece.

Embodiment 3

[0052] The difference between the third embodiment and the first embodiment is that, as attached image 3 And attached Image 6 As shown, a second cavity is formed between the inner sleeve 17 and the outer sleeve 21, the inner sleeve 17 is provided with a chute 42 and an air passage 41 communicating with the chute 42, and the chute 42 is vertically slidably connected with The extruding shaft 43 located above the air passage 41 communicates with the second cavity. The air passage 41 is provided with a solenoid valve 44 which is electrically connected to the controller.

[0053] In this embodiment, the first electric control cylinder 19 drives the clamping seat 191 to move towards the inner sleeve 17 until it touches the inner sleeve 17, and the inner sleeve 17 slides horizontally in the outer sleeve 21 under the action of the clamping seat 191 , until the pressure sensor 172 is against the outer sleeve 21, during this process, the operator can open the solenoid valve 44 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com