Unloading device for motor commutator automatic visual detecting system

A motor commutator, visual inspection technology, applied in sorting and other directions, can solve the problem of easy damage to the commutator, and achieve the effect of avoiding damage, avoiding mechanical damage, and avoiding dust adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

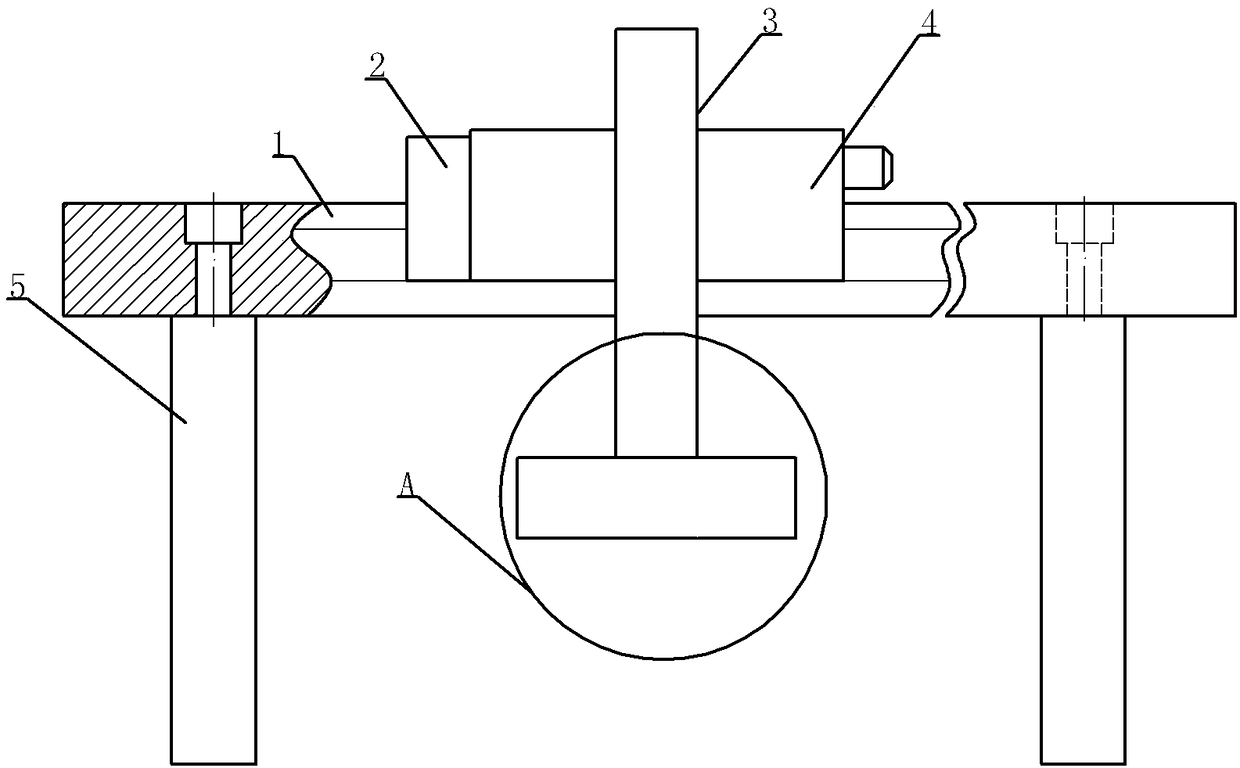

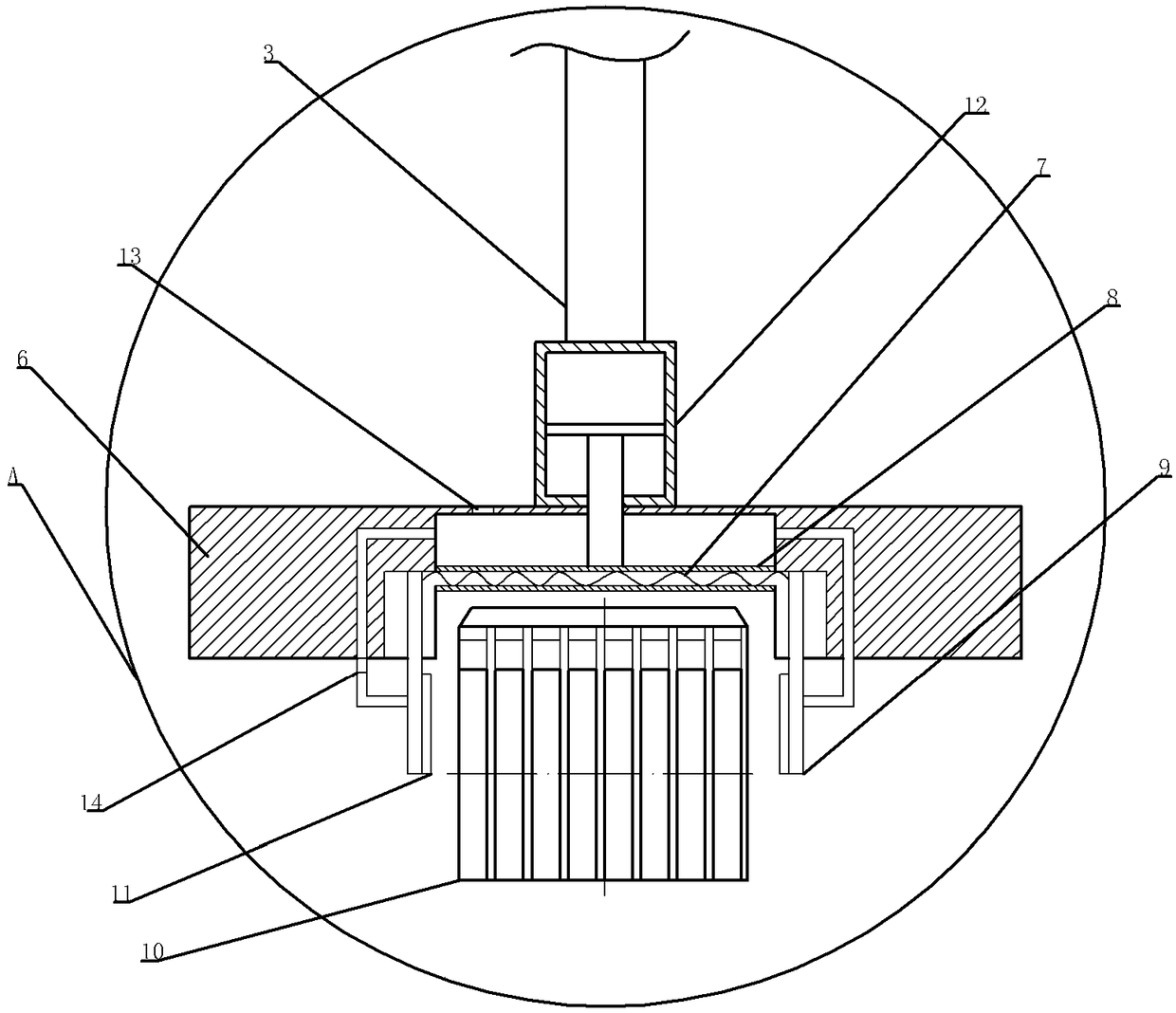

[0020] as attached figure 1 And attached figure 2 As shown, an unloading device for an automatic visual inspection system of a motor commutator includes a sliding shaft 1 and a linear servo module 4 of the model W40-10, and two ends of the sliding shaft 1 are fixed by fastening bolts. It is used to support the support column 5 of the sliding shaft 1. The linear servo module 4 is slidingly connected to the sliding shaft 1, and the linear servo module 4 can slide horizontally on the sliding shaft 1. The linear servo module 4 is electrically connected to the PLC controller 2, and the PLC controller 2 can control the linear servo module. Group 4 slides to the specified position on sliding axis 1. A hydraulic cylinder 3 is fixed on the linear servo module 4 through fastening bolts, the hydraulic cylinder 3 is electrically connected to the PLC controller 2 , and a controllable cylinder 12 electrically connected to the PLC controller 2 is fixed on the bottom of the hydraulic cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com