Fully automatic transplanting combined machine

A combined operating machine and fully automatic technology, applied in the field of agricultural machinery, can solve the problems of damage to the seedling body, planting efficiency, rice transplanter's planting speed is incomparable, and the verticality of the seedling body is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

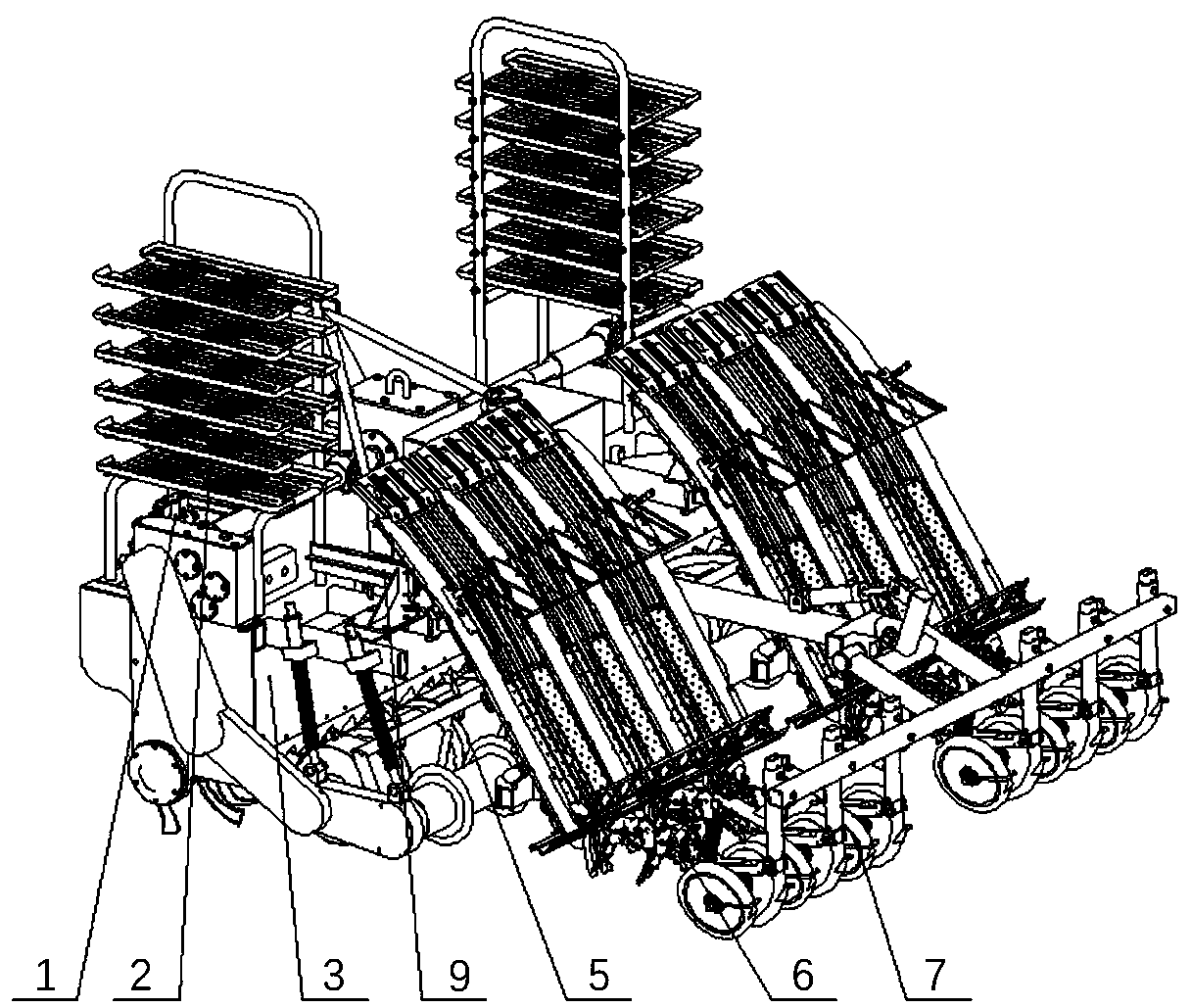

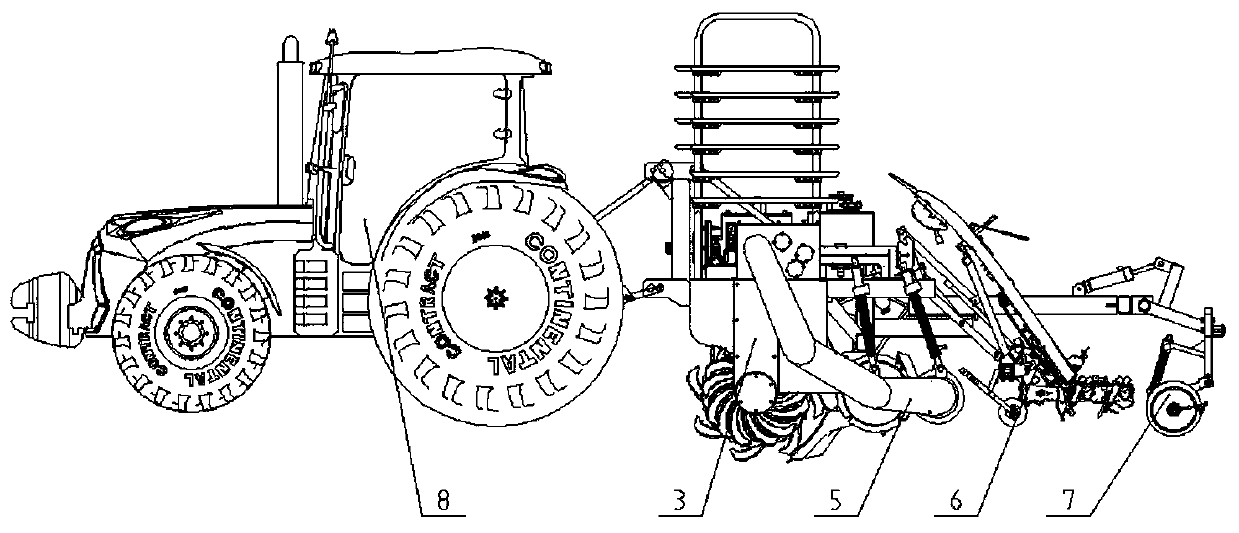

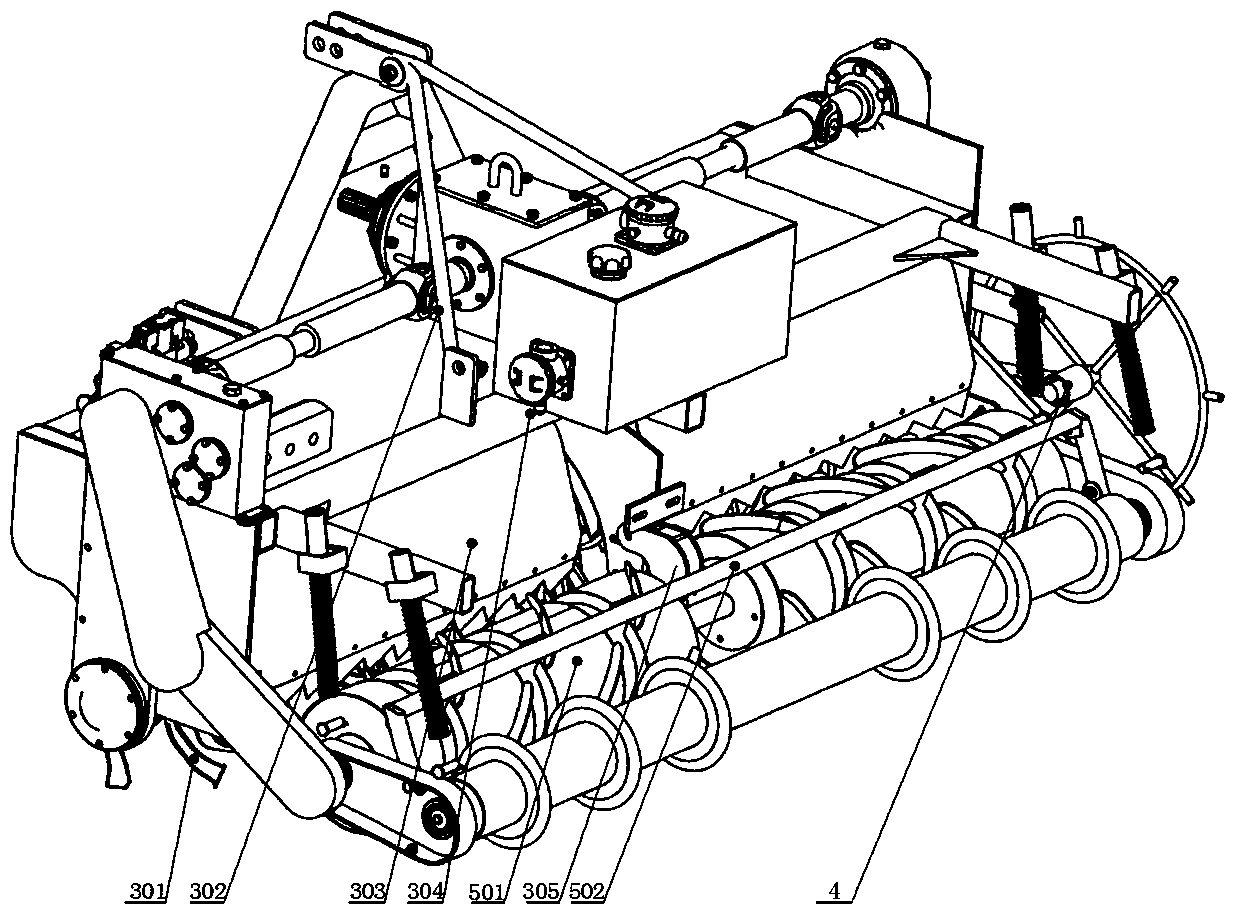

[0119] Such as figure 1 , figure 2 The combined transplanting operation machine shown includes an operation console, a control system, a main body frame, a hydraulic drive system 1, a seedling rack 2, a rotary tillage ditching system 3, a ground wheel speed measurement system 4, and a micro-soil preparation narrow ditch system 5. Planting system 6, covering soil suppression system 7, traction equipment 8 and ground profiling system 9 and other components. The hydraulic drive system 1, the seedling rack 2, the rotary tillage ditching system 3, the ground wheel speed measurement system 4, the rotary tillage ditching system 5, the planting system 6, the covering soil suppression system 7, the traction equipment 8 and the ground profiling system 9 are respectively Installed on the main frame. In this embodiment, the traction device 8 is a tractor, and the front end of the main body frame is connected with the tractor through a three-point suspension mechanism 302, and the tract...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Material hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com